Patents

Literature

44results about How to "Good for dehydration and drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

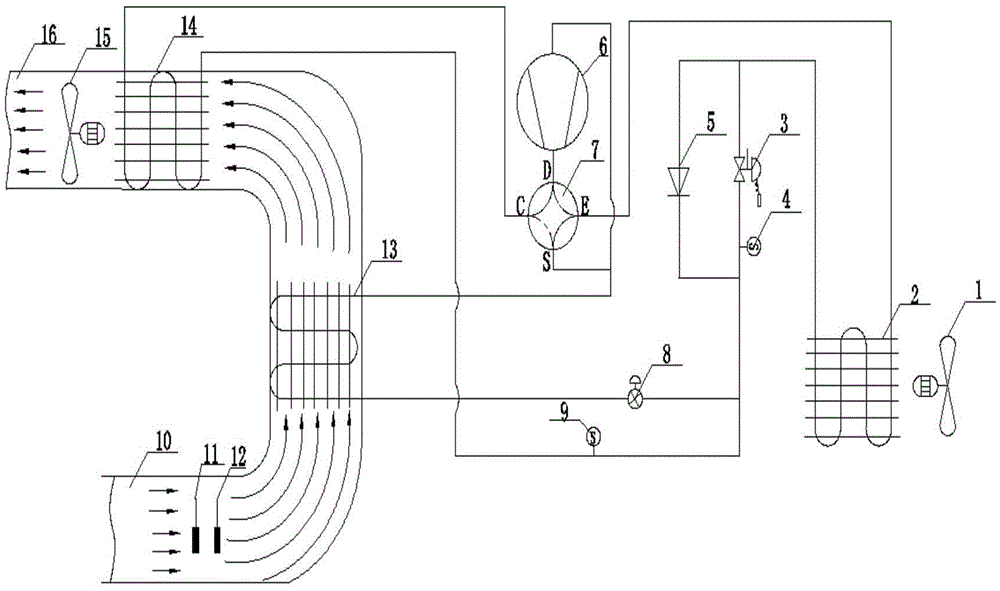

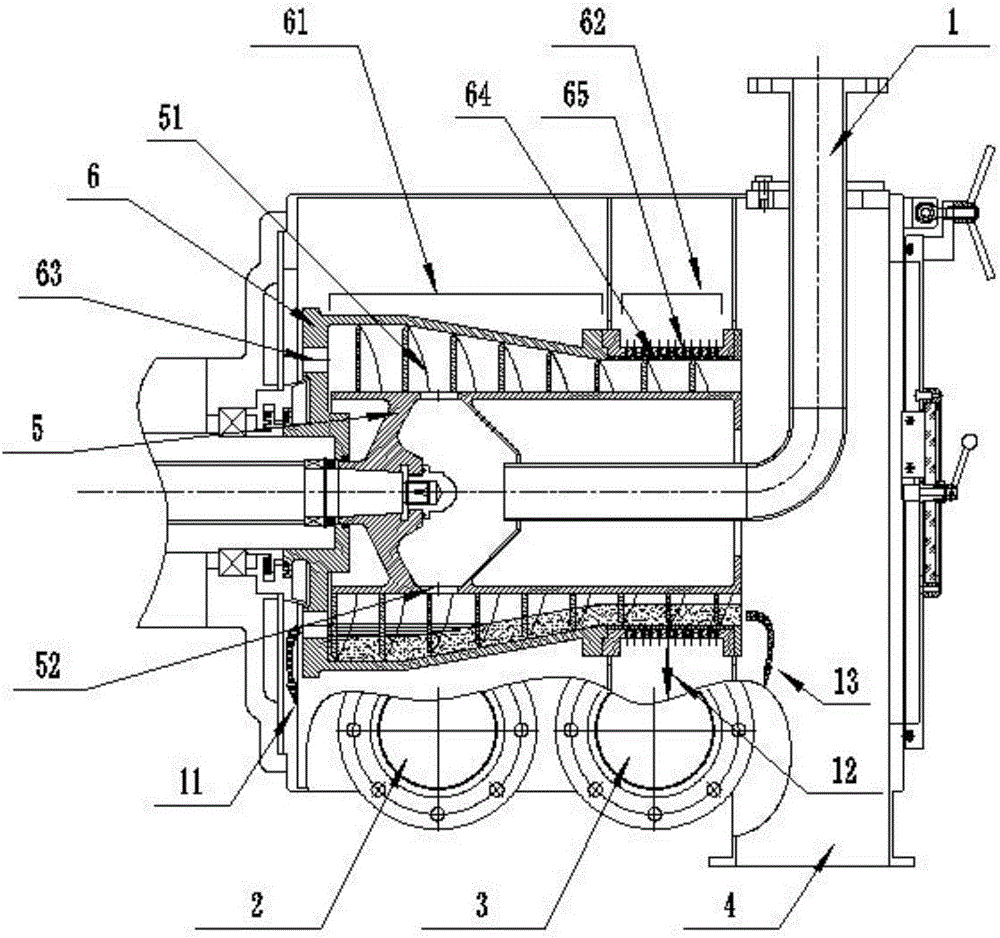

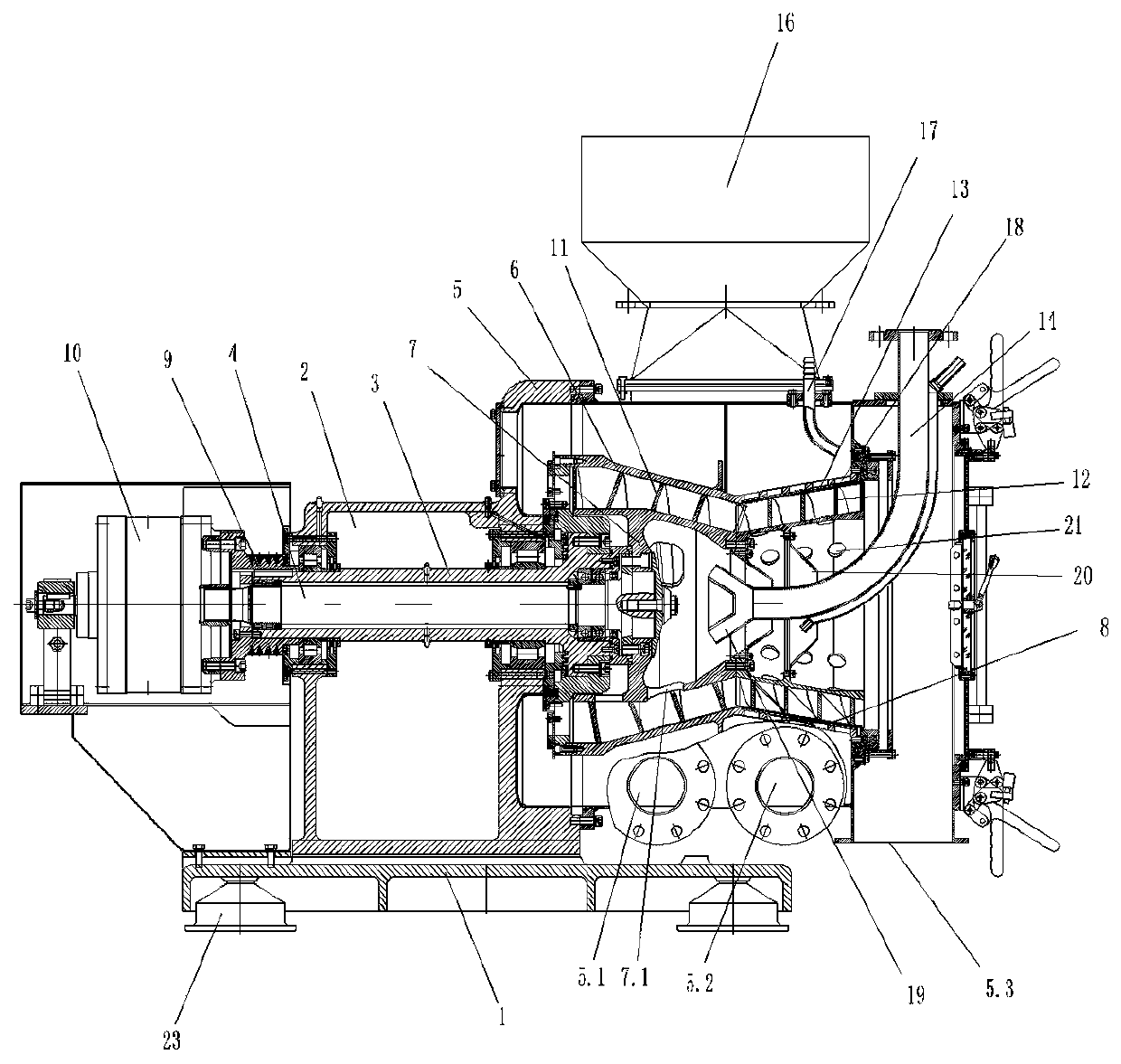

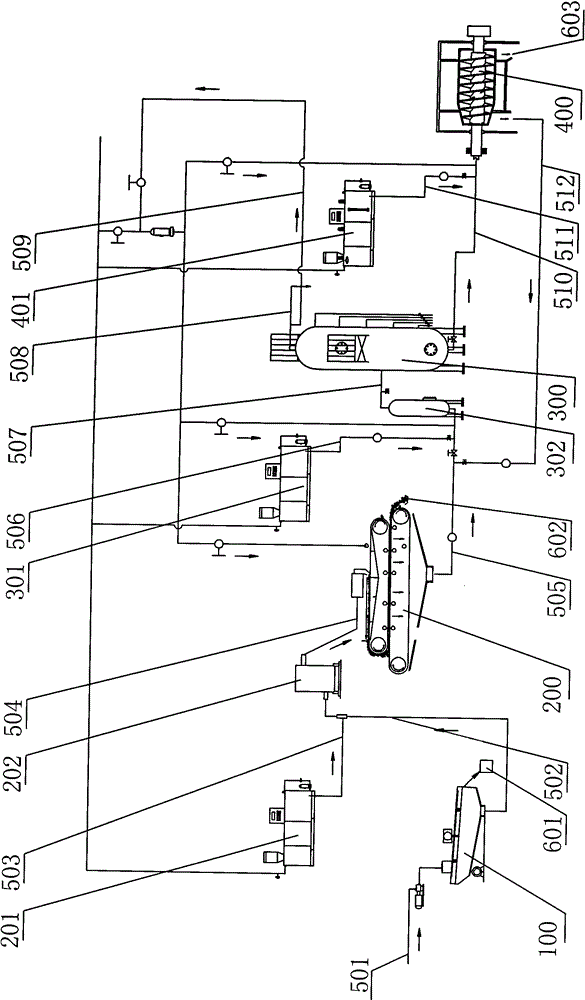

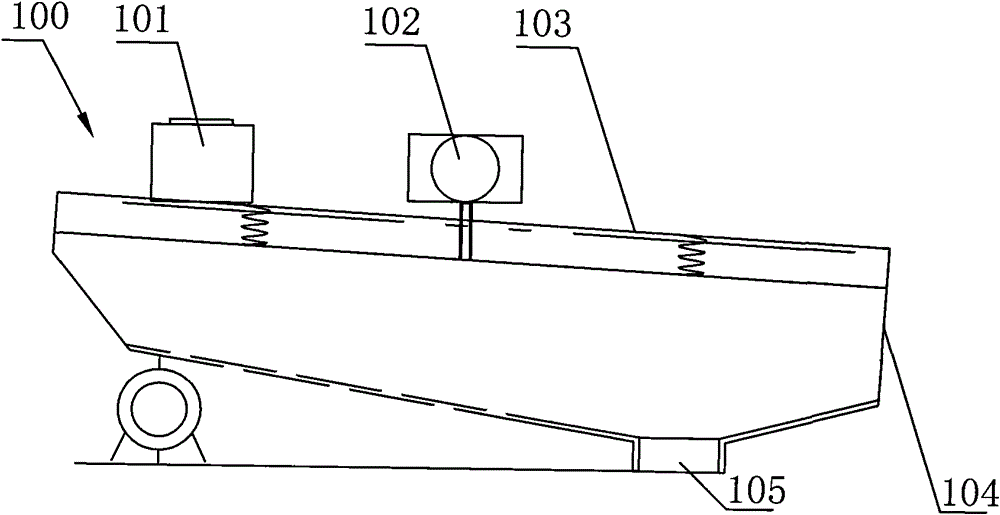

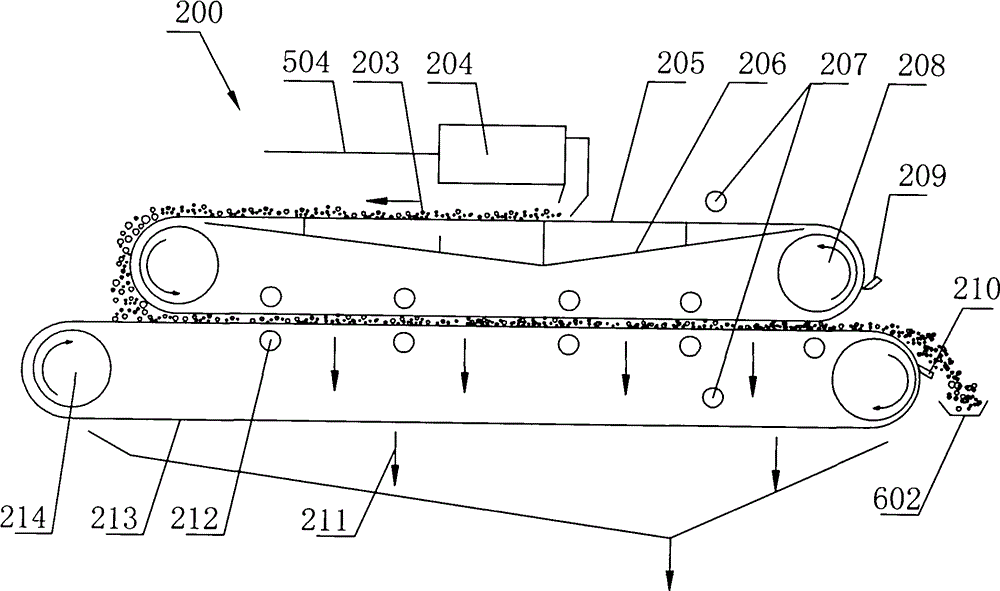

Device and method for dewatering and drying mud under water

InactiveCN101921050AAvoid inefficiencyEfficient dehydration and drying treatmentSludge treatment by de-watering/drying/thickeningContinuous operationSmall footprint

