Cold patch material for disease repair of asphalt road pavements and preparation method thereof

A technology of asphalt pavement and cold patching material, which is applied in the field of cold patching material for asphalt pavement disease maintenance and its preparation, and can solve the problem of poor cold and high temperature resistance of cold patching material, low initial strength of cold patching material, and unevenness of road surface. Poor and other problems, to achieve the effect of improving the degree of wetting, excellent water stability and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

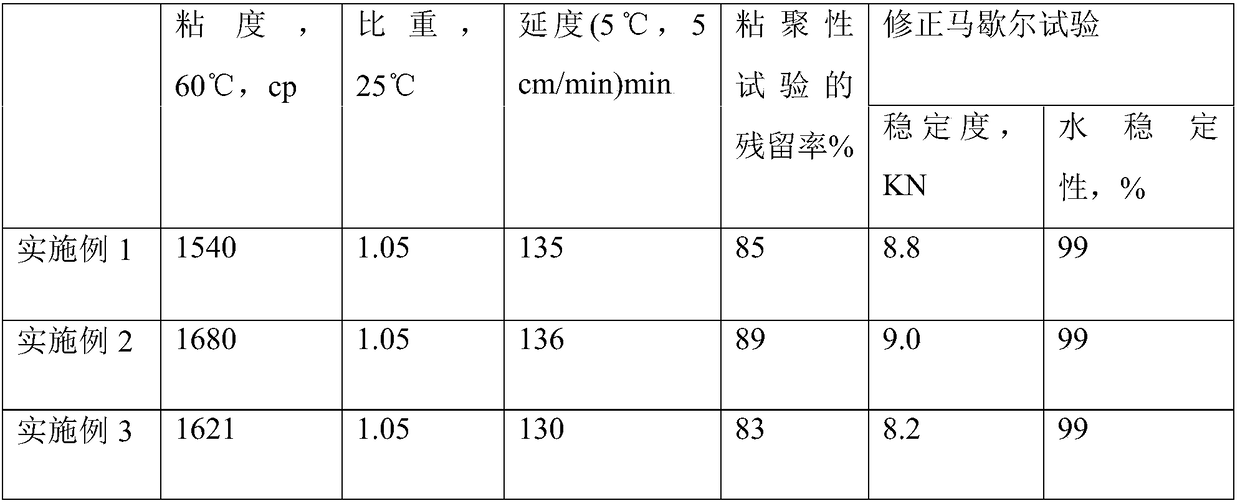

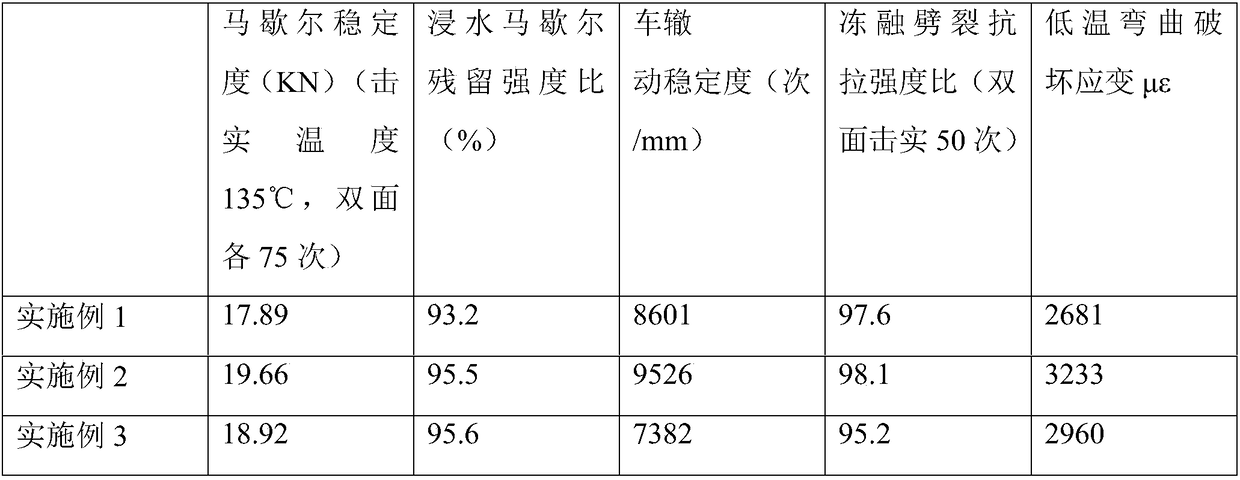

Embodiment 1

[0019] An asphalt cold patching agent is composed of the following ingredients in parts by mass: 32% of terpene resin, 2% of epoxy resin, 16% of heavy oil and 50% of diesel. Weigh terpene resin, epoxy resin, heavy oil, and diesel oil in proportion, and mix them uniformly by mechanical stirring or pump circulation device to obtain asphalt cold repair agent, which is a yellow oily liquid.

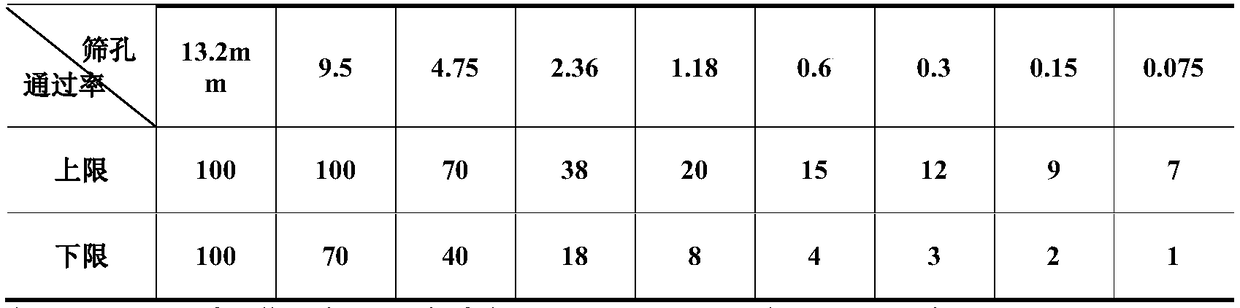

[0020] A kind of asphalt pavement disease maintenance cold patching material, comprising 4 parts of asphalt, 12 parts of 10-15mm crushed stone, 47 parts of 5-10mm crushed stone, 44 parts of 0-5mm machine-made sand, and 1.3 parts of above-mentioned asphalt cold patching agent, Wherein the crushed stone particle size is 5mm-16mm, the type of cold patching material of the present invention is AMR-13, and the mixing ratio of AMR-13 cold patching material is 10-15mm: 5-10mm: 0-5mm=11%: 46%: 43% , the gradation ranges of all aggregates and fillers are shown in Table 1;

