Two-way multi-share plough unit

A multi-share plough and unit technology, which is applied to ploughs, agricultural machinery and implements, applications, etc., can solve the problems of the multi-share plough being too long before and after, and achieve the effect of improving the operation efficiency and reducing the use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

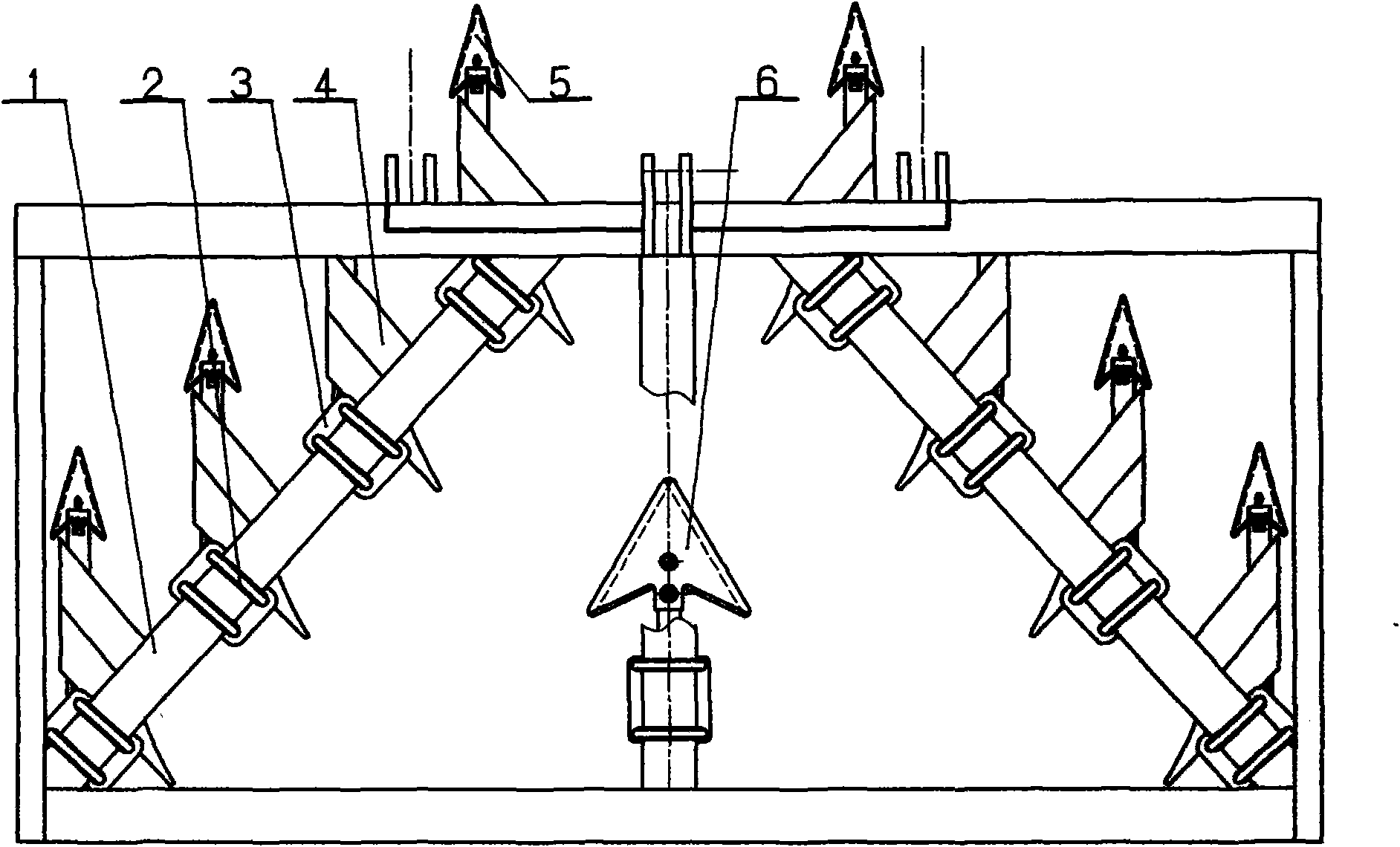

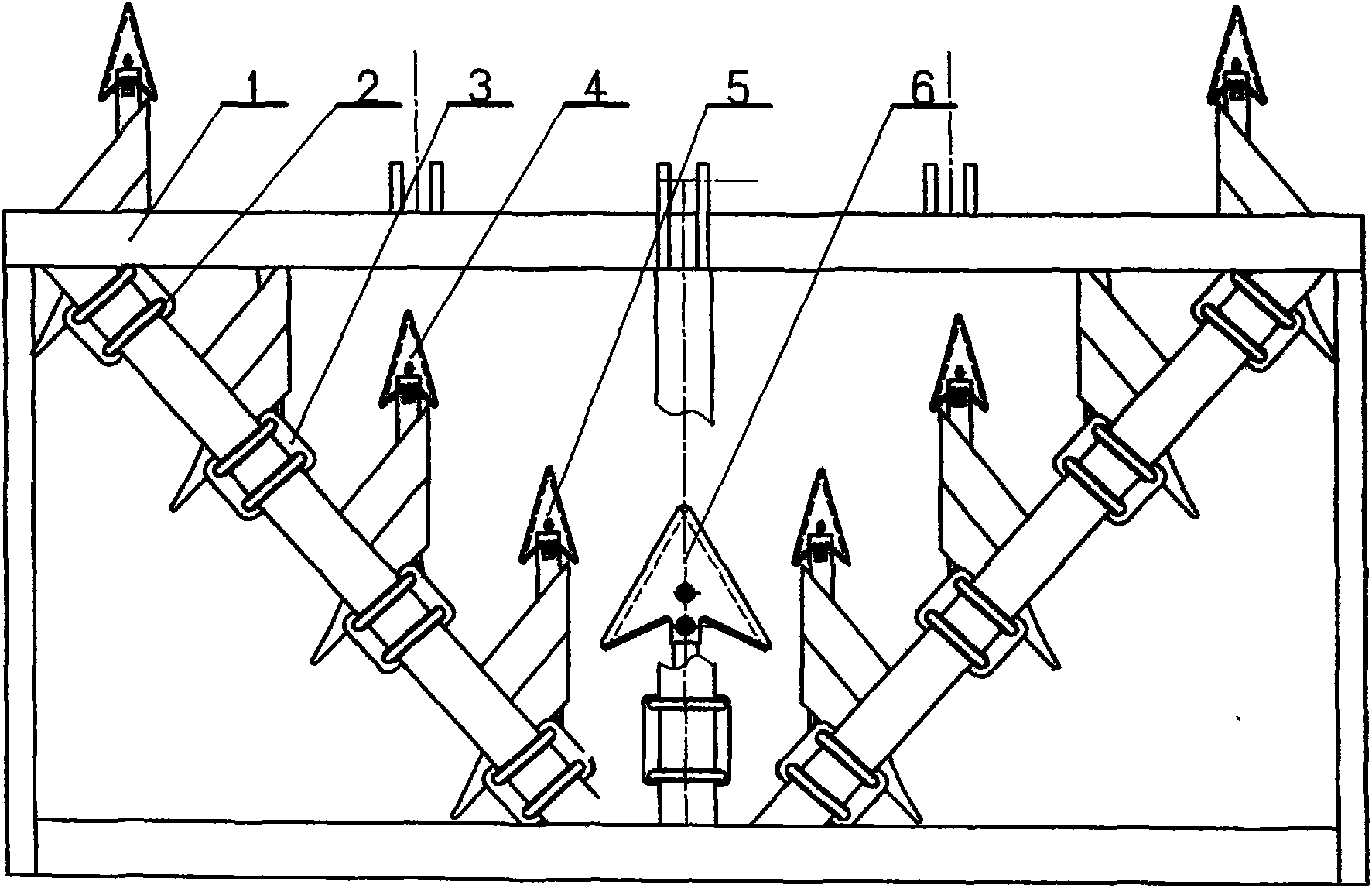

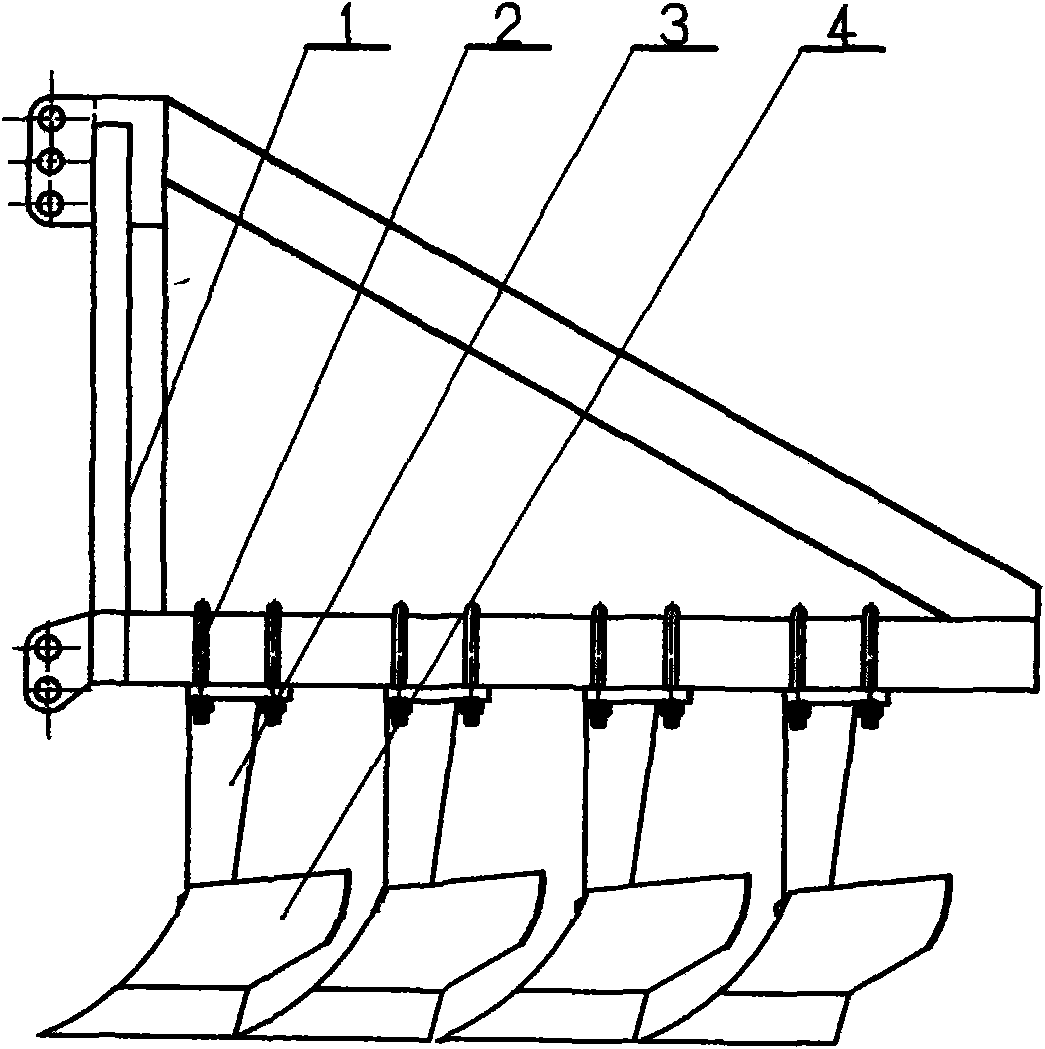

[0012] The present invention is mainly composed of a plow frame 1, a U-bolt 2, a plow post 3, a plow share 4, a subsoiling shovel 5, an intermediate plow shovel 6, etc. The specific implementation methods are as follows:

[0013] 1. The plow column 3 is fixed under the plow frame 1 through the U-shaped bolt 2, the plow share 4 is installed in the middle of the plow column 3, the subsoiler shovel 5 is installed at the bottom of the plow column 3, and the middle plow shovel 10 is installed on the plow frame 1 below the center stringer. In this way, the plowshare turns over the shallow soil, turns the weeds on the surface and the diameter of the crops to the ground, turns the shallow fertile soil to the top, and the deep loosening shovel loosens the deep soil, eliminating the need for traditional plows. The plow bottom layer caused by ground operations is conducive to the growth of crop root systems and prevents water, soil, and fertilizer loss.

[0014] 2. In order to increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com