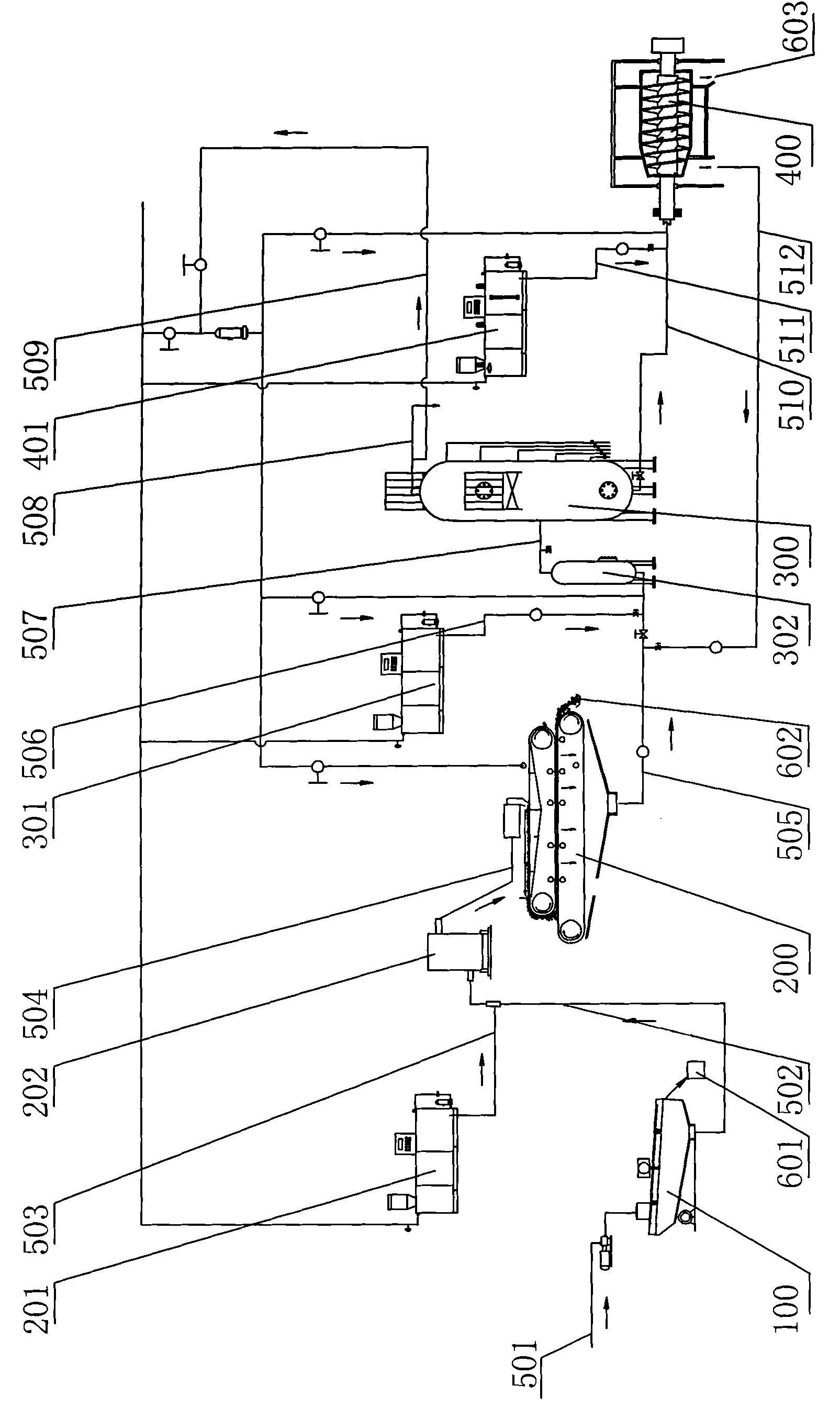

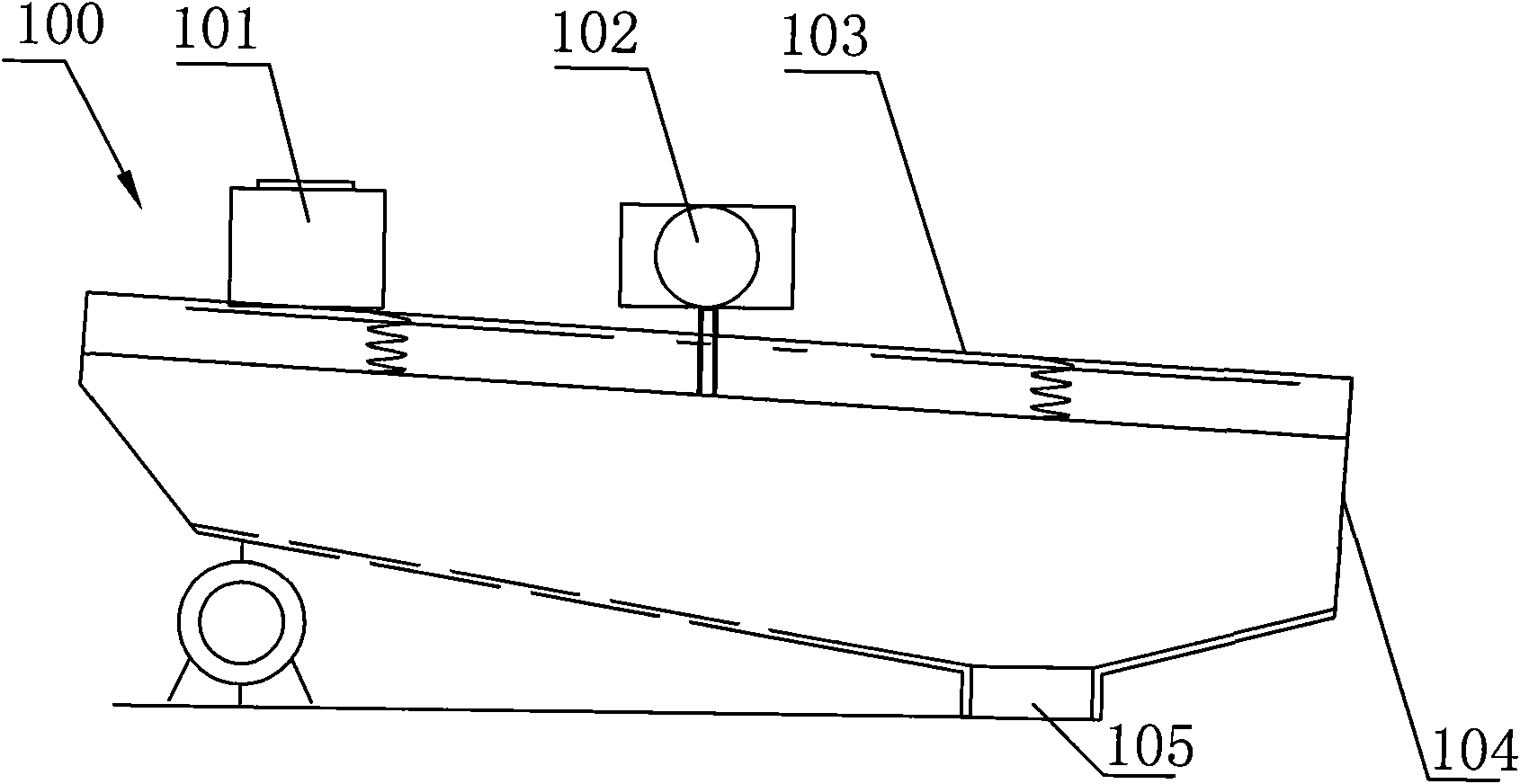

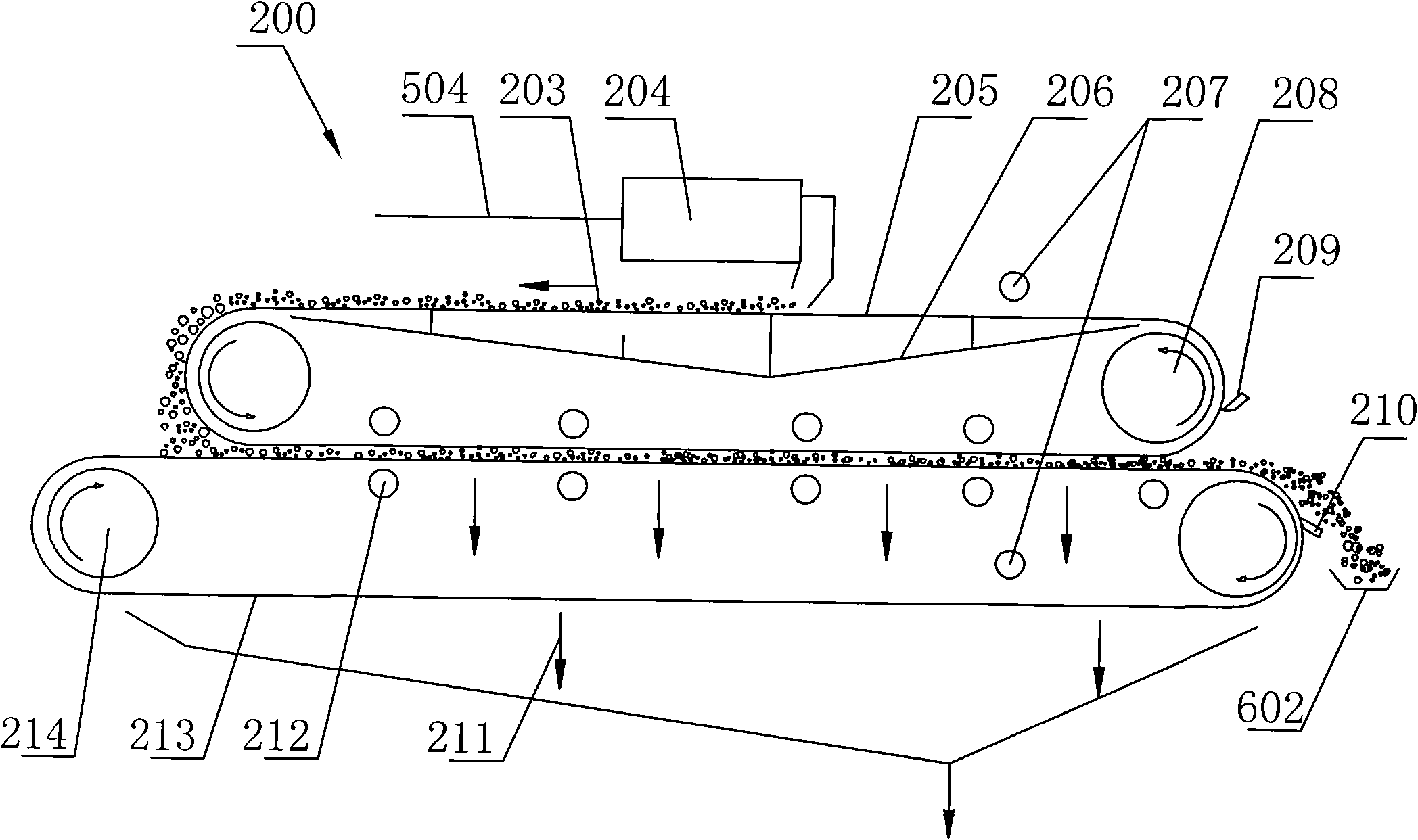

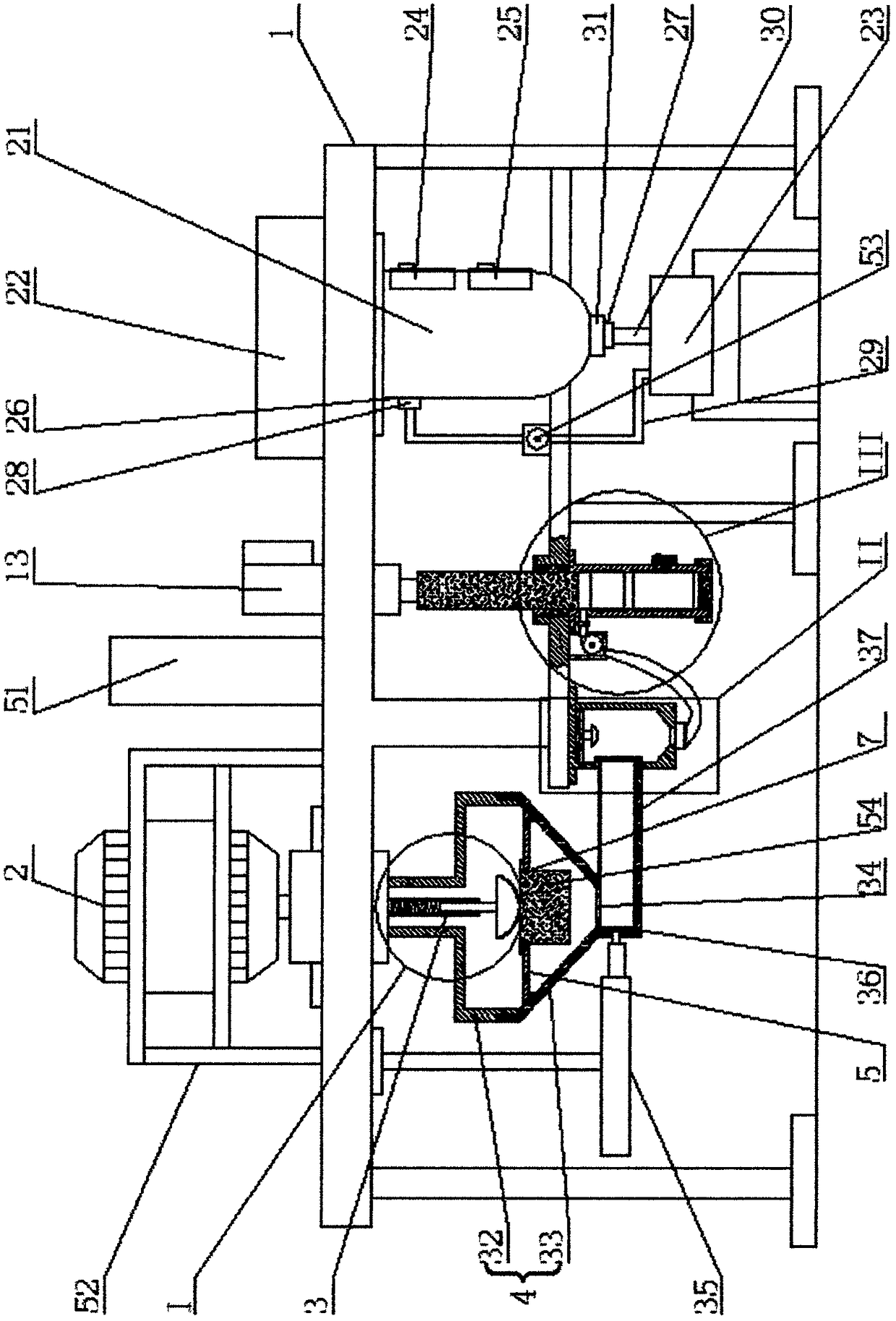

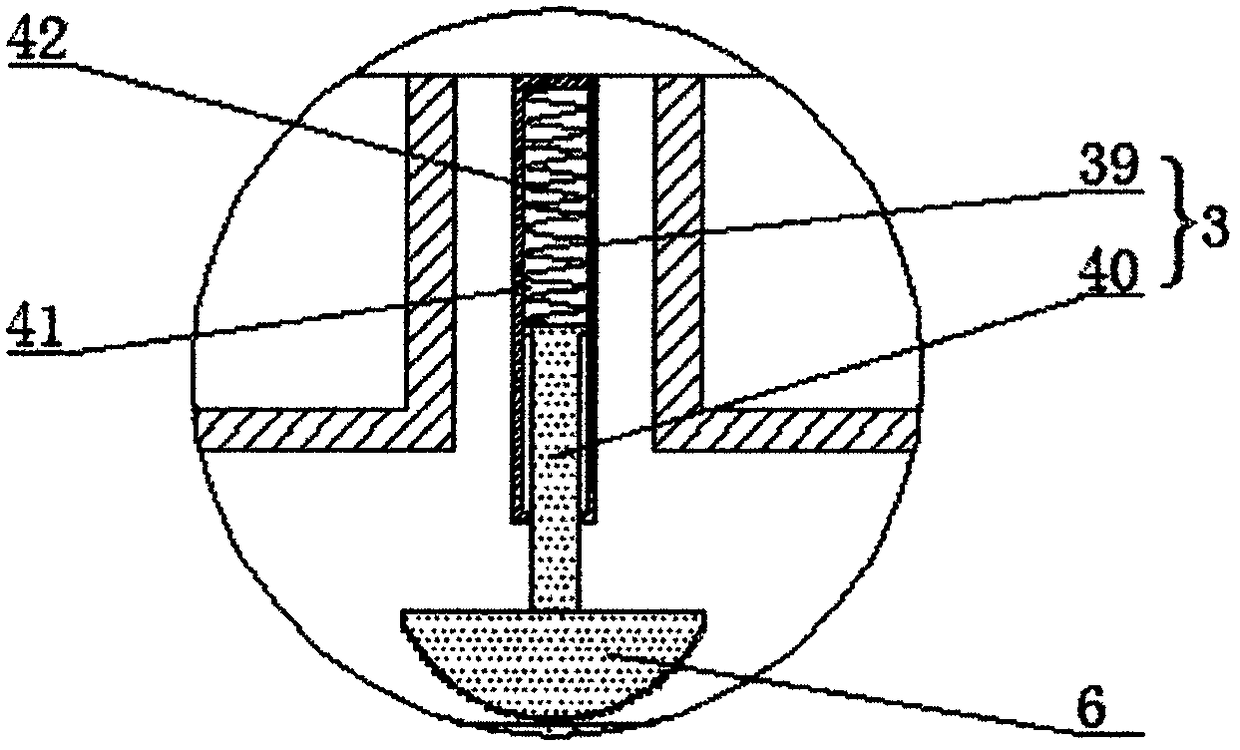

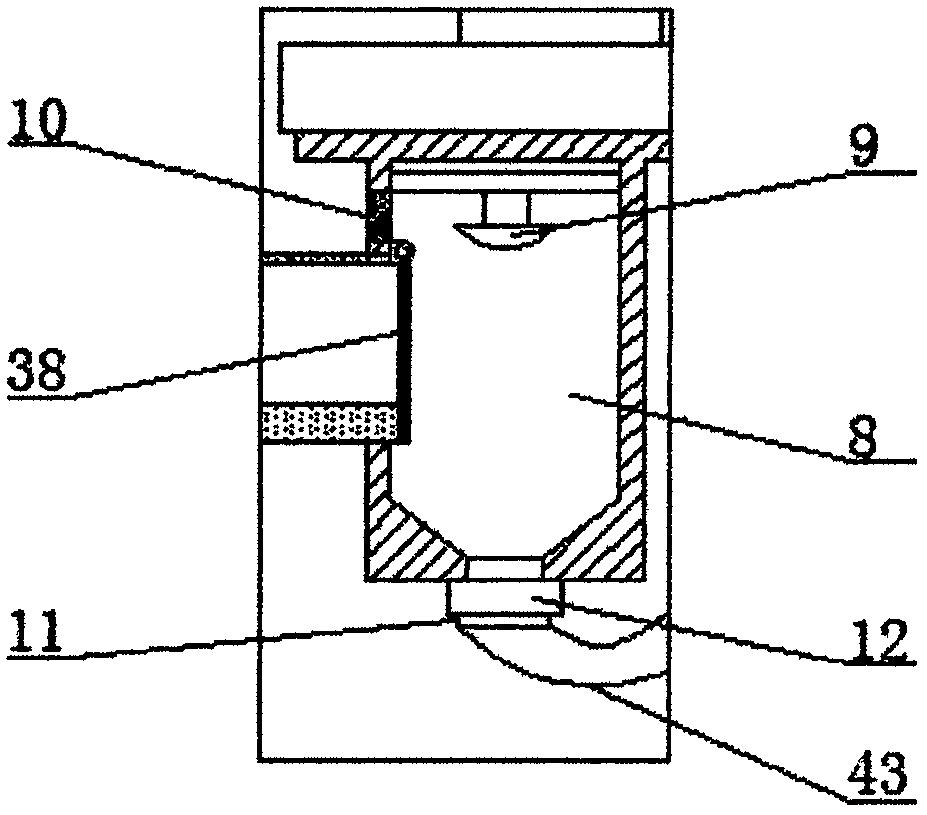

The invention relates to a device and a method for dewatering and drying mud under water. The device comprises a filter sieve, a filter press, a purification tower and a centrifugal machine, wherein the filter sieve is connected in series with a delivery pump through a pipeline; input pipelines of the filter press, the purification tower and the centrifugal machine are provided with flocculating agent adding machines; and a water outlet of the centrifugal machine is connected to an input port of the purification tower. A plurality of water treatment equipment are selected reasonably and a complete set of device is established based on the advantages of various equipment, so that the defect of low treatment efficiency of single equipment is overcome and dewatering and drying treatment can be efficiently performed on mud under water. The device and the method have the characteristics of reducing time needed by natural drying of a mud yard, improving mud treatment efficiency, greatly lowering dredging cost and meeting the requirement of mass, batched and engineered mud treatment, along with small floor area, low energy consumption, no blocking in continuous operation, high mud yield, good mobility, convenient arrangement on a mud treatment site and the like.

Owner:中国船舶重工集团公司第七〇二研究所

Sludge fuel and preparation method thereof

The invention discloses a sludge fuel and a preparation method thereof; the sludge fuel is mixed by the following composition of raw materials according to mass percent: 29.5-85 percent of water-contained sludge, 10-70 percent of rice husk ash, and 0.5-5 percent of deodorization bactericide. The sludge fuel solves the problem of difficult sludge treatment in cities and greatly reduces the cost ofsludge treatment, the sludge is prepared into fuel, the energy stored in the sludge is recycled, the sludge fuel ash after being combusted not only leads heavy metals to be passivated in a way of oxidizing materials, but also can utilizes silica highly contained in the ash to be prepared into building materials, thereby thoroughly carrying out safety treatment of sludge and rice husk ash and obtaining recycling utilization.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Medical equipment disinfecting device with medicine stirring function

PendingCN107519513AGood for dehydration and dryingComprehensive cleaningDrying gas arrangementsLavatory sanitoryMedical equipmentApparatus instruments

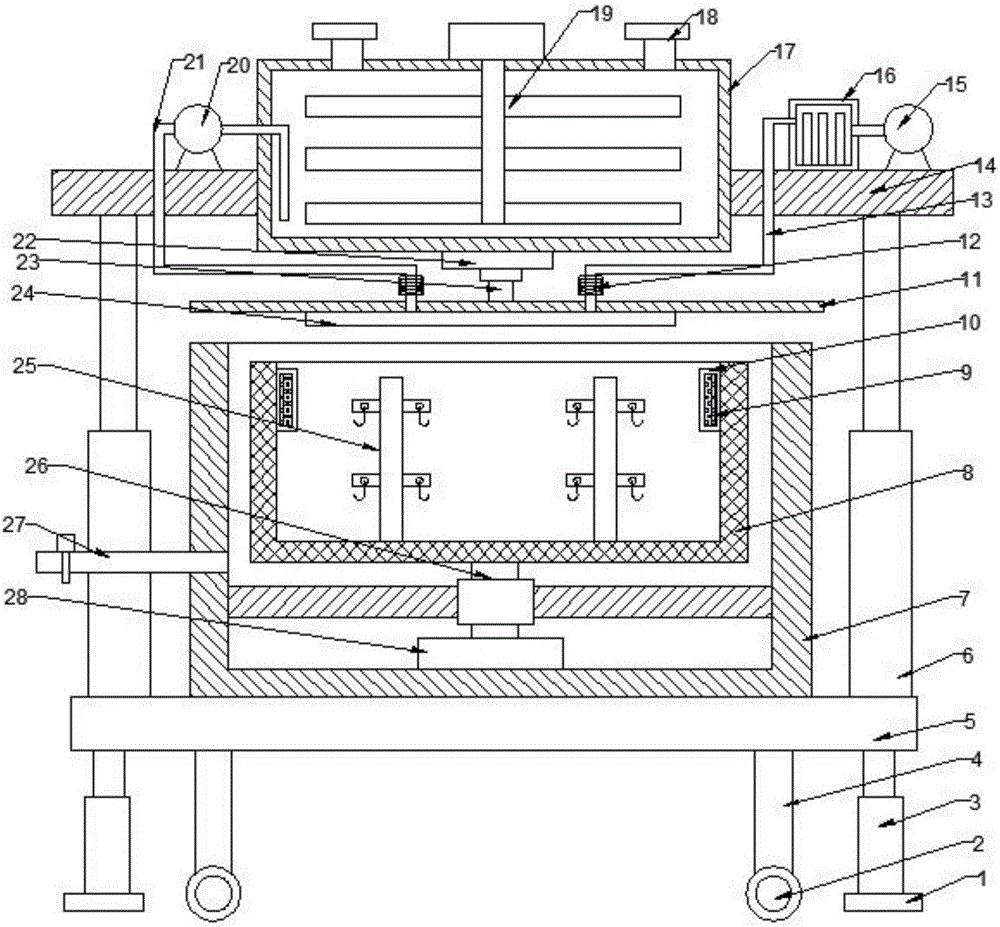

