Fuel cell bipolar plate

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as hindering electrochemical reactions, water cannot be drained in time, PEMFC performance, and lifespan decline, so as to avoid adverse effects and avoid The effect of uneven distribution of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

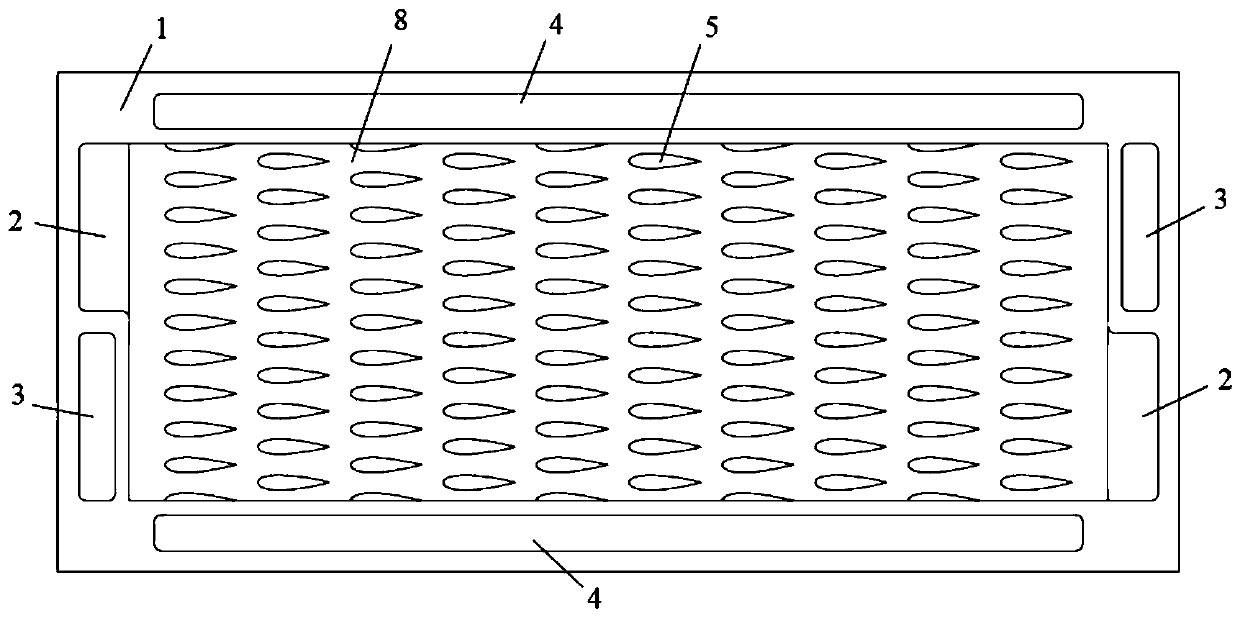

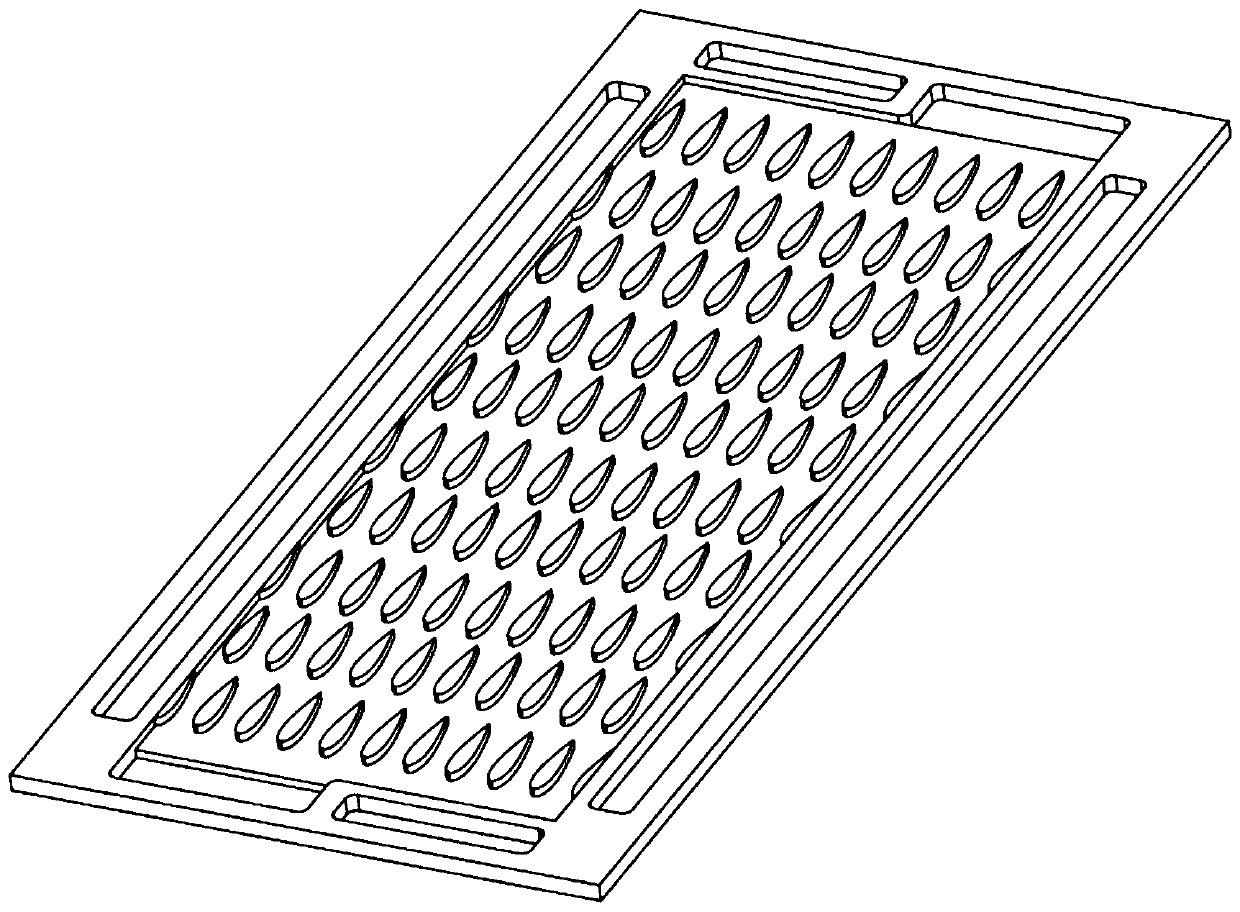

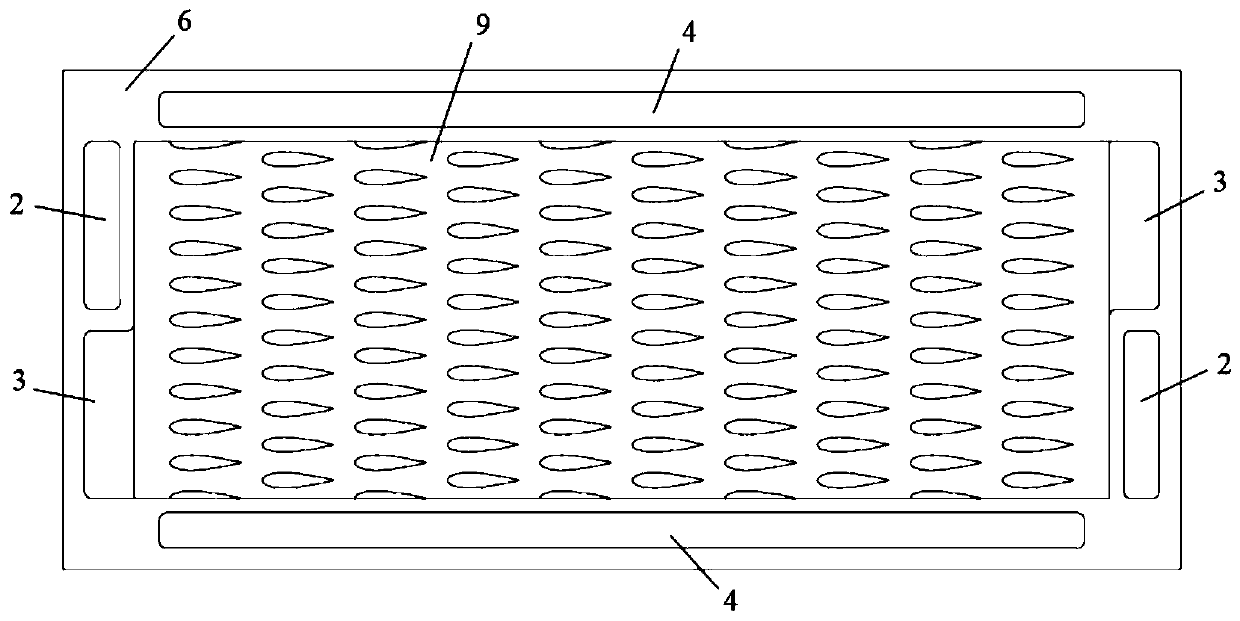

[0029] refer to Figure 1 to Figure 6 , the fuel cell bipolar plate anode plate 1, cathode plate 6 and two cooling plates 7 according to the present invention, wherein, the anode plate 1 and one cooling plate 7 are overlapped and connected sequentially from bottom to top, and the cathode plate 6 is connected to the other cooling plate The cooling plate 7 is stacked and covered sequentially from top to bottom, and the anode plate 1 and the cathode plate 6 form a fuel cell unit with the membrane electrode sandwiched between the anode plate 1 and the cathode plate 6. Specifically, the anode plate 1 and the cathode plate 6 and the cooling plate 7 are connected by means of bolt connection, welding or bonding.

[0030] The upper surface of the anode plate 1 is provided with a hydrogen horizontal flow channel 8, the upper surface of the cathode plate 6 is provided with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com