A dual ion beam metal coating automation equipment

An automated equipment, metal coating technology, applied in the direction of ion implantation coating, metal material coating process, sputtering coating, etc., can solve the problems of reducing the service life of the device, the influence of the device, and the inability to achieve the cooling effect, and achieve improvement. Combined strength, improved heat dissipation protection, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

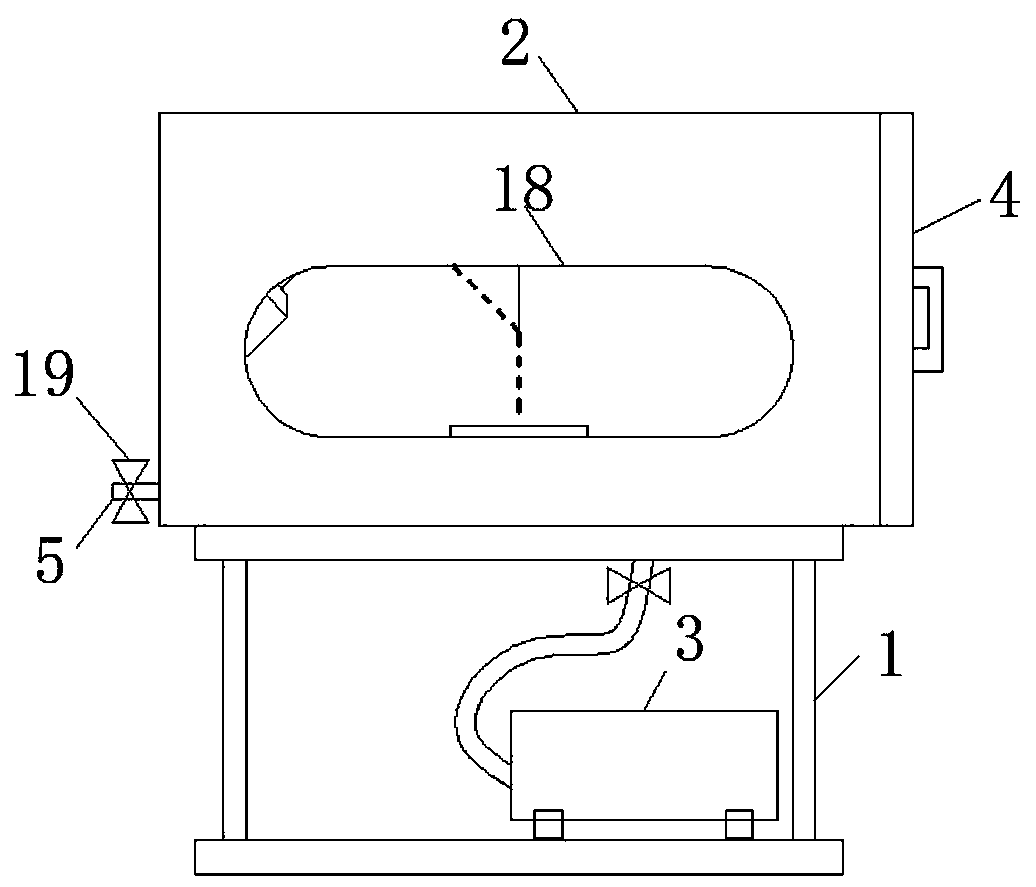

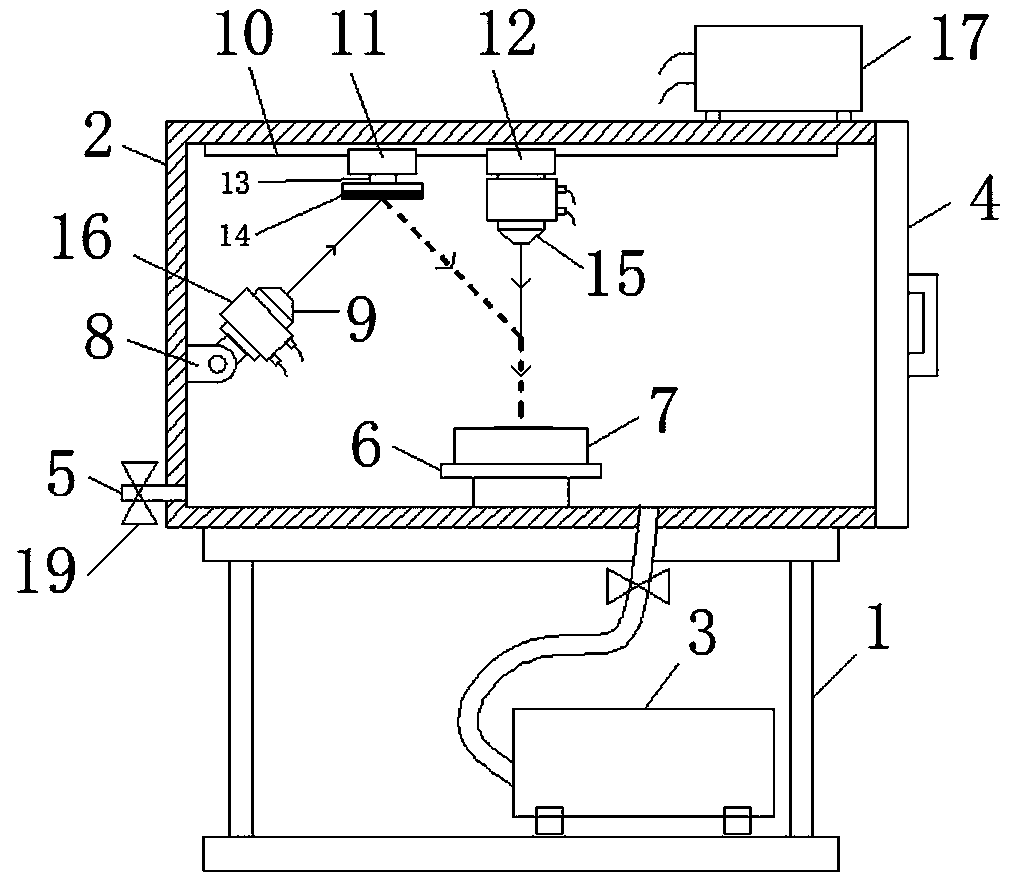

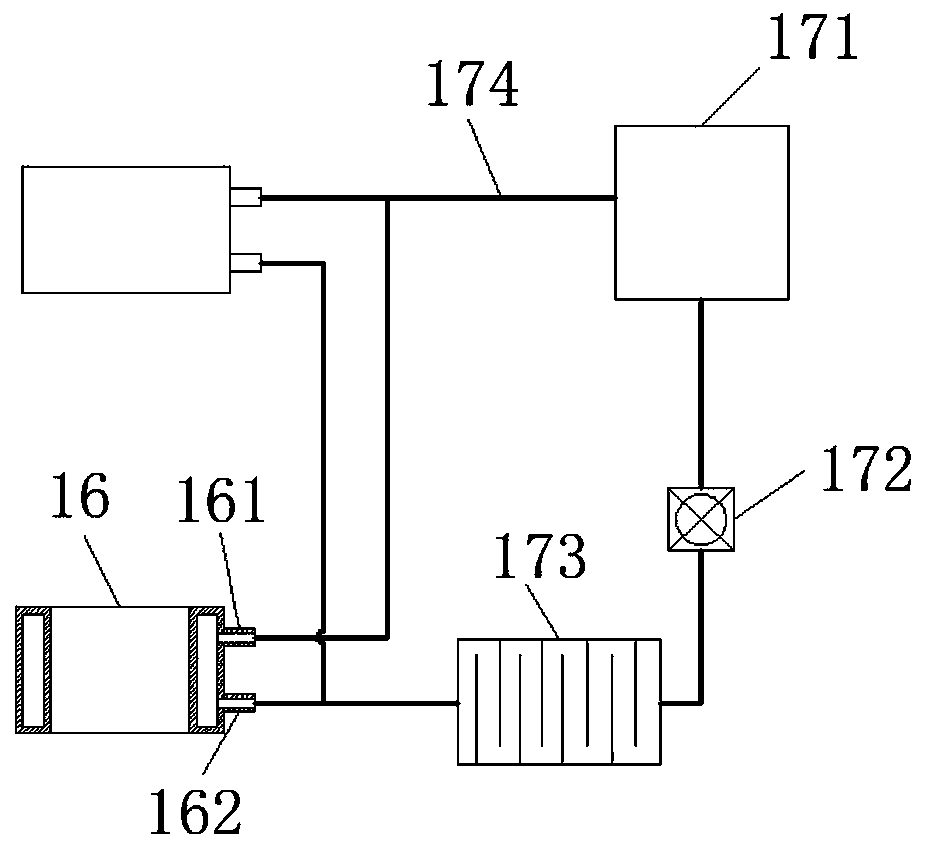

[0026] Preferred embodiment one of the present invention, such as Figure 1~3As shown, the present invention provides a kind of technical scheme: a kind of double ion beam metal coating automation equipment, comprises equipment frame 1, and the top of equipment frame 1 is provided with vacuum coating chamber 2, and the front side wall of vacuum coating chamber 2 is provided with Observation window 18, in order to observe the working situation in the vacuum coating chamber 2, the bottom of the inner chamber of the equipment frame 1 is provided with a vacuum device 3, the vacuum device 3 is connected with the vacuum coating chamber 2, and the right side wall of the vacuum coating chamber 2 is arranged There is a sealed door body 4, the left side wall bottom of the vacuum coating chamber 2 is provided with an air inlet 5, and the connecting pipe between the vacuum device 3 and the vacuum coating chamber 2 and the air inlet 5 are all provided with a valve 19 to control the air flow...

Embodiment 2