The invention provides a medical equipment disinfecting device with a medicine stirring function, and belongs to the technical field of disinfection of medical equipment. A cover plate is fixedly arranged on the lower side of a telescopic rod; the right end of a water pump is connected with a water pipe and a disinfecting liquid box; the left end of the water pump is connected with a water spraying plate through the water pipe; a device placing net vessel is arranged at the upper end of an electromotor through a rotating shaft; two suspending frames are arranged in an inner cavity of the device placing net vessel; an ultraviolet sterilizer is fixedly arranged above the left side and the right side of the inner cavity of the device placing net vessel. Uniform spray holes are formed in the lower end of the water spraying plate, so that the device has the function of spraying disinfectin liquid in a cleaning vessel by the water pump or blasting by a blast blower; the device placing net vessel is arranged at the upper end of the electromotor through the rotating shaft, the device has the functions of rotating to facilitate complete cleaning and facilitating dehydrating and drying; the device has the characteristics of simple structure, high practicability and good disinfecting effect.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Novel method for producing cured beef

The invention discloses a method for processing cured beef, and belongs to the technical field of meat science. The method is characterized in that: under manual control, low-temperature high-moisture preservation (temperature is 4 to 8 DEG C, RH is roughly 80 percent and time is 21 to 28 days), intermediate-temperature low-moisture air preservation (temperature is 15 DEG C, RH is roughly 55 percent and time is 30 days) and high-temperature intermediate-moisture fermentation fragrance generation(temperature is 25 DEG C, RH is roughly 65 percent and time is 30 days) are adopted; and the conventional wet curing method is changed into the dry curing method, so that the cured beef can be produced without seasonal restrictions. The method has the advantages that: 1, the method is not limited by seasons, and the cured beef can be produced all year round; 2, the standardized production is realized under manual control; 3, the dry curing method is adopted, and a fault rate is lowered; and 4, the product has a better flavor, and the quality of the product is more stable.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Drying dehumidifier

InactiveCN105546876AReduce the temperatureReduce humidityMechanical apparatusHeat pumpsControl systemProcess engineering

The invention provides a drying dehumidifier. The drying dehumidifier comprises a compressor, an indoor condenser, an indoor evaporator, a first throttle valve, an outdoor heat exchanger and a control system among which a high-temperature dehumidifying circulation pipeline and a low-temperature dehumidifying circulation pipeline are formed, a controller controls a coolant to circulate in the corresponding circulation pipelines to realize high-temperature dehumidification or low-temperature dehumidification of materials. The drying dehumidifier overcomes the shortcomings that a drying dehumidifying heat pump unit in the prior art only has a high-temperature dehumidifying mode but cannot realize low-temperature dehumidification of the materials.

