Catalytic microelectrolysis packing, as well as preparation method and application thereof

A technology of micro-electrolysis and spherical fillers, which is applied in chemical instruments and methods, water/sewage treatment equipment, textile industry wastewater treatment, etc., can solve the problems of reduced treatment effect, increased difficulty of replacing micro-electrolytic fillers, and decreased treatment efficiency. Achieve the effect of improving pollutant removal rate and wastewater COD removal rate, good catalytic reaction effect, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

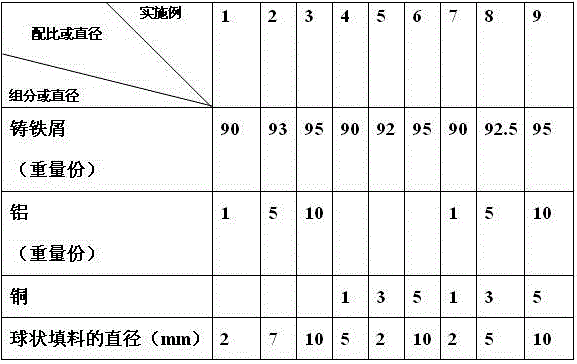

Examples

preparation example Construction

[0035] Two, the preparation method of described each embodiment:

[0036] The preparation can be completed by operating according to the second technical scheme, and it should be noted that:

[0037] 1. The melting temperature of each embodiment can be selected from 1300-1600°C.

[0038] 1. The principle of selecting a spherical mold with an inner cavity is to select the mold corresponding to the diameter of the spherical filler in each embodiment.

[0039] 3. Examples of the application of catalytic micro-electrolytic fillers in wastewater treatment:

Embodiment 10

[0040] Embodiment 10 (using the micro-electrolysis filler described in Embodiment 5 for the treatment of antibiotic waste water):

[0041] Put the catalytic micro-electrolysis filler described in Example 5 into the swirl micro-electrolysis reactor with the patent number ZL201420467908.9, and introduce the wastewater from the antibiotic secondary sedimentation tank into the swirl micro-electrolysis reactor. The quality of the wastewater: COD=550mg ∕L, pH=3, BOD5∕COD=0.09, the wastewater undergoes an electrochemical reaction through the catalytic micro-electrolysis filler, the reaction time is 1h, the pH value of the effluent is adjusted to 9-10, the precipitation is 30mm, the supernatant is discharged, and the detection. The COD of the effluent is 226mg / L, BOD5 / COD=0.59, which significantly improves the biodegradability of the wastewater. After 120 days of continuous reaction, the catalytic micro-electrolysis filler has no hardening phenomenon.

Embodiment 11

[0042] Example 11 (using the micro-electrolytic filler described in Example 2 to treat heavy metal wastewater):

[0043] The catalytic micro-electrolysis filler described in Example 2 is loaded into the swirl micro-electrolysis reactor whose patent number is ZL201420467908.9, and heavy metal wastewater is introduced into the swirl micro-electrolysis reactor. The waste water quality Cr +6 =20mg / L, total chromium is 35mg / L, Zn 2+ =97mg / L, Cu 2+ =285mg / L, the reaction time is 60min, the effluent is added with alkali to adjust the pH value to 8-9, and the effluent is left to settle for 30min, and the supernatant is discharged for detection. After 120 days of continuous reaction, the catalytic micro-electrolysis filler has no hardening phenomenon, and the average value of the effluent Cr +6 =0.03mg / L, total chromium is 0.04mg / L, Zn 2+ =0.12mg / L, Cu 2+ =0.67mg∕L, which meets the requirements of GB21900-2008 of Discharge Standard for Electroplating Wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com