Fischer-Tropsch synthesis method

A technology of Fischer-Tropsch synthesis and synthesis gas, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the production of hydrocarbons from carbon oxides. It can solve the problems of large axial temperature difference in the reactor, difficult control of the reaction temperature, and obvious hot spots. To achieve the effect of reducing the risk of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

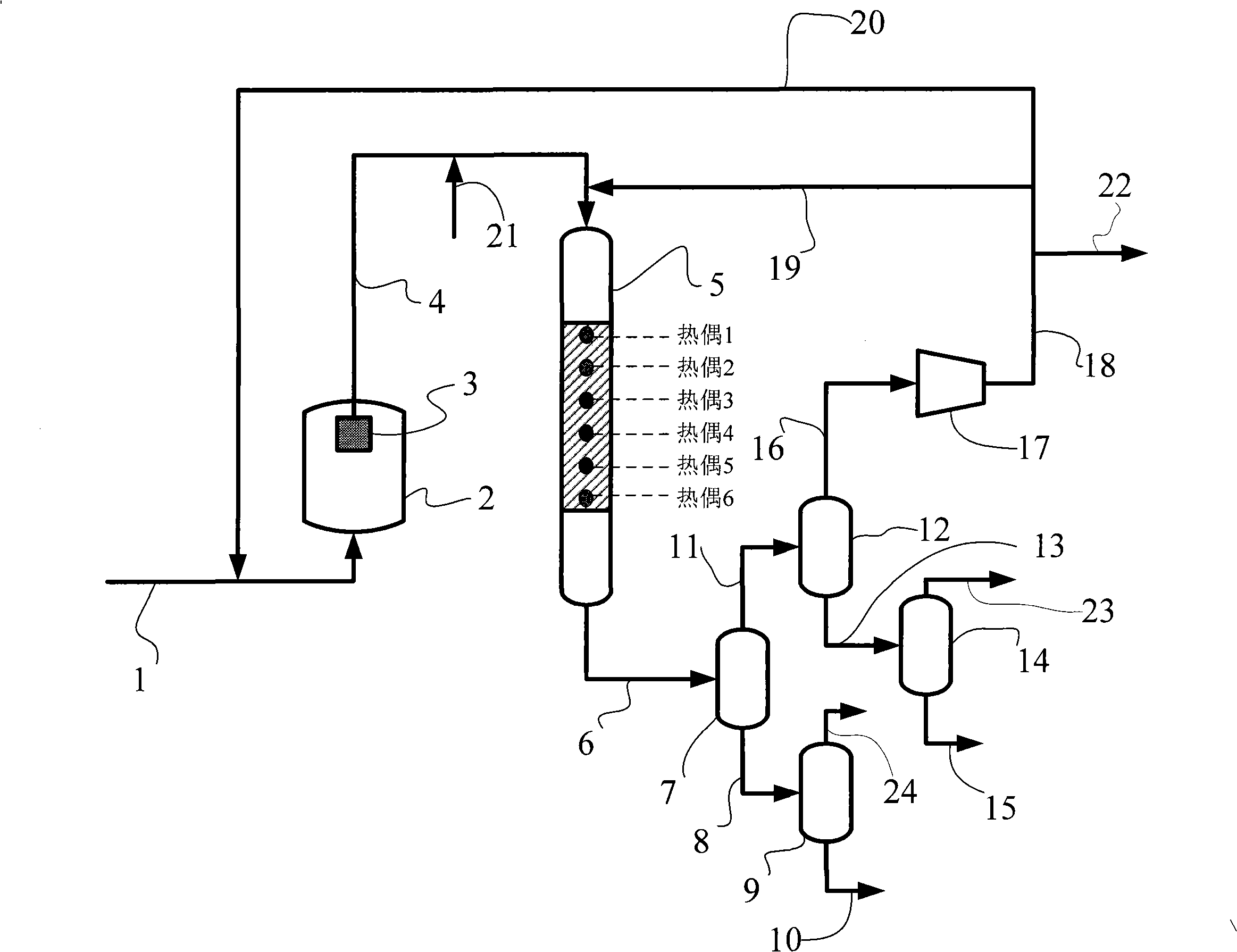

[0050] This embodiment adopts figure 1 In the technical scheme shown, all the reaction products of the first Fischer-Tropsch synthesis reactor (slurry bed reactor) enter the second Fischer-Tropsch synthesis reactor (fixed-bed reactor).

[0051] The operating conditions of the slurry bed reactor are: temperature 210°C, pressure 3.0MPa, reactor inlet H / C molar ratio 2.11.

[0052] The operating conditions of the fixed bed reactor are: the average temperature is 215°C, the pressure is 3.0MPa, and the H / C molar ratio at the reactor inlet is 1.98.

[0053] The gas flow rate is: the fresh synthesis gas flow rate is 16.67L / min (gas volume space velocity is 1000h -1 ), the reactor 2 circulation gas flow rate is 50.01L / min, and the reactor 5 circulation gas flow rate is 20.01L / min.