Owner:ZHEJIANG AMA & HIEN TECH

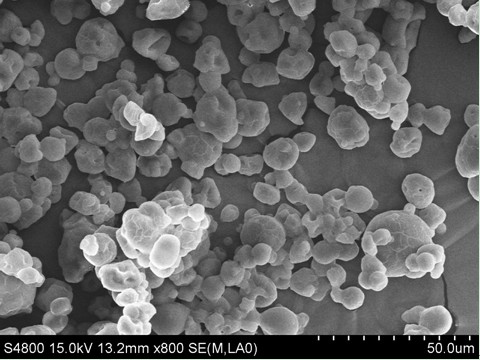

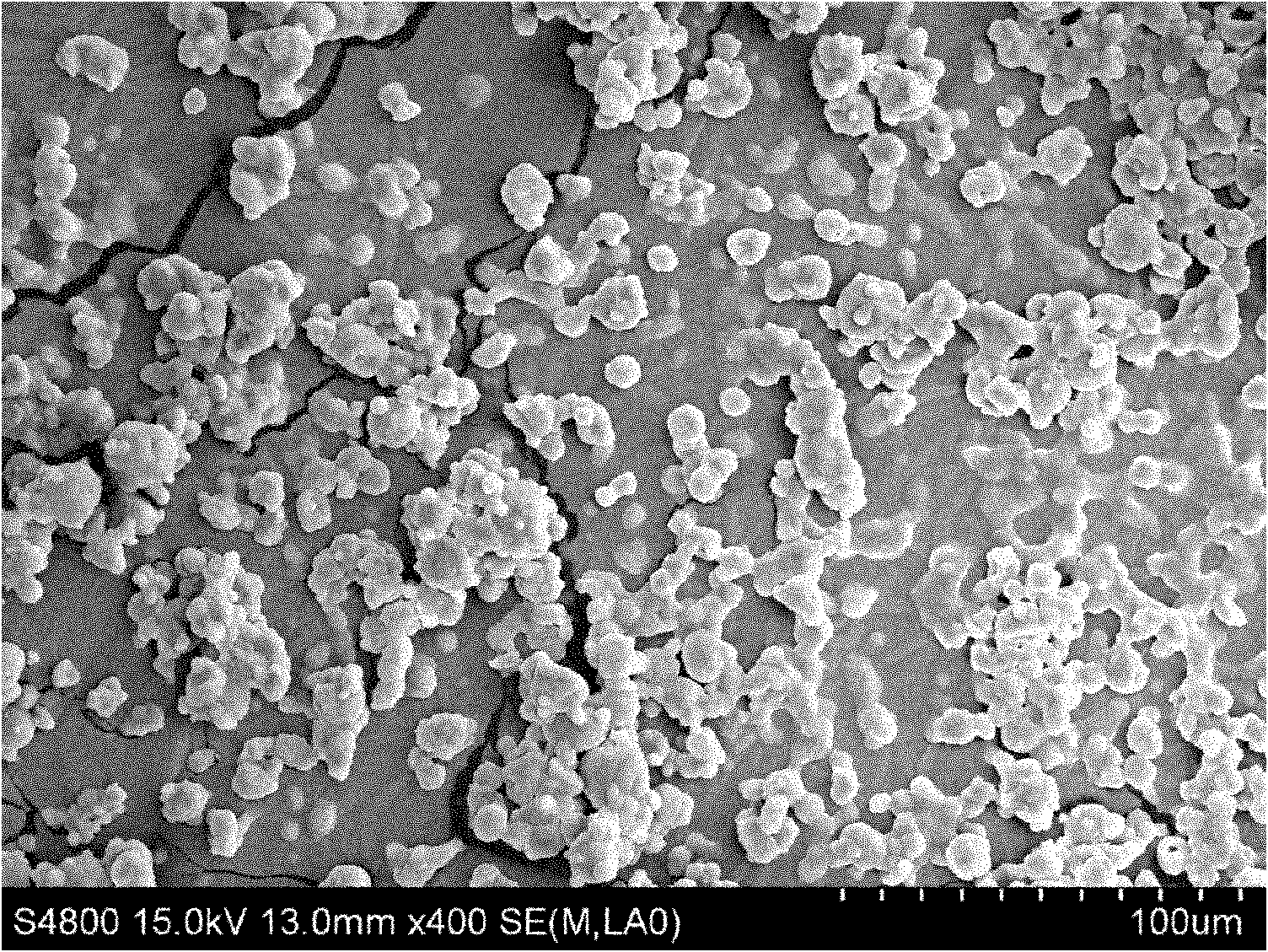

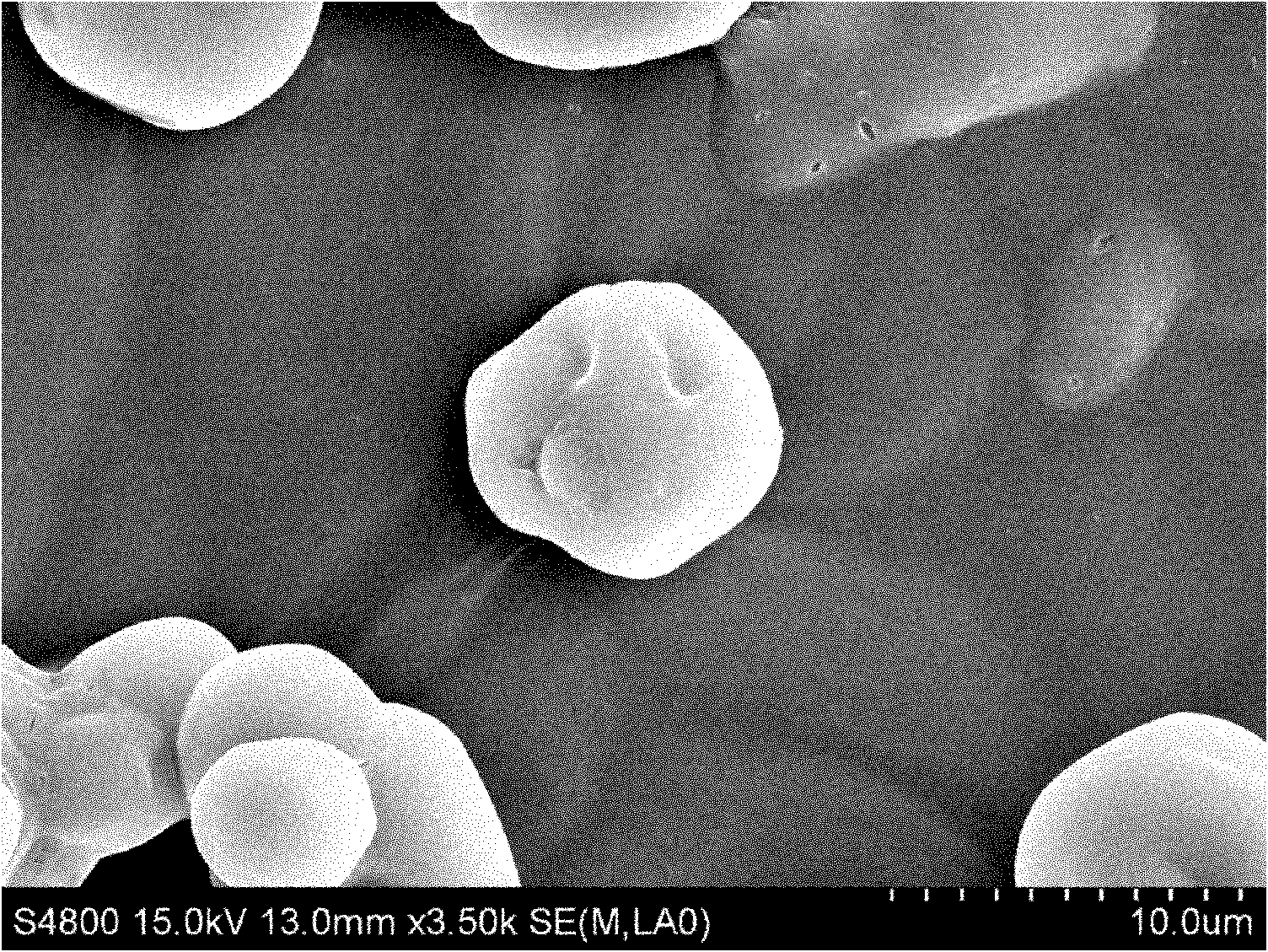

Preparation method of yolk antibody sustained-release preparation for preventing gosling plague

InactiveCN102205123AGood immune protectionEffective controlPowder deliveryAntiviralsYolkGrowth promoting

The invention discloses a preparation method of a yolk antibody sustained-release preparation for preventing gosling plague, and belongs to the technical field of biological products. A healthy egg layer is immunized with a gosling plague live vaccine and a gosling plague inactivated vaccine successively; the laid egg is collected, and the yolk is separated; the yolk is well mixed with a sodium chloride solution, and a proper amount of porous starch is added for full adsorption; the above solution is well mixed with a sodium alginate solution; the mixed solution is dehydrated by a spray drying device; and a yolk antibody sustained-release preparation for preventing gosling plague is obtained. The method of the invention is scientific, has simple process, low cost, and minimal loss; the preparation has the characteristics of obvious efficacy, convenient preservation, good sustained-release performance, easy absorption, no toxicity, no residues, and the like. Compared with traditional yolk antibody injections, the yolk antibody sustained-release preparation for preventing gosling plague not only has a prolonged protective period, but also can be administered through an oral route without any stress response, and the preparation also has a certain growth-promoting effect.

Owner:JIANGSU INST OF POULTRY SCI

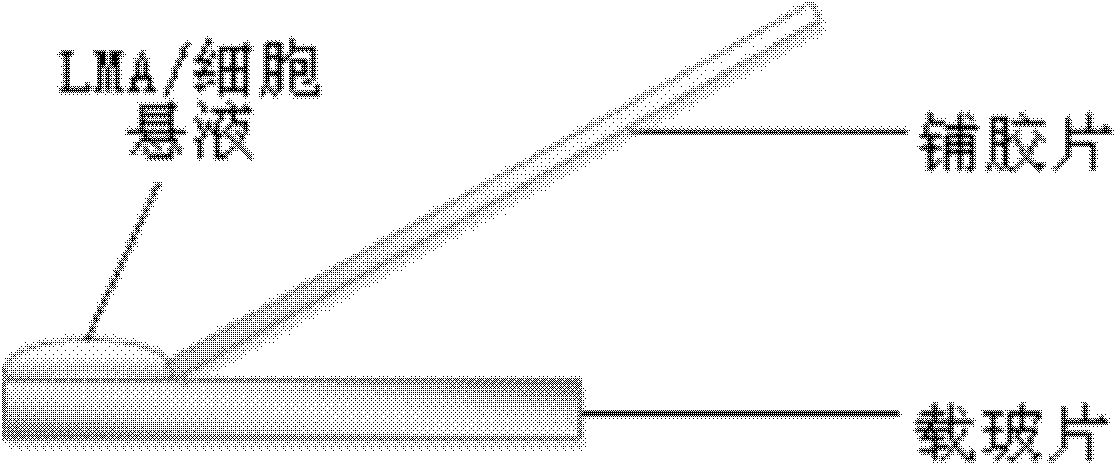

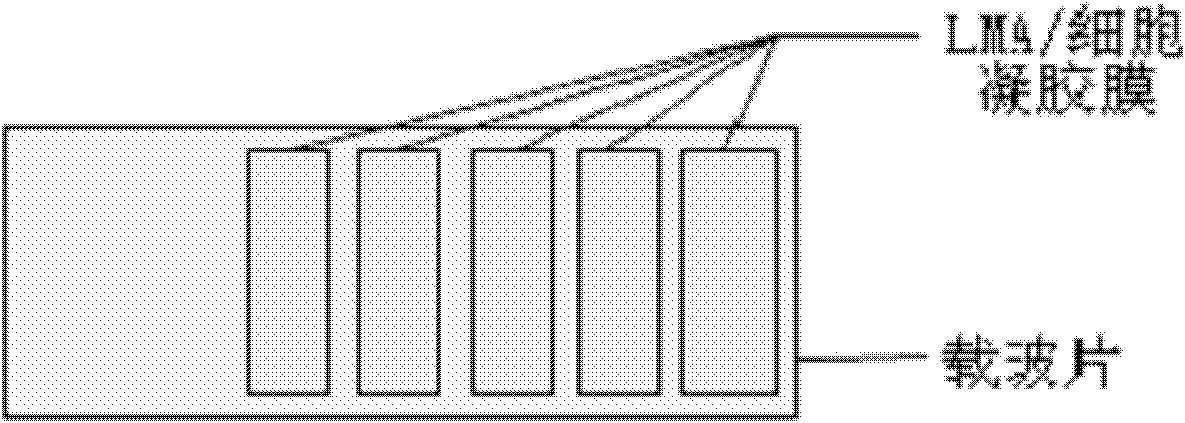

Gel paving method by using single cell gel electrophoresis

InactiveCN101865877AEasy to handleIncrease success ratePreparing sample for investigationMaterial analysis by electric/magnetic meansElectrophoresisGel electrophoresis

The invention discloses a gel paving method by using a single cell gel electrophoresis, which comprises the following steps: (1) immersing a clean glass slide in a 0.2-1.0% agarose solution with a constant melting point, and then baking the glass slide at 37 DEG C for further use; (2) uniformly mixing a cell suspension with 1% agarose solution with a low melting point in a volume ratio of 1:1 and dropping the mixed solution onto the coated glass slide; and (3) approaching a gel paving sheet to the cell suspension at an angle of 30-45 degrees, pulling the gel paving sheet backwards at a constant speed, expanding the suspension along the front end of the gel paving sheet, ending the gel paving after the cell suspension is paved to be in a film shape, and solidifying the gel for 2-3 minutes at 4 DEG C. The degumming rate of the gel paving method is reduced to 0, while the gel paving speed is high; furthermore, the method is simple to operate and easy to master and particularly facilitates the large-scale processing on samples.

Owner:NORTHWEST UNIV

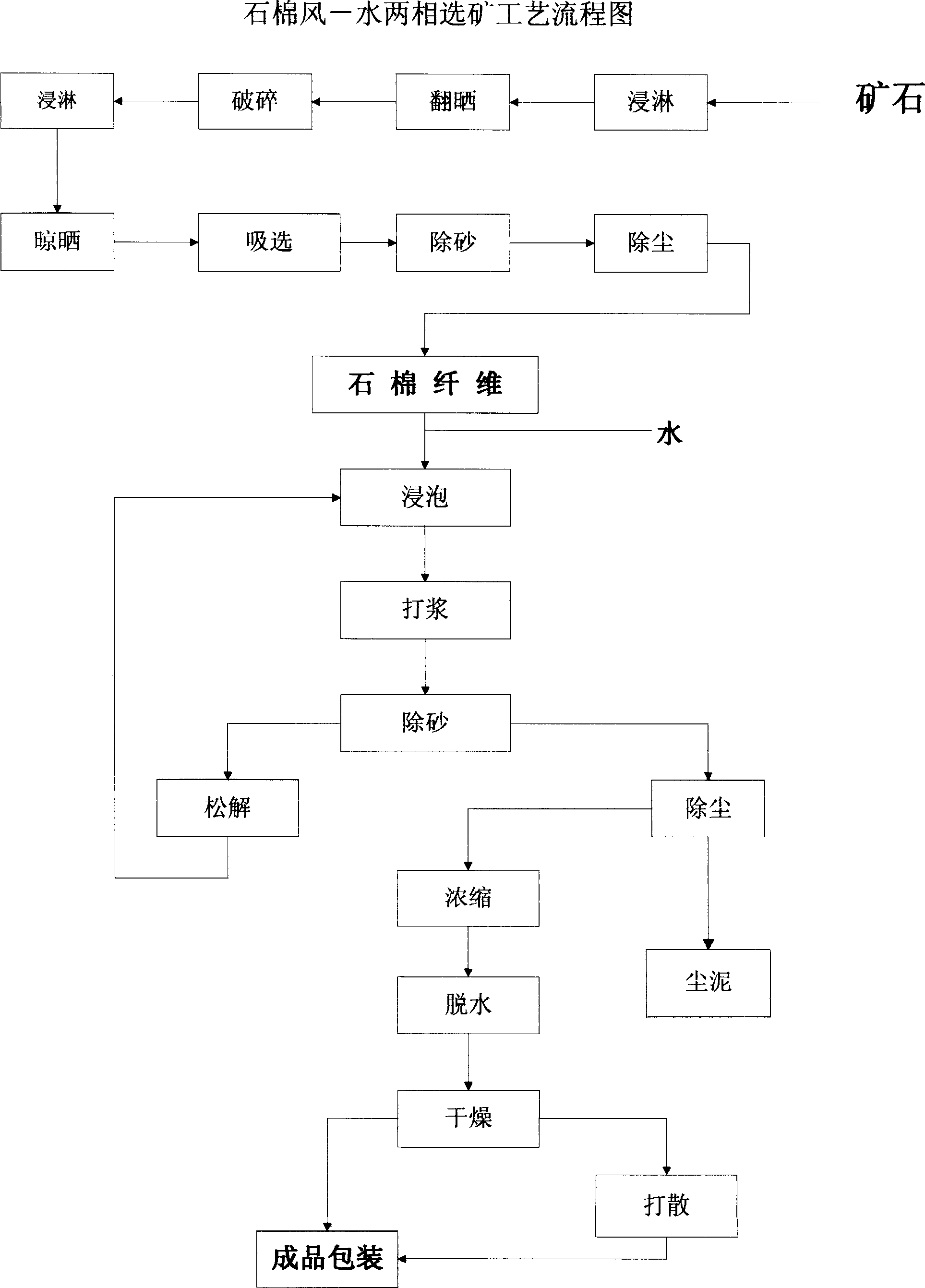

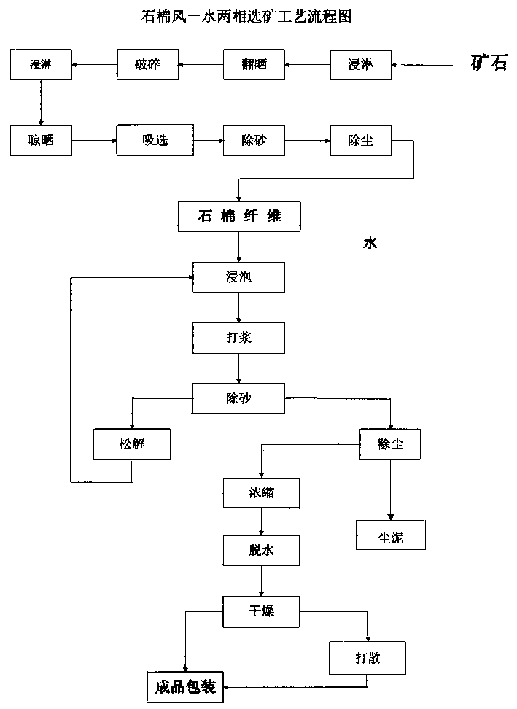

Asbestos wind-water two-phase concentrating technology

The present invention relates to a mineral separation process of asbestos mine, combining dry pneumatic separation and wet separation, which is characterized by that it makes the ore undergo the processes of soaking, showering, stacking, airing and breaking in dampness so as to implement its preparation process, in which dry pneumatic separation can obtain crude concentrate asbestos, most of sand and dust can be removed, then it makes wet separation operation, incluidng, removing sand, removing dust, opening and die-pressing and dewatering to obtain the invented high-quality asbestos with high yield and good degree of opening of fiber.

