Batch type microwave grain dryer and drying method

A grain dryer and grain technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of reduced grain drying quality, reduced drying efficiency, and small drying and ventilation area, so as to reduce excessive heating The risk of drying, the effect of ensuring drying quality and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

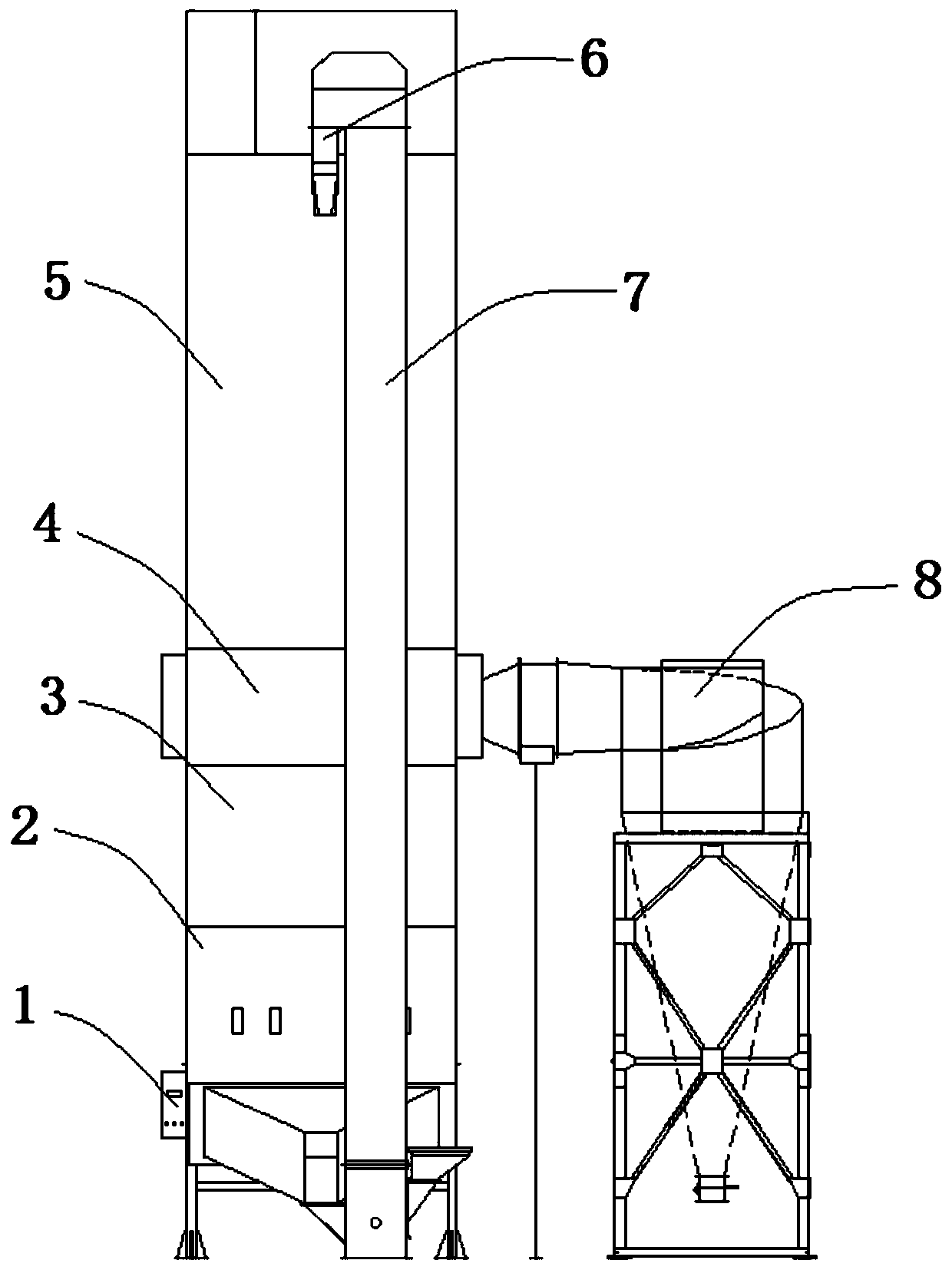

[0034] Batch Microwave Grain Dryer

[0035] Such as figure 1 , figure 2 As shown, a grain hoist 7 is provided, and from top to bottom, there are interconnected slowing warehouses 5, a drying chamber 4, a collection chamber 3, and a microwave heating device 2. The drying chamber 4 is used to dry and dehumidify the grain. The microwave heating device 2 is used for microwave heating of grain. The discharge port on the grain hoist 2 upper end is communicated with the slow Su warehouse 5. The upper and lower parts of the Susu warehouse are equipped with material level gauges and height gauges respectively, and the grain volume changes in the warehouse are monitored during the drying process. During implementation, the discharge port at the upper end of the grain hoist is provided with an upper auger 6, and the upper auger 6 is provided with a screw auger, an even distributor and an electric grain discharge device. The discharge port of the microwave heating device 2 is communi...

