GPS/BD-based multisource integration mine drilling operation monitoring system and monitoring method

A technology for operation monitoring and mining, which is applied to the automatic control system of drilling, radio wave measurement system, satellite radio beacon positioning system, etc. It can solve the problems of difficult operation quality monitoring and low drilling positioning accuracy, and achieve the guaranteed accuracy , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

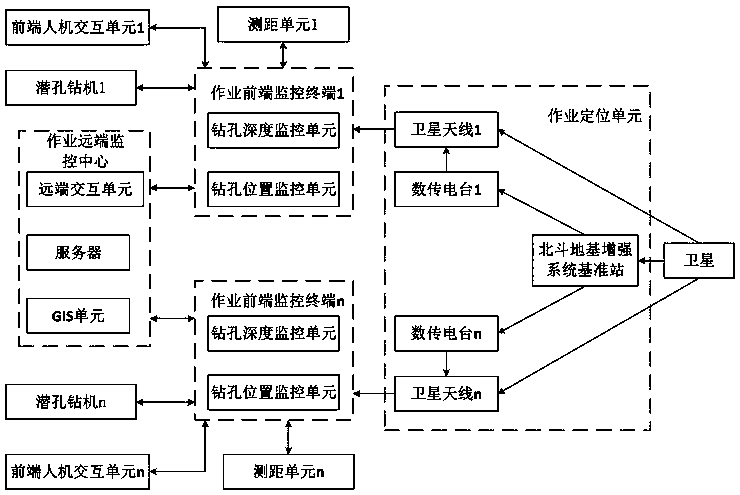

[0054] Embodiment 1: as attached figure 1 As shown, the GPS / BD-based multi-source fusion mine drilling operation monitoring system includes:

[0055] The operation remote monitoring center issues drilling tasks and control commands;

[0056] Operation front-end monitoring terminal, each down-the-hole drilling rig is equipped with an operation front-end monitoring terminal, which controls the operation of the corresponding down-the-hole drilling rig according to the drilling task, monitors the drilling depth and drilling speed, and receives real-time positioning information from the operation positioning unit. Determine and monitor the real-time position of the drilling position through carrier phase difference technology;

[0057] The operation positioning unit, through GPS positioning and Beidou positioning, respectively performs real-time positioning of the drilling positions of each drilling hole;

[0058] The distance measuring unit, each DTH drilling rig is equipped wit...

Embodiment 2

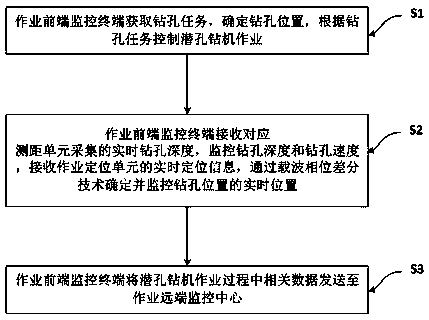

[0078] Embodiment 2: as attached figure 2 As shown, the monitoring method of the GPS / BD-based multi-source fusion mine drilling operation monitoring system includes:

[0079] S1, the operation front-end monitoring terminal obtains the drilling task, determines the drilling position, and controls the operation of the down-the-hole drilling rig according to the drilling task;

[0080] S2, the operation front-end monitoring terminal receives the real-time drilling depth collected by the corresponding ranging unit, monitors the drilling depth and drilling speed, receives the real-time positioning information of the operation positioning unit, and determines and monitors the real-time position of the drilling position through carrier phase difference technology ;

[0081] S3, the front-end monitoring terminal of the operation sends relevant data during the operation of the down-the-hole drilling rig to the remote monitoring center of the operation, and the relevant data includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com