Induction cyclone separator

A technology of cyclone separator and truncated cone, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc. It can solve problems such as affecting efficiency, blocking air flow channels, and equipment cannot operate normally, so as to prevent aggregation , small impact on the flow field, and the effect of reducing the frequency and time of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

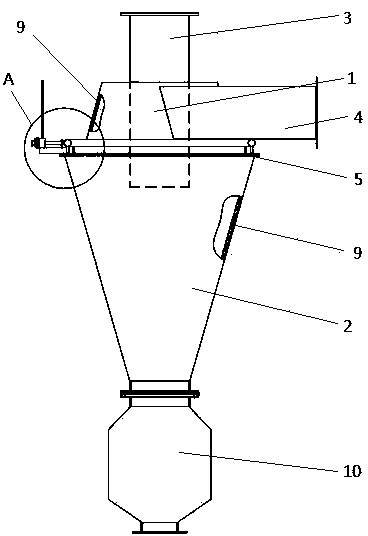

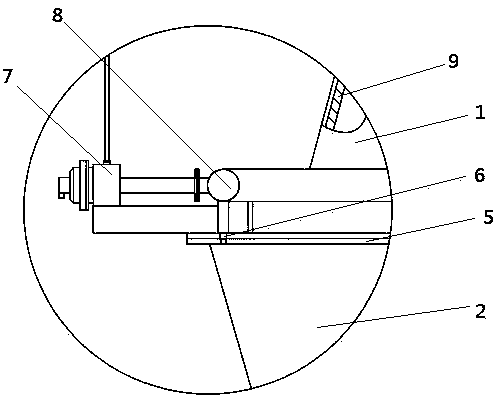

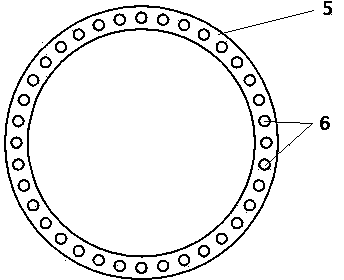

[0015] See figure 1 and figure 2 The main body of the induction cyclone separator in this embodiment includes an upper truncated cone cylinder 1 with a small top and a large bottom and a lower truncated cone cylinder 2 with a large upper bottom and a small bottom. The top of the upper truncated cone cylinder 1 is closed, and the lower part The frusto-conical cylinder 2 is open at both ends, and the lower end of the truncated-conical cylinder 2 is connected to the ash hopper 10 . The upper truncated cone cylinder 1 is provided with a vertical air guide tube 3, the air guide tube 3 is used to discharge the gas after the impurities are separated, the upper end of the air guide tube 3 protrudes from the top of the upper truncated cone tube 1, and the lower end of the air guide tube 3 is lower than the upper truncated cone The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com