Low-temperature adsorption and high-temperature desorption efficient oil gas recovery method

A recovery method, oil and gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as unfavorable treatment and utilization, uneven regeneration, and reduction of regeneration tail gas concentration, so as to achieve efficient utilization and ensure stable operation. , the effect of high oil and gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings. For those not described, conventional technical means in the field can be used.

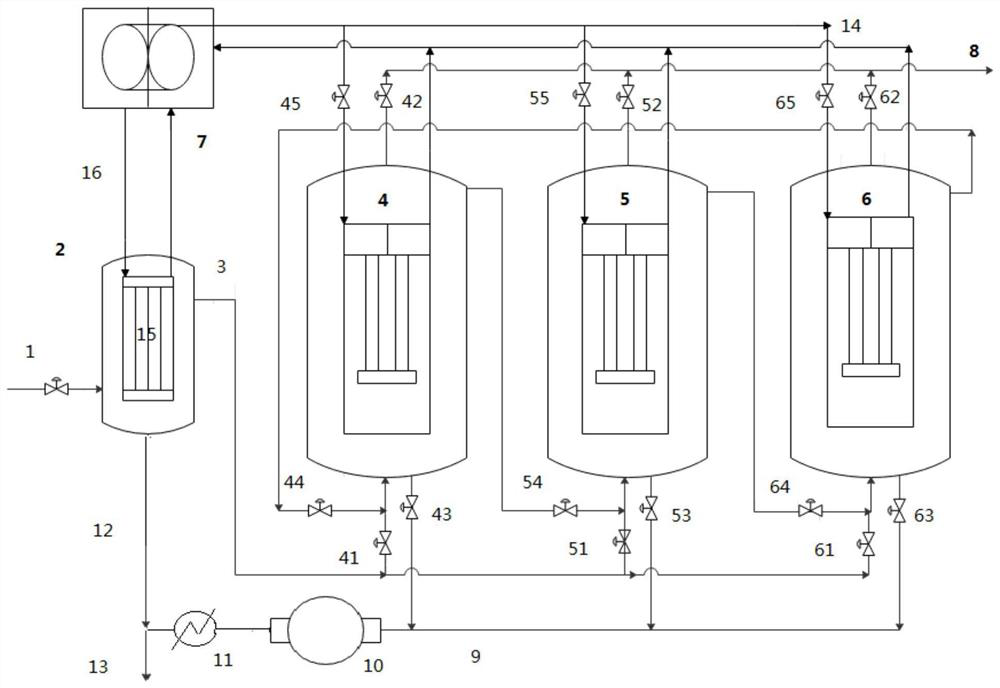

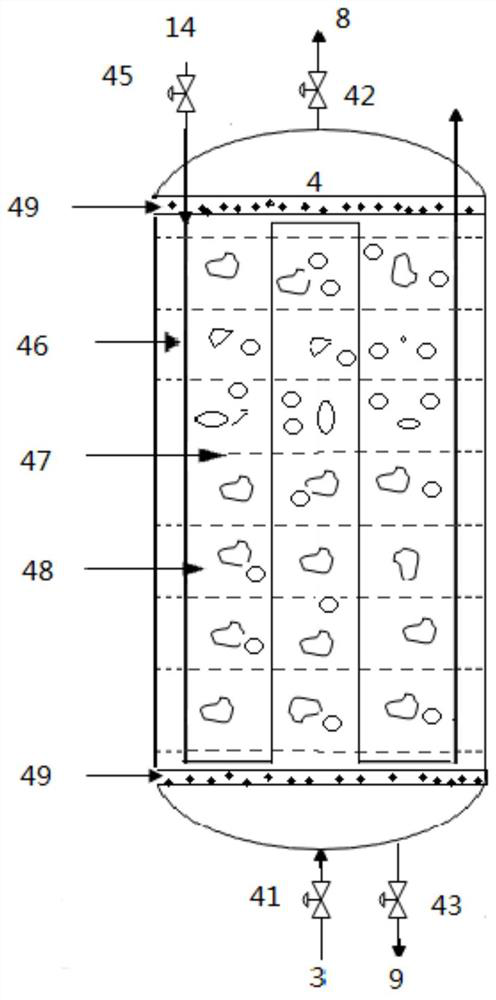

[0025]The present invention can perform adsorption at low temperature and desorption at high temperature, and adopt multiple adsorption towers (at least 3 adsorption towers, two of which are used for series adsorption, and the rest of the adsorption towers are in desorption state or pre-adsorption state) for efficient adsorption and separation The oil and gas recovery method of oil and gas components, the characteristics of this method: first, low-temperature adsorption and high-temperature desorption to achieve high-efficiency adsorption; second, adopt at least two towers in series adsorption scheme to improve the utilization efficiency of the adsorption bed; third, use heat pump method Realize the heat transfer inside the oil and gas recovery system, and reduce the energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com