Method for improving process of displacement gas of reactor of continuous reformer

A reforming device and reactor technology, which is applied in the petroleum industry, naphtha treatment, etc., can solve problems such as excessive discharge of non-methane hydrocarbons, deteriorating operating conditions, regeneration air release, catalyst oil affecting lifting and transportation, etc., to achieve The effect of improving the operating conditions and reducing the hidden danger of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

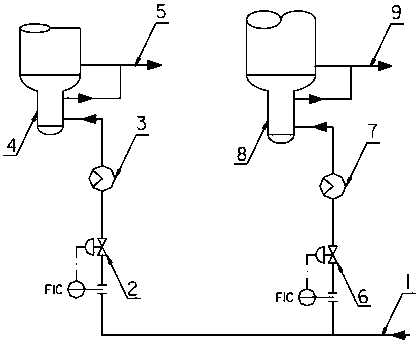

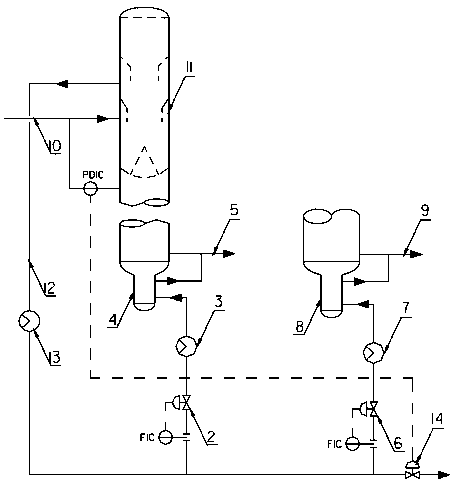

[0022] The present invention will be further explained below in conjunction with the drawings:

[0023] As attached figure 1 As shown, the gas source hydrogen 1 with less hydrocarbon content introduced from the device is divided into two strands. One strand is used as the replacement gas of the No. 1 reactor and is adjusted by the No. 1 reactor replacement gas flow control valve 2 and then passed through the No. 1 reactor. The replacement gas heat exchanger 3 exchanges heat to 120-140°C, and enters the second reactor catalyst collector 4 to purge the oil and gas on the catalyst under its own weight from the second reactor, and the catalyst that blows off the oil and gas is upgraded to the third reactor buffer In section, the replacement gas enters the second intermediate heating furnace along with the reaction product 5 of the second reactor. One is used as the replacement gas of the second reactor to be adjusted by the replacement gas flow control valve 6 of the second reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com