Continuous salinity gradient power generation device and method

A power generation device and salt difference technology, applied in the field of continuous salt difference power generation device, can solve the problems of increasing process complexity and power generation cost, device operation stability, adverse impact of input cost, large amount of salt and fresh water supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

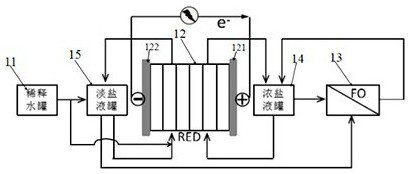

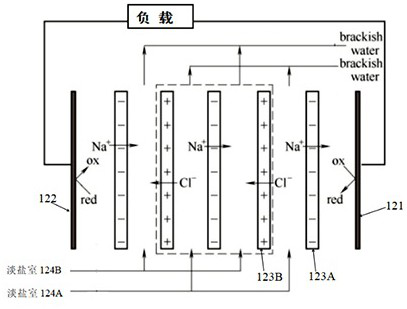

[0050] combine figure 1 and figure 2 As shown, the ion exchange membrane resistance of the reverse electrodialyzer 12 is 2 Ω·cm 2 , the membrane surface flow rate is 4.5 cm / s; the forward osmosis membrane of the forward osmosis device 13 is a hollow fiber membrane with a composite functional layer of silicon oxide nanoparticles, and the flow rate of the feed liquid is twice the flow rate of the draw liquid; the salt in the concentrated salt solution tank 14 Liquid is 10% sodium chloride solution, and the salt solution of light salt solution tank 15 is 0.5% sodium chloride solution. The forward osmosis draw solution of the forward osmosis device 13 is 23% ammonium chloride solution. The anode 122 and cathode 121 were tested with a wire connected load with a power density of 7.2 W / m 2 .

Embodiment 2

[0052] combine figure 1 and figure 2 As shown, the ion exchange membrane resistance of the reverse electrodialyzer 12 is 2 Ω·cm 2 , the membrane surface flow rate is 4.5 cm / s; the forward osmosis membrane of the forward osmosis device 13 is a hollow fiber membrane with a composite functional layer of silicon oxide nanoparticles, and the flow rate of the feed liquid is 1.5 times of the flow rate of the draw liquid; the salt of the concentrated salt solution tank 14 Liquid is 5% sodium chloride solution, and the salt solution of light salt solution tank 15 is 0.3% sodium chloride solution. The forward osmosis draw solution of the forward osmosis device 13 is 20% ammonium bicarbonate solution. The anode 122 and cathode 121 were tested with a wire connected load with a power density of 5.6 W / m 2 .

Embodiment 3

[0054] combine figure 1 and figure 2 As shown, the ion exchange membrane resistance of the reverse electrodialyzer 12 is 2 Ω·cm 2 , the membrane surface flow rate is 5 cm / s; the forward osmosis membrane of the forward osmosis device 13 is a hollow fiber membrane with a composite functional layer of titanium oxide nanoparticles, and the flow rate of the feed liquid is twice the flow rate of the draw liquid; the salt of the concentrated salt solution tank 14 Liquid is 12% sodium chloride and sodium sulfate mixed solution, and the salt solution of light salt solution tank 15 is 0.3% sodium chloride and sodium sulfate mixed solution. The forward osmosis draw solution of the forward osmosis device 13 is 23% ammonium chloride solution. The anode 122 and the cathode 121 are tested by connecting the load with a wire, and the power density is 8.7W / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com