Patents

Literature

47results about How to "Not easy to cause accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data transmission method and device

ActiveCN107979449ANot easy to cause accumulationAvoid cloggingError prevention/detection by using return channelProtocol for Carrying Authentication for Network AccessData transmission

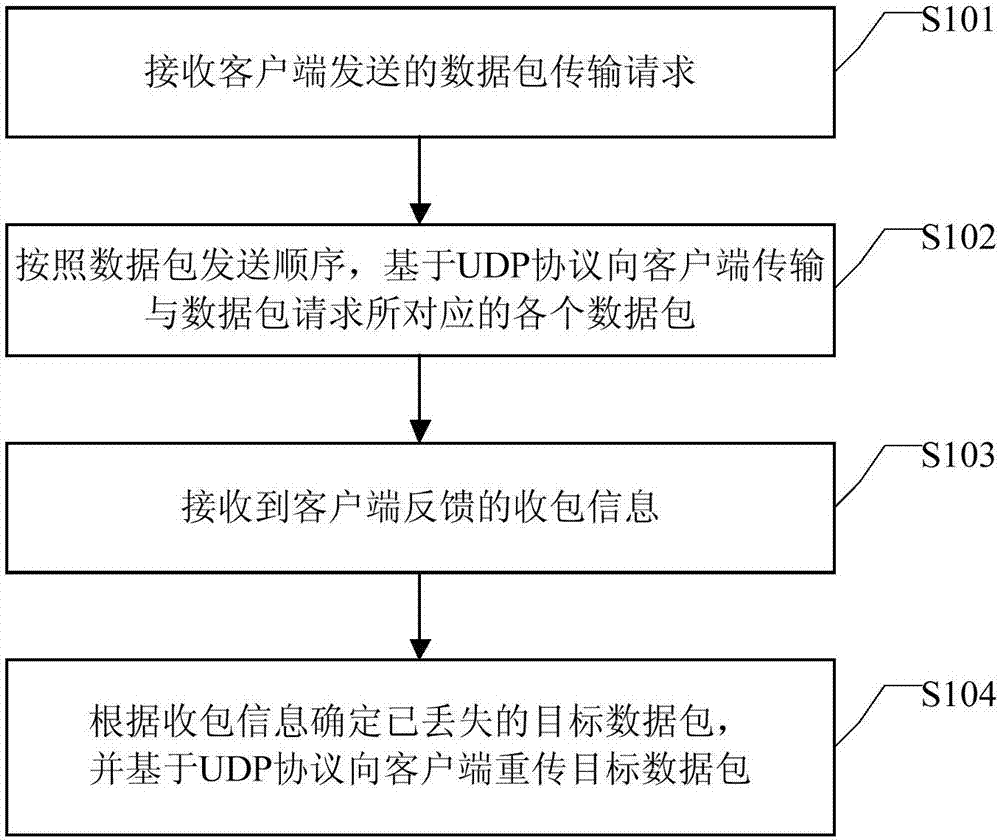

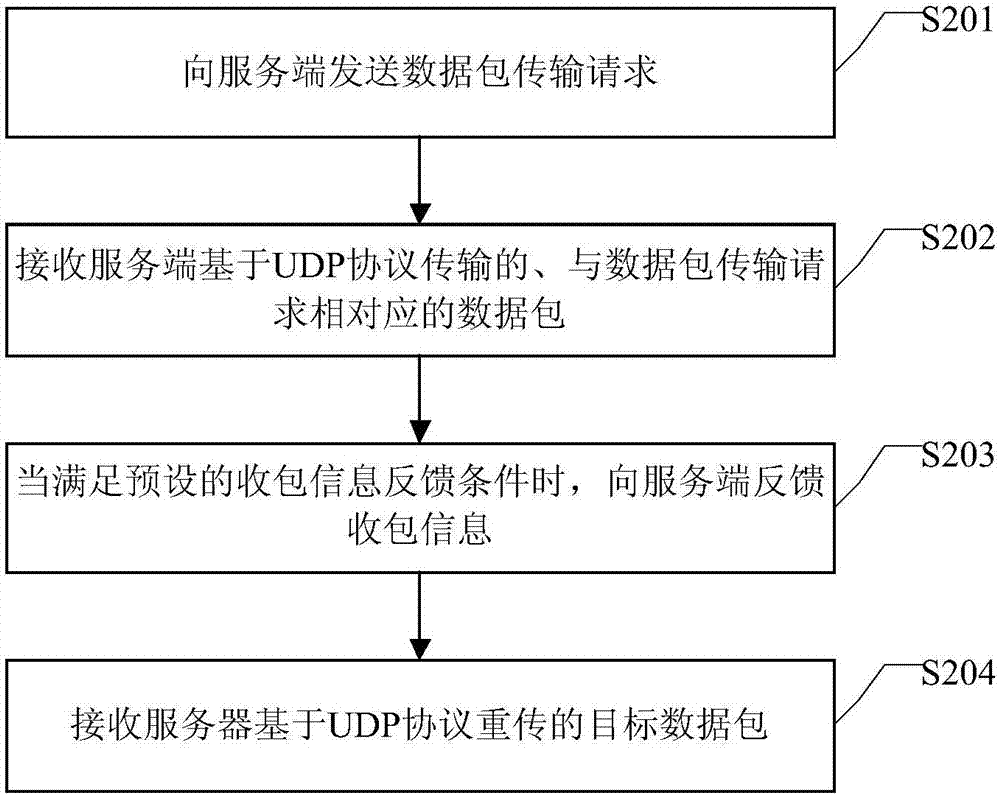

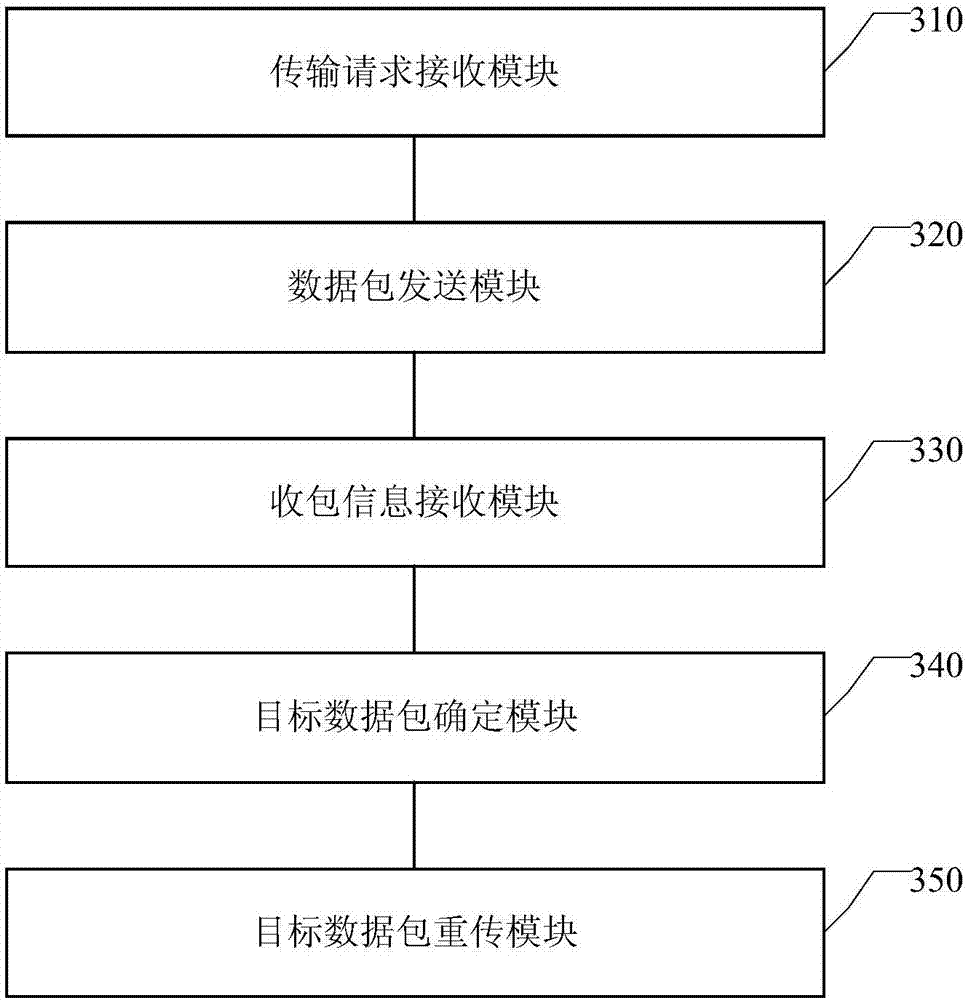

Embodiments of the invention provide a data transmission method and device. The method comprises the following steps of receiving a data packet transmission request sent by a client; transmitting eachdata packet corresponding to the data packet request to the client based on a UDP according to a data packet sending sequence, wherein each data packet carries a serial number corresponding to the data packet, and the data packet sending sequence is a sequence determined according to the serial number of each data packet; receiving packet receiving information fed back by the client; and determining a lost target data packet according to the packet receiving information, and retransmitting the target data packet to the client based on the UDP. When a scheme provided by the embodiments of theinvention is applied for data transmission, a server transmits each data packet to the client based on the UDP, and the lost target data packet is retransmitted according to the packet receiving information, and furthermore, when the data packet is lost, the UDP does not need to narrow the frequency band width of a transmission network, accumulation of data packets is hardly caused, and a problemof data packet blockage is avoided.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Aloe/viscose/modal function sweater and manufacture method thereof

ActiveCN103156302AHigh strengthGood hygroscopicityWeft knittingProtective garmentManufacturing technologyGram

The invention relates to an aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater. The aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater are characterized by utilizing fabric weave which is plain weave. Yarn is formed by twisting two strings of 32S fiber siro spun yarn made of 40 percent of aloes, 40 percent of modal and 20 percent of viscose. The doubling twist degree is 320 twist / m, and gram weight is 285g / square meter. Manufacture technology includes that three kinds of fiber siro spun yarn undergo rewinding, panel knitting, looping, flat sewing, hand sewing, washing, drying, pressing, packaging and warehouse entering. In the process of spinning the three kinds of fiber siro spun yarn, main body rough yarn do not pass by a rear roller on a spinning machine, the rough yarn is assisted in feeding with interruption through the rear roller, and diameter runout of the roller is controlled to be small than 0.03mm. The aloe / viscose / modal function sweater is low in cost, less in hairiness, and good in bacteria resistance.

