Cooling assembly for cable extrusion production line

A cooling component and cable extrusion technology, which is applied in the direction of electrical components, cable/conductor manufacturing, conductor/cable insulation, etc., can solve the problems of unsatisfactory cooling effect and poor product quality, and achieve excellent cooling effect, quality improvement, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings:

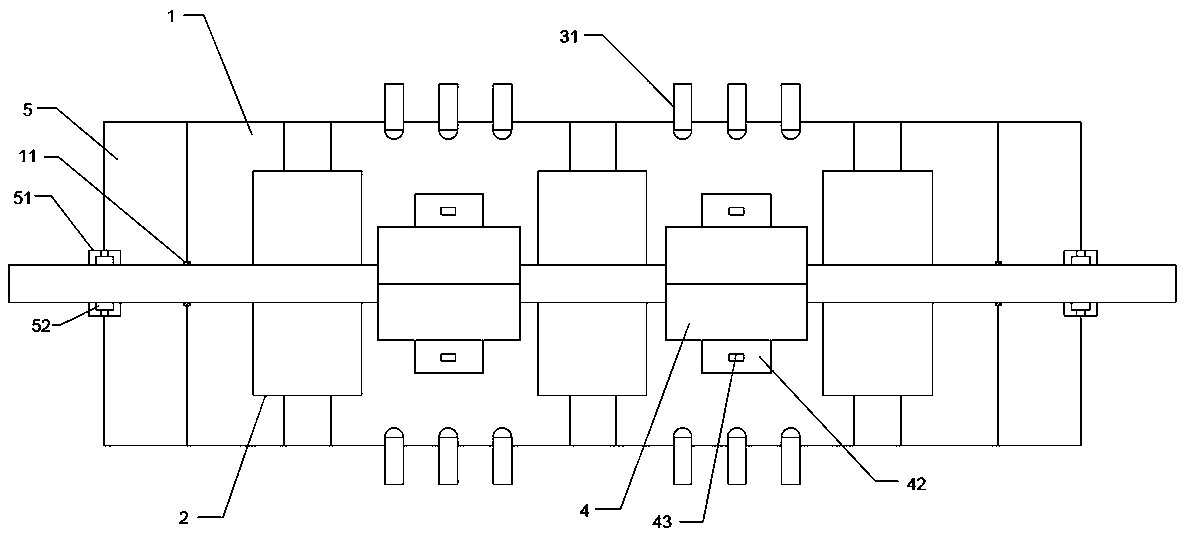

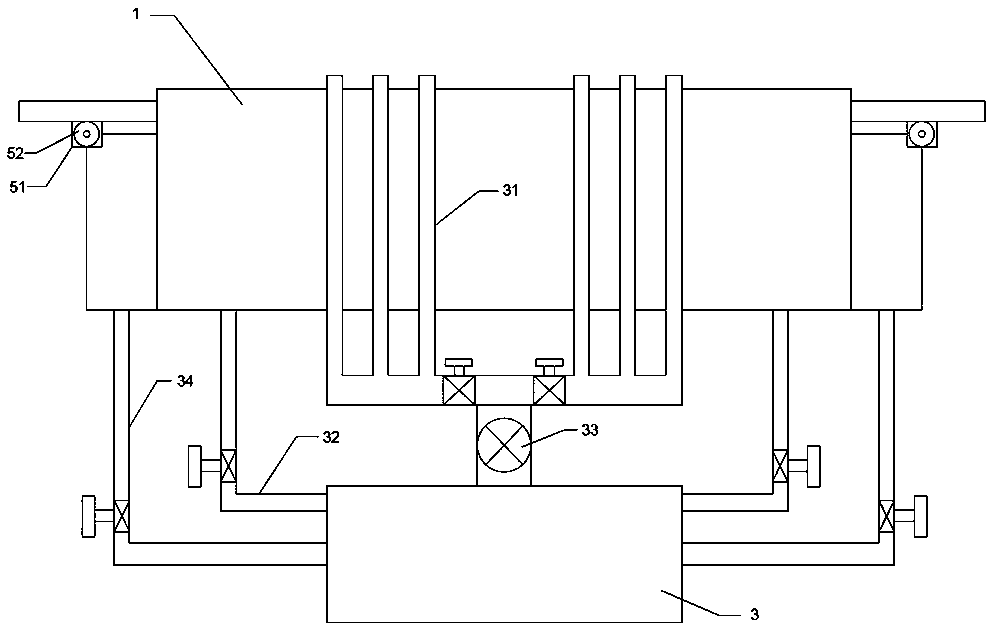

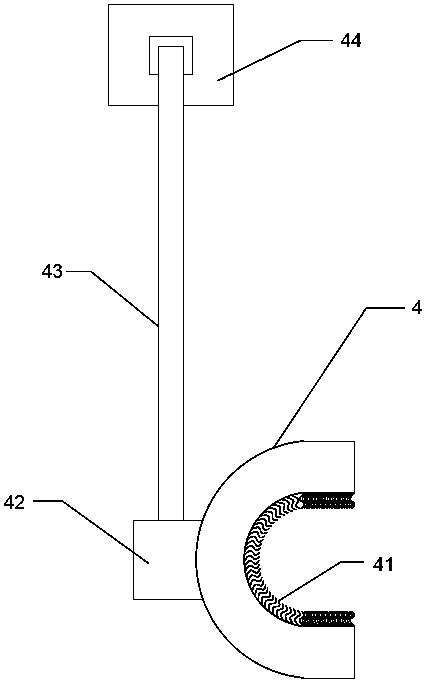

[0018] see figure 1 , figure 2 , image 3 , A cable extrusion production line cooling assembly, including a cooling water tank 1, a circulating water mechanism and a de-bubble mechanism; in the cooling water tank 1 there are a plurality of conveying rollers 2 spaced along the cable conveying direction, and the cooling water tank 1 is in the cable conveying The two ends in the direction are provided with cable passages, and the two ends are respectively connected with guide parts. The cable passages are provided with water blocking sponges 11 arranged around the inner ring surface of the cable; the circulating water mechanism includes the inlet The water pipe 31, the water outlet pipe 32, the water storage tank 3 and the water pump 33, the water inlet pipe 31 and the water outlet pipe 32 are all connected with the water storage tank 3, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com