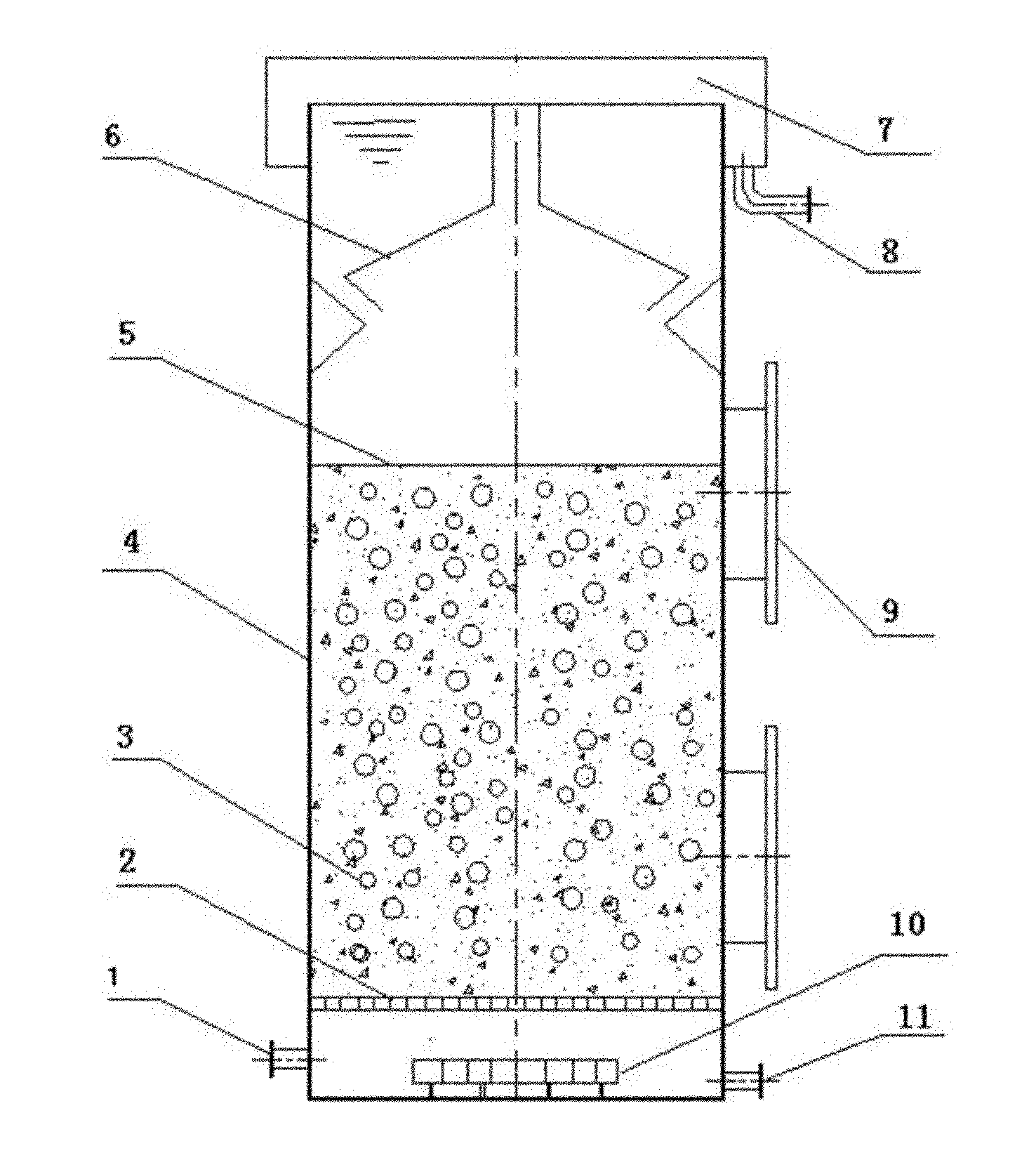

Integrated laboratory waste water treatment method and device

A wastewater treatment, integrated technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Determine and other issues to achieve considerable economic and social benefits, high performance and added value, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Treatment object: Acidic wastewater discharged from the analytical chemistry laboratory of a chemical building in a university in Wuhan.

[0029] Influent water quality: pH: 2.5~4.8

[0030] Main process parameters:

[0031] Iron / carbon ratio: 3:1

[0032] Hydraulic retention time: 50-70min

[0033] Gas-liquid ratio: 10:1

[0034] Effluent water quality: pH: 6.1 ~ 7.2, up to the discharge standard.

Embodiment 2

[0036] Treatment object: organic wastewater discharged from the organic synthesis laboratory of a chemical building in a university in Wuhan.

[0037] Influent water quality: COD: 150~230mg / L

[0038] Main process parameters:

[0039] Iron / carbon ratio: 1:3

[0040] Hydraulic retention time: 90-110min

[0041] Gas-liquid ratio: 15:1

[0042] Effluent water quality: COD: 75~90mg / L, meeting the first-class discharge standard of GB8978-1996.

Embodiment 3

[0044] Treatment object: Mixed average water samples from the sewage discharge outlet of a chemical building in a university in Wuhan for one month.

[0045] Influent water quality: pH: 5.75, COD: 46.5mg / L, TOC: 25.1mg / L, volatile phenol: 1.327mg / L, Cr(VI): 0.592mg / L, Pb 2+ : 0.113mg / L, Cu 2+ : 1.516mg / L, Zn 2+ : 2.628mg / L, Mn 2+ : 2.356mg / L.

[0046] Main process parameters:

[0047] Iron / carbon ratio: 1:2

[0048] Hydraulic retention time: 70-100min

[0049] Gas-liquid ratio: 12:1

[0050]Effluent water quality: pH: 6.48, COD: 35.6mg / L, TOC: 18.7mg / L, volatile phenol: 0.0199mg / L, Cr(VI): 0.0219mg / L, Pb 2+ : 0.0237mg / L, Cu 2+ : 0.0394mg / L, Zn 2+ : 0.202mg / L, Mn 2+ : 0.118mg / L. Reach GB8978-1996 level one emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com