[0032] Embodiment 2 When adjusting the target slider 11 and the auxiliary source slider 12, the expansion and contraction of the electric adjustment devices 2024 on both sides can make the corresponding adjustment device 202 have a displacement change in the vertical direction. In theory, as long as the adjustment device 202 is in the The displacement length in the vertical direction is sufficient, and the translation adjustment device 203 as a whole can perform a large swing, with left high and right low or left low and right high, and at the same time, the driving of the electric reel 2032 can synchronously adjust the target slider 11 and the auxiliary source slider 12, this structure is especially suitable for the case where there is a large area of arc in the special-shaped processing surface, which can significantly improve the quality of processing.

[0033] Such as Figure 6 In the third preferred embodiment of the present invention, the linear guide rail 10 in the fi...

Embodiment 3

[0035] Embodiment 3 When adjusting the target slider 11 and the auxiliary source slider 12, the distance between the target slider 11 and the auxiliary source slider 12 in the horizontal direction can be adjusted, and both can be rotated at the same time. Considering the improvement of the rotation adjustment Angle, to avoid the rest of the workpiece, also considering the cost reduction and the complexity of the industrial control adjustment system, directly on the adjustment seat 211 is provided with a fine-tuning slider 2111 that can be ejected in a straight line, which is more convenient in control and basically It can play the role of the universal device, and the third embodiment is more suitable for irregular surfaces to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com