[0054] The synthesis reaction effect, the distribution of synthetic oil products and the axial temperature distribution of the fixed bed reactor are shown in Table 1.

[0055] Table 1

[0056] ...

Embodiment 2

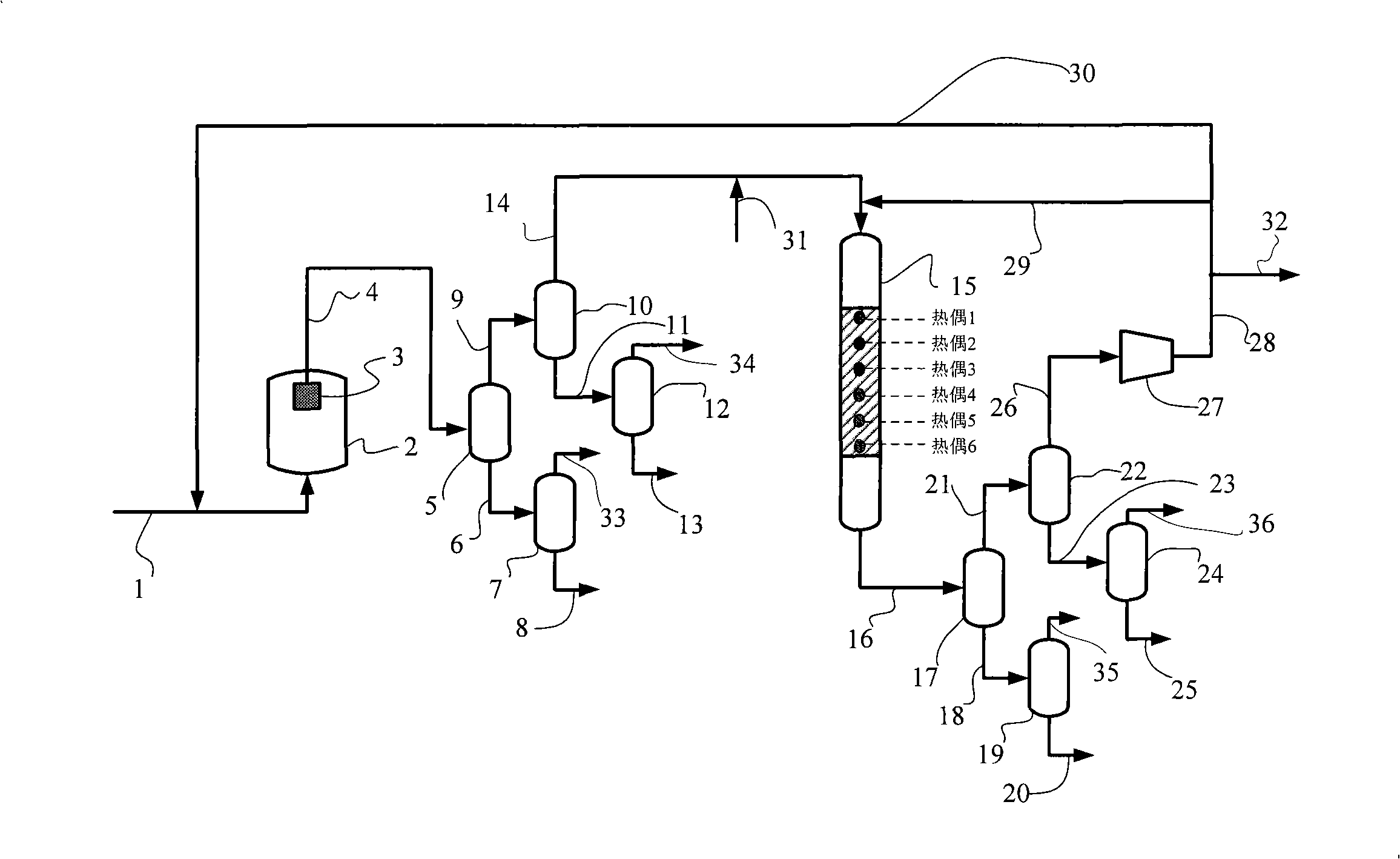

[0058] This embodiment adopts figure 2 In the technical scheme shown, the gas I obtained by separating the reaction effluent of the first Fischer-Tropsch synthesis reactor (slurry bed reactor) enters the second Fischer-Tropsch synthesis reactor (fixed-bed reactor).

[0059] The operating conditions of the slurry bed reactor are: temperature 212°C, pressure 2.8MPa, reactor inlet H / C molar ratio 2.05.

[0060] The operating conditions of the fixed-bed reactor are: temperature 219°C, pressure 2.8MPa, reactor inlet H / C molar ratio 2.00.

[0061] The gas flow rate is: fresh syngas flow rate 12.50L / min (gas volume space velocity is 750h -1 ), the reactor 2 circulation gas flow rate is 43.75L / min, and the reactor 15 circulation gas flow rate is 15.00L / min.

[0062] The synthesis reaction effect of the slurry bed and the fixed bed together, the distribution of the synthetic oil product and the axial temperature distribution of the fixed bed reactor are shown in Table 2.