[0021] Table 1 Grading ran...

Embodiment 2

[0036] An asphalt cold patching agent is composed of the following formula components in parts by mass: 33% of terpene resin, 3% of epoxy resin, 17% of heavy oil and 47% of diesel.

[0037] A kind of cold repair material for asphalt pavement disease maintenance, comprising 5 parts of asphalt, 11 parts of 10-15mm crushed stone, 46 parts of 5-10mm crushed stone, 43 parts of 0-5mm machine-made sand, and 1.4 parts of the above-mentioned asphalt cold repair agent, Wherein the crushed stone particle size is 5mm-16mm, the type of cold patching material of the present invention is AMR-13, and the mixing ratio of AMR-13 cold patching material is 10-15mm: 5-10mm: 0-5mm=11%: 46%: 43% , the gradation ranges of all aggregates and fillers are shown in Table 1; the preparation method is the same as in Example 1.

Embodiment 3

[0039] An asphalt cold patching agent is composed of the following formula components in parts by mass: 34% of terpene resin, 3% of epoxy resin, 18% of heavy oil and 45% of diesel oil.

[0040] A kind of cold patching material for asphalt pavement disease maintenance, including 5 parts of asphalt, 12 parts of 10-15mm crushed stone, 46 parts of 5-10mm crushed stone, 43 parts of 0-5mm machine-made sand and 1.4 parts of the above-mentioned asphalt cold patching agent. The type of cold patching material invented is AMR-13, and the mixing ratio of AMR-13 cold patching material is 10-15mm: 5-10mm: 0-5mm = 12%: 46%: 43%. The gradation range of all aggregates and fillers is as follows Shown in table 1; Preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com