Owner:XIANYANG NONMETALLIC ORE CHEM

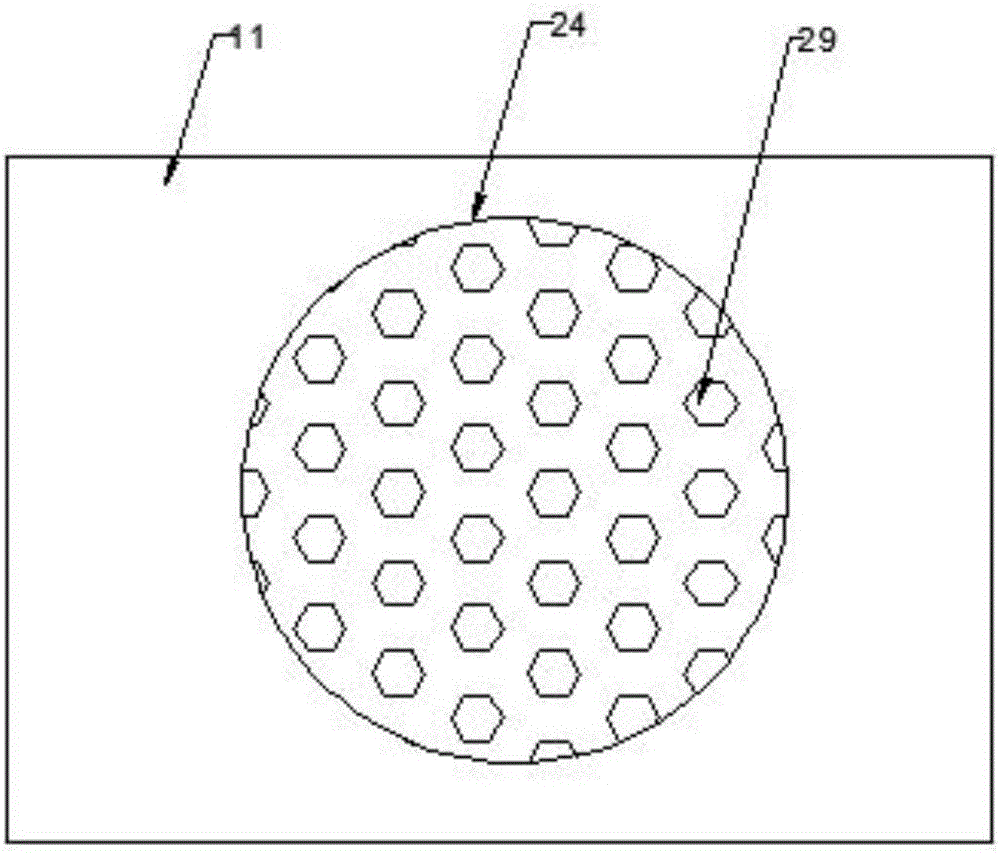

Urban ecological river sediment pre-treatment system and treatment method

InactiveCN110372161AGuaranteed winding effectEasy to handleSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationSewage

The invention discloses an urban ecological river sediment pre-treatment system. The urban ecological river sediment pre-treatment system comprises a treatment box, the treatment box is internally provided with a water strainer plate arranged in an inclined mode, the water strainer plate separates the inner part of the treatment box into a treatment cavity and an accumulated water cavity which arearranged up and down, the treatment cavity is divided into a filtering cavity, a winding cavity, an adsorption cavity and a flocculation cavity from left to right, the winding cavity is internally provided with a winding assembly, a sewage cleaning assembly is arranged on the upper part of the winding assembly, a sewage accumulating box is arranged on the right side of the winding assembly, and the adsorption cavity is internally provided with an adsorption assembly. A treatment method comprises the following steps of (1) filtering treatment, (2) winding and impurity removing treatment, (3) adsorption treatment, (4) flocculation dehydration treatment, and (5) cleaning and maintenance. According to the urban ecological river sediment pre-treatment system and the treatment method, stone, impurities and the like in sediment are removed through the filtering cavity, suspended impurities in the sediment are removed in a winding mode through design of the winding cavity, magnetic materialsin the sediment are adsorbed through the absorption cavity, and finally flocculation is conducted on the sediment through the flocculation cavity, and follow-up dehydration and drying treatment is conveniently conducted on the sediment.