[0063] T...

Embodiment 3

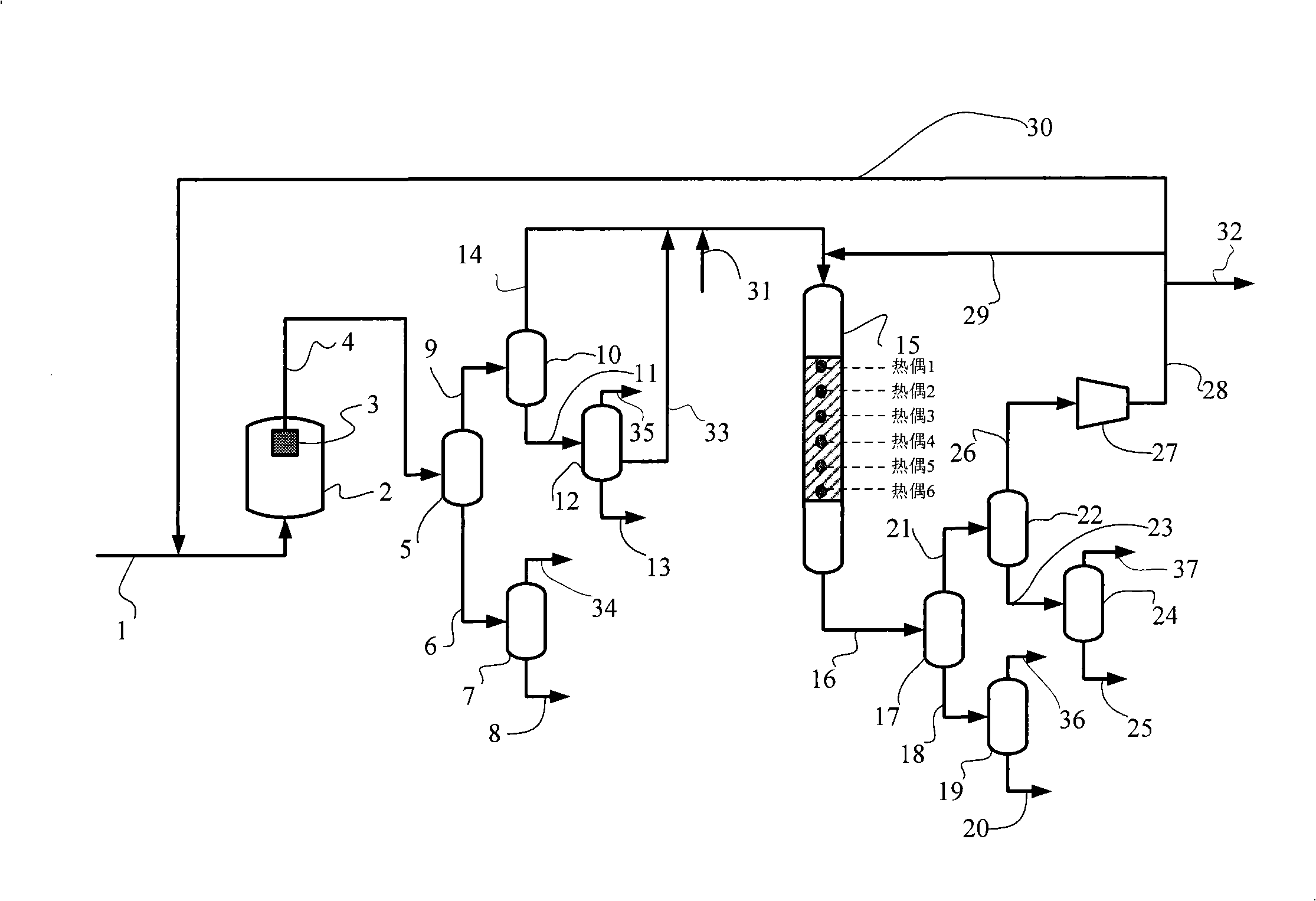

[0066] This embodiment adopts image 3 In the technical scheme shown, the first Fischer-Tropsch synthesis reactor (slurry bed reactor) reaction effluent separation gas I and low-temperature condensate enter the second Fischer-Tropsch synthesis reactor (fixed-bed reactor).

[0067] The operating conditions of the slurry bed reactor are: temperature 212°C, pressure 3.0MPa, reactor inlet H / C molar ratio 2.02.

[0068] The operating conditions of the fixed bed reactor are: temperature 215°C, pressure 3.0MPa, reactor inlet H / C molar ratio 1.92.

[0069] The gas flow rate is: fresh syngas flow rate 8.33L / min (gas volume space velocity is 500h -1 ), the circulating gas flow rate of reactor 2 is 33.32 L / min, and the circulating gas flow rate of reactor 15 is 11.65 L / min.

[0070] The synthesis reaction effect of the slurry bed and the fixed bed together, the distribution of the synthetic oil product and the axial temperature distribution of the fixed bed reactor are shown in Table 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com