Owner:JIANGYIN XIANGFEI APPAREL

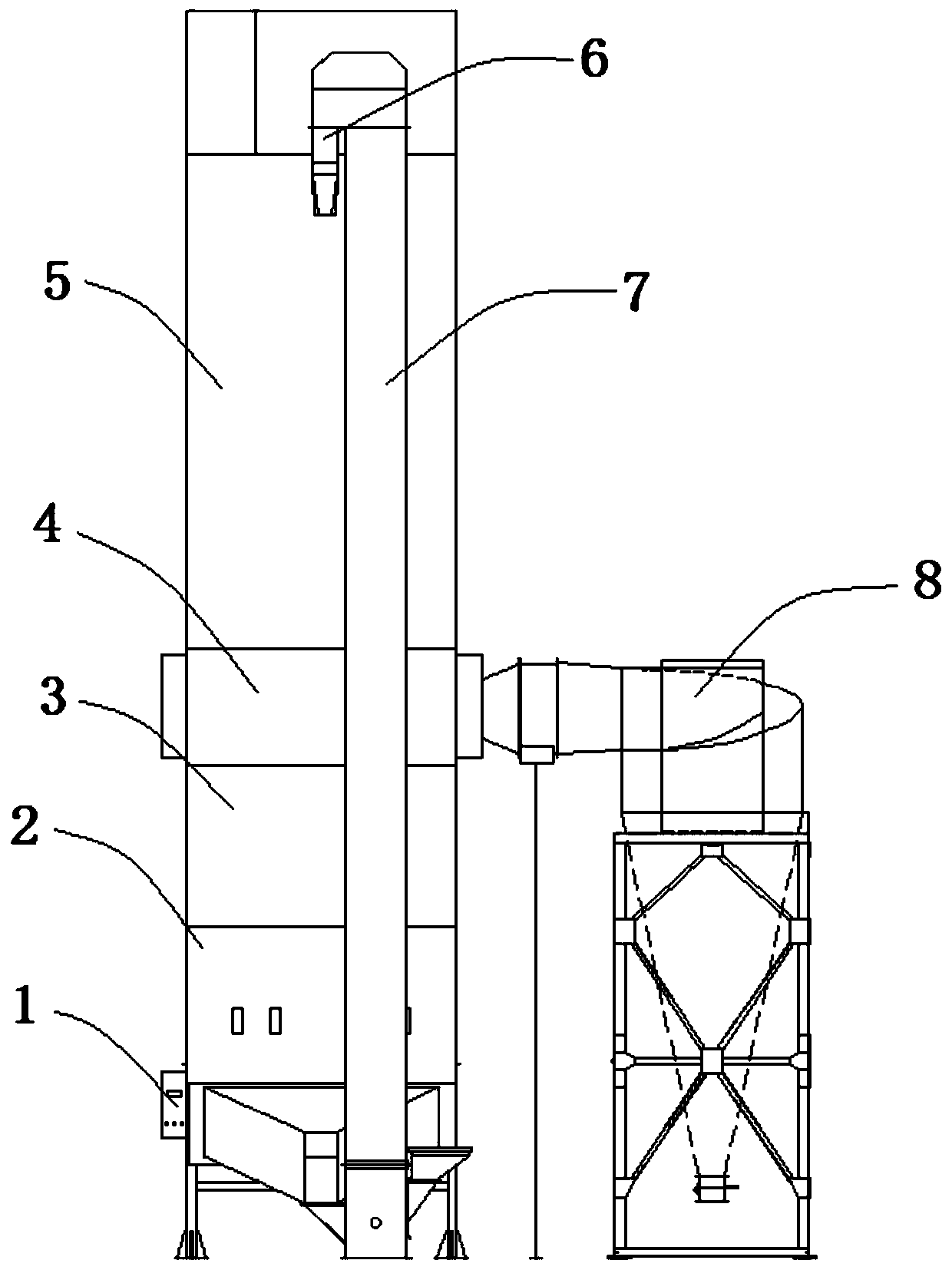

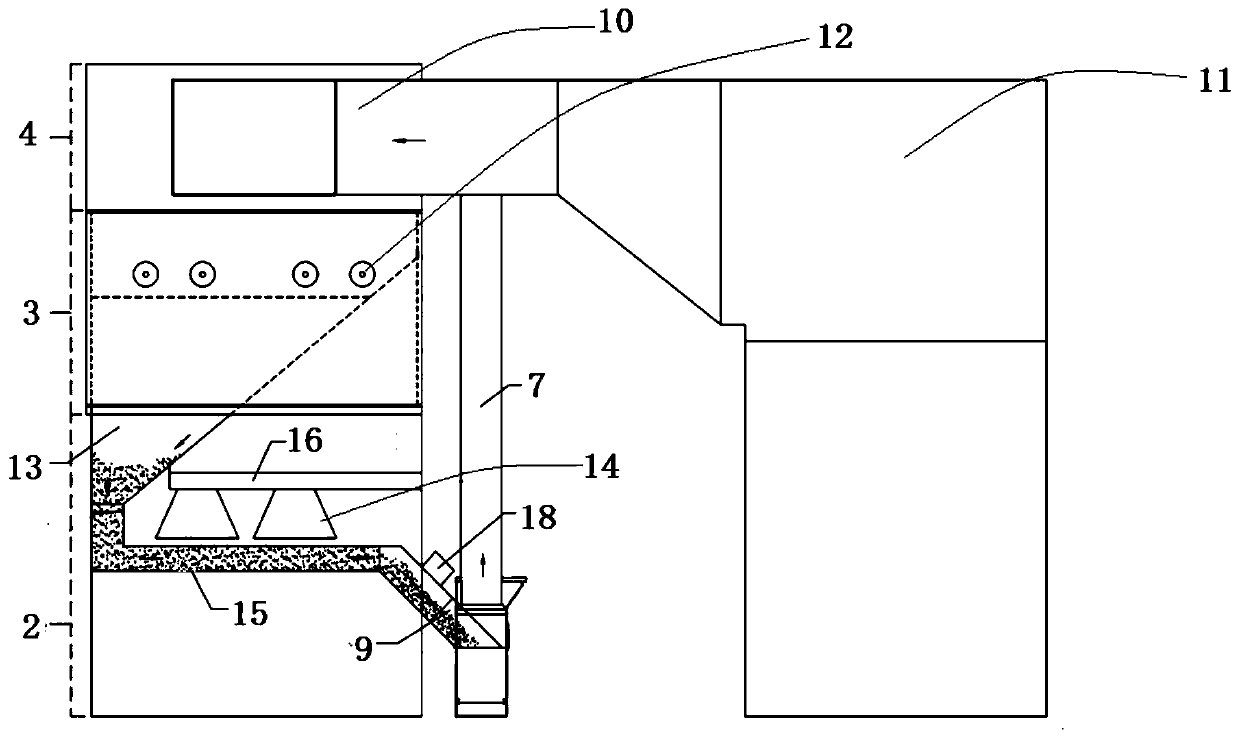

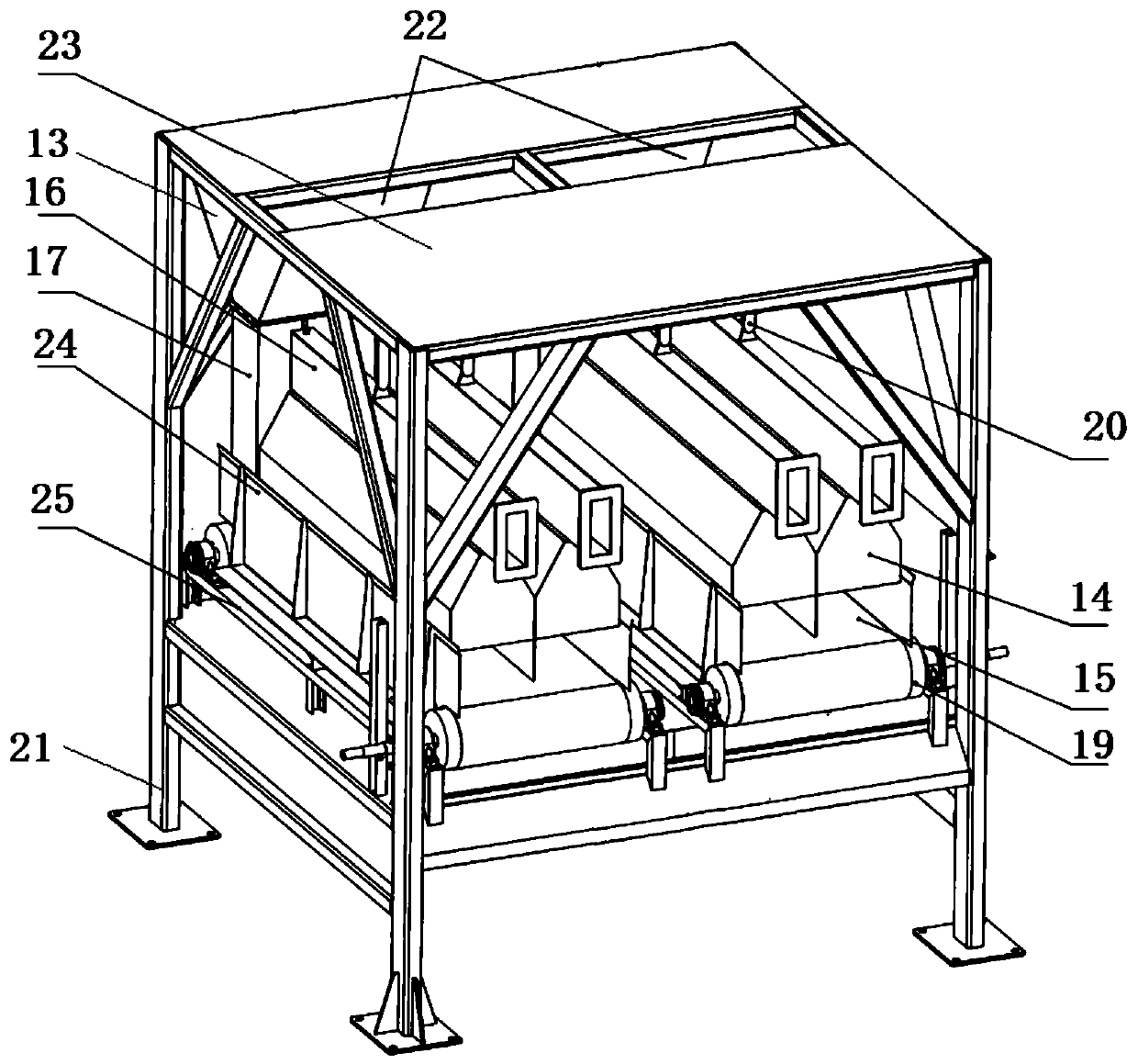

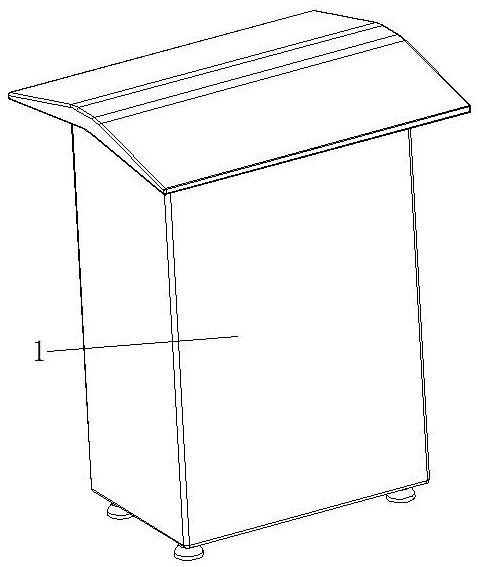

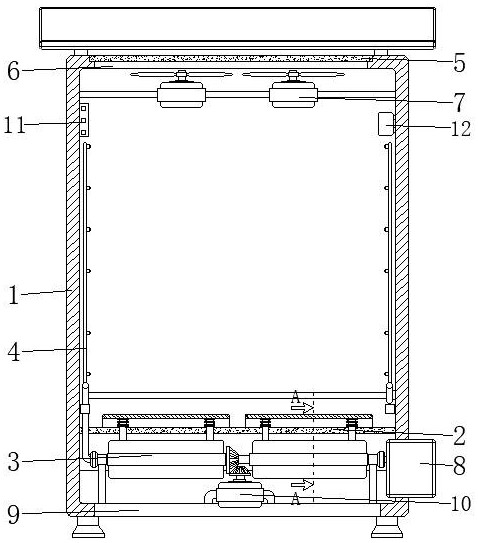

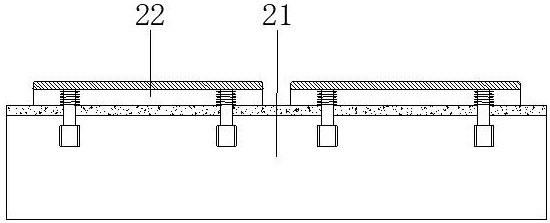

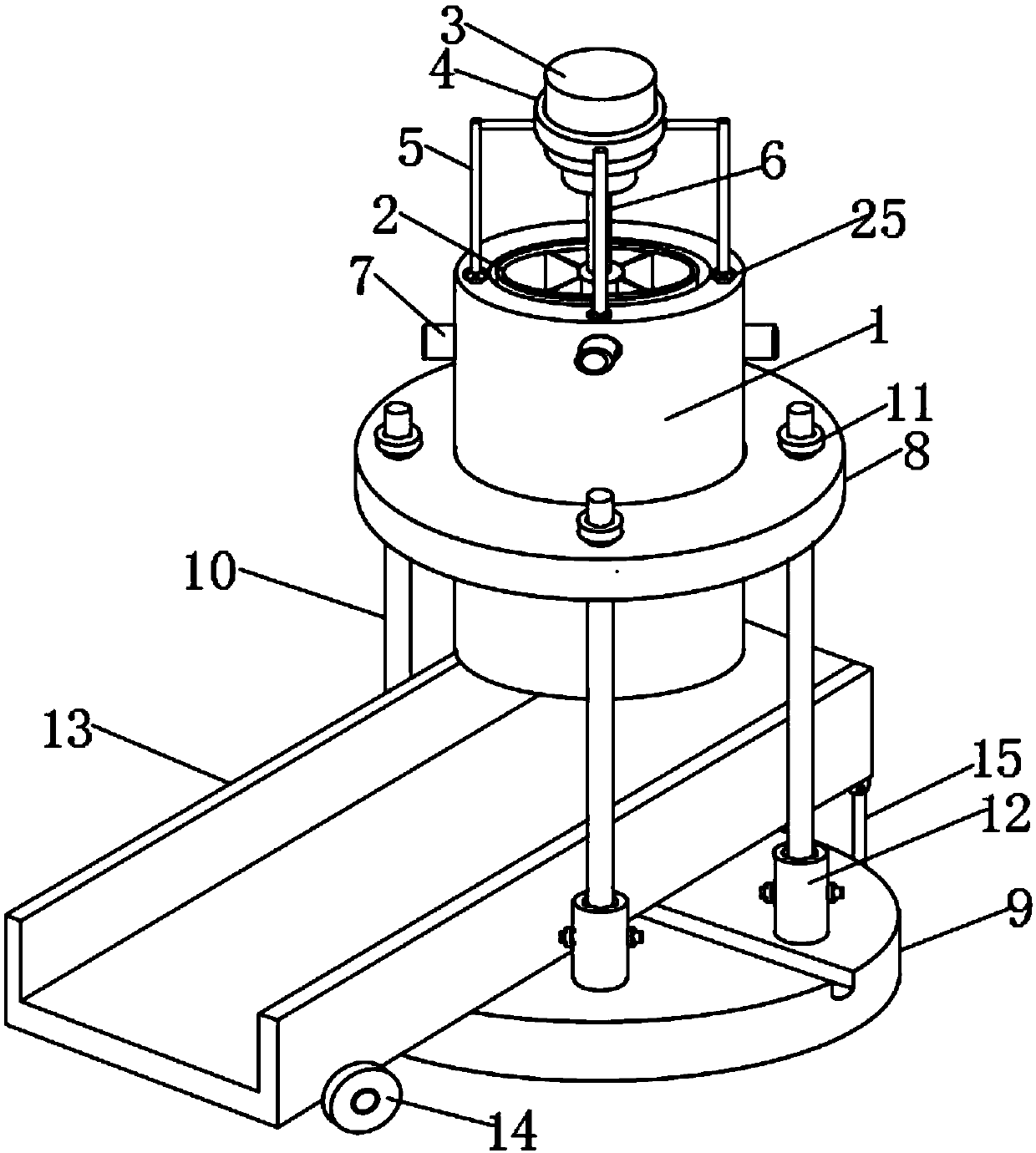

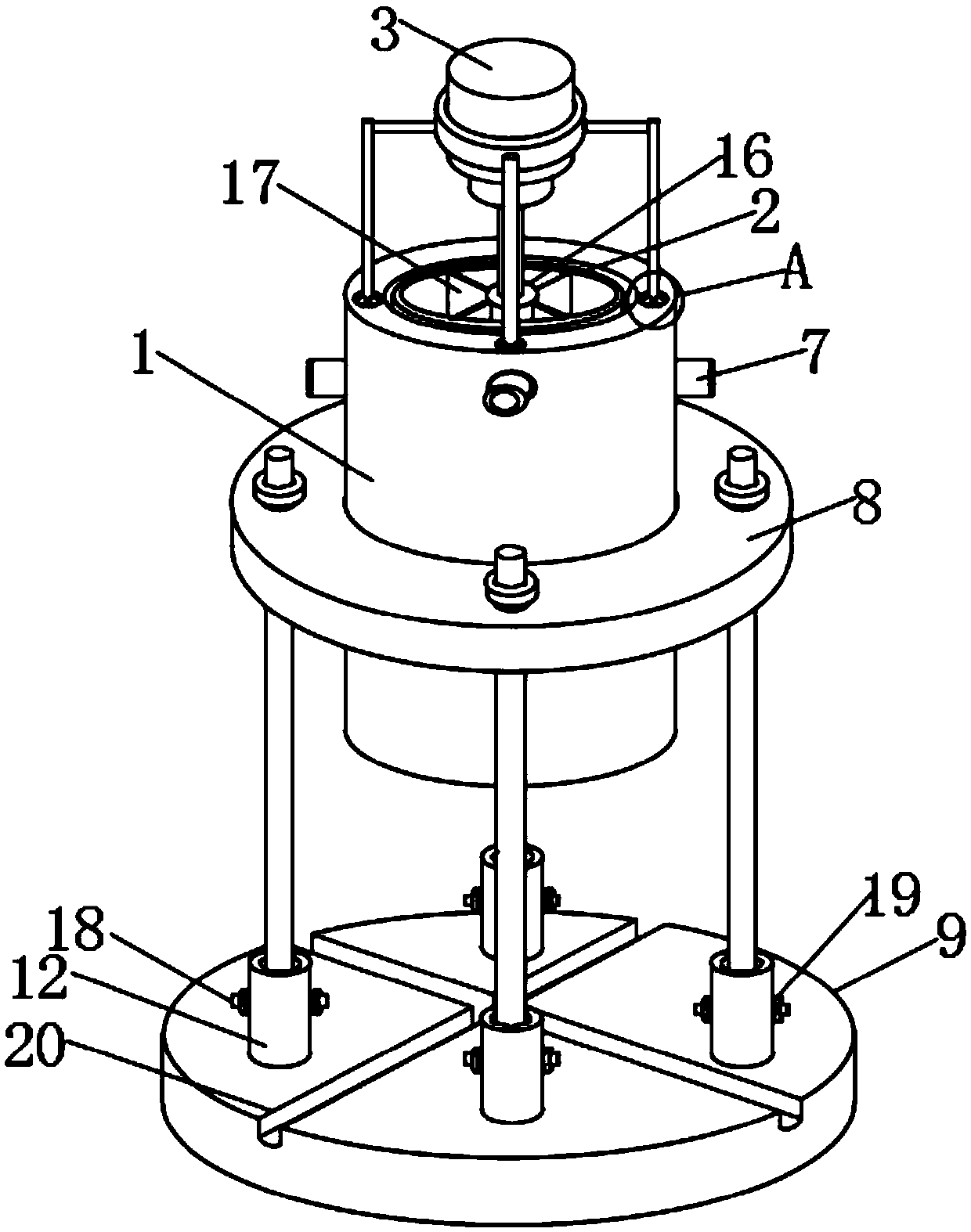

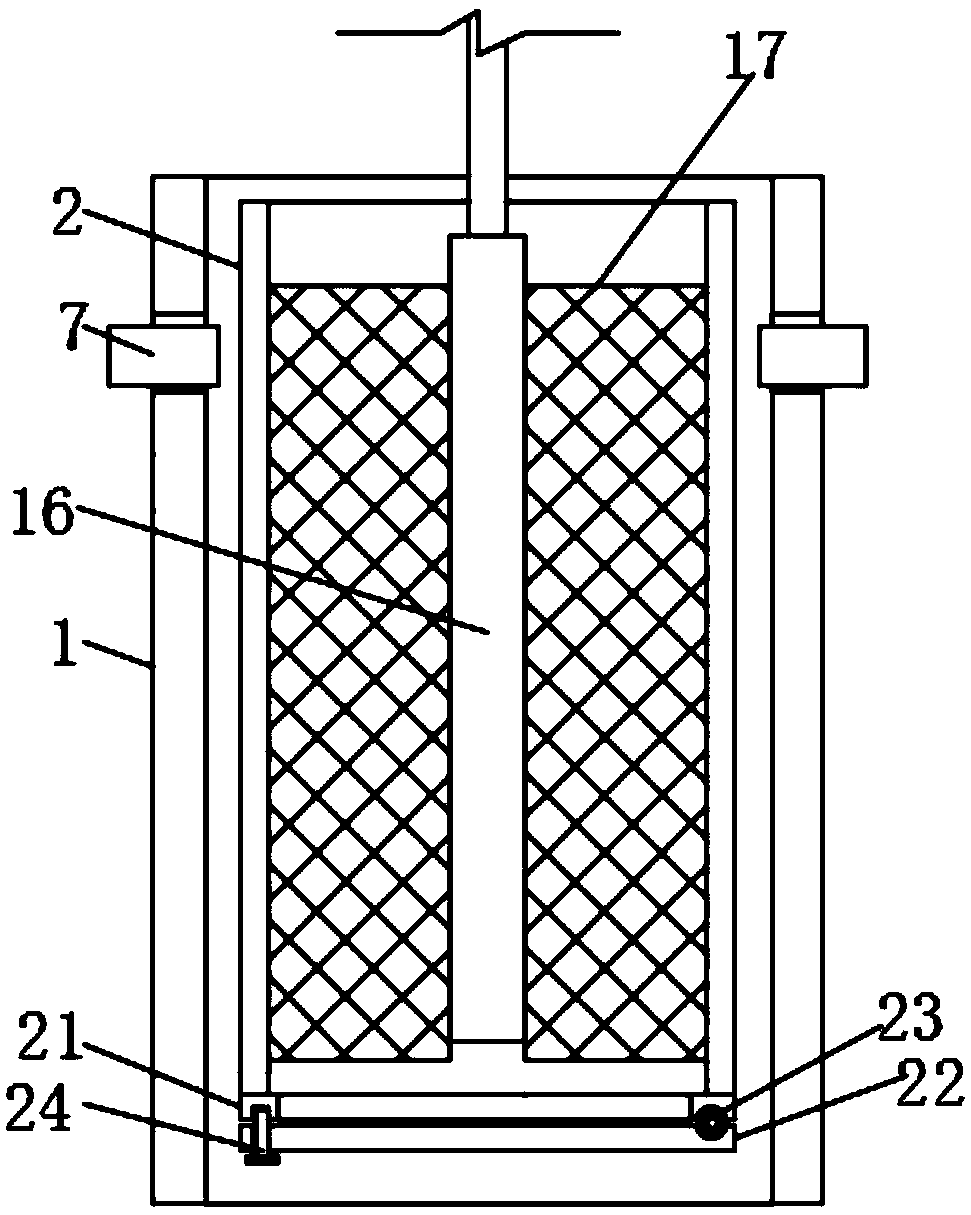

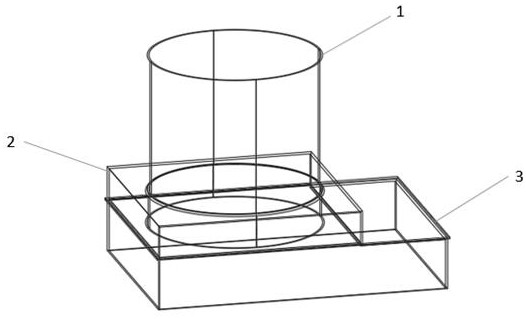

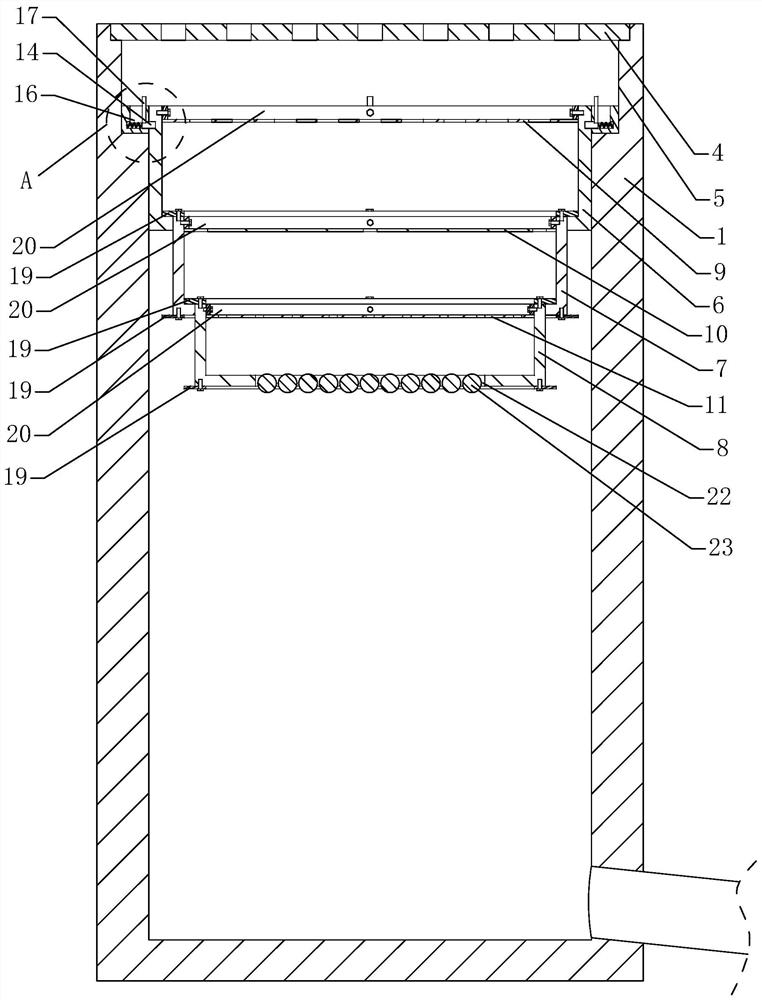

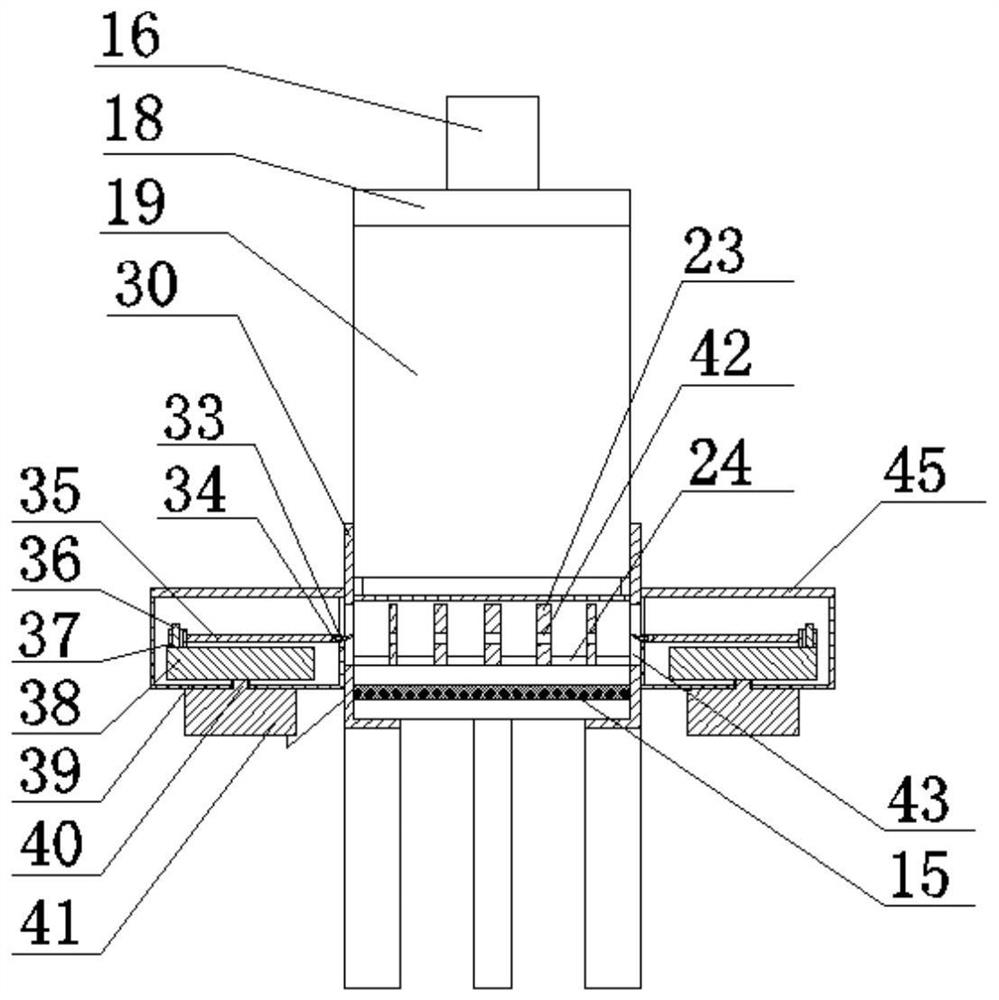

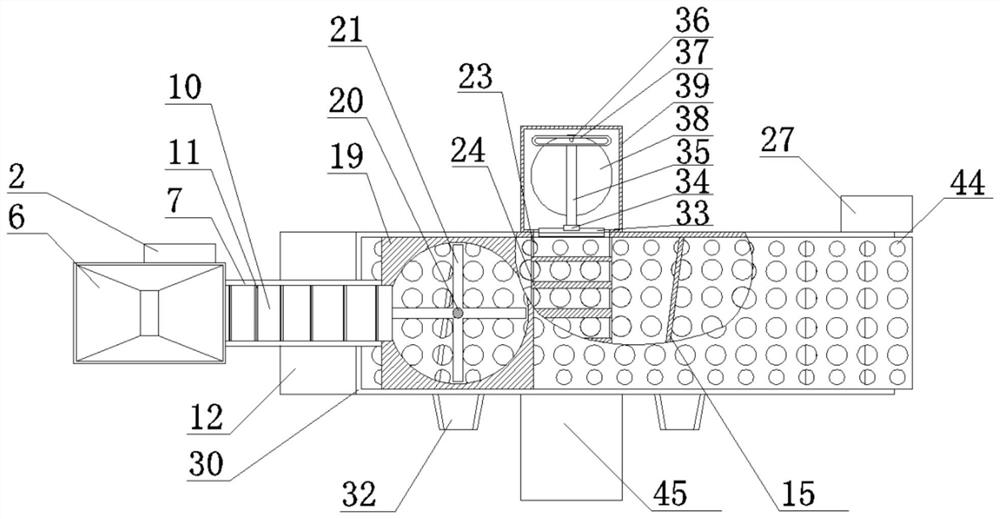

Batch type microwave grain dryer and drying method

PendingCN110094944AReduce waist burst rateReduce moisture gradientDrying solid materials with heatDrying gas arrangementsMicrowaveGrain elevator

The invention relates to a batch type microwave grain dryer and a drying method. The batch type microwave grain dryer is provided with a grain elevator, and a tempering bin, a drying chamber, a collecting chamber and a microwave heating device which are connected with each other are sequentially arranged from top to bottom, wherein the drying chamber is used for drying and dehumidifying grains, and the microwave heating device is used for microwave heating of grains; a discharging port at the upper end of the grain elevator is connected with the tempering bin, and a discharging port of the microwave heating device is connected with a feeding port at the lower end of the grain elevator. According to the batch type microwave grain dryer, the grain discharging speed, the microwave heating radiation frequency and the temperature and humidity of the drying chamber hot air are controlled according to grain temperature and grain moisture, so that variable temperature and variable frequency drying are realized, and the drying efficiency of the grain is effectively improved.

Owner:ZOOMLION HEAVY MASCH CO LTD

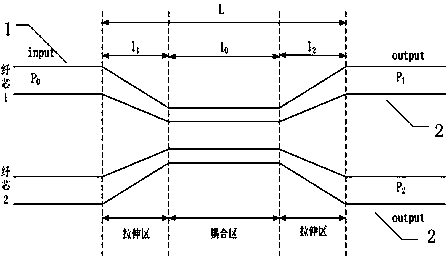

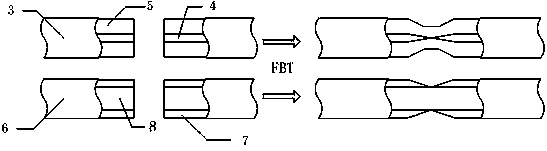

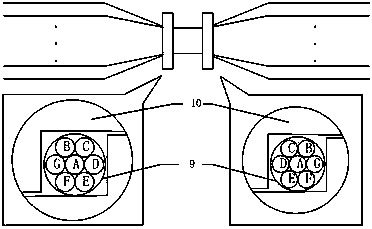

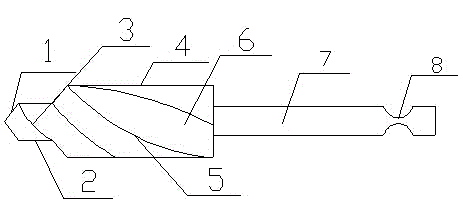

Great-core-diameter optical fiber coupler and manufacturing method of great-core-diameter optical fiber coupler

ActiveCN104345388AHigh energy laserReduce the risk of distortionCoupling light guidesLight spotTransmittance

The invention discloses a great-core-diameter optical fiber coupler, which comprises an input optical fiber and n output optical fibers, wherein the n is greater than or equal to 1 but smaller than or equal to 6, the core diameter of the input optical fiber is 200 to 600mum, the core-to-sheath ratio range of the input optical fiber is 1:1.04 to 1:1.25, the core diameter of each output optical fiber is 200 to 400mum, the core-to-sheath ratio of the output optical fiber is identical to that of the input optical fiber, the input optical fiber and the output optical fibers are fixed and twisted in a coupling region, one end, in the coupling region, of the input optical fiber is the output end of the input optical fiber, the other end of the input optical fiber is the input end of the input optical fiber, one end, in the coupling region, of each output optical fiber is the input end of each output optical fiber, and the other end of each output optical fiber is the output end of the output optical fiber. The great-core-diameter optical fiber coupler has the advantages that the optical fiber coupling difficulty is low, the light splitting ratio of the coupler is uniform, the optical fiber uncoaxiality caused by optical fiber accumulation in the coupling region is reduced, the light spot divergence angle is smaller than 30 degrees, the transmittance is greater than 70 percent, any light splitting ratio can be realized, and the light splitting ratio deviation is + / -7 percent.

