Vortex solid-liquid separator

A solid-liquid separator, eddy current technology, applied in filtration separation, separation methods, water/sludge/sewage treatment, etc., can solve the problems of low discharge efficiency, high equipment cost, complex structure, etc., to improve discharge efficiency and shorten the time. The effect of discharging stroke and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] The present invention improves the traditional compression filter with the purpose of simplifying the structure of the entire solid-liquid separator, reducing its processing difficulty, reducing production costs, shortening the discharge stroke of the filter cake, and improving the discharge efficiency of the filter cake, so as to improve the solid-liquid separator. The market utilization rate of the separator gradually expands the scope of environmental protection.

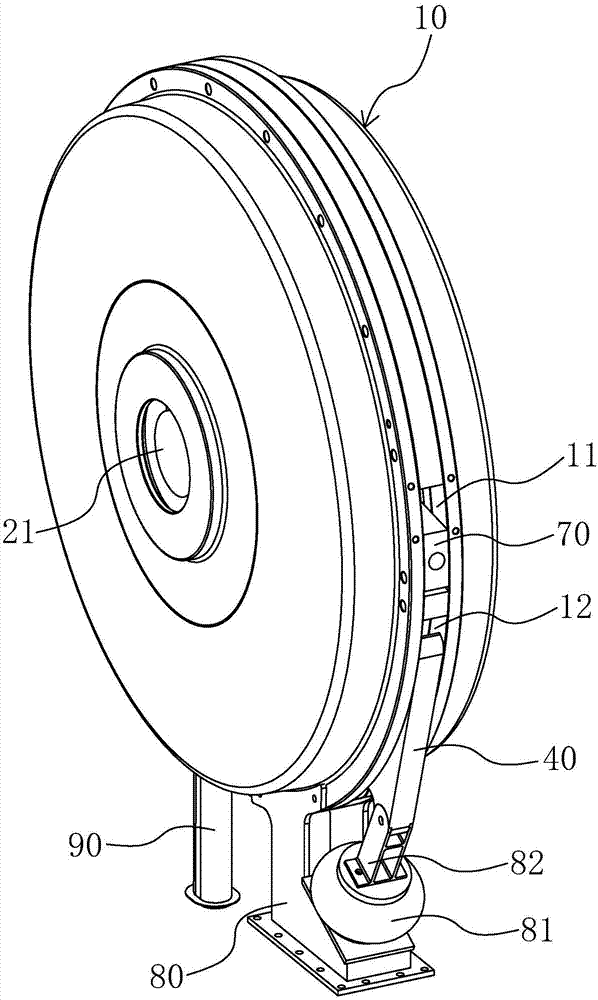

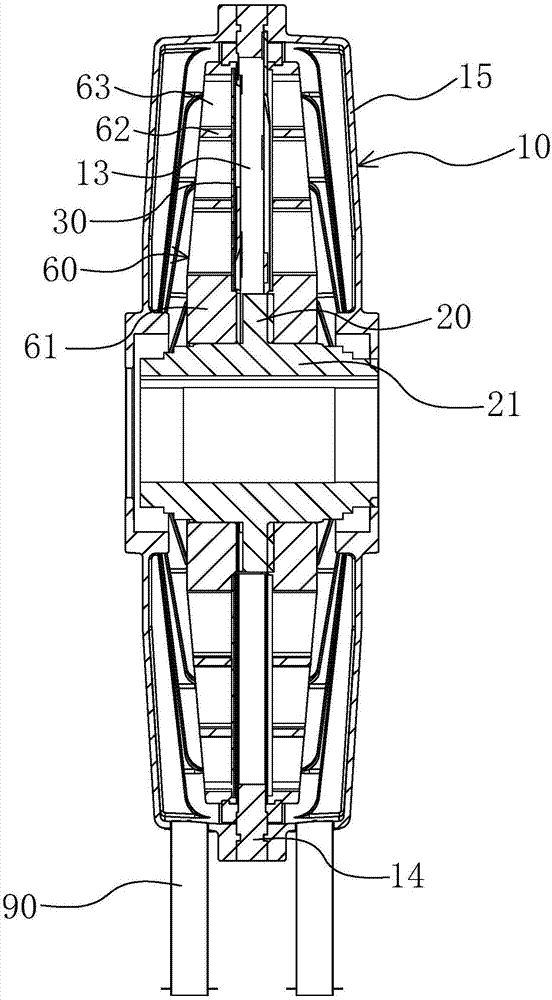

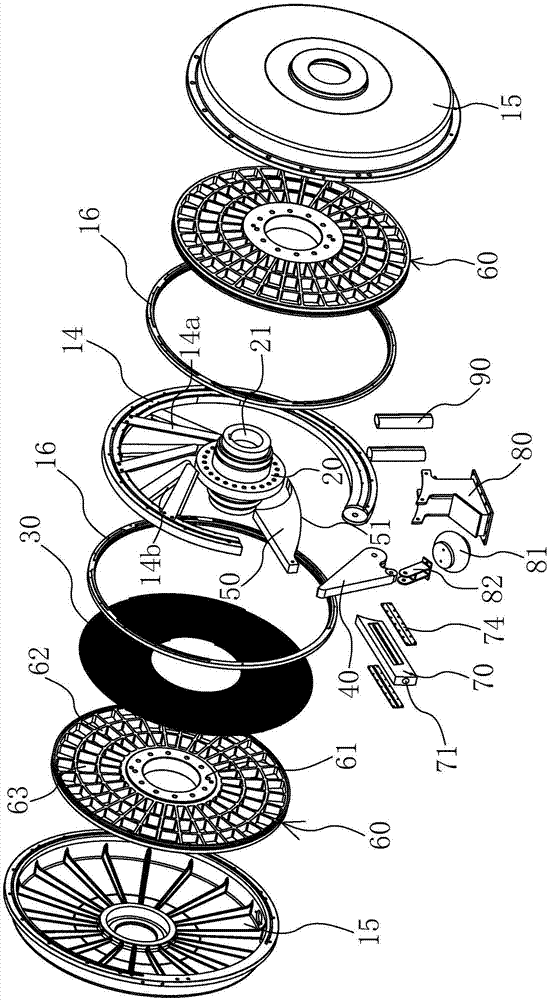

[0037] Such as Figure 1 to Figure 3 As shown, a vortex solid-liquid separator of the present invention includes a casing 10, an inner ferrule 20, a filter screen 30 and a back pressure plate 40.

[0038] The casing 10 is an upright circular flat holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com