Owner:浙江永安工程咨询集团有限公司

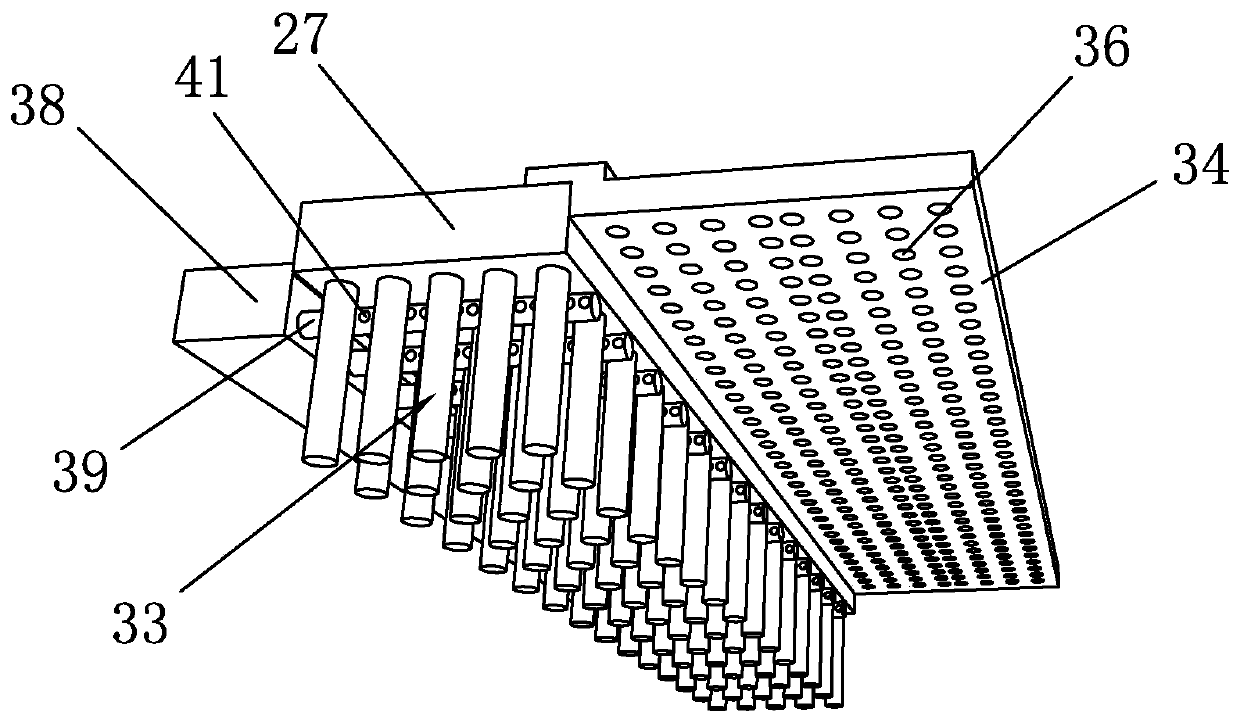

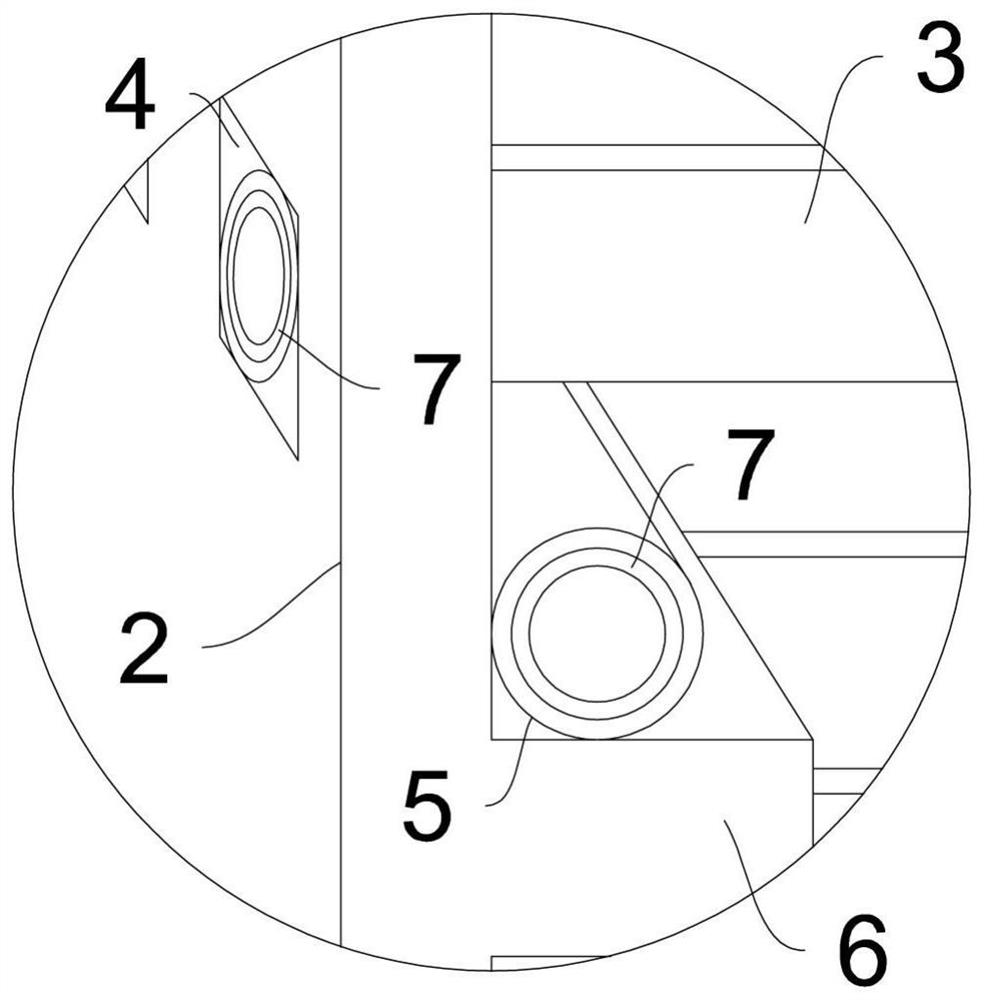

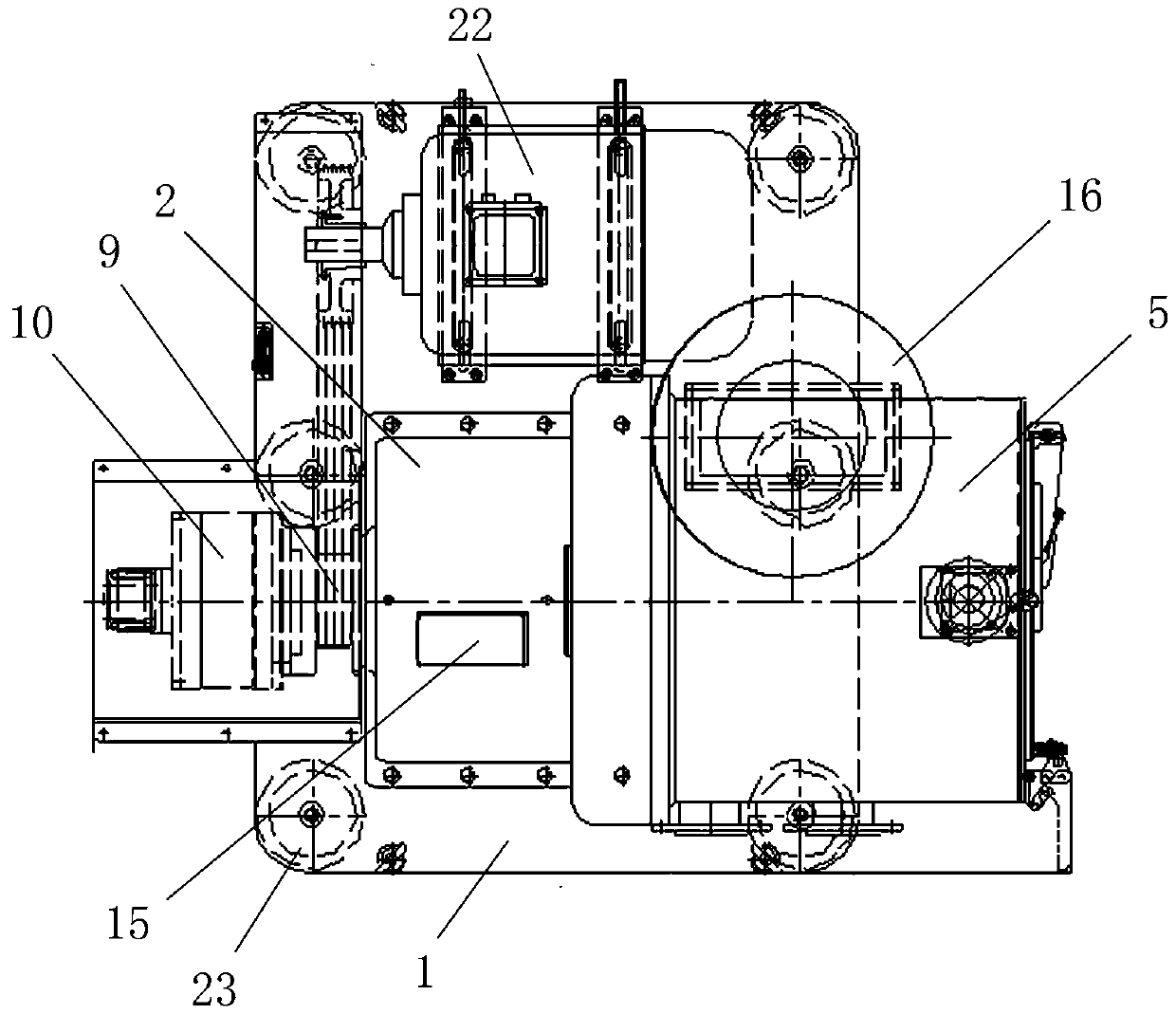

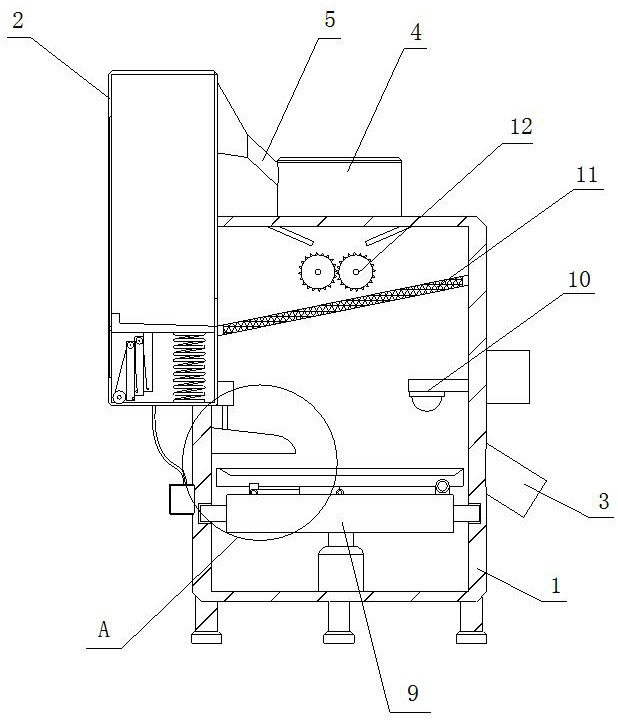

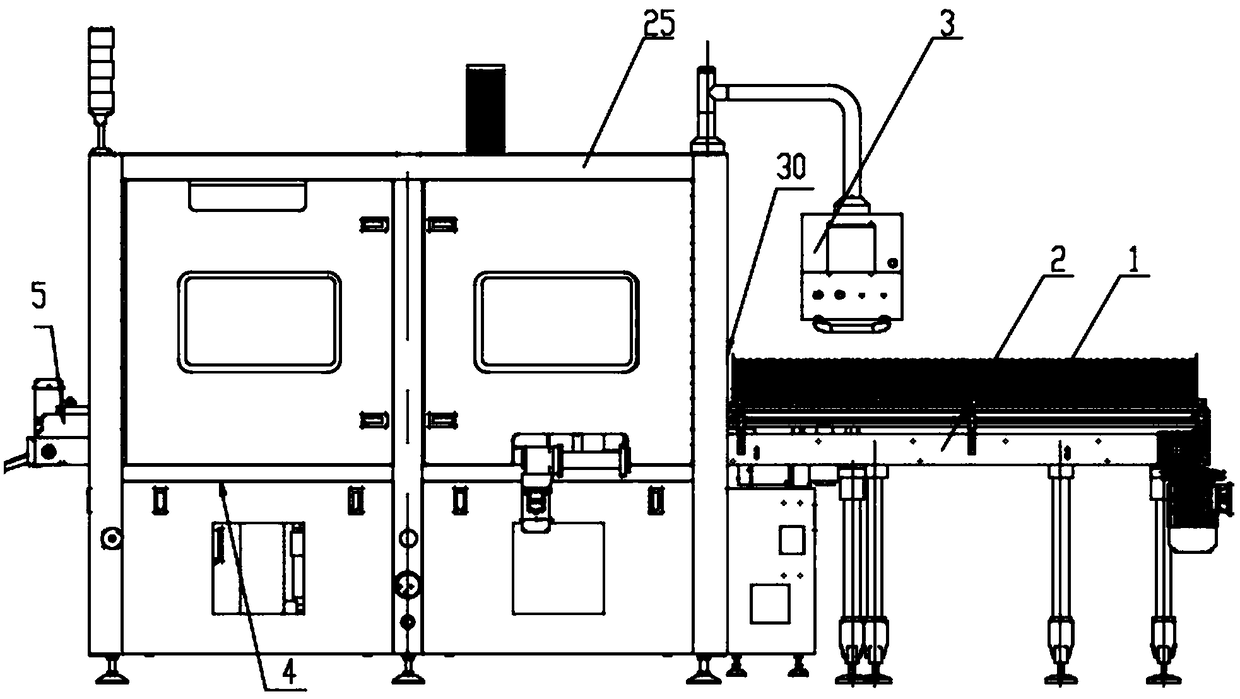

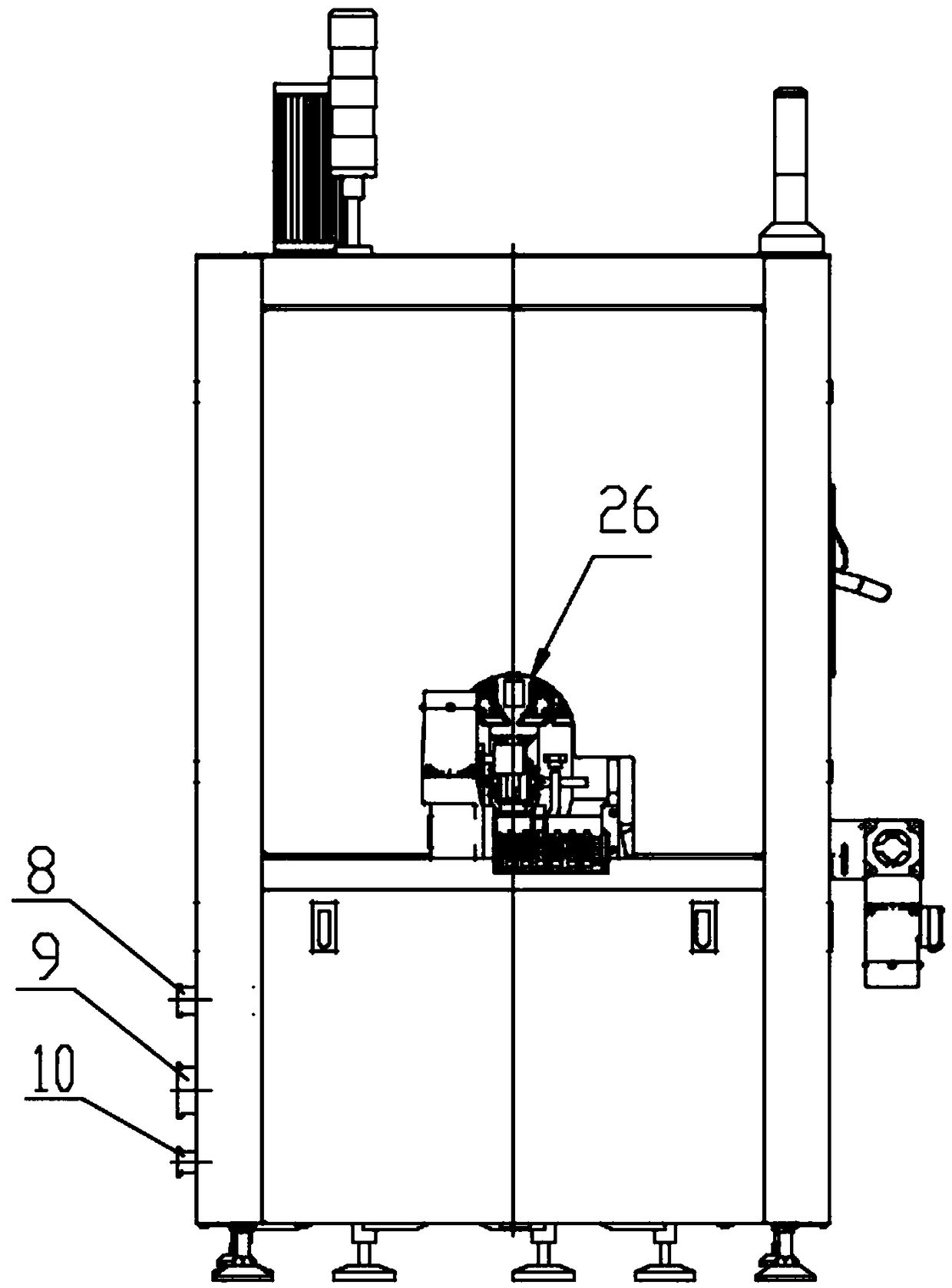

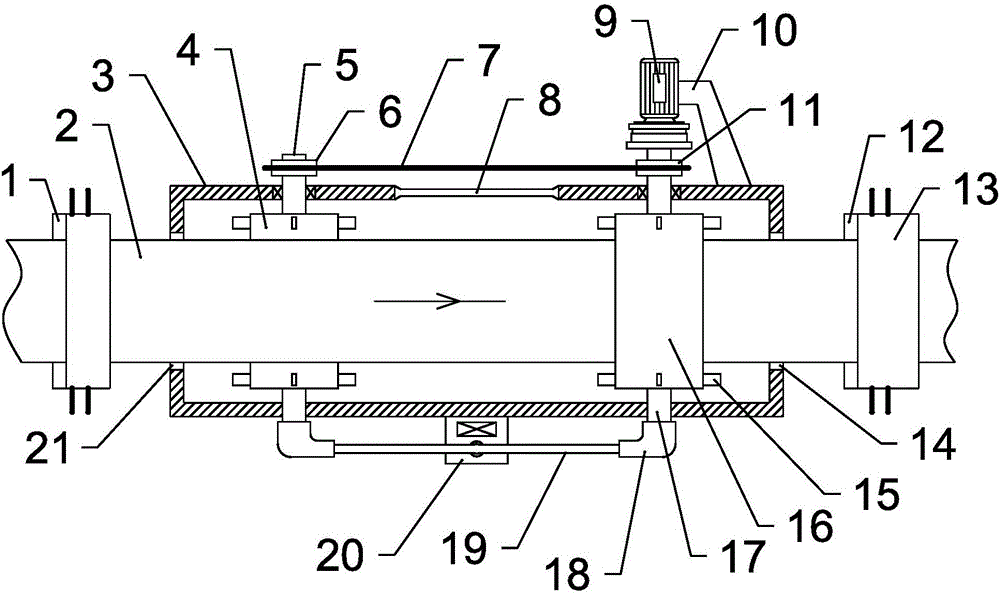

Horizontal type spiral settling and filtering centrifuge

InactiveCN106179777AReduce moisture contentGood for dehydration and dryingRotary centrifugesParticle flowFiltration

The invention discloses a horizontal type spiral settling and filtering centrifuge which comprises a machine enclosure; a feeding pipe, an overflow and liquor discharge pipe, a filtration and liquor discharge and a solid outlet are arranged on the machine enclosure; an inner rotary drum and an outer rotary drum are arranged in the machine enclosure; a spiral blade and at least one discharge hole are arranged on the inner rotary drum; the outer rotary drum comprises a settling and concentrating region and a filtering region; a concentration and overflow hole is formed in the settling and concentrating region; and a filter screen and a filter hole are arranged in the filter region. According to the horizontal type spiral settling and filtering centrifuge disclosed by the invention, characteristics of the settling and filtering centrifuge are combined with those of the rotary drums, so that a to-be-separated solid-liquor mixture is firstly concentrated and thickened in the settling region in a separating process, and then is dehydrated and dried through the filter region, and therefore, moisture content of solid materials is reduced; and for materials with low solid content and many fine particles, the pre-concentrated fine particles flow back into mother liquor through overflow liquor, so that the purposes of thickening and removing the fine particles are achieved, and therefore, the materials reaching the filter region are dehydrated and dried easier.

Owner:ZHANGJIAGANG SHENGLITAI CENTRIFUGE MFG

Cucumis melo processing method

InactiveCN105053929ANot easy to breakNot easy to dehydrate and dryFood preparationChange colorPreservative

The present invention discloses a cucumis melo processing method which comprises the following steps: 1), selecting cucumis melo; 2), cutting the cucumis melo into strips, and keeping still at a pressure of 200-400 Mpa; 3), adding honey to the cucumis melo trips, pickling with ginger juice and cucumis melo seed oil, steaming and irradiating with infrared and ultraviolet; 4), drying with circulating hot air at 46 DEG C for half an hour, cooling to room temperature, spraying with mist, drying at 46 DEG C for 1 hour, cooling to room temperature, spraying with mist, and drying at 50-60 DEG C for 4-6 hours; and 5), pumping in ozone and nitrogen containing gas to conduct sterilization. The cucumis melo is processed by high pressure, and does not change color after being dried. The added honey and cucumis melo seed oil are used as a protective film, which enables the cucumis melo to maintain a good shape and the same color and luster after being heated and dried, and at the same time reduces the loss of nutrients. The cucumis melo is cool in nature, and by adding the ginger juice to neutralize the cool nature of the cucumis melo, the cucumis melo is suitable for more people to consume. The cucumis melo processing time is short, and no preservatives and pigments are added.

Owner:杨明彰 +1

Preparation method for microencapsulated oral live vaccine of gosling plague

The present invention discloses a preparation method for a microencapsulated oral live vaccine of gosling plague. The preparation method comprises: preparing a gosling plague SYG strain into a vaccine half finished product by goose embryo proliferation culture; adding a 5% sucrose and skimmed milk solution after a sterility test is qualified, and uniformly stirring; adding 20-40% porous starch tothe half finished product solution, stirring for 20-40 minutes at a certain temperature, wherein the temperature is controlled to 37 DEG C; mixing the resulting liquid and a 1-2.5% sodium alginate solution, completely stirring, and then carrying out dehydration and drying by a fluidized bed to prepare the microencapsulated vaccine dry powder of the gosling plague, wherein the volume of the resulting liquid is the same as the volume of the sodium alginate solution. The method of the present invention ha characteristics of science, simpleness, stable and reliable production, less loss of vaccine titer. With adopting the vaccine microencapsulation technology, the live vaccine of the gosling plague can be adopted for immunization by the oral route, the stress reaction is reduced, the sustained release function is provided for the live vaccine of the present invention, and the breeder goose in the laying period can use the live vaccine as usual.

Owner:HANGZHOU JIANLIANG VETERINARY BIOLOGICAL PREPARATIONS CO LTD

Modular wallboard sintering production process

PendingCN112372803AMeet the requirementsOvercome the problem of not being able to produce large-size productsCeramic shaping apparatusFurnace typesTunnel kilnBrick

The invention relates to a modular wallboard sintering production process. The process comprises the following steps that firstly, construction waste is selected and ground into powder of 60-200 meshes for later use, coal cinder is ground into powder of 200-300 meshes for later use, argil accounting for 30%-50% of the total mass is added after the construction waste powder and the coal cinder powder are mixed according to the weight ratio of 3:5-2:3, a proper amount of water is gradually added while stirring to prepare a mixture with the water content of 14%-16%, the mixture is guided into anaging tank to be aged for 7 days, and a wallboard water blank is made through an extruder, wherein the construction waste is concrete blocks, stone, gravel or waste bricks; secondly, the wallboard water blank is moved to a prefabricated bracket to be dried in shade and is fed into a drying chamber to be primarily dried, and then a wallboard dry blank is made; and thirdly, the wallboard dry blank and the prefabricated bracket are jointly fed into a tunnel kiln to be sintered, and a wallboard finished product is made. According to the scheme, first supporting rolling rods can roll freely and canassist the wallboard dry blank in internal stress release, and therefore the situation that the wallboard dry blank has cracks or a special-shaped surface in the dewatering and drying process is prevented.