Owner:NANJING CHUNHUI SCI & TECH IND

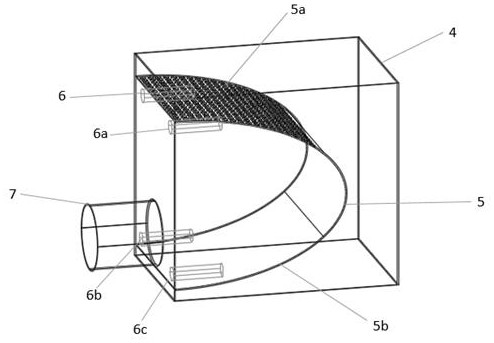

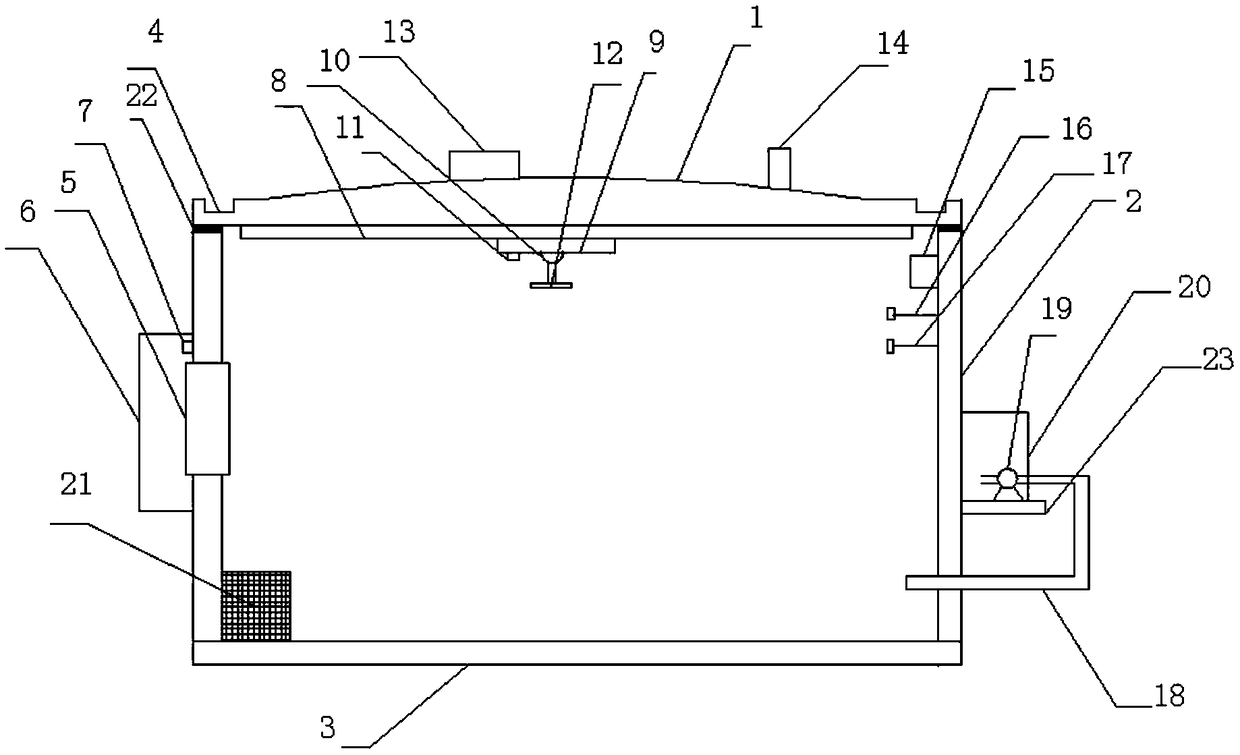

Intelligent power supply equipment based on front-end power utilization monitoring

ActiveCN113725745AReduce entryNot easy to cause accumulationDispersed particle filtrationSubstation/switching arrangement cooling/ventilationControl engineeringDust control

The invention discloses intelligent power supply equipment based on front-end power utilization monitoring. The intelligent power supply equipment comprises a box body, a filtering device, a driving device and an air injection device, wherein the filtering device is arranged in the box body and is close to the bottom, the driving device is arranged at the bottom of the inner wall of the box body and is located below the filtering device, a cleaning device is connected to the top of the surface of an arc-shaped filter screen in a matched mode, a guide rod is fixed to the bottom of an arc-shaped shell and slidably connected with the arc-shaped filter screen, a reset tension spring is fixed between the two corresponding sides of the bottom of the arc-shaped shell and the top of the arc-shaped filter screen and located on the surface of the guide rod, and a knocking devices are arranged on the two corresponding sides of the surface of the arc-shaped shell. The invention relates to the technical field of power supply equipment. According to the intelligent power supply equipment based on front-end power utilization monitoring, the effects of heat dissipation and dust removal are achieved, rapid heat dissipation can be conducted on the equipment, dust entering the equipment is reduced, dust accumulation is not likely to happen, self-cleaning can be conducted, the blocking situation is not likely to happen, and the use performance is improved.

Owner:佐力西江苏物联科技有限公司

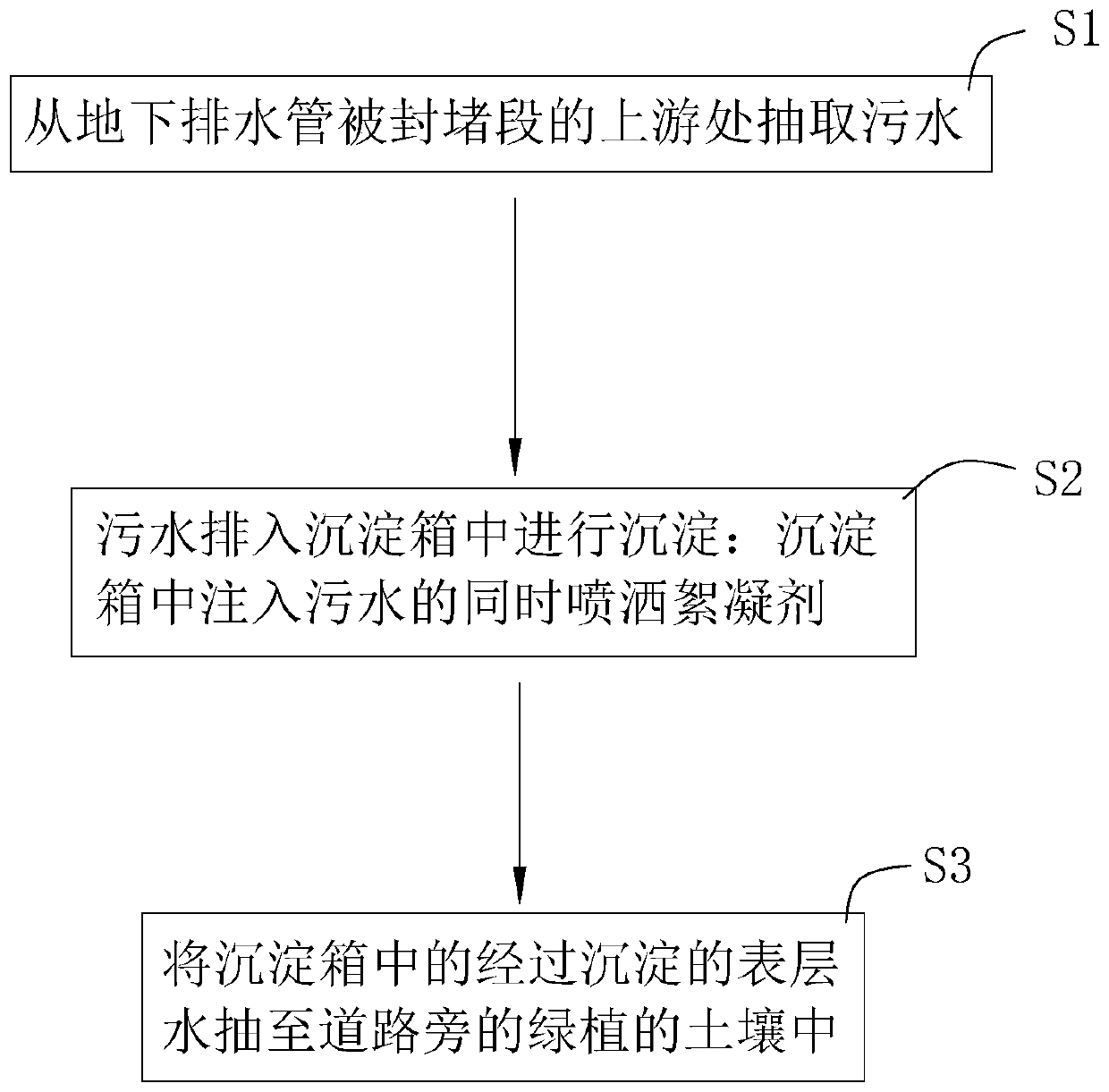

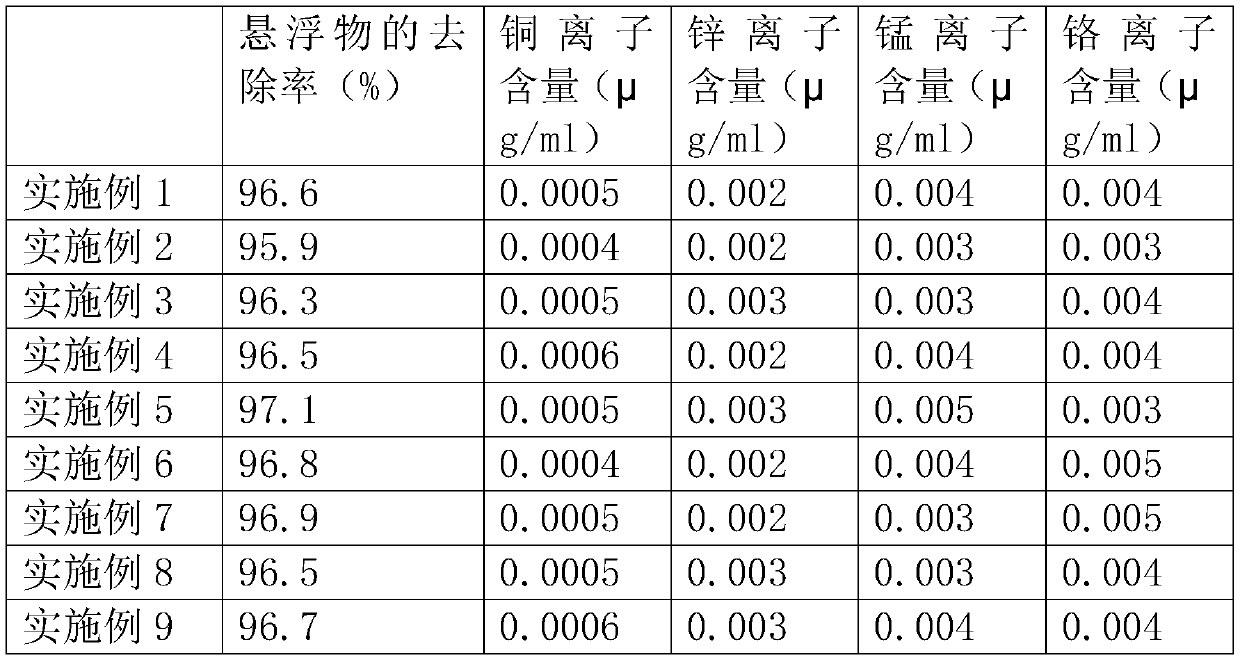

Treatment method of urban domestic sewage

InactiveCN110526369AEasy to salvageLess prone to hard-to-clean situationsWater/sewage treatment by flocculation/precipitationSubsurface drainageFiltration

The invention relates to the technical field of sewage treatment and provides a treatment method of urban domestic sewage for solving the problem that sewage is prone to being accumulated when an underground drainage pipe is maintained. According to the technical scheme, the treatment method comprises the steps that S1, the sewage is pumped from the upstream part of a blocked section of the underground drainage pipe; S2, the sewage is discharged into a settling tank to be precipitated, and meanwhile, a flocculant is sprayed; and S3, precipitated surface water in the settling tank is pumped into soil of green plants beside a road, wherein the flocculant is prepared from the following components in parts by mass: 100 parts of polyacrylamide, 15-20 parts of casein, 33-36 parts of methylcellulose, 3-5 parts of zinc oxide and 5-8 parts of activated carbon, and the settling tank is internally provided with an underwater ultraviolet lamp. The sewage is pumped out, treated and then dischargedinto the soil of the green plants beside the road, thus plant growth is not prone to being affected, through further filtration by soil and the plants, the treated sewage is discharged into the soil and then further purified, thus the sewage is not prone to being accumulated, the environment is not prone to being polluted, and environmental friendliness is realized.