Embodiment 2

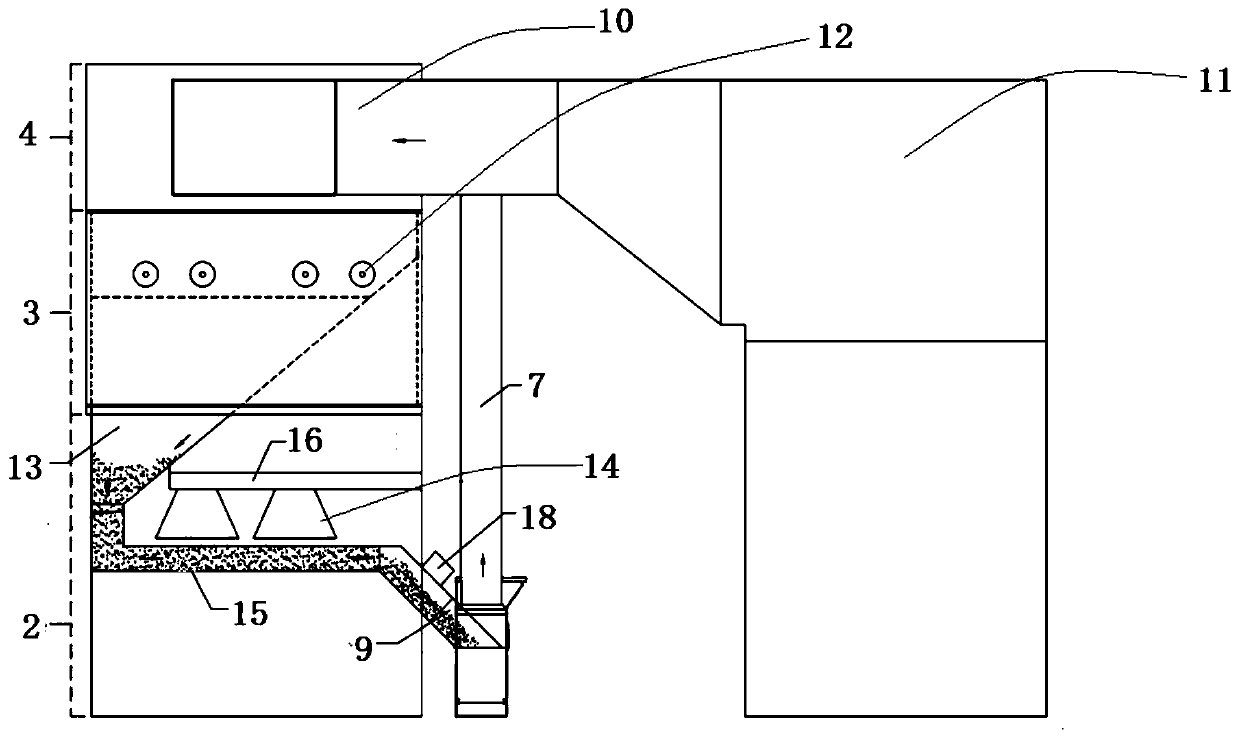

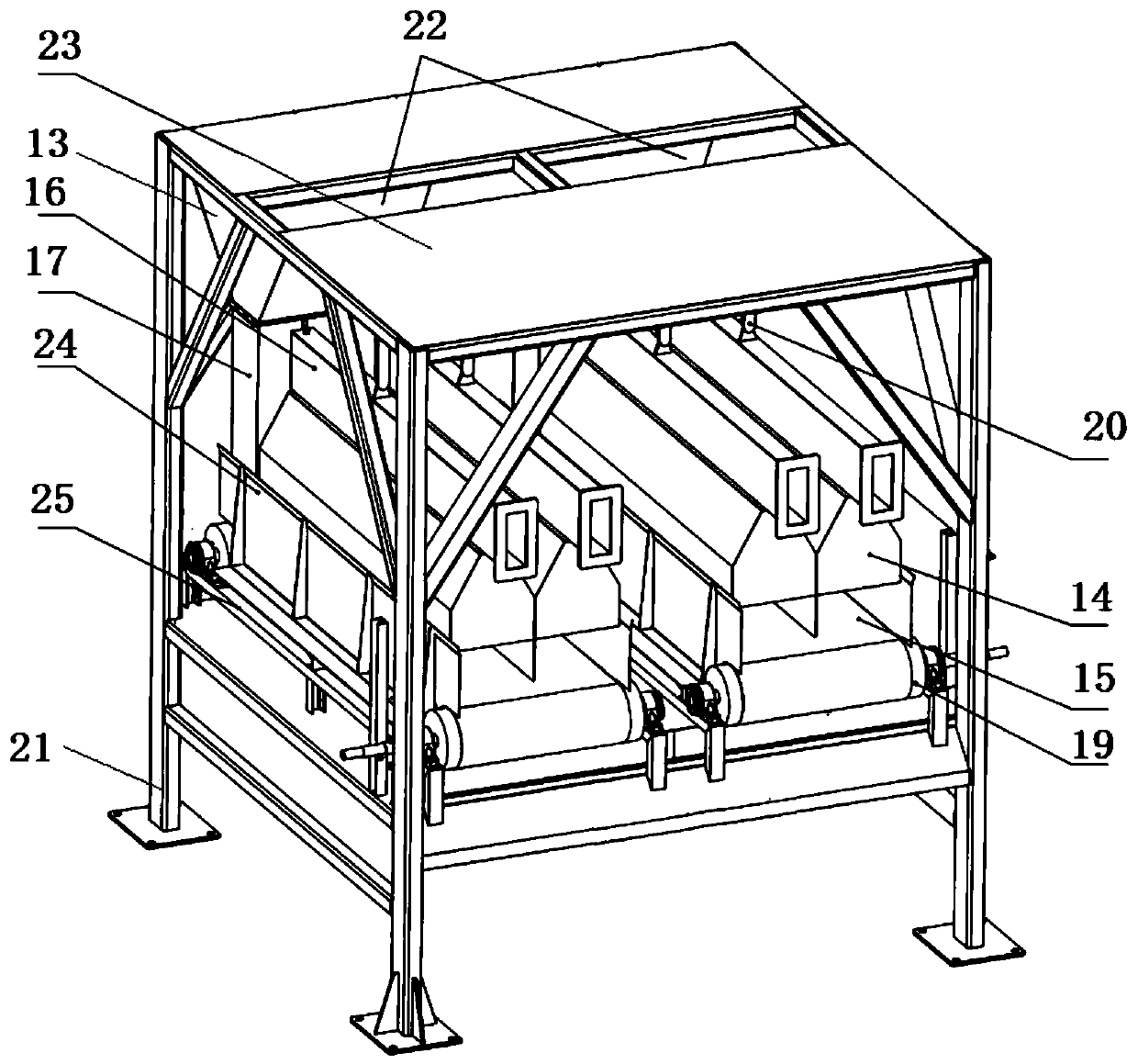

[0038] Batch Microwave Grain Dryer

[0039] The difference between the second embodiment and the first embodiment lies in the structure of the microwave heating device. Such as figure 2 , image 3 As shown, the microwave heating device comprises a collection hopper 13, a microwave heater 14 and a horizontally arranged grain conveyor belt 15, the microwave heater 14 is positioned above the grain conveyor belt 15, and the feed inlet at the top of the collection hopper 13 and the discharge at the bottom of the collection chamber 3 The mouth is connected, and the discharge port of collecting bucket 13 links to each other with the feeding end of grain conveyer belt 15, and the discharge end of grain conveyer belt 15 is connected with the feed port of grain hoist 7 lower ends through gathering box 9. The microwave heater 14 consists of a radiation box, a waveguide, and a horn-shaped transmitting antenna. The waveguide and the transmitting antenna are located in the radiation box....

Embodiment 3

[0042] Drying method based on the above-mentioned batch microwave grain dryer

[0043] The wet grain enters through the feed port of the grain hoist, and performs circulation drying. Such as Figure 5 Shown, drying method comprises the steps:

[0044] Step 1: The grain is dried and dehumidified by hot air in the drying chamber, and then enters the microwave heating device through the collection chamber through the action of the grain discharge wheel in the collection chamber;

[0045] Step 2: The grain is microwave-heated in the microwave heating device, and the inside and outside of the grain are evenly heated at the same time to accelerate the internal moisture transfer rate, and then enter the slow-sum warehouse through the grain elevator;

[0046] Step 3: The grain is tempered in the tempering warehouse, and the moisture inside the grain is fully transferred to the outside in the tempering warehouse and then enters the drying room; the tempering time is not less than 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com