Owner:重庆市荣昌区新兴建材有限公司

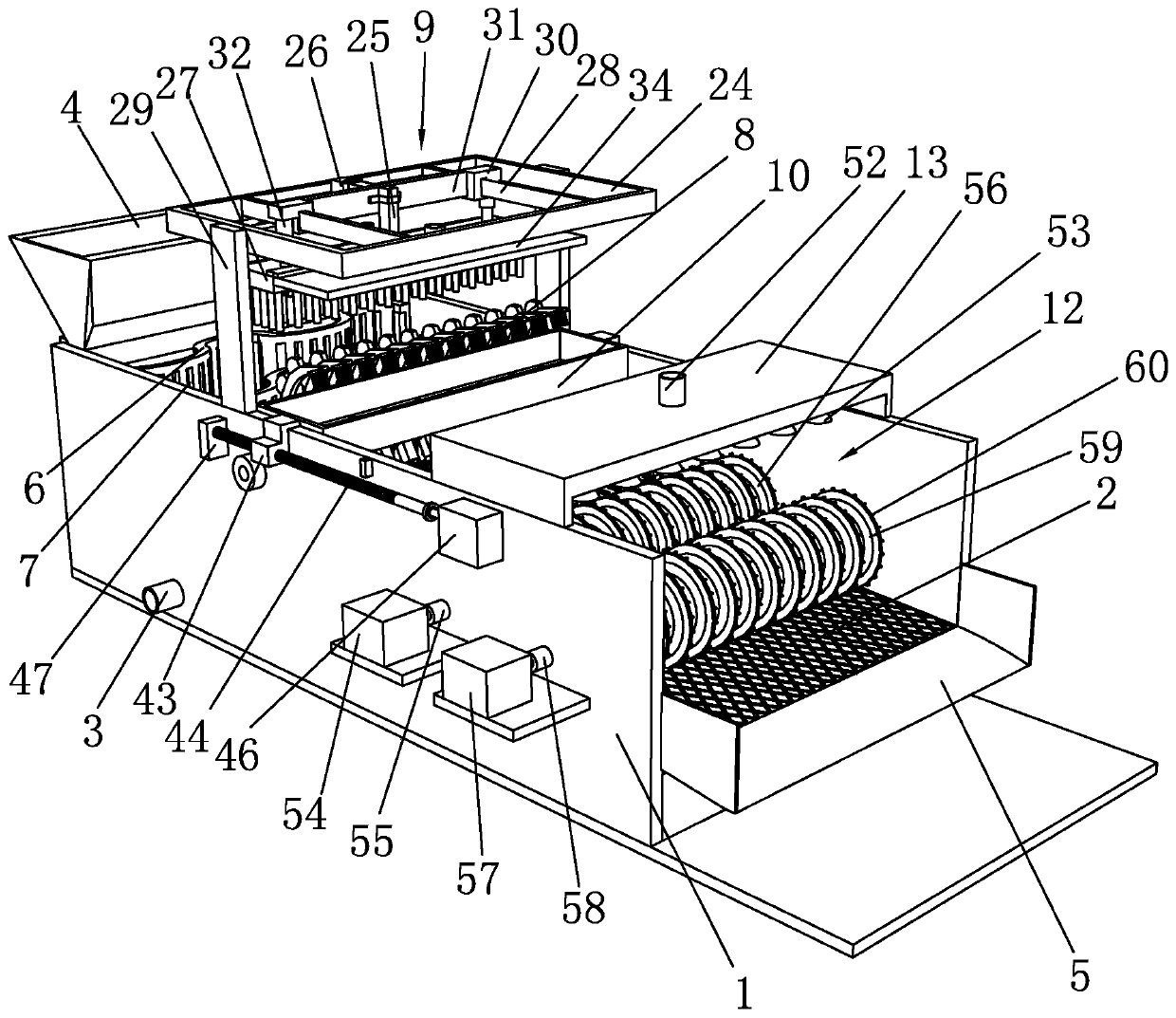

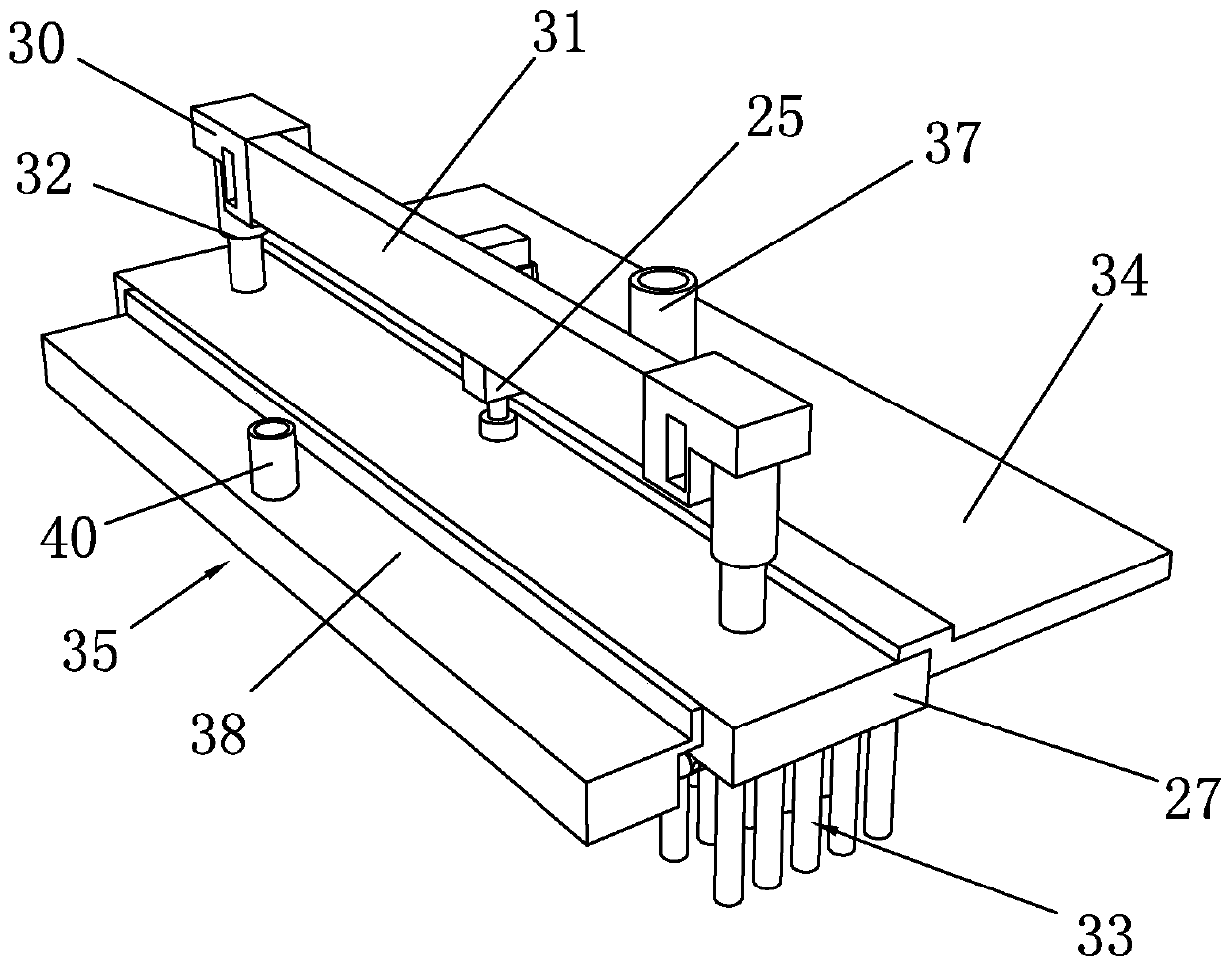

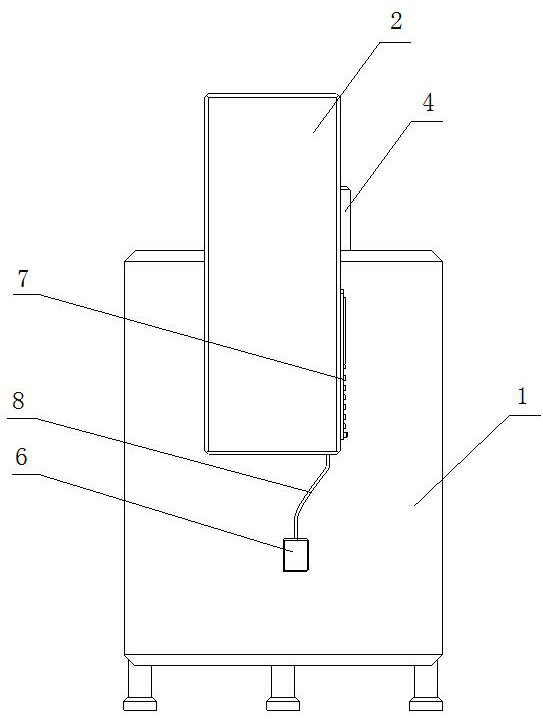

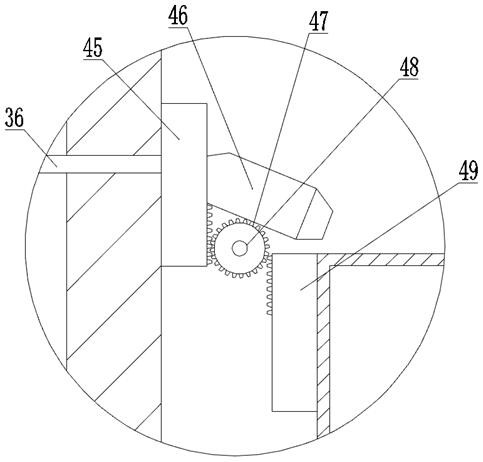

Horizontal spiral filtering centrifugal machine

PendingCN111495612AReduce moisture contentEasy to dehydrate and dryRotary centrifugesControl engineeringProcess engineering

The invention relates to a horizontal spiral filtering centrifugal machine. The horizontal spiral filtering centrifugal machine comprises a machine base, and a supporting base and a machine shell areinstalled on the machine base, a shaft sleeve is movably connected in the supporting base, a main shaft is movably connected in the shaft sleeve, an outer rotary drum is arranged in the machine shell,a concentration rotary drum and a filtering rotary drum which are connected with each other are arranged in the outer rotary drum, one end of the shaft sleeve is connected with the concentration rotary drum, the other end of the shaft sleeve is connected with a driving wheel which is connected with a hydraulic differential, and the hydraulic different is connected with the main shaft. The horizontal spiral filtering centrifugal machine has the advantages that characteristics of a sedimentation centrifuge drum and characteristics of a filtering centrifuge drum are combined together, so that solid-liquid mixed liquid needing to be separated is concentrated and thickened through a sedimentation area firstly and then dehydrated and spin-dried through a filtering area in a separation process,the purpose of reducing the water content of solid materials is achieved, the separation effect is good, suspension liquid can be continuously fed, concentrated, washed, dehydrated and discharged during full-speed operation, and the horizontal spiral filtering centrifugal machine is widely applied to the industries of chemical engineering, food, salt, mining, pharmacy and the like.

Owner:BENGBU LANGCHEN CHEMICAL EQUIPMENT CO LTD

Method for preparing chondroitin sulfate

The invention discloses a method for preparing chondroitin sulfate. The method comprises the following steps: adding water to immerse cartilage, adjusting the pH value to be 8-9 with alkali, and carrying out heat preservation at 55-60 DEG for 4-6 hours; adding 2709 alkaline protease, stirring for 6-8 hours, heating until boiling, and filtering to obtain chondroitin sulfate liquid; adding sodium chloride to the chondroitin sulfate liquid, adding ethyl alcohol which is 2-3 times of volume of the liquid, standing for 6 hours, and filtering to obtain chondroitin sulfate sediments; adding water to the chondroitin sulfate sediments for dissolving, simultaneously adding sodium chloride to water, and adjusting pH value to be 10-12; adding hydrogen peroxide which is 1%-3% of weight of the liquid, oxidizing for 6 hours, and filtering to obtain filtrate; adjusting the pH value of the chondroitin sulfate filtrate to 5-6, adding ethyl alcohol which is 4-6 times of volume of the filtrate, and participating for the second time, so as to obtain chondroitin sulfate sediments; pouring the chondroitin sulfate sediments into a dewatering tank with an emulsifier; pumping ethyl alcohol which is 3-5 times of volume of the chondroitin sulfate sediments into the dewatering tank, carrying out suction filtration, collecting sediments, and drying to obtain a chondroitin sulfate product. The chondroitin sulfate obtained by the method is loose in texture, small in particles, easy to dewater and dry, low in energy consumption, very low in organic solvent residue and short in production cycle.

Owner:QINGDAO JIULONG BIO PHARMA

Production method of aluminium fluoride

InactiveCN1830794AReduce manufacturing costLess investmentAluminium fluoridesHydrofluoric acidAluminium sulfate

A process for preparing aluminum fluoride from kaolinite and hydrofluoric acid includes such steps as pulverizing kaolinite, reaction between sulfuric acid solution and said kaolinite, filtering to obtain aluminum sulfate solution, reacting on dyrofluoric acid, crystallizing, filtering, washing and drying. It has low cost.

Owner:DO FLUORIDE CHEM CO LTD

Method for processing Chinese yam by low-sulfur fumigation combined with salt grilling

ActiveCN102524361AReduce residueGuarantee the quality of medicinal materialsFruits/vegetable preservation by dehydrationSulfur dioxideSalt solution

The invention relates to a method for processing medicinal Chinese yam by low-sulfur fumigation combined with salt grilling, which is characterized in that the method comprises the following steps: fumigating peeled Chinese yam in a fumigating box, infiltrating the fumigated peeled Chinese yam in salt solution. The method of the invention can effectively reduce the amount of residual sulfur dioxide in Chinese yam, and ensures the quality of medicinal materials. Through the method, Chinese yam is easy in dehydration and drying, has white color and beautiful appearance, and is convenient for long-term preservation.