Owner:鸿粤智慧环境科技有限公司

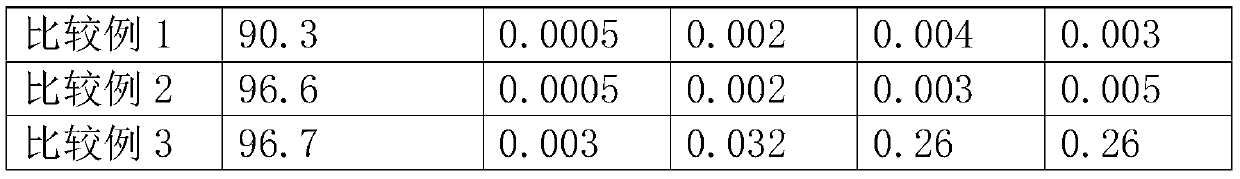

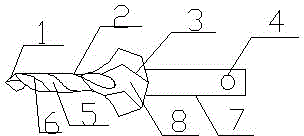

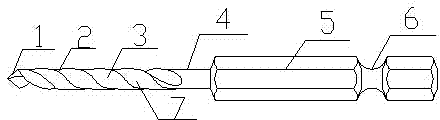

Hard alloy reaming drill bit

InactiveCN104858842AExtended service lifeReduce drilling effortPortable percussive toolsEngineeringAlloy

The invention discloses a hard alloy reamer bit which is formed by connecting a drill body and a drill handle. The hard alloy reamer bit is characterized in that an S-shaped cutter and a front cutter are arranged on the drill body; the drill handle is of a cylindrical structure; a locating groove is formed in the drill handle and close to the tail end of the drill handle. The front cutter, the S-shaped cutter and a chip removing groove are effectively combined, in work, the front cutter is in contact with a workpiece, then the S-shaped cutter conducts cutting, the drilling strength of the S-shaped cutter is reduced, the S-shaped cutter is protected, the service life of the drill bit is prolonged, the drilling efficiency is high, and the chip is smoothly removed.

Owner:启东市吕四科技创业中心有限公司

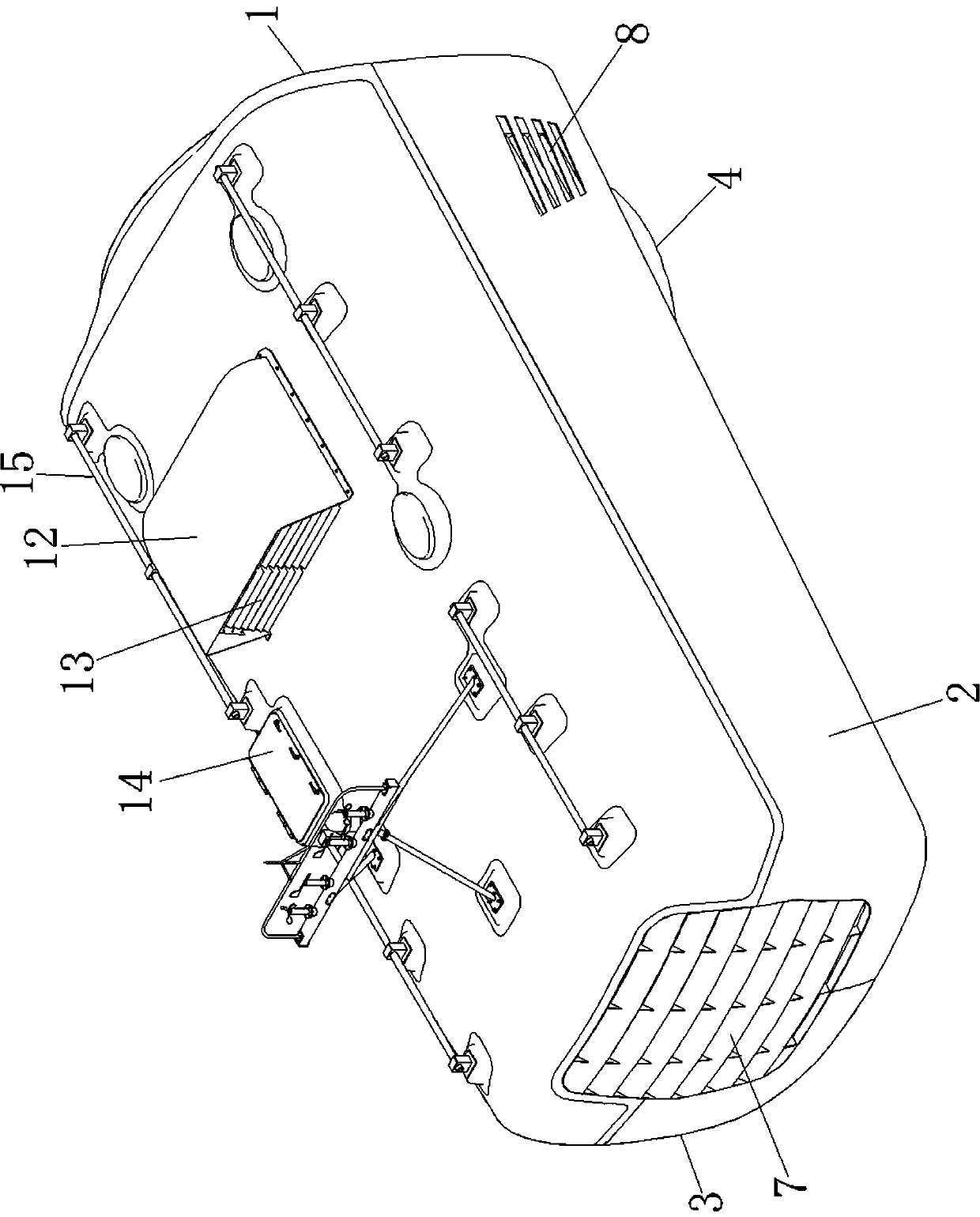

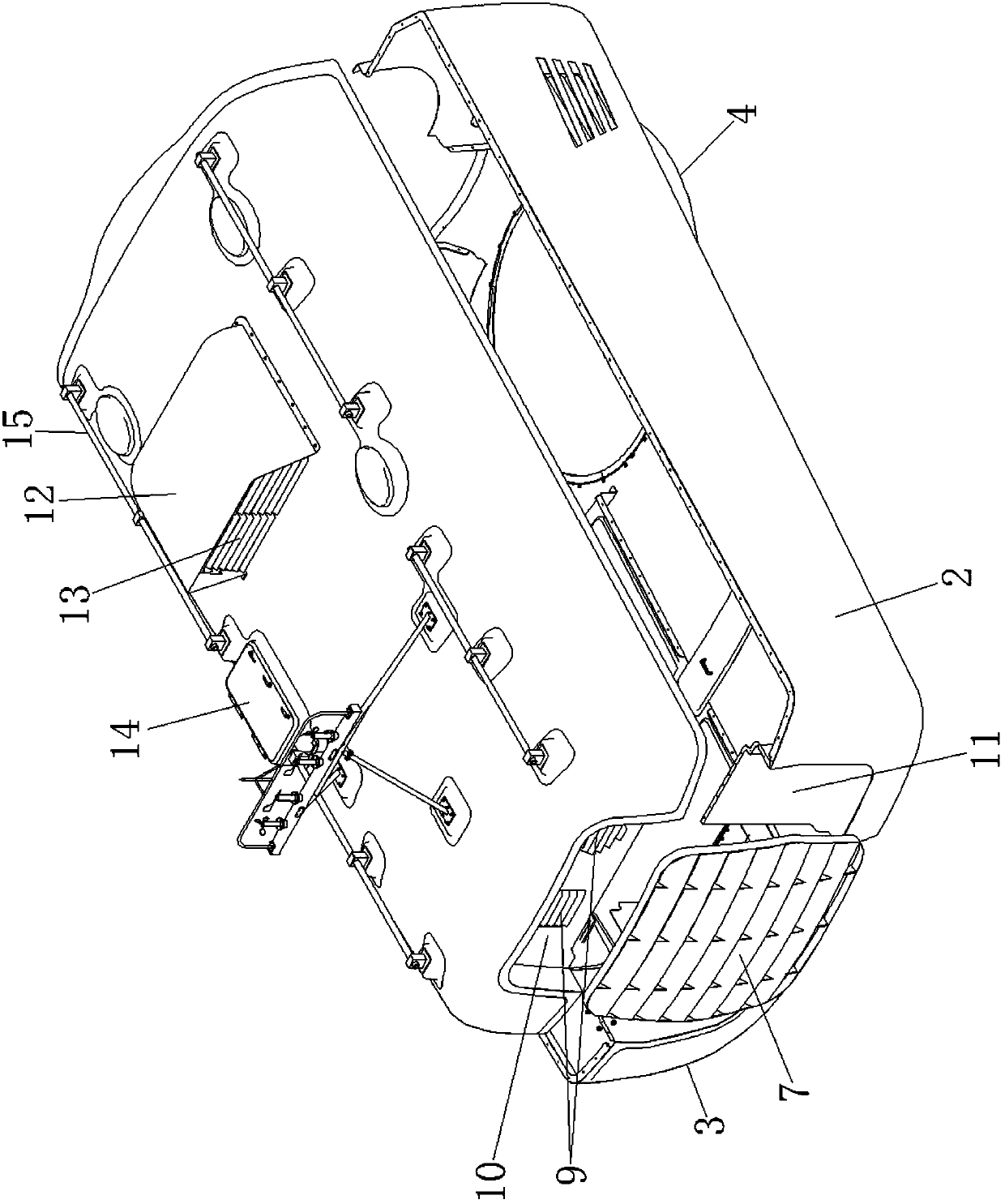

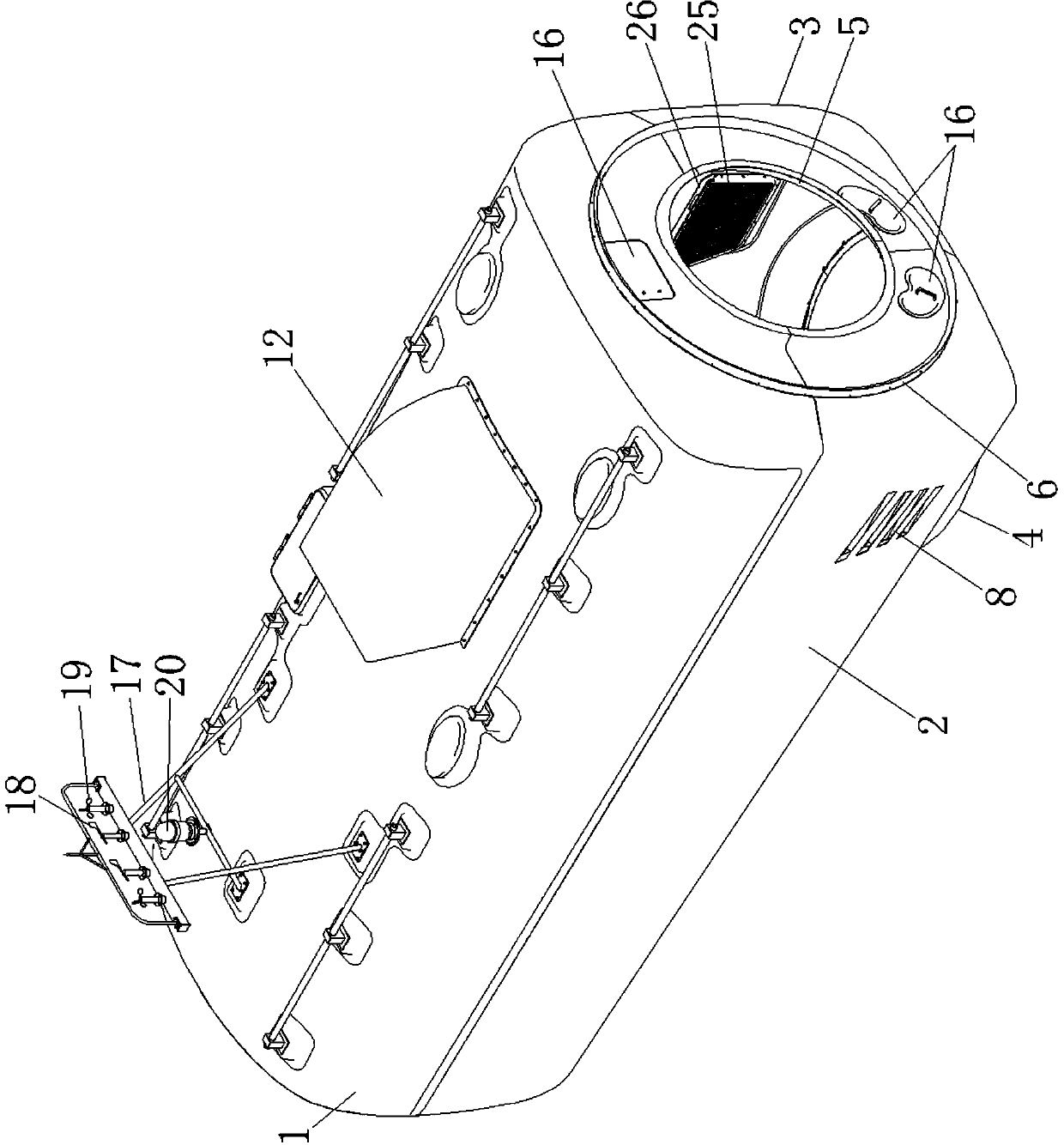

Nacelle cover of wind turbine and processing method thereof

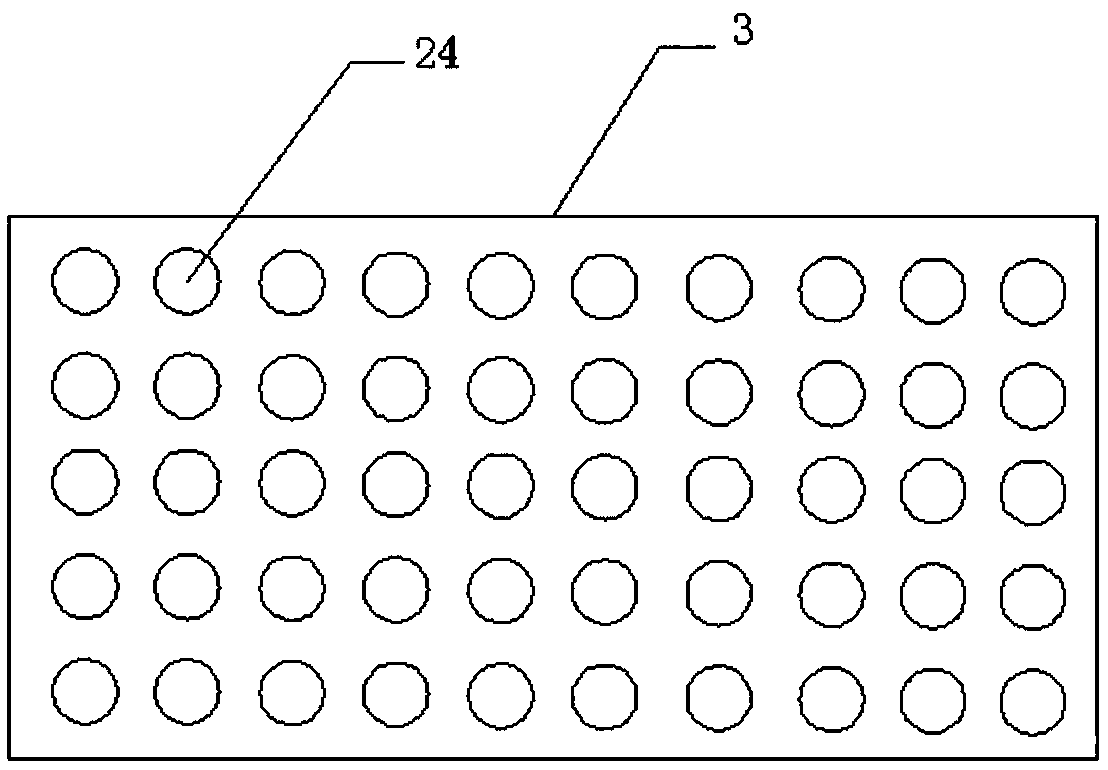

PendingCN109944752ASimple positioningSave production time and laborMachines/enginesWind energy generationNacelleLower body

The invention discloses a nacelle cover of a wind turbine and a processing method thereof. The nacelle cover of the wind turbine comprises a nacelle cover body, wherein the front end of the nacelle cover body is provided with a rotor locking disc opening; the bottom end of the front part of the nacelle cover body is provided with a tower cylinder mounting opening; the nacelle cover body comprisesa left nacelle lower body, a right nacelle lower body connected to the right side of the left nacelle lower body through bolts and an nacelle upper cover connected above the right nacelle lower body and the left nacelle lower body through bolts; and the left nacelle lower body, the right nacelle lower body and the nacelle upper cover are each composed of a PVC contour plate with a plurality of through holes, an inner glass fiber reinforced plastic layer formed on the inner layer of the PVC contour plate, an outer glass fiber reinforced plastic layer formed on the outer layer of the PVC contourplate, and unsaturated polyester resin columns formed in the through holes of the PVC contour plate. The nacelle cover is more reasonable in structure and easier to process, and the ventilation cooling and dustproof waterproof effect is better by additionally arranging a ventilation cooling and dustproof waterproof structure.

