Electrolytic type oxy-hydrogen generation device

A generation device, hydrogen-oxygen technology, applied in the electrolysis process, electrolysis components, chemical industry and other directions, can solve the problems affecting the stability and safety of the electrolytic cell, electrode short circuit, arcing and other problems, and achieve the possibility of reducing the electrolysis efficiency, The effect of reducing volume and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

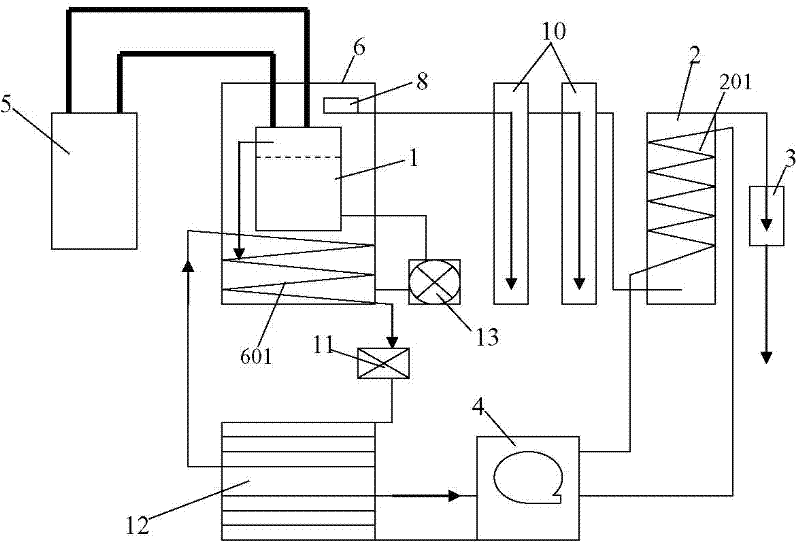

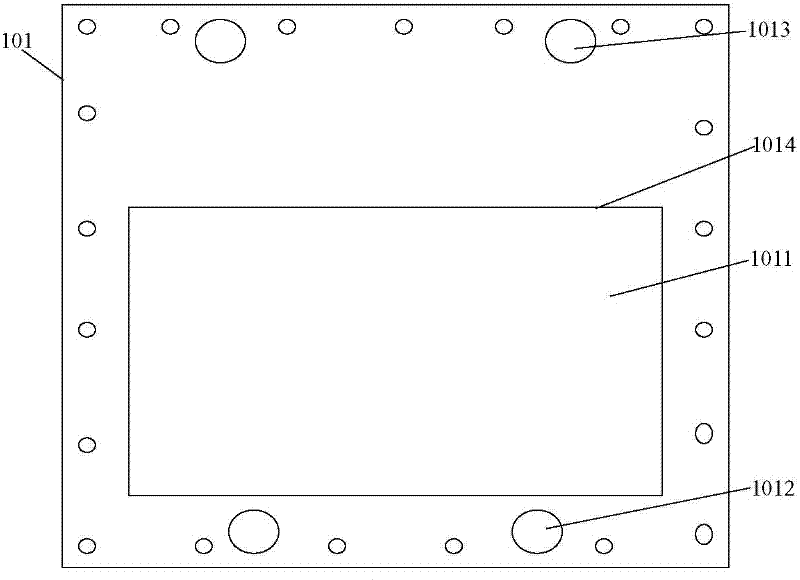

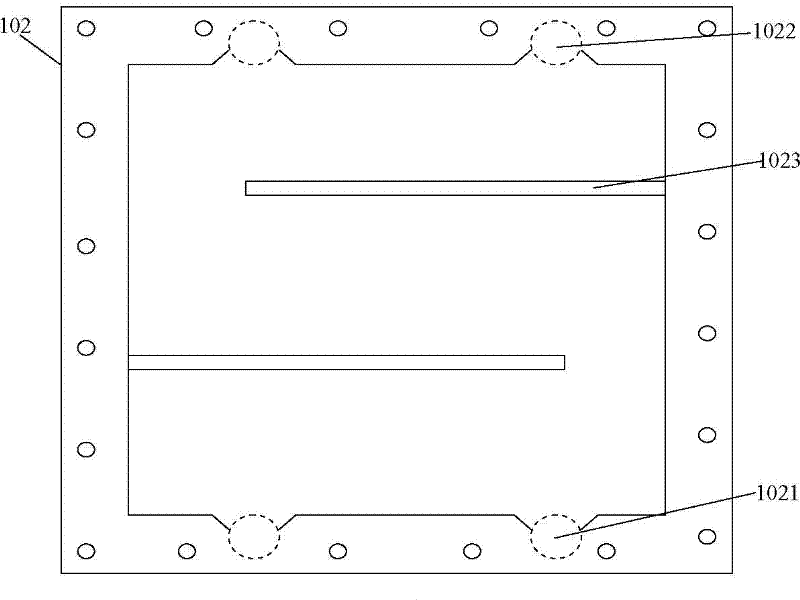

[0030] see Figure 1~Figure 5 As shown, the electrolytic hydrogen-oxygen generator of the present invention includes an electrolytic cell 1, an evaporator 2, an anti-flashback device 3 connected to the outlet of the evaporator 2, a compressor 4 connected to the refrigeration pipe 201 in the evaporator 2, and an electrolytic cell 1 connected DC power supply 5, the electrolytic cell 1 is arranged in a closed box body 6, an electrolyte 7 is installed below the electrolytic cell 1 in the box body 6, and a steam-water separator 8 is arranged above the electrolytic solution 7, and the steam-water separator The outlet of 8 is connected to the evaporator 2, and the electrolytic cell 1 includes at least two electrode separators 101 side by side and a water-conducting separator 102 arranged between every two electrode separators 101, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com