Water cooled wall type fixed bed gasifier capable of supplying oxygen in grading way

A fixed-bed gasifier and water-cooled wall technology, applied in the field of coal gasification, can solve the problems of polluting the environment, over-temperature of the furnace grate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

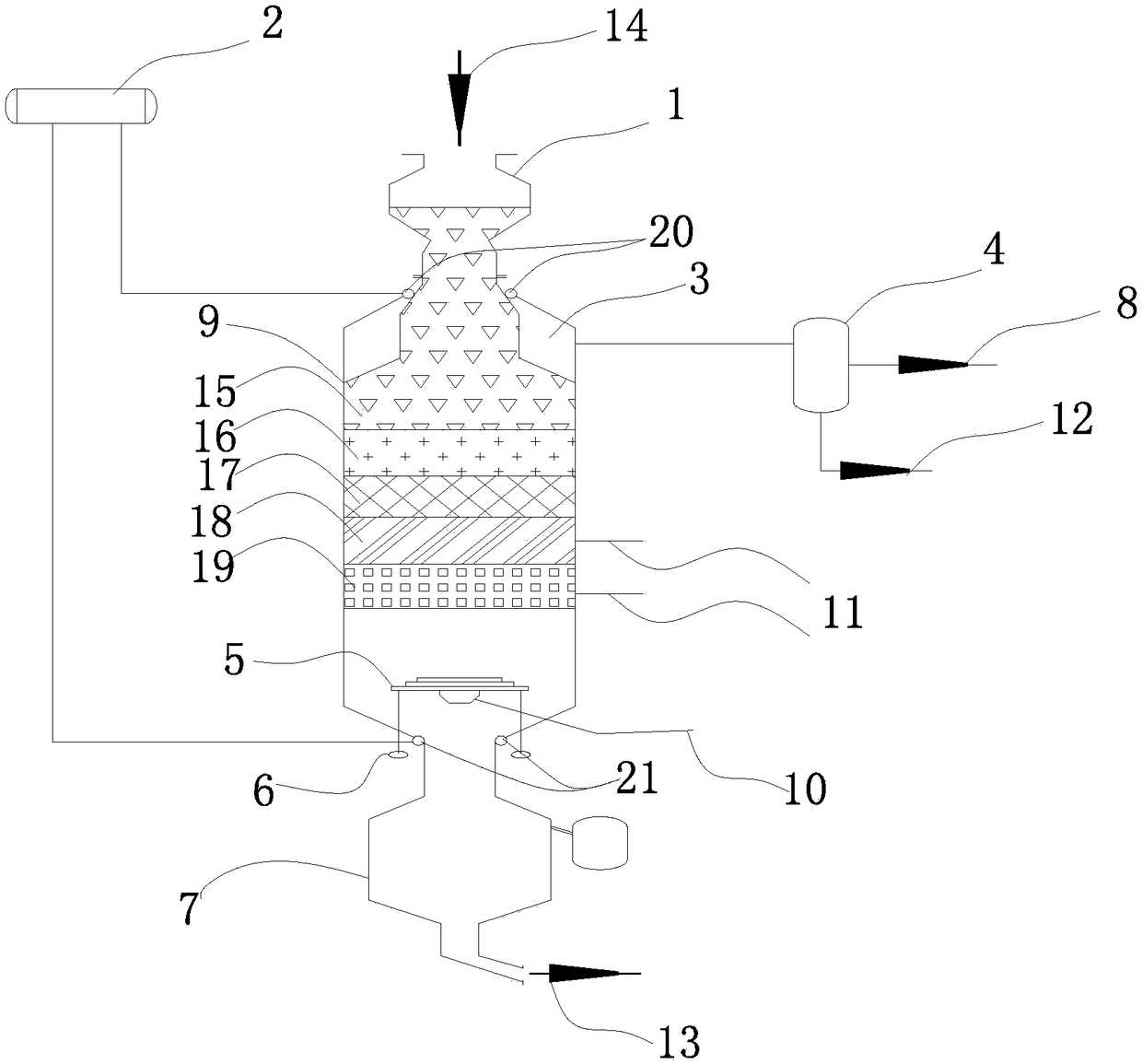

[0030] Such as figure 1 As shown, the water-cooled wall type fixed-bed gasifier with graded oxygen supply includes: water-cooled wall shell 9, gas-liquid separator 2, washing cooler 4, grate system, coal lock 1, ash lock 7 and graded oxygen supply device.

[0031] Specifically, a gasification combustion chamber 3 is defined inside the water-cooled wall casing 9 , and an upper port and a lower port are respectively opened on the top and bottom of the water-cooled wall casing 9 . The water-cooled wall shell 9 includes: multiple water-cooled tubes and multiple sealing sheets, the water-cooled tubes are in a tubular structure, and the multiple water-cooled tubes are respectively arranged at intervals along the circumference of the gasification combustion chamber 3 . Each water-cooled tube respectively includes: a main body, a first curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com