Owner:GUODIAN UNITED POWER TECH CHIFENG

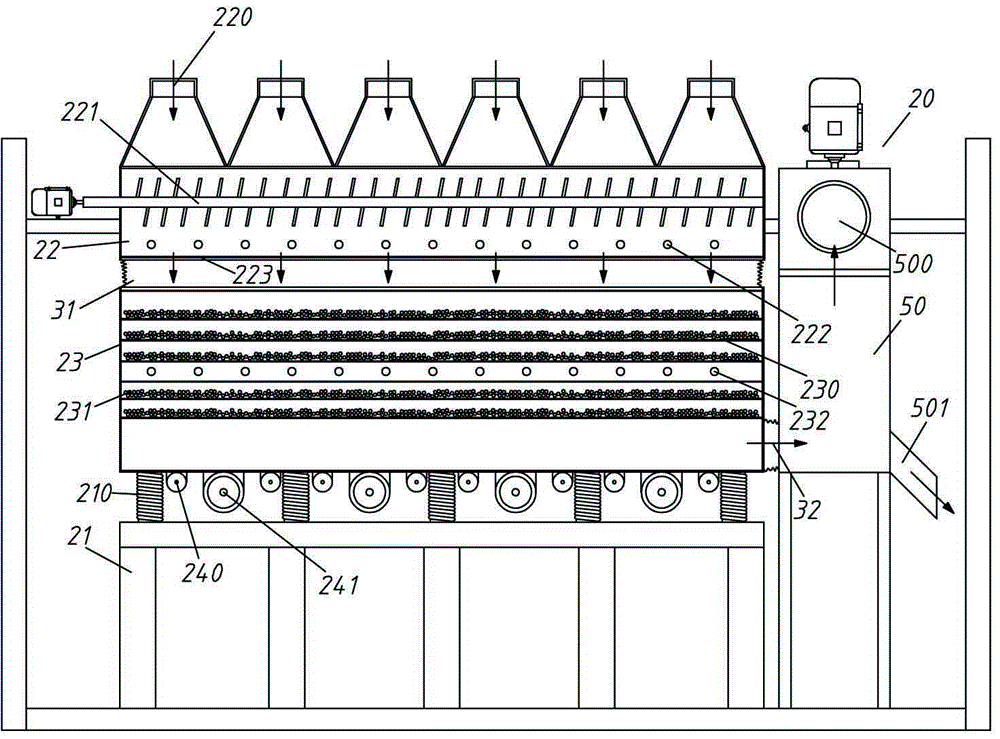

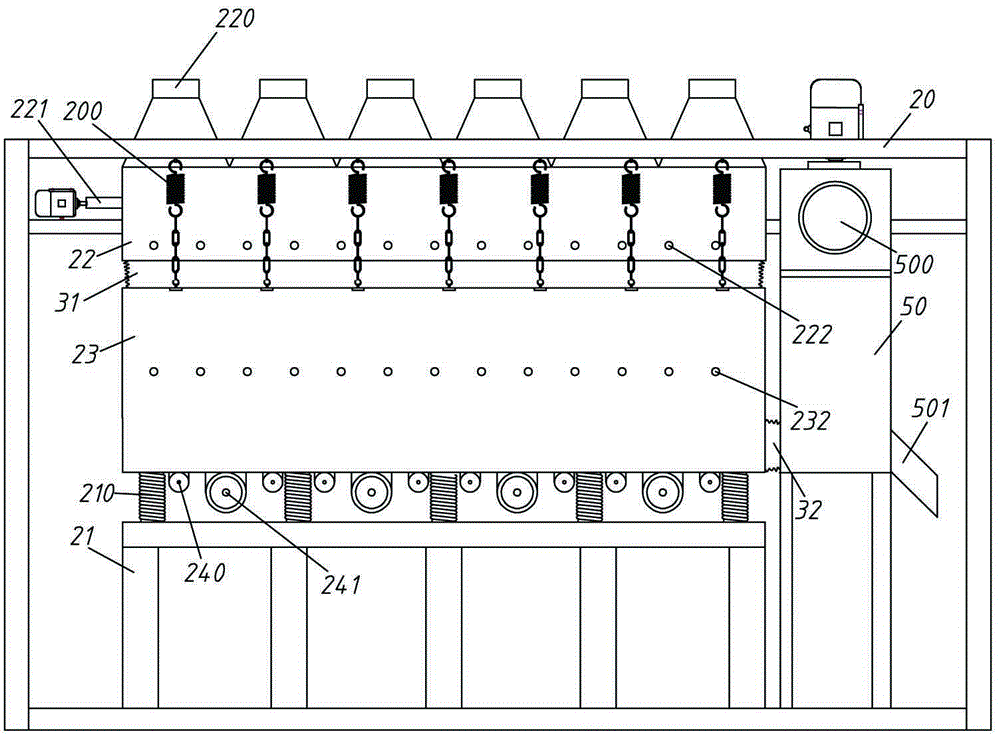

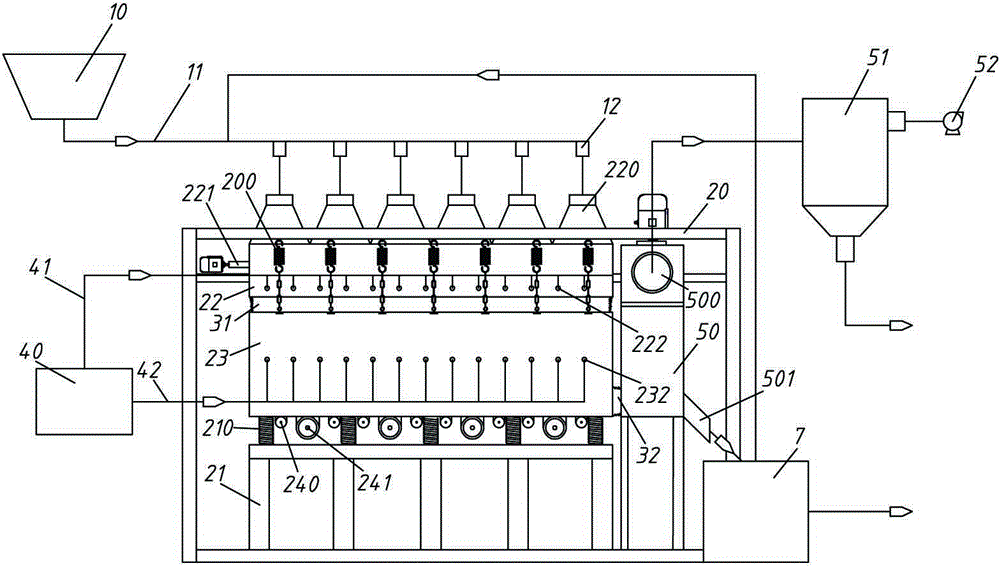

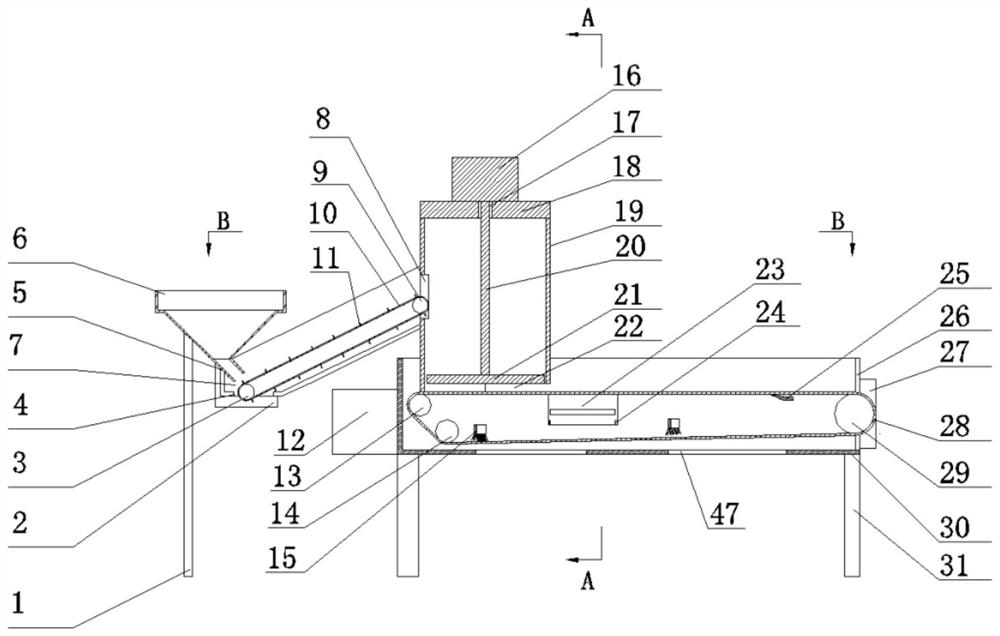

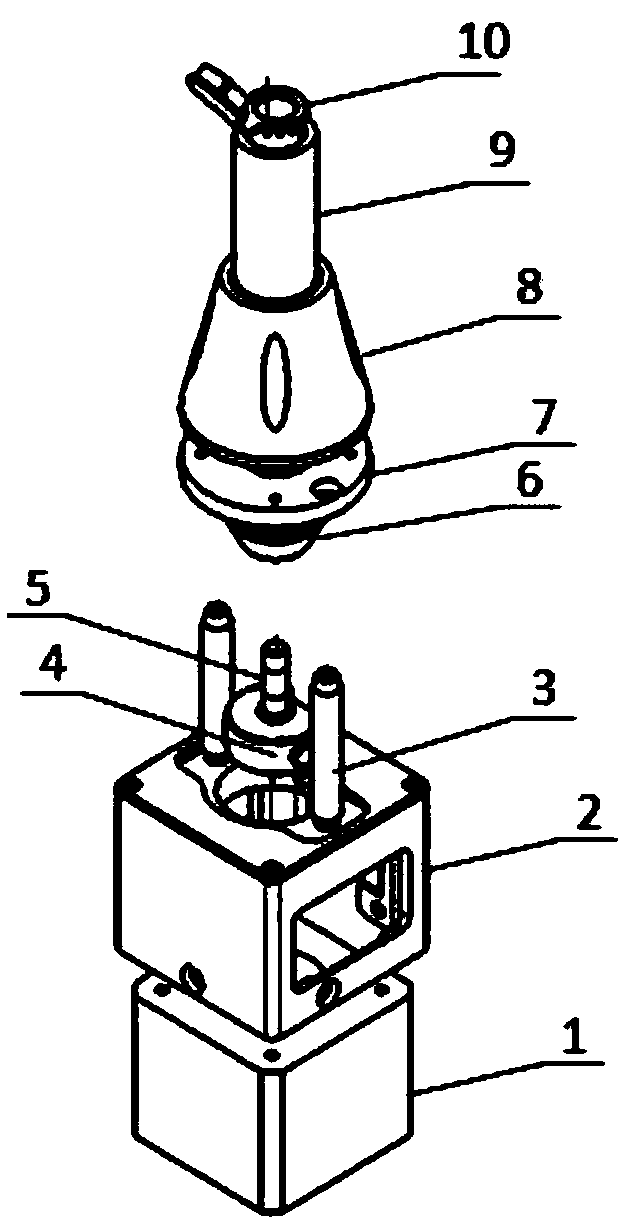

Manufacturing device integrating drying, grinding and powder selecting

The invention discloses a manufacturing device integrating drying, grinding and powder selecting. The manufacturing device integrating drying, grinding and powder selecting comprises the following components: a feeding system, a drying and grinding system connected with the feeding system, and a powder selecting system connected with the drying and grinding system. According to the invention, the drying and grinding system comprises a base, a drying and grinding box set on the base and a vibrator arranged at the bottom of the drying and grinding box; the drying and grinding box is connected with the base by a buffer cushion; a feeding hopper is set on the drying and grinding box and a plywood is arranged inside the drying and grinding box; the plywood is provided with a material feeding opening and filled with grinding bodies in the upper part; air inlets are formed in the drying and grinding box to let high-temperature air in; the material feeding opening is positioned under the plywood on the drying and grinding box; and the material feeding opening is connected with the powder selecting system by a first soft connecting mechanism. The invention is characterized by integrating drying, grinding and powder selecting, so as to shorten process route, decrease floor space, reduce labor force, increase production efficiency and cut down energy consumption.

Owner:厦门兑泰新材料科技有限公司

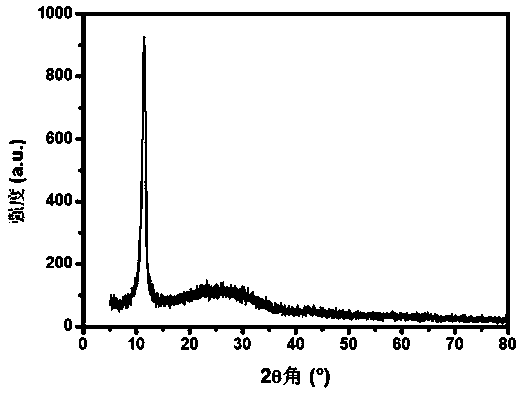

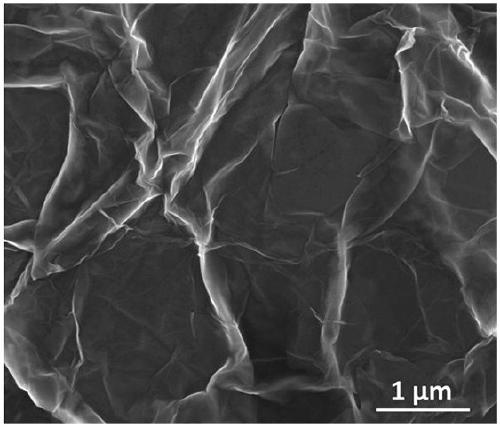

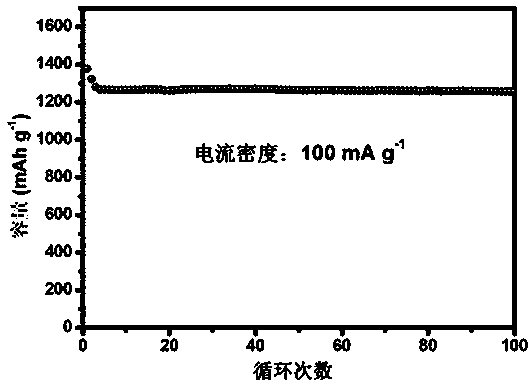

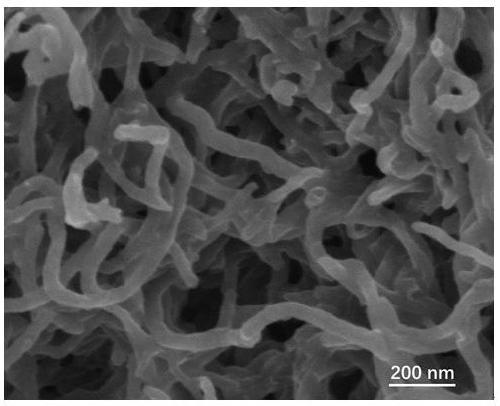

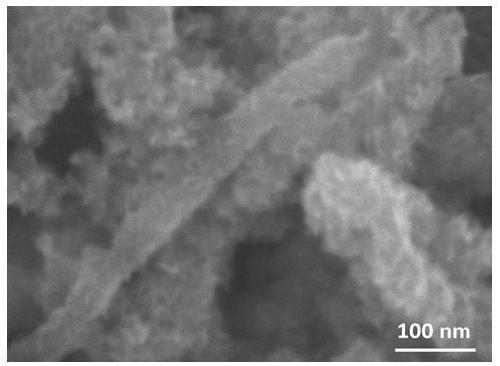

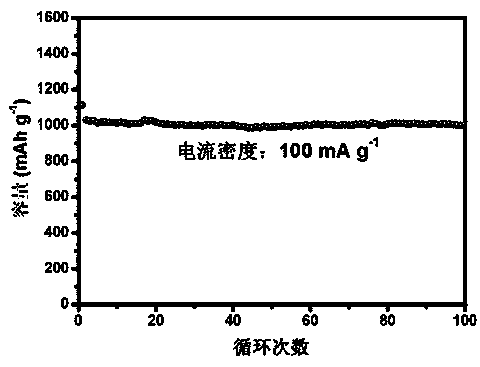

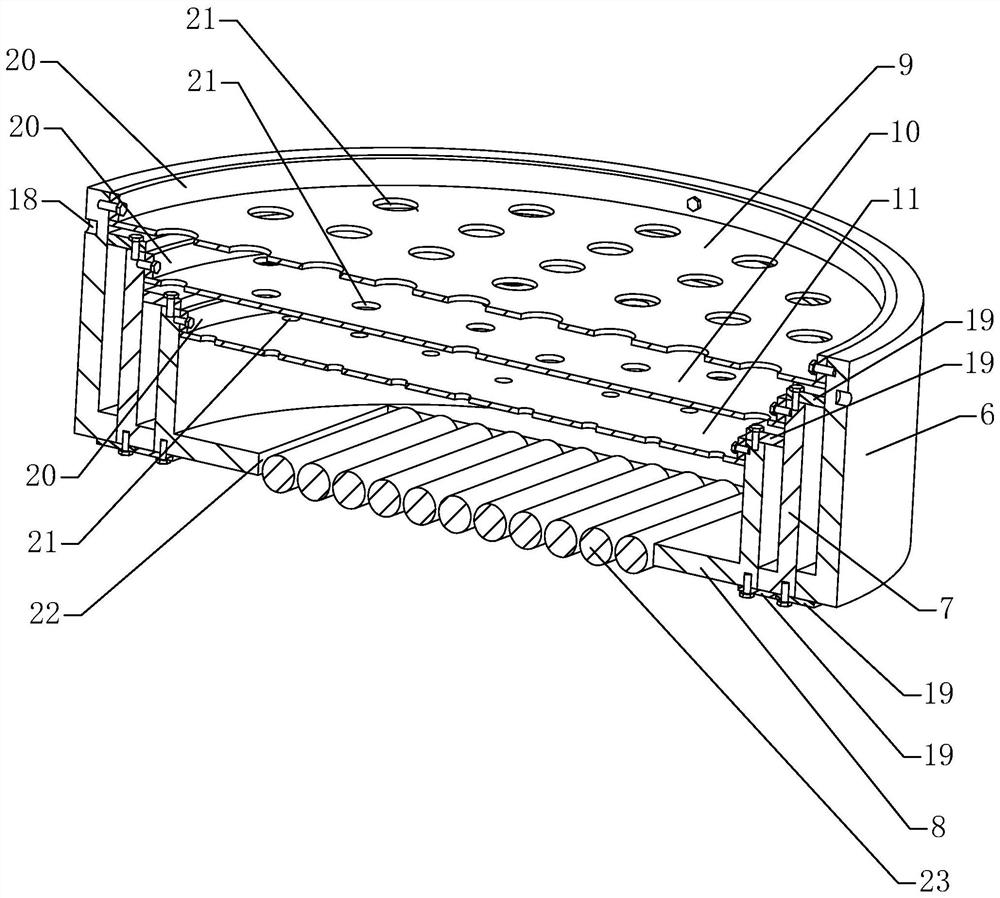

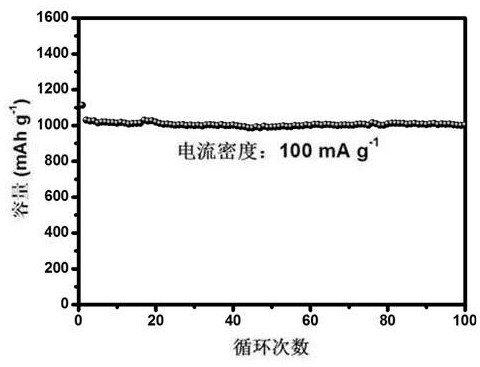

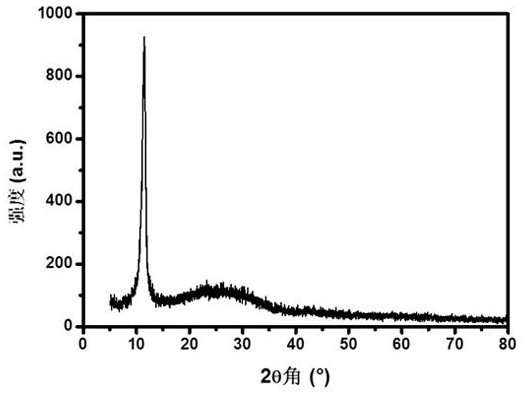

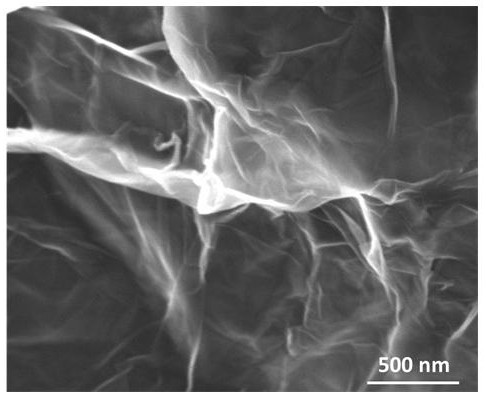

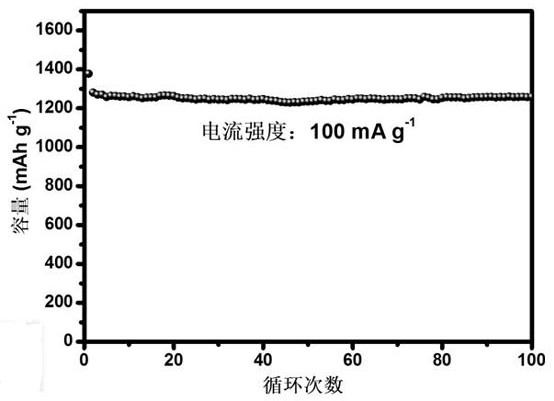

Nitrogen-doped molybdenum disulfide/graphene composite material

The invention discloses a nitrogen-doped molybdenum disulfide / graphene composite material. The preparation method comprises the following steps: taking formaldehyde as a bridge, and carrying out moderate crosslinking on the formaldehyde and melamine to form a nitrogen-doped precursor; then, carrying out hydrothermal reaction to make the nitrogen-doped precursor, an active component and graphene interacted and uniformly fused; and carrying out solvent-free microwave reaction to synthesize the high-nitrogen-content-doped molybdenum disulfide / graphene composite material. In the preparation process of the composite material, the loss caused by sublimation of the nitrogen-doped precursor in the heating process in the traditional nitrogen doping process is avoided, and the nitrogen doping efficiency is improved; and the reaction conditions are progressively increased from mild to intense, and uniform fusion of the nitrogen-doped precursor, the active component and the graphene through interaction is realized. The prepared nitrogen-doped molybdenum disulfide / graphene composite material is good in stability, not prone to denaturation in air, easy to store and large in specific surface area; a good channel is provided for lithium ion transmission when the nitrogen-doped molybdenum disulfide / graphene composite material is used as a lithium ion battery negative electrode material; and thenitrogen-doped molybdenum disulfide / graphene composite material has large specific capacity and good cycling stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

