Proportional cooling control method used for differential temperature heating technology heat treatment furnace

A control method and a technology of differential temperature heating, applied in the field of heat treatment, can solve problems such as difficult determination of the cooling slope, prolonging the production cycle, and prolonging the production cycle, so as to avoid the risk of metal overheating, shorten the production cycle, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1. Hardware configuration

[0033] The basic configuration requirements of the heating or heat treatment furnace using this method are as follows:

[0034] 1. Heating system and cooling system (directly mixed with cold air or using heat exchanger to cool down);

[0035] 2. The process control is completed by a programmable controller to realize the start-stop and switching of the heating system and the cooling system, and the process settings are input and set by the computer man-machine interface;

[0036] 3. A thermocouple is installed in the furnace to control and detect the temperature of the furnace gas. The programmable controller reserves a metal temperature detection channel. During production, the metal detection thermocouple is connected to this interface to collect the metal temperature and monitor the process. control.

[0037] 2. Control scheme

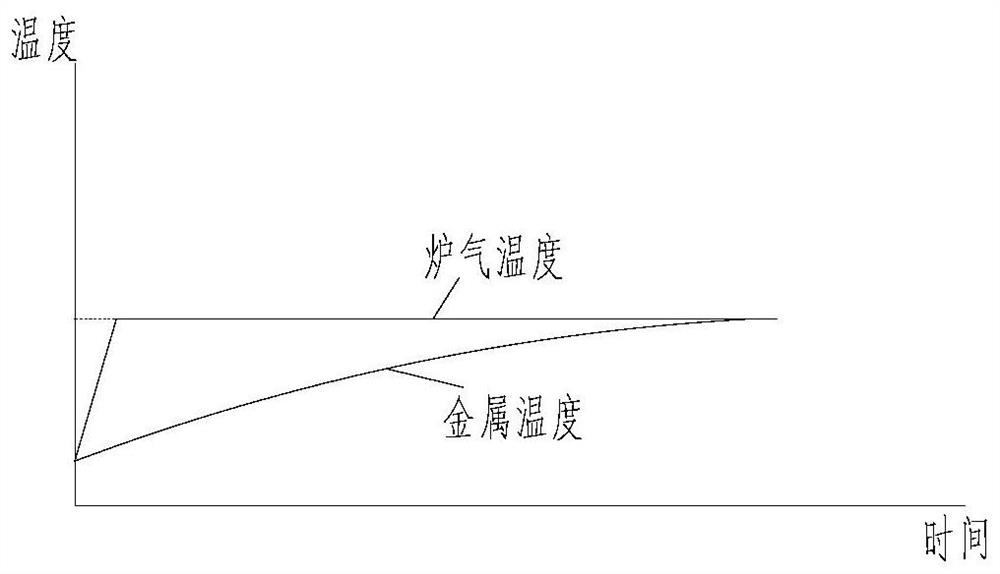

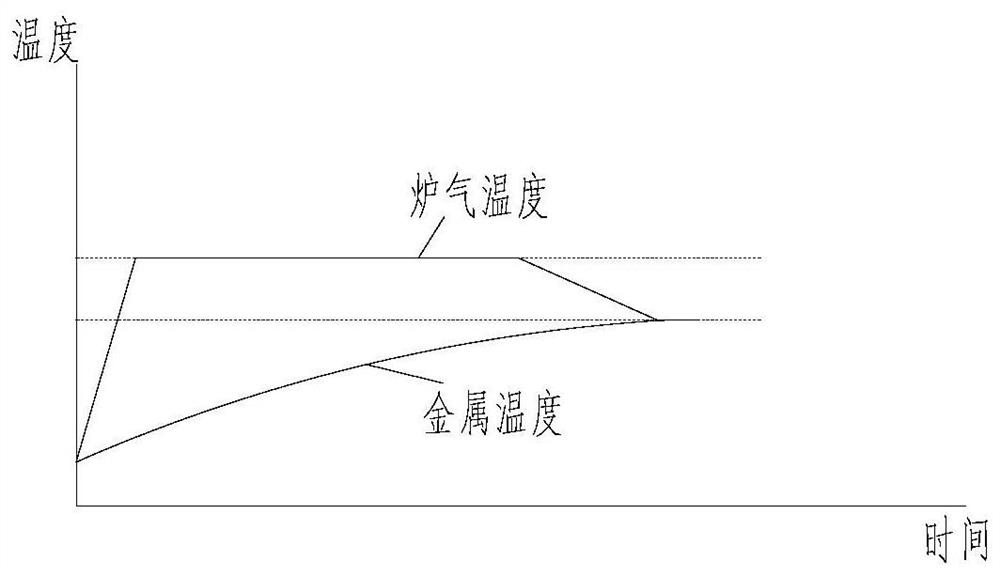

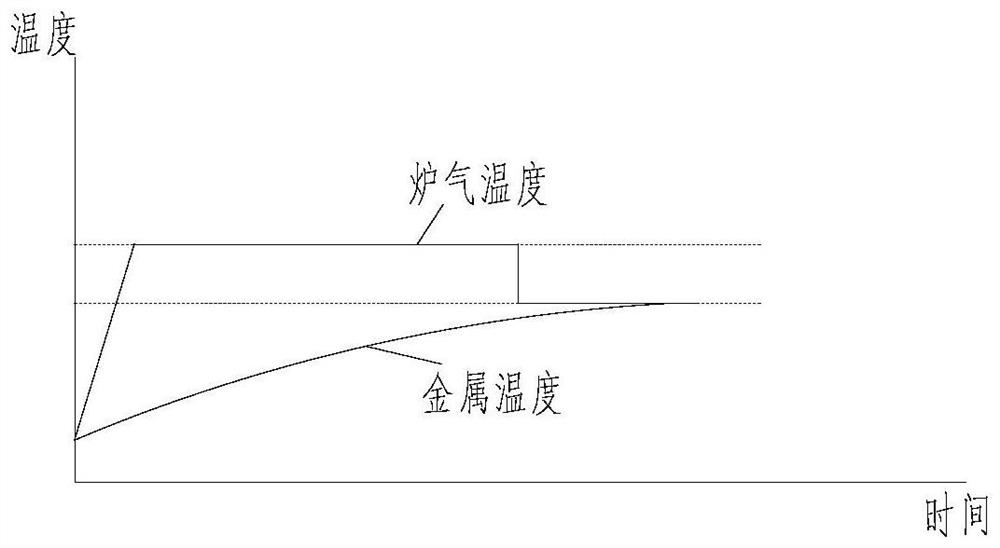

[0038] The programmable controller detects the furnace gas temperature and product temperature (metal tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com