Heat dissipation structure based on LED corn lamp

A technology of LED corn lamp and heat dissipation structure, which is applied to the cooling/heating device of lighting device, lighting and heating equipment, components of lighting device, etc. Shortening and other problems, to achieve the effect of increasing the light decay time, increasing the service life, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

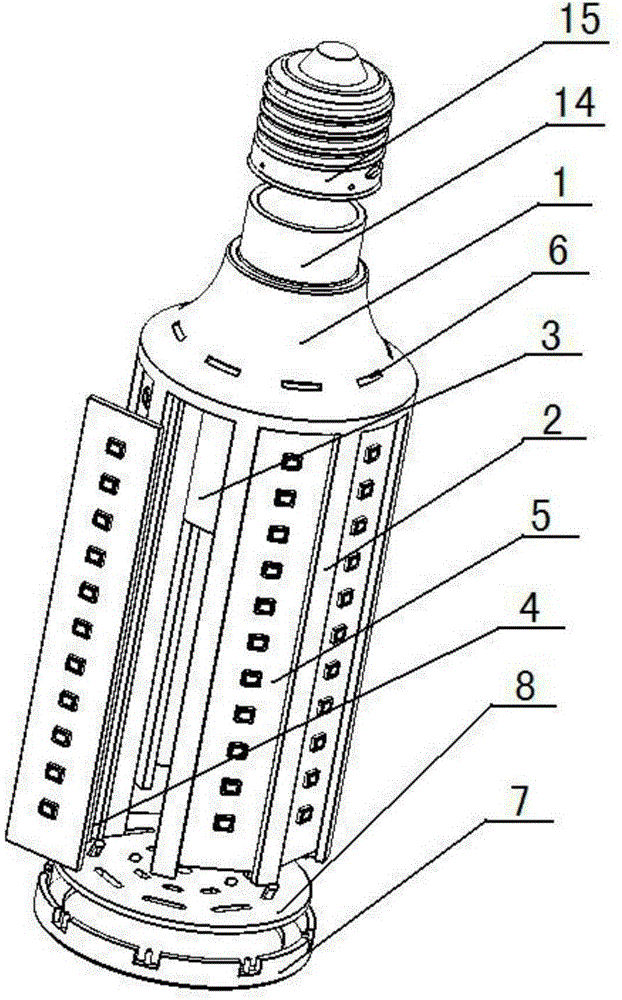

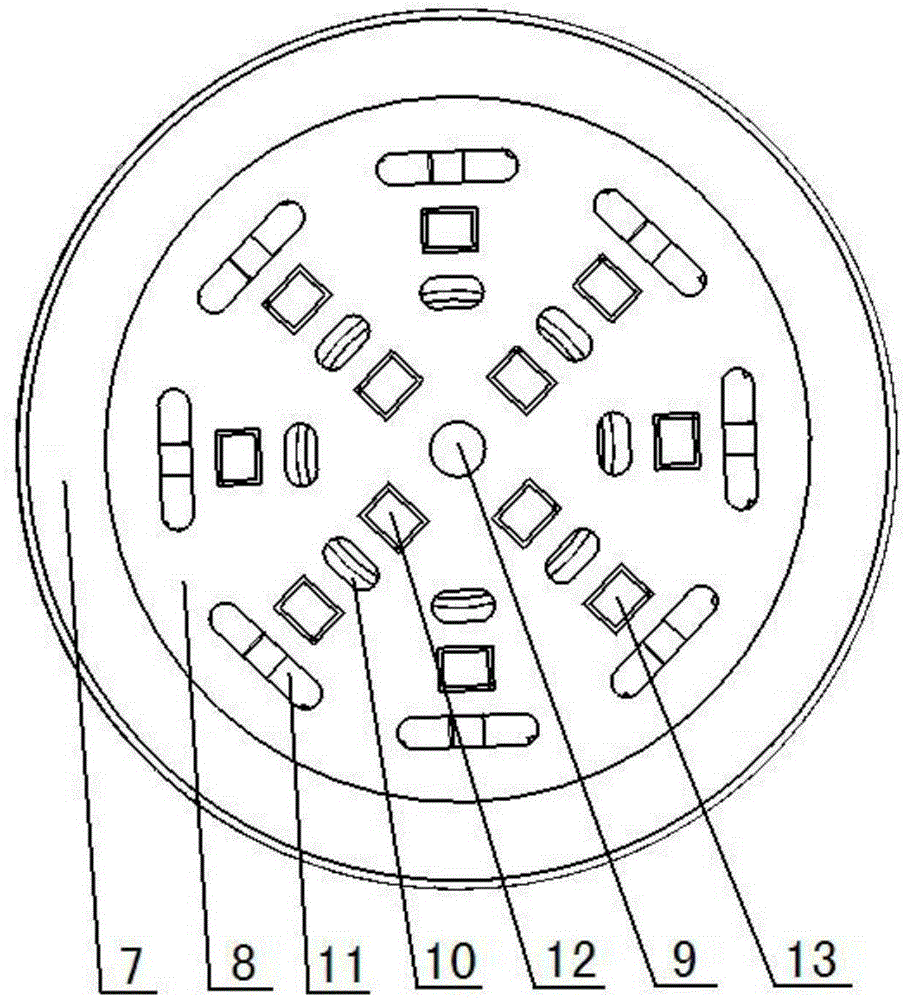

[0012] Reference attached figure 1 , 2 , the present invention includes: a heat dissipation structure based on LED corn lamps, including a base 1, a lamp cap 15 connected to the upper end of the base 1 through a fixing column 14, several fixing ribs 2 integrally arranged on the edge of the lower end surface of the base 1 and set on The annular driving power supply compartment 3 in the middle of the lower end surface of the base 1 is used to install the driving power supply. There are wire grooves 4 on the side walls of the left and right sides of several fixing ribs 2, and the two adjacent fixing ribs 2 The strip light board 5 is fixed through the slot 4, and the base 1 is provided with a number of upper ventilation holes 6, which are located between the outer wall of the annular drive power supply compartment 3 and the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com