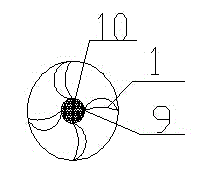

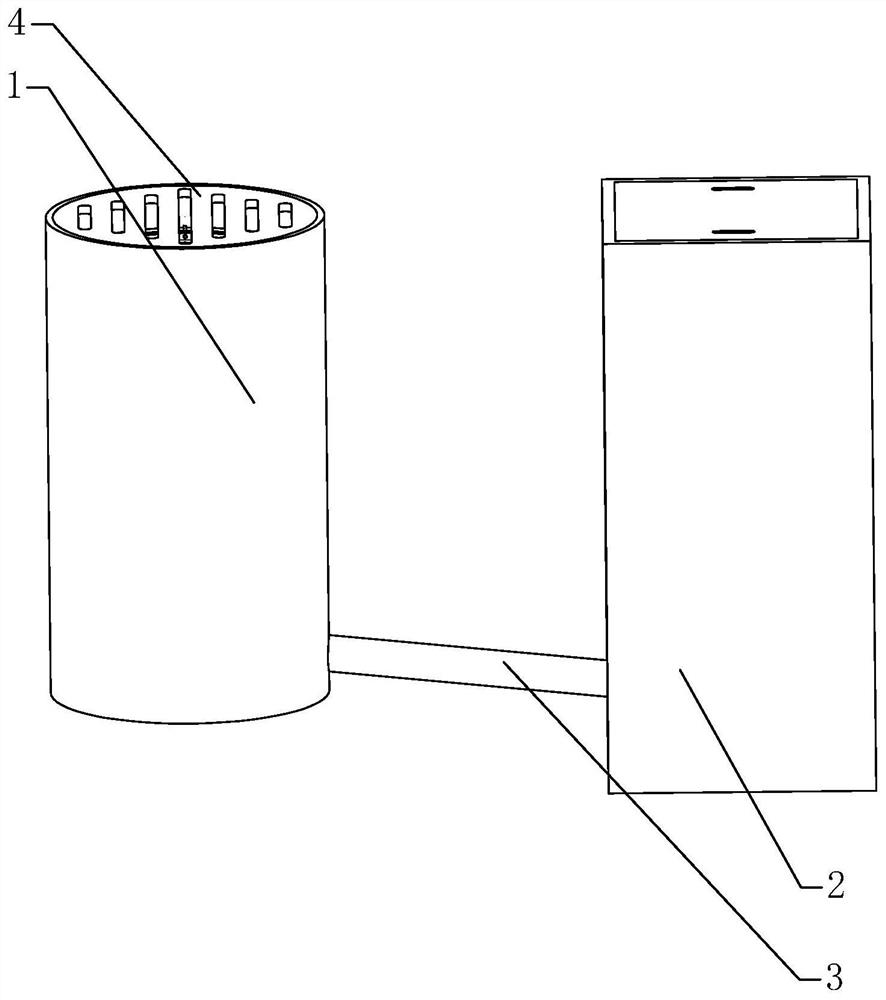

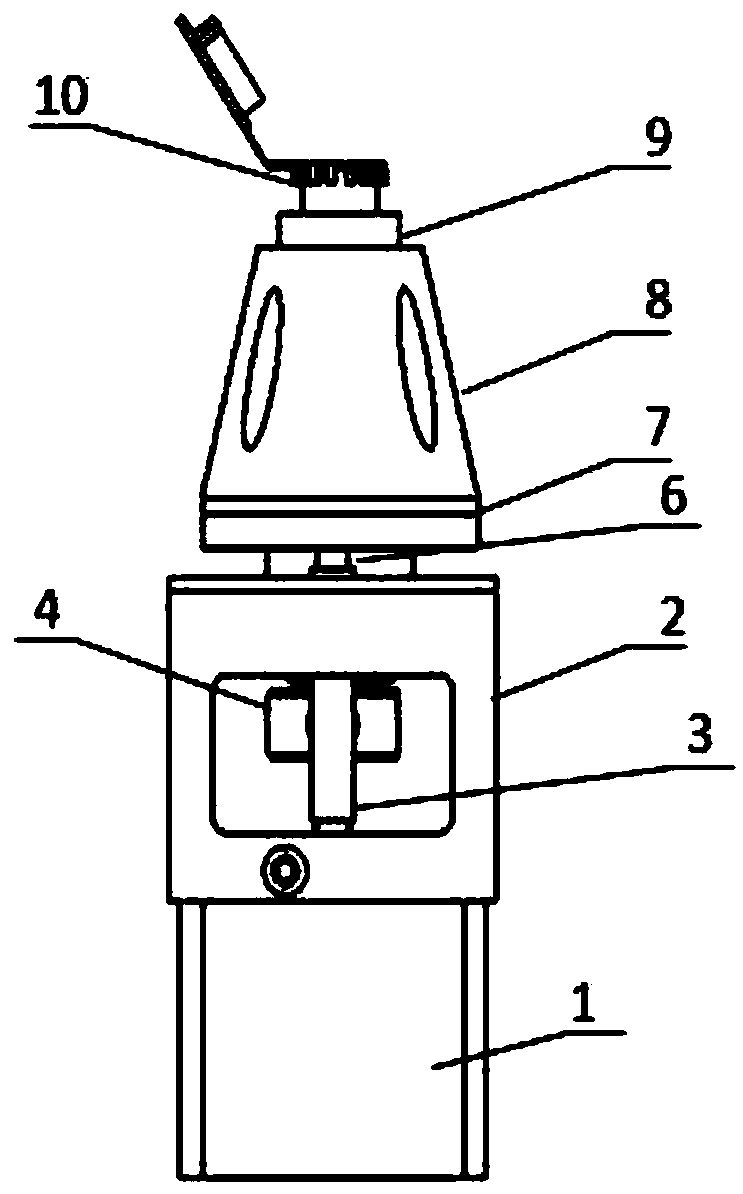

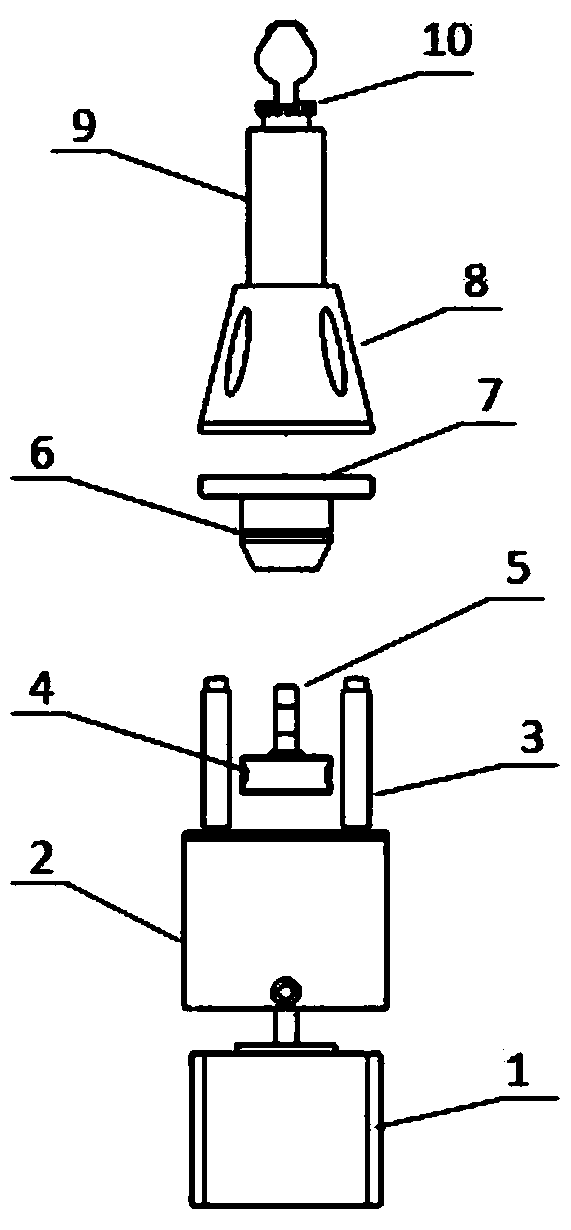

Quick potato cleaning device for agricultural vegetable base

InactiveCN108669586ANot easy to cause accumulationEasy to useFood treatmentAgricultural engineeringDrive motor

The invention discloses a quick potato cleaning device for an agricultural vegetable base. The cleaning device comprises a cleaning outer cylinder, wherein a cleaning net cylinder is arranged on the inner side of the cleaning outer cylinder; a circular bottom net plate is hinged on one side of the lower end of a bottom connecting ring through a hinge shaft; a mounting nozzle is fixed in each mounting through hole; a driving motor is arranged above the cleaning outer cylinder; a supporting plate is fixedly connected with the lower end of each L-shaped fixing rod, the four supporting plates aresupported at four ends of the upper surface of the cleaning outer cylinder respectively, and the supporting plates and the cleaning outer cylinder are fixedly connected through connecting bolts; the middle of the outer side of the cleaning outer cylinder is fixedly sleeved with a fixing outer ring, a fixing base plate is arranged below the cleaning outer cylinder, and a U-shaped discharging plateis arranged between the fixing base plate and the cleaning outer cylinder. The quick potato cleaning device is very convenient to use, high in cleaning speed and high in cleaning efficiency, saves a large amount of time and labor, has low cost and high practicability, and is beneficial to popularization.

Owner:陈赛芬

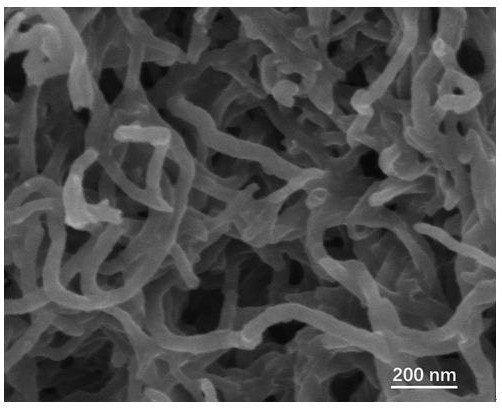

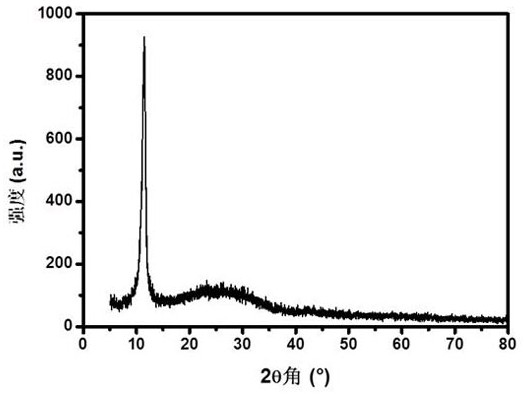

Nitrogen-doped molybdenum disulfide/C/carbon nanotube composite material

ActiveCN111106318AAvoid the problem of low doping efficiencyEvenly blendedCell electrodesSecondary cellsNanotubeNitrogen doped

The invention discloses a nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material. The preparation method comprises the following steps: taking formaldehyde as a bridge, and carryingout moderate crosslinking on formaldehyde and melamine to form a nitrogen-doped precursor; carrying out hydrothermal reaction to make the nitrogen-doped precursor, an active component precursor and carbon nanotubes interact and uniformly fused; and carrying out solvent-free microwave reaction to synthesize the high-nitrogen-content-doped molybdenum disulfide / C / carbon nanotube composite material. In the preparation process of the composite material, loss caused by sublimation of the nitrogen-doped precursor in the heating process in the traditional nitrogen doping process is avoided, the nitrogen doping efficiency is improved, the reaction conditions are progressively increased from mild to intense, and uniform fusion of the nitrogen-doped precursor, the active component precursor and the carbon nanotubes through interaction is realized. The prepared nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material is good in stability, not prone to denaturation in air, easy to store and large in specific surface area, a good channel is provided for lithium ion transmission when the nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material is used as a lithiumion battery negative electrode material, and large specific capacity and good cycling stability are shown.

Owner:CHINA PETROLEUM & CHEM CORP +1

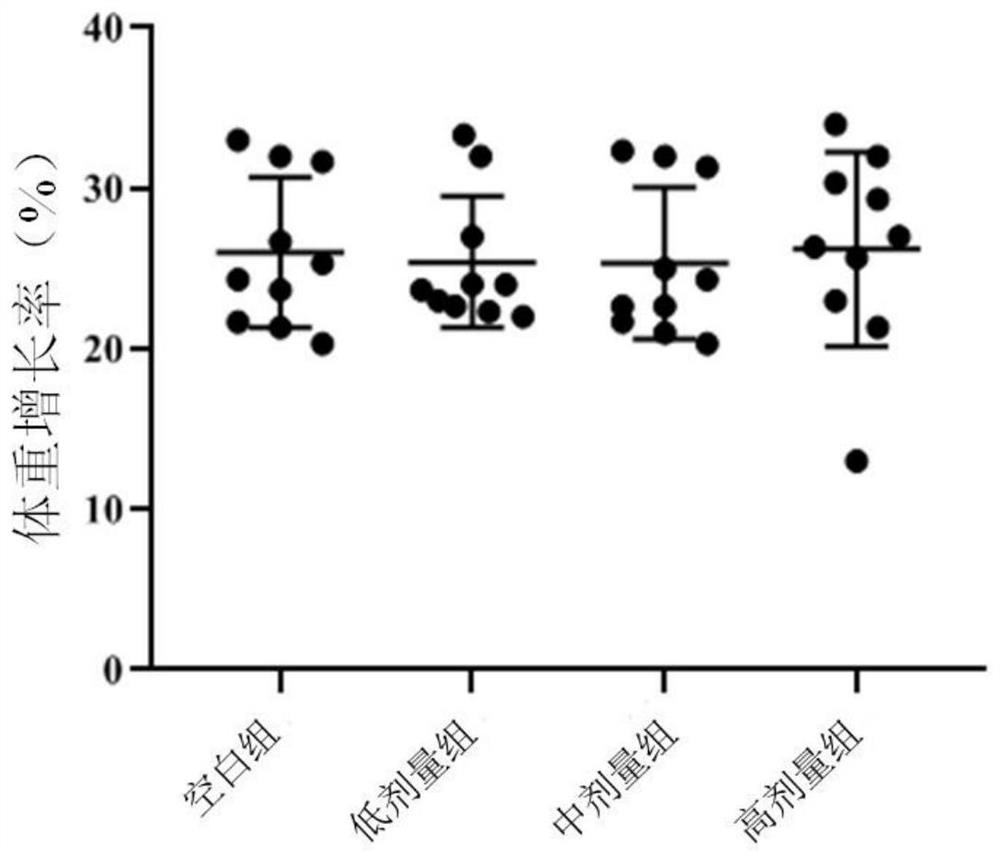

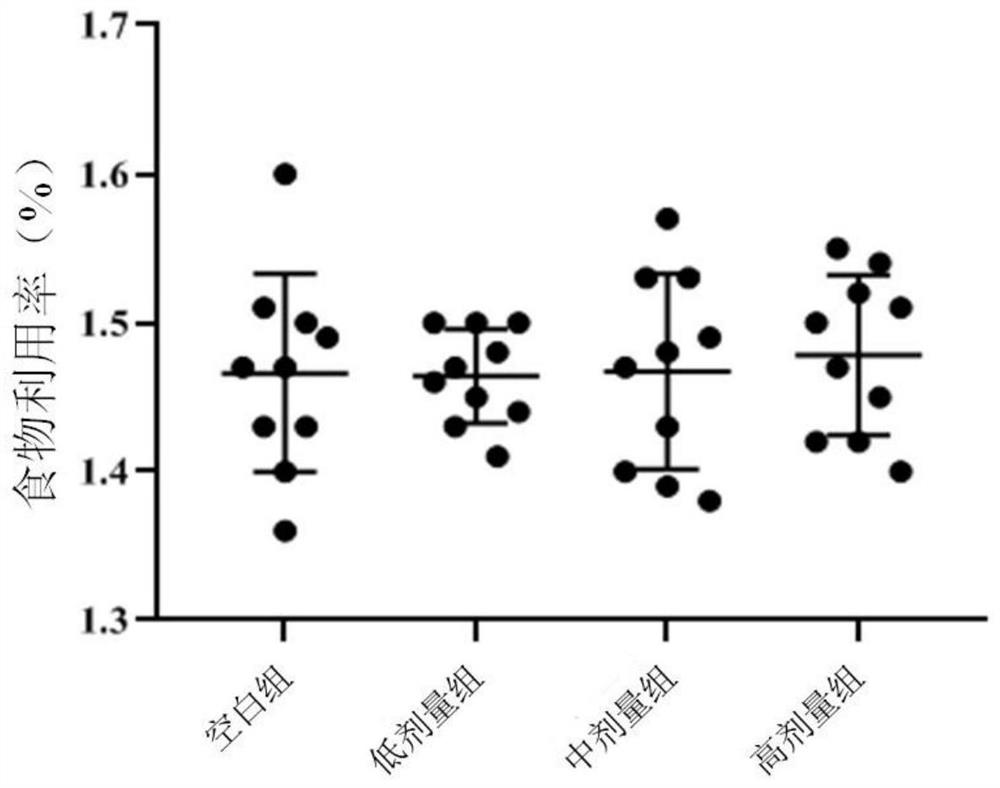

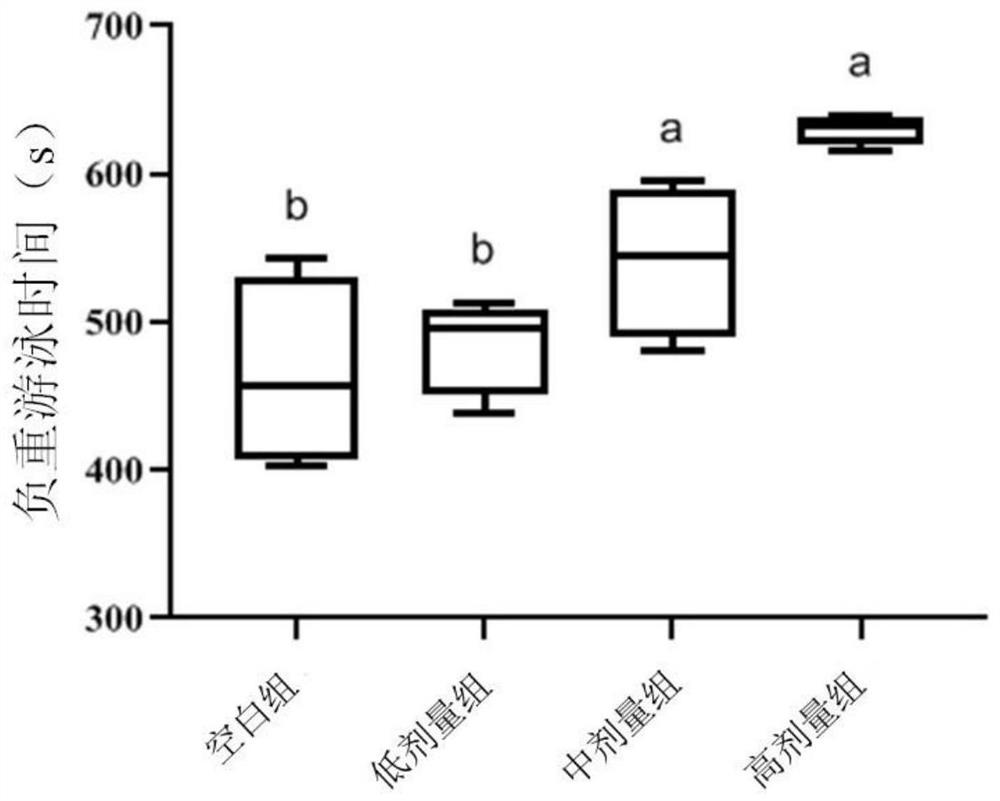

Qi-tonifying, kidney-tonifying and fatigue-relieving liquid beverage and preparation method thereof

PendingCN112401246AImprove staminaPromote clearanceFood ingredient as taste affecting agentNatural extract food ingredientsFruit drinksFructose

The invention belongs to the technical field of functional foods, and relates to a qi-tonifying, kidney-tonifying and fatigue-relieving liquid beverage and a preparation method thereof. Specifically,the liquid beverage is prepared from the following components: ginseng powder, Chinese wolfberry powder, polygonatum kingianum powder, kudzuvine root powder, nicotinic acid, blueberry powder, pomegranate juice powder, fructo-oligosaccharide, maltooligosaccharide, nisin and water. Extracts from various medicinal and edible raw materials are added into the formula of the liquid beverage, and synthesis of glycogen and energy, metabolism performance and oxidative stress regulation are comprehensively promoted, so that the effects of improving endurance, delaying fatigue and the like are achieved,and meanwhile, nicotinic acid is matched to further promote elimination of metabolites and accelerate fatigue relieving. Furthermore, the liquid beverage also has the advantages of no additive, low calorie, good taste, direct drinking, portability and the like.

Owner:JIANGYIN TIANJIANG PHARMA

Novel auger bit

The invention discloses a novel auger bit. The novel auger bit is formed by connecting a drill handle and a drill body. The novel auger bit is characterized in that the structure of the drill body is composed of a drill point and a main drill body in an integrated forming mode; the main drill body is formed in the manner that an 8-shaped drill body front end part with the small diameter and an 8-shaped drill body rear end part with the large diameter are integrally formed in the same axis, wherein the two ends of the 8-shaped drill body front end part with the small diameter are straight end faces, and the two ends of the 8-shaped drill body rear end part with the large diameter are straight end faces; a horizontal S-shaped main cutter is arranged on the drill body front end part along the 8-shaped part, a horizontal S-shaped auxiliary cutter is arranged on the drill body rear end part along the 8-shaped part, the drill handle is of a fine and long cylinder structure, and a positioning groove is formed in the position, close to the end, of one end of the drill handle. According to the novel auger bit, the drill point, the main cutter, the auxiliary cutter and a chip removal structure are effectively combined, three-level drilling and one-time forming are achieved, chip removal is smooth, and the smoothness of the drilling cut face is achieved.

Owner:启东市吕四科技创业中心有限公司

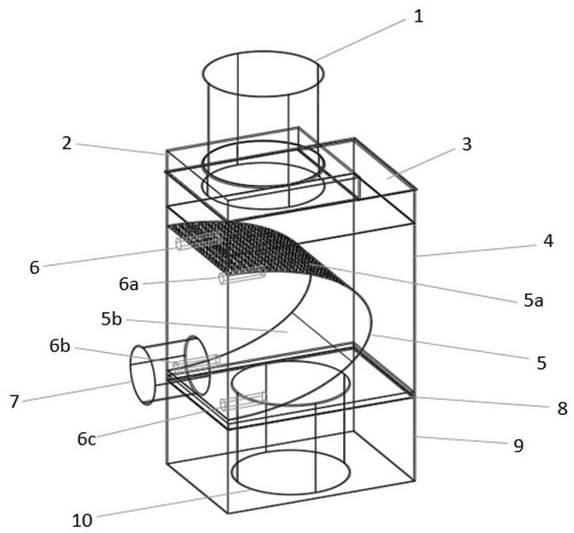

Rainwater filter and filtering method thereof

InactiveCN112057920AEasy maintenanceEasy to installStationary filtering element filtersSewage outfallMechanical engineering

The invention discloses a rainwater filter and a filtering method thereof. The rainwater filter comprises a shell; a rainwater inlet formed in the upper part of the shell; a filter screen assembly arranged in the shell and dividing an inner cavity of the shell into a rainwater filtering chamber and a sewage draining chamber; a rainwater outlet formed in the side, located on the bottom cavity wallof the rainwater filtering cavity, of the shell; and a sewage draining exit arranged at the bottom of the sewage draining chamber. The filter screen assembly is an oval cambered surface filter screenassembly, and the oval cambered surface filter screen assembly comprises two arc section parts, namely a first arc section part and a second arc section part. The first arc section part is a filter screen part with a filtering function and is arranged right opposite to the lower part of the water inlet. The second arc section part is a waterproof part, is positioned at the bottom of the rainwaterfiltering chamber and is used for guiding rainwater into the rainwater outlet.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Novel drill having cooling housing

InactiveCN104985236ANot easy to breakLarge cutting areaTurning machine accessoriesConstructionsDrill bitCooling fluid

The invention discloses a novel drill having a cooling housing. The novel drill having the cooling housing is composed of a drill handle and a drill body which are connected together. The novel drill having the cooling housing is characterized in that the drill body is composed of a drill bit and a drill body main body which are formed in a whole body, a cooling liquid through hole is disposed in the drill and through the transversal central line, the diameter of the cooling liquid through hole is 0.5 to 1 mm, and the front end of the drill bit is provided with a filer screen. The drill body main body is composed of a drill body front end portion and a drill body rear end portion which are coaxially formed in a whole body, the drill body front end portion has two straight end faces and are 8-shaped, and the drill body rear end portion has two straight end faces and are 8-shaped. The drill handle is a long and thin cylinder, and one end, close to the end portion, of the drill handle is provided with a positioning groove. The drill can be cooled, and chippings cannot jam the cooling liquid through hole through cooperation of the cooling liquid through hole and the filter screen.

Owner:启东市吕四科技创业中心有限公司

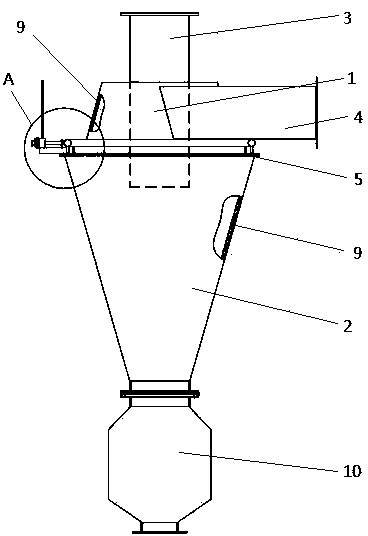

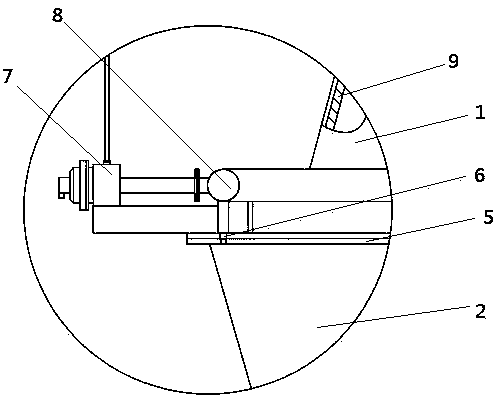

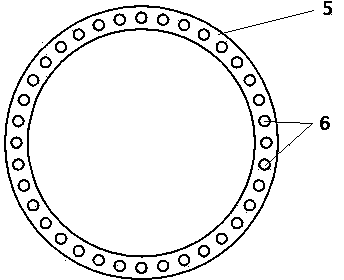

Vortex solid-liquid separator

PendingCN107335271AReduce volumeEasy to processSludge treatment by de-watering/drying/thickeningMoving filtering element filtersBiochemical engineeringSlag

The invention provides a vortex solid-liquid separator, belongs to the technical field of dewatering equipment and solves the technical problems of complicated structure, inconvenient processing and high cost of filters in the prior art; a vortex solid-liquid separator, the vortex solid-liquid separator comprises a casing, an inner sleeve ring, filter nets, a filter chamber and a back pressure plate, the casing is an internal empty hollow structure, the casing is provided with a liquid inlet and a slag discharge port which are separated, the inner sleeve ring is arranged in the casing, and is movably connected with the casing; the two pieces of filter nets are arranged in the casing, the two pieces of filter nets are separated and fixedly connected with the inner sleeve ring; the filter chamber is formed in the casing, the inner sleeve ring and the filter nets, the filter chamber is communicated with the liquid inlet and the slag discharge port, the back pressure plate is arranged at the slag discharge port, and is movably connected with the bottom of the casing, the back pressure plate can rotate relative to the casing, the inner sleeve ring can rotate according to the direction from the liquid inlet to the slag discharge port, the filter nets can rotate synchronously with the inner sleeve ring, a linear part of a traditional structure is omitted, and the vortex solid-liquid separator is relatively small in volume, simple in processing and relatively low in production cost.

Owner:象山德曼机械有限公司

Stainless-steel high-speed drill bit

InactiveCN104842416AExtended service lifeSmooth chip removalWood turning toolsWood boring toolsDrill bitPetroleum engineering

The invention discloses a stainless-steel high-speed drill bit which is formed by connecting a drill handle and a drill body. The stainless-steel high-speed drill bit is characterized in that the drill body is integrally formed by a drill body front end portion with two ends to be 8-shaped bodies with straight end faces and a drill body thing-in-itself of a cylindrical structure on a same axis, a main cutting knife and an S-shaped cutting knife are arranged on the drill body front end portion, the drill handle is of a lathy hexahedron, and a positioning groove is formed in a position, close to the end, at one end of the drill handle. The stainless-steel high-speed drill bit effectively combines the main cutting knife, the S-shaped cutting knife and a chip groove which are made by stainless steel, two-stage drilling and one-time forming are realized, the stainless-steel high-speed drill bit is smooth in chip removal, and service life of the drill bit is prolonged.

Owner:启东市吕四科技创业中心有限公司

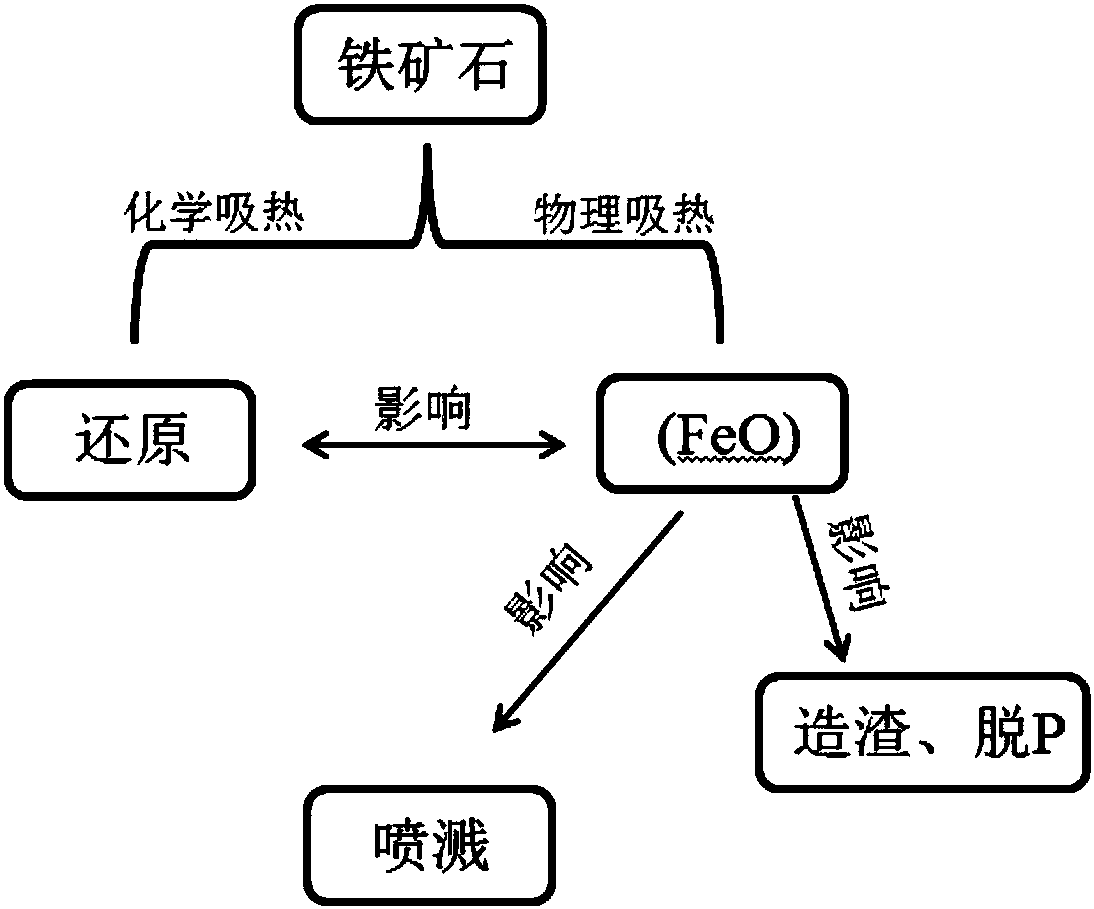

Method for controlling reduction rate of iron ore in converter

The invention discloses a method for controlling the reduction rate of iron ore in a converter, and belongs to the technical field of ferrous metallurgy. In the method, according to the different molten pool temperatures during the converter smelting period, the reduction rate of the iron ore during complete melting can be effectively controlled by controlling the adding quantity of the added ironore and the particle size of the iron ore. The method specifically comprises the steps that in the converter smelting initial period, the molten pool temperature ranges from 1,300 DEG C to 1,450 DEGC, and the practical size equivalent diameter of the added iron ore ranges from 5.0 mm to 20.0 mm; and in the converter smelting middle and later periods, the molten pool temperature ranges from 1,450DEG C to 1,600 DEG C, and the practical size equivalent diameter of the added iron ore ranges from 20.0 mm to 50.0 mm. According to the method, on one hand, in the converter smelting initial period,the quantity of (FeO) in slag can be fast increased in the iron ore melting process, and fast slag forming of lime in the earlier period can be ensured; and on the other hand, in the converter smelting middle and later periods, the cooling effect of a small quantity of iron ore is not remarkable in the melting process, the situation that a large amount of (FeO) in the slag is instantly accumulatedcannot be prone to happening, and splashing is avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Intelligent combined bus duct

InactiveCN108963927ASolve drainage problemsNot easy to cause accumulationCooling bus-bar installationsTotally enclosed bus-bar installationsCooling effectExhaust pipe

The present invention discloses an intelligent combined bus duct. The intelligent combined bus duct comprises a bus duct body and a cover plate, the upper end of the bus duct body is fixedly connectedwith the cover plate to each other through bolts, the bus duct body is formed by a side plate and a bottom plate which are fixedly connected through welding, the side plate at one end of the bus ductbody is provided with a ventilation opening which is provided with an air cooler, the air cooler is connected with a motor controlling the rotation of the air cooler, the side plate at the other endof the bus duct body is provided with a dust exhaust apparatus consisting of a dust exhaust pipe, a dust exhaust pump and a dust exhaust box, the dust exhaust pipe is arranged in a hole groove arranged on the side plate at the other end of the bus duct body and is connected with the dust exhaust pump installed in the dust exhaust box, the dust exhaust box is installed at the side plate at the other end of the bus duct body through the support plate, a slide rail is installed at the inner wall of the cover plate, and the slide rail is provided with a fire extinguishing apparatus. The intelligent combined bus duct is simple in structure and good in cooling effect, can effectively avoid too high temperature of the bus duct and can achieve a self fire extinguishing function when a fire occurs.

Owner:ZHENJIANG YIBAO ELECTRICAL TECH CO LTD

Initial rainwater collection device for municipal roads based on rain and sewage diversion

ActiveCN113215916BPromote circulationNot easy to spillFatty/oily/floating substances removal devicesSewerage structuresRainwater harvestingRoad surface

Owner:江阴市港城市政工程有限公司

A nitrogen-doped molybdenum disulfide/c/carbon nanotube composite material

ActiveCN111106318BAvoid the problem of low doping efficiencyEvenly blendedCell electrodesSecondary cellsNanotubeNitrogen doped

The invention discloses a nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material. The preparation method comprises the following steps: taking formaldehyde as a bridge, and carryingout moderate crosslinking on formaldehyde and melamine to form a nitrogen-doped precursor; carrying out hydrothermal reaction to make the nitrogen-doped precursor, an active component precursor and carbon nanotubes interact and uniformly fused; and carrying out solvent-free microwave reaction to synthesize the high-nitrogen-content-doped molybdenum disulfide / C / carbon nanotube composite material. In the preparation process of the composite material, loss caused by sublimation of the nitrogen-doped precursor in the heating process in the traditional nitrogen doping process is avoided, the nitrogen doping efficiency is improved, the reaction conditions are progressively increased from mild to intense, and uniform fusion of the nitrogen-doped precursor, the active component precursor and the carbon nanotubes through interaction is realized. The prepared nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material is good in stability, not prone to denaturation in air, easy to store and large in specific surface area, a good channel is provided for lithium ion transmission when the nitrogen-doped molybdenum disulfide / C / carbon nanotube composite material is used as a lithiumion battery negative electrode material, and large specific capacity and good cycling stability are shown.

Owner:CHINA PETROLEUM & CHEM CORP +1

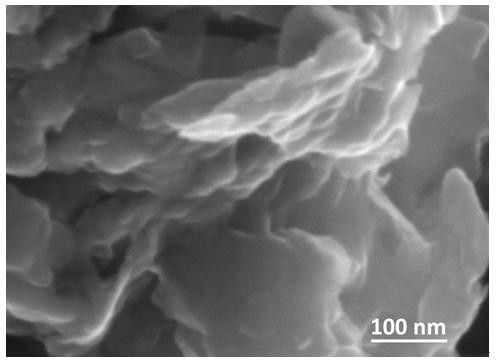

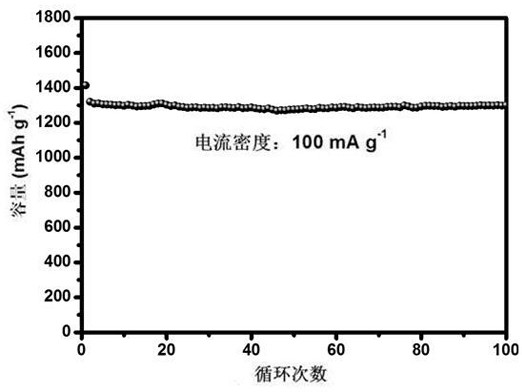

A nitrogen-doped molybdenum disulfide/c/3D graphene composite

ActiveCN111106320BAvoid the problem of low doping efficiencyEvenly blendedCell electrodesLi-accumulatorsElectrical batteryNitrogen doped

A nitrogen-doped molybdenum disulfide / C / three-dimensional graphene composite material, which uses formaldehyde as a bridge to make it moderately cross-linked with melamine to form a nitrogen-doped precursor, and then undergoes hydrothermal reaction to make the nitrogen-doped precursor and active group The precursors and three-dimensional graphene interact and fuse uniformly, and then perform solvent-free microwave reaction to synthesize high nitrogen content doped molybdenum disulfide / C / three-dimensional graphene composites. The composite material of the present invention avoids the loss caused by the sublimation of the nitrogen-doped precursor in the heating process in the traditional nitrogen doping process during the preparation process, improves the nitrogen doping efficiency, and the reaction conditions are progressive from mild to strong, realizing the nitrogen-doped precursor, The active component precursors interact with graphene and fuse uniformly. The prepared nitrogen-doped molybdenum disulfide / C / 3D graphene composite material has good stability, is not easily denatured in the air, is easy to store, and has a large specific surface area. As a negative electrode material for lithium-ion batteries, it provides a good channel for lithium ion transmission. Show a larger specific capacity and better cycle stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

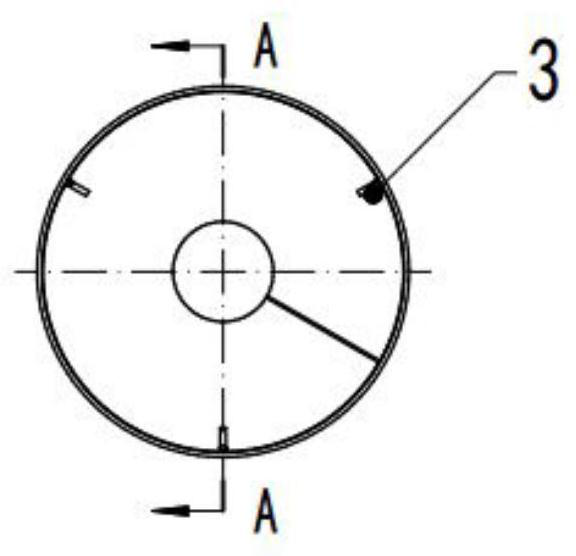

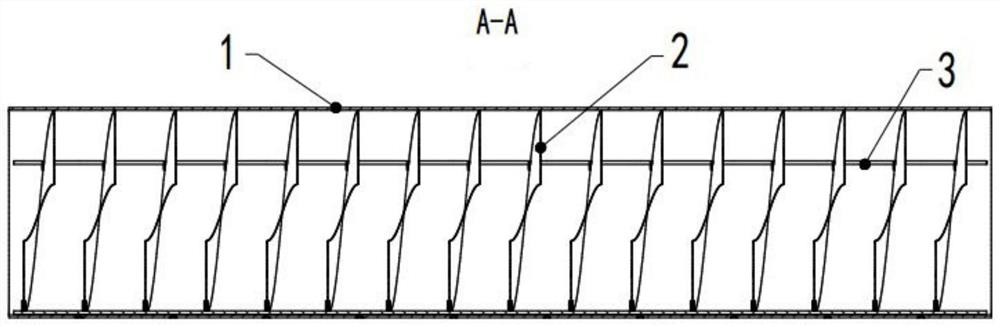

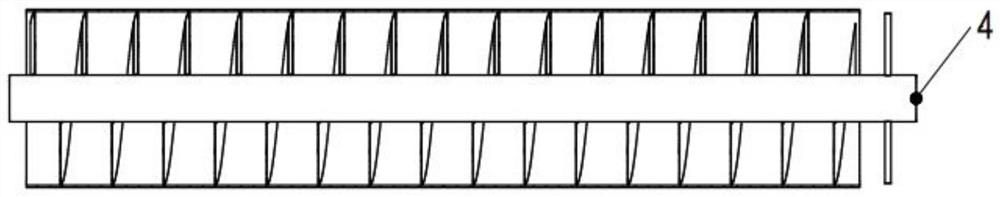

A kind of manufacturing method of powder material high temperature calcining rotary furnace furnace tube

ActiveCN109737735BGood for dehydration and dryingEvenly heatedRotary drum furnacesEngineeringNitrogen gas

The invention discloses a high-temperature roasting rotary furnace furnace-tube for a powder material. The high-temperature roasting rotary furnace furnace-tube comprises a tube body, spiral sheets and a connecting rod, which are integrated in a welding mode, wherein three connecting rod mounting holes which are used for welding and fixing the spiral sheets to position are uniformly distributed onthe tube body; three grooves used for positioning are formed in the spiral sheets; after the spiral sheets are processed and welded in sections, the connecting rods are blocked into the three groovesof the spiral sheets; the connecting rod and the spiral sheets are welded or adopt a bayonet blocking structure; the spiral sheets are blocked into the tube body; and the spiral sheets are rotated for enabling the connecting rod to align to the three mounting holes in the tube body, so that the connecting rod and the tube body are welded into an integer. Compared with the prior art, the high-temperature roasting rotary furnace furnace-tube is not liable to cause accumulation of the powder material, enables the material to be mutually dispersed, is more in turnover times, is high in heat conduction speed, and is complete in sintering; and during working, production efficiency is high, the yield is twice or more that of a conventional rotary furnace, and power consumption and nitrogen gas consumption are saved by 60% or more in comparison with those of the conventional rotary furnace.

Owner:HENGLI ELETEK

A device for automatically removing stems and roots of shiitake mushrooms and its application method

ActiveCN112716007BNot easy to cause accumulationLess prone to damageFood treatmentEngineeringShiitake mushrooms

An automatic shank cutting and root cutting device for shiitake mushrooms, comprising a feeding hopper, a support box, a material setting box, a material transfer rod, and a box body. It falls into the circular through hole on the second conveyor belt, and after passing through the discharge opening slot at the bottom of the feeding box, it is controlled by the baffle plate, and then the rotary cutter wheel is driven by the motor to rotate to realize the telescopic function of the blade to cut the root of the mushroom. , will not damage the stem of the mushroom, the accuracy is high, the processing efficiency is improved, and it is not easy to accumulate on the inner side of the device, reducing the life of the device.

Owner:吴昌御

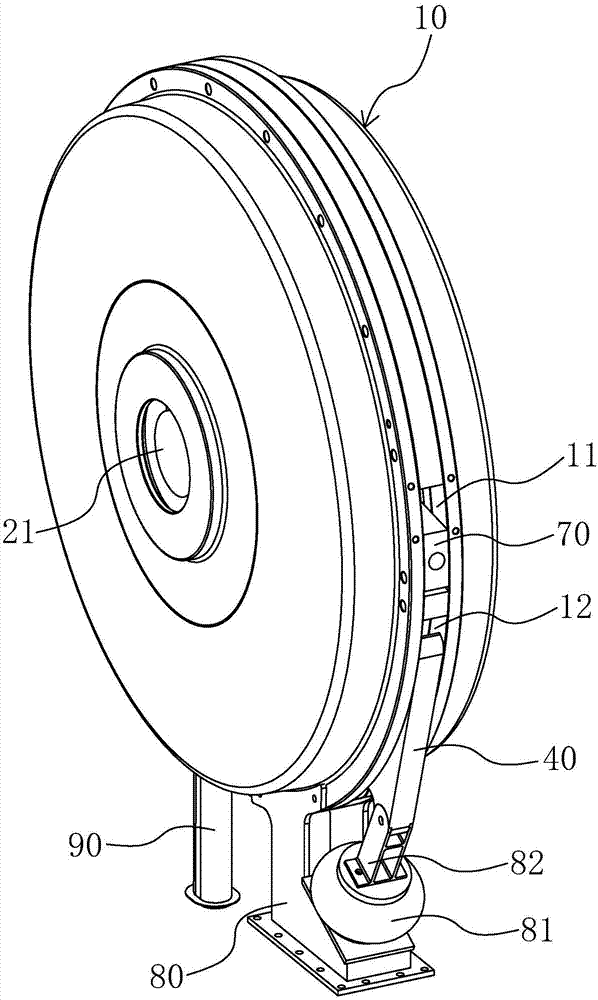

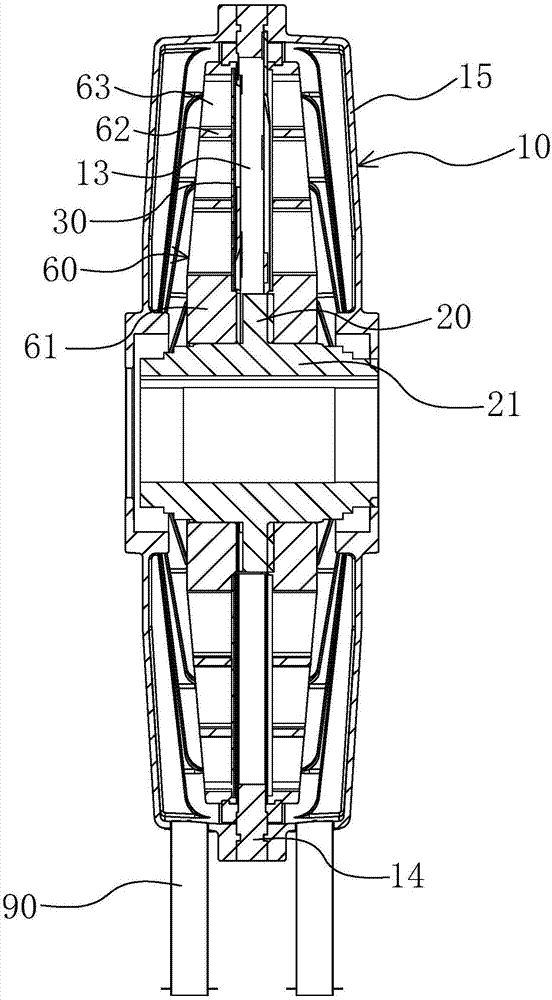

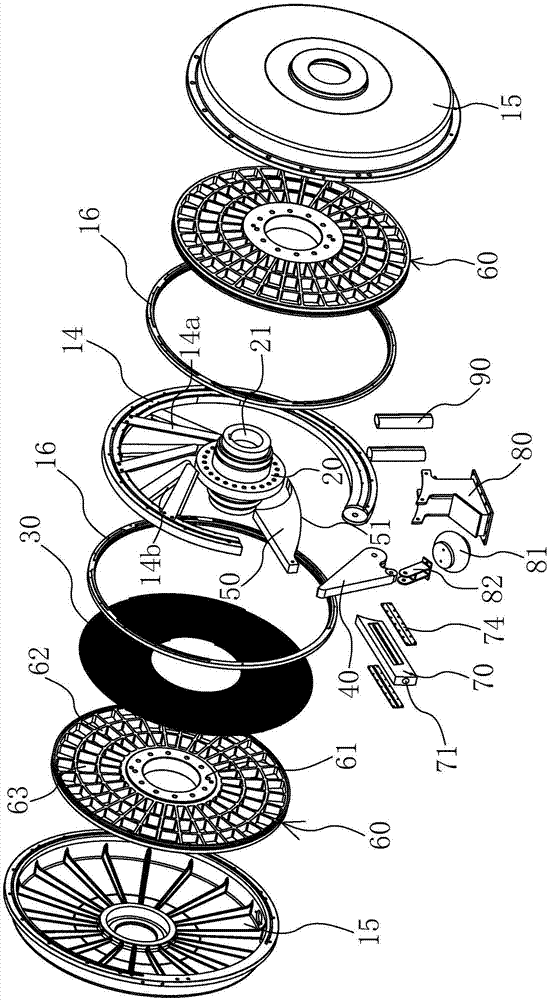

Magnetic bead mixer for biology, and application thereof

InactiveCN109022275ANot easy to cause splashAvoid lostBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadMechanical engineering

The invention discloses a magnetic bead mixer for biology, and an application thereof, and belongs to the field of biology. The mixer comprises a driving device, a transmission device, a magnetic beadcontainer carrying device, and a control device provided with the control software; the driving device, the transmission device and the magnetic bead container carrying device are sequentially connected from bottom to top, the control device is respectively connected with the driving device, the transmission device and the magnetic bead container carrying device, and the control device controls the driving device and / or the transmission device and / or the magnetic bead container carrying device to cooperatively work; the driving device and the transmission device are sleeved; the driving device is used for providing power for the mixer; the transmission device is used for transmitting the driving power to the magnetic bead container carrying device; and the magnetic bead container carryingdevice is used for converting the transmitted driving force into vortex vibration of the mixer in order to realize the uniform dispersion of magnetic beads. The magnetic bead mixer can keep the concentration distribution of a magnetic bead suspension uniform, ensures the distribution of an equal volume of magnetic beads in all reaction holes, and ensures the accuracy of experiments.

Owner:佛山市顺德区欧罗拉生物科技有限公司

A nitrogen-doped molybdenum disulfide/c/graphene composite material

ActiveCN111106325BAvoid the problem of low doping efficiencyAchieve preparationCell electrodesNitrogen dopedLithium electrode

A nitrogen-doped molybdenum disulfide / C / graphene composite material, which uses formaldehyde as a bridge to make it moderately cross-linked with melamine to form a nitrogen-doped precursor, and then undergoes a hydrothermal reaction to make the nitrogen-doped precursor and active component The precursor and graphene interact and fuse uniformly, and then perform a solvent-free microwave reaction to synthesize a high nitrogen content doped molybdenum disulfide / C / graphene composite. The composite material of the present invention avoids the loss caused by the sublimation of the nitrogen-doped precursor in the heating process in the traditional nitrogen doping process during the preparation process, improves the nitrogen doping efficiency, and the reaction conditions are progressive from mild to strong, realizing the nitrogen-doped precursor, The active component precursors interact with graphene and fuse uniformly. The prepared nitrogen-doped molybdenum disulfide / C / graphene composite material has good stability, is not easily denatured in the air, is easy to store, and has a large specific surface area. As a negative electrode material for lithium-ion batteries, it provides a good channel for lithium ion transmission. It has a larger specific capacity and better cycle stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aloe/viscose/modal function sweater and manufacture method thereof

ActiveCN103156302BHigh strengthGood hygroscopicityWeft knittingProtective garmentManufacturing technologyGram

The invention relates to an aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater. The aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater are characterized by utilizing fabric weave which is plain weave. Yarn is formed by twisting two strings of 32S fiber siro spun yarn made of 40 percent of aloes, 40 percent of modal and 20 percent of viscose. The doubling twist degree is 320 twist / m, and gram weight is 285g / square meter. Manufacture technology includes that three kinds of fiber siro spun yarn undergo rewinding, panel knitting, looping, flat sewing, hand sewing, washing, drying, pressing, packaging and warehouse entering. In the process of spinning the three kinds of fiber siro spun yarn, main body rough yarn do not pass by a rear roller on a spinning machine, the rough yarn is assisted in feeding with interruption through the rear roller, and diameter runout of the roller is controlled to be small than 0.03mm. The aloe / viscose / modal function sweater is low in cost, less in hairiness, and good in bacteria resistance.

Owner:JIANGYIN XIANGFEI APPAREL

Sucrose-free low-fat turkey-noodle-flavored popcorn and production method thereof

PendingCN111772105ALow metabolic caloriesLow cariogenicityFood ingredient functionsFood additiveChilli con carne

The invention discloses sucrose-free low-fat turkey-noodle-flavored popcorn and a production method thereof. The sucrose-free low-fat turkey-noodle-flavored popcorn is produced from the following rawmaterials by weight: 100-130 parts of microwave-safe corn kernels, 65-90 parts of erythritol, 2-8 parts of evaporated milk, 1-4 parts of maltitol, 1-4 parts of tomato sauce, 20-50 parts of chilli sauce, 1-2 parts of black pepper, 1-2 parts of curry powder and / or a food additive, and the balance water. By means of the sucrose-free low-fat turkey-noodle-flavored popcorn and the production method thereof, the problems that existing popcorn-type puffed food has high calories and single flavors, is high in sucrose content, and can easily make a negative impact on health of human bodies are solved.

Owner:董思悦 +1

Induction cyclone separator

ActiveCN103111381BAvoid gatheringNot easy to cause accumulationReversed direction vortexCycloneProduct gas

The invention discloses an induction cyclone separator. The induction cyclone separator comprises an upper docking cone tube with s small upper part and a large lower part and a lower docking cone tube with a large upper part and a small lower part, wherein the lower end diameter of the upper part docking cone tube is less than the upper end diameter of the lower part docking cone tube; the lower end of the upper part docking cone tube is connected with the upper end of the upper end of the lower part docking cone tube through an annular cover plate with a blowing hole, and the blowing hole is provided with an impulse blowing device; and the impulse blowing device comprises an impulse valve and a blowing pipe, and the blowing pipe is connected with the outlet of the impulse valve and the blowing hole. The induction cyclone separator provided by the invention has the advantages that the gas viscosity impurities are effectively separated, the interval blowing has small influence on the separator, the separation efficiency is high, the inner wall of the docking cone tube of the separator has small possibility of causing gather and cumulation of viscidity impurities; the induction cyclone separator is operated for a long time and at high efficiency and is free from cleaning maintenance by manpower; and the times of the cleaning maintenance and time are reduced, and the operation economy of the equipment is improved.

Owner:JIANGSU XINHUANENG ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com