Owner:瑞金市工业投资发展有限公司

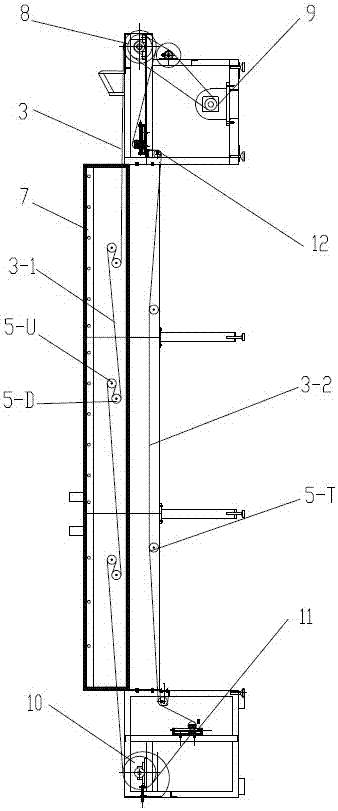

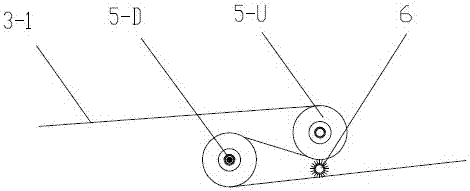

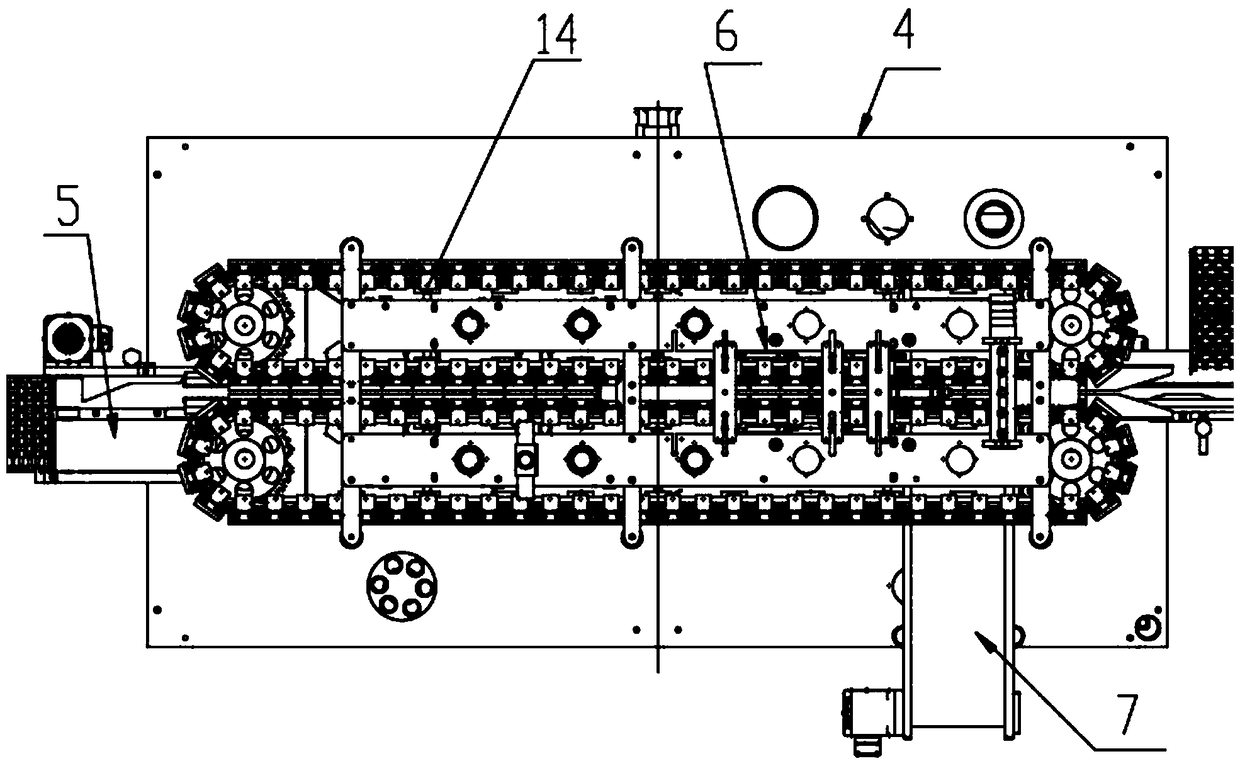

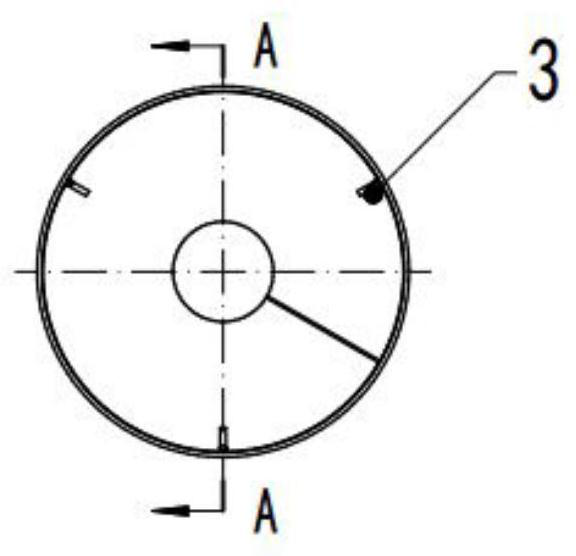

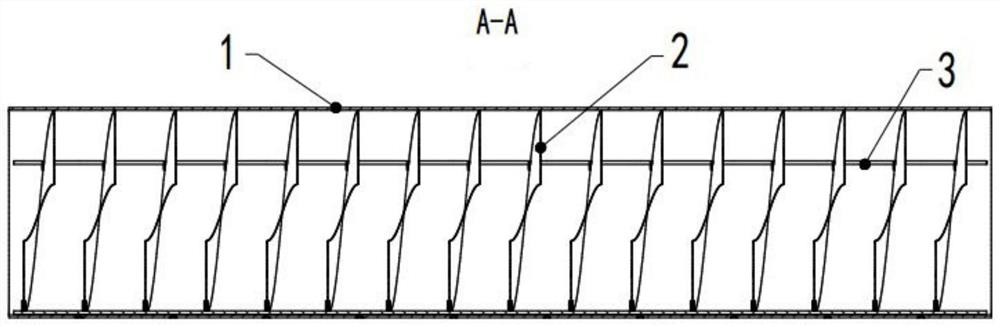

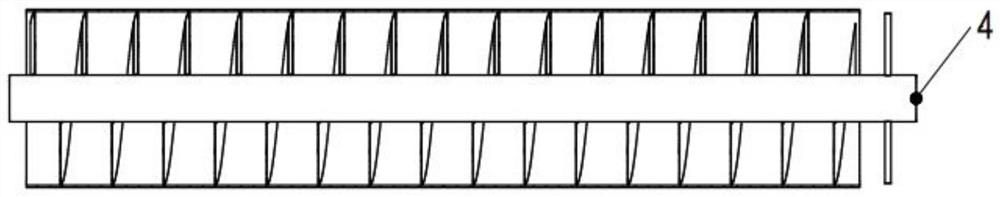

Step type continuous-dehydrating anti-deviating conveyor

The invention relates to a step type continuous-dehydrating anti-deviating conveyor, and belongs to the technical field of conveying equipment. The step type continuous-dehydrating anti-deviating conveyor comprises a drive wheel and a drive wheel which are separately arranged outside the two ends of a tunnel type drying tunnel and surround a conveyor belt as well as a tension device, wherein the conveyor belt is provided with a feeding section which passes through the inner part of the drying tunnel and a return section which passes through the lower portion of the drying tunnel; the feeding section is provided with a Z-shaped bend which is distributed in a spaced mode; the Z-shaped bend is formed by enabling the conveyor belt to steer around a front upper roller and a rear lower roller in sequence; and conveyor belt portions at the two sides of the rear lower roller are separately in externally circular contact with bristles of the brush roller supported below the front upper roller. The step type continuous-dehydrating anti-deviating conveyor is beneficial for drying and dehydrating different planes of materials, so that the materials are easily baked; and moreover, material bonding and coking phenomena caused by unsmooth water evaporation loss of long-time contact surfaces of the materials and the conveyor belt can be avoided, so that the dehydrating and drying quality of crops such as fruits, vegetables and tea is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

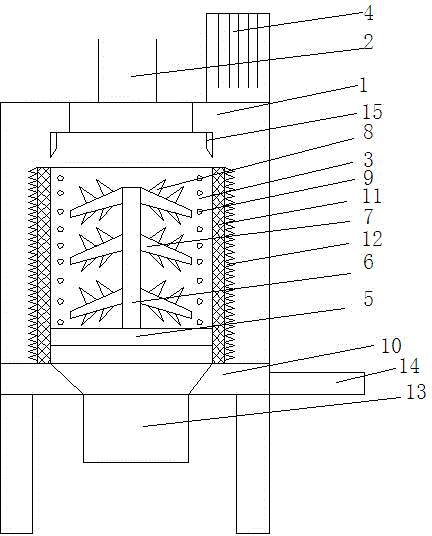

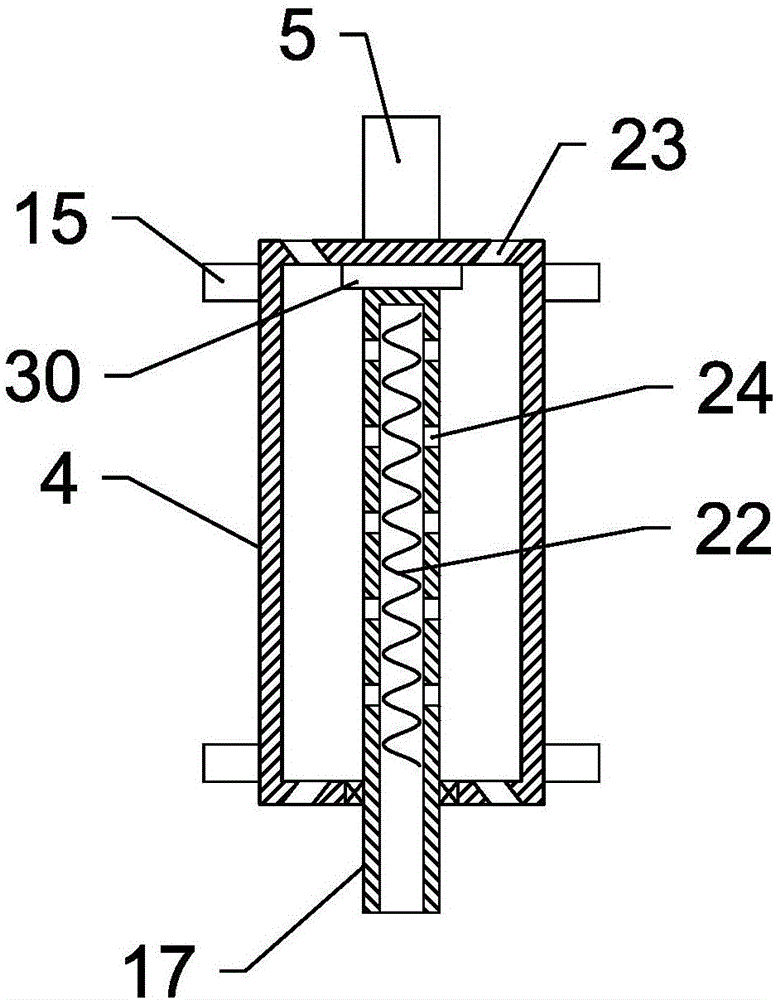

Modified material crushing and drying machine

InactiveCN105841451AAvoid damageGood for dehydration and dryingDrying chambers/containersDrying solid materialsPerseverationPulp and paper industry

The invention relates to a modified material crushing and drying machine. The modified material crushing and drying machine comprises a housing, the upper end of which is provided with a feeding port. A roller is arranged in the housing. The top of the housing is provided with a motor. A stirring device is connected with the roller via a support rack and comprises a stirring shaft arranged on the support rack. Two sides of the stirring shaft are provided with stirring blades, on which cutters are arranged. Leakage holes are arranged in the roller. The bottom of the housing is provided with a water collection tank. A heat-perseveration water-proof layer is arranged around the roller. A heating layer is enclosed by the heat-perseveration water-proof layer. The bottom of the roller is connected with a discharge port. The modified material crushing and drying machine has following advantages: the stirring device in the roller can stir material such that material get loosen and is conveniently dried and dehydrated; in the meantime, the cutter of the stirring device can cut large-sized material into small pieces; damage to the drying machine is reduced; and service lifetime is prolonged.

Owner:JIANGSU TAIQI HEAVY IND

Sludge fuel and preparation method thereof

InactiveCN101597532BIncrease contact areaBreak the prisonBiofuelsSolid fuelsSilicon dioxideHeavy metals

The invention discloses a sludge fuel and a preparation method thereof; the sludge fuel is mixed by the following composition of raw materials according to mass percent: 29.5-85 percent of water-contained sludge, 10-70 percent of rice husk ash, and 0.5-5 percent of deodorization bactericide. The sludge fuel solves the problem of difficult sludge treatment in cities and greatly reduces the cost of sludge treatment, the sludge is prepared into fuel, the energy stored in the sludge is recycled, the sludge fuel ash after being combusted not only leads heavy metals to be passivated in a way of oxidizing materials, but also can utilizes silica highly contained in the ash to be prepared into building materials, thereby thoroughly carrying out safety treatment of sludge and rice husk ash and obtaining recycling utilization.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

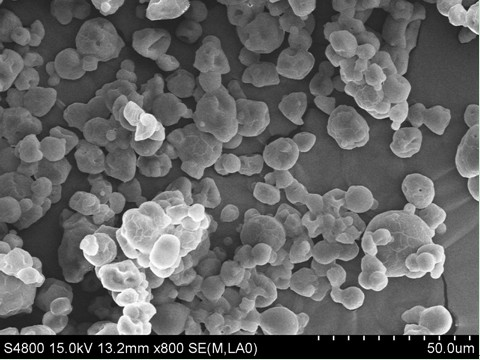

Rapid dewatering and crushing device for metal powder material production

InactiveCN112496328ASpread evenlySmooth rotationTransportation and packagingMetal-working apparatusElectric machineryEngineering

The invention discloses a rapid dewatering and crushing device for metal powder material production. The rapid dewatering and crushing device comprises a main body, wherein the outer wall of one sideof the main body is fixedly connected with a material conveying device, and the outer wall of one side, away from the material conveying device, of the main body is fixedly connected with a discharging hopper; the top of the main body is fixedly connected with a feeding hopper; and one side of the feeding hopper is fixedly connected with a material conveying pipe. Through the arrangement of a rotating device and a drying device, the drying device is used for drying and dehydrating metal powder placed on a material placing disc. A driving motor is started to drive a motor shaft to rotate, and when the motor shaft rotates, a rotating plate rotates and drives an extension spring to stretch. When the rotating plate gradually rotates to one side of a wedge block, the rotating plate extrudes thewedge block and extrudes an extrusion spring to one side of a fixed disc. At the moment, extrusion force of the wedge block and a rotating disc is released, the rotating disc rotates conveniently, and the powder is dried uniformly and conveniently. Local overheating caused by one-place drying is avoided, drying is more uniform and thorough, and drying is rapid and efficient.

Owner:HUIJIN ATOMIZING SCI

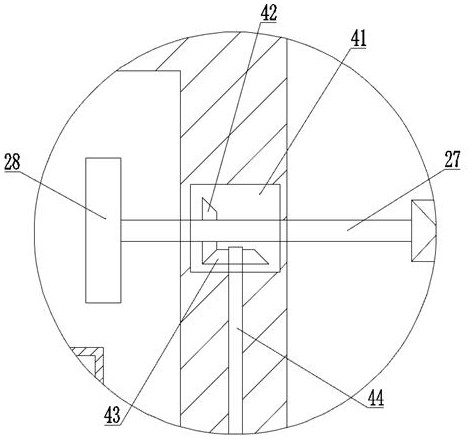

Rotating drum device for horizontal spiral filter centrifuge

PendingCN111495616AReduce moisture contentEasy to dehydrate and dryRotary centrifugesChemical industryDrive wheel

The invention relates to a rotating drum device for a horizontal spiral filter centrifuge. The rotating drum device comprises a machine shell, wherein an outer rotating drum is arranged in the machineshell, a concentrating rotating drum and a filtering rotating drum which are connected with each other are arranged in the outer rotating drum, one end of a shaft sleeve is connected with the concentrating rotating drum, the other end of the shaft sleeve is connected with a driving wheel, the driving wheel is connected with a hydraulic differential, and the hydraulic differential is connected with a mandrel. The device has the advantages that the device combines the settling centrifuge rotating drum characteristics with the filter centrifuge rotating drum characteristics, and in the separation process, a solid-liquid mixed solution needing to be separated is subjected to concentration thickening through a settling zone and then is dehydrated and spin-dried through a filtering zone, so that the purpose of reducing the water content of a solid material is achieved, the separation effect is good, a suspension liquid can be continuously fed, concentrated, washed, dehydrated and dischargedduring full-speed operation, and the device is widely applied to industries such as chemical industry, food, salt, mining, and pharmacy.

Owner:BENGBU LANGCHEN CHEMICAL EQUIPMENT CO LTD

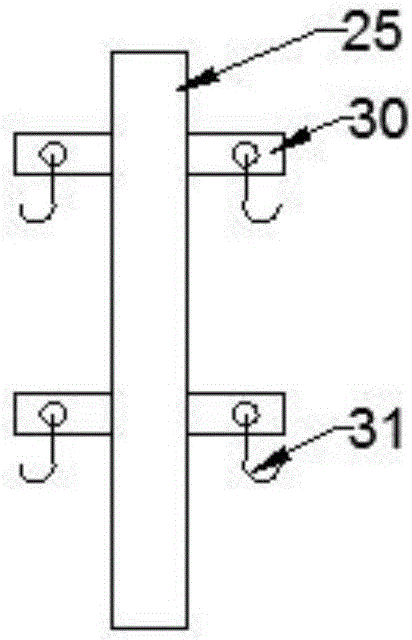

Soft bag direct-mounted hot and cold air continuous drying equipment

PendingCN109140981AContinuous dryingWithout compromising qualityDrying gas arrangementsDrying machines with progressive movementsCold airEngineering

The invention discloses soft bag direct-mounted hot and cold air continuous drying equipment. Two vertical synchronous belts are symmetrically arranged on a machine frame in a case; a drying device isarranged at the lower end of the space between the synchronous belts; material clamping plates are arranged on the synchronous belts evenly; the material clamping plates on the two synchronous beltsat the same position cooperate with each other to form the material clamping plates for clamping soft bags; a bottle holding railing opened in a splayed shape is arranged between the feeding ends of the synchronous belts and a feeding conveying belt; the drying device comprises a collecting cover at the bottom; compressed air knife nozzles are symmetrically distributed on the two sides in one endof the collecting cover, and high pressure hot air knife nozzles are symmetrically distributed on the two sides in the other end of the collecting cover; a top wind nozzle is distributed on the upperportion of the collecting cover; a liquid drain pipe is arranged at the lower end of the collecting cover; the compressed air knife nozzles are located at the feeding ends of the synchronous belts; and the high pressure hot air knife nozzles are located at the discharging ends of the synchronous belts. The problems of low production efficiency and incomplete drying in the drying process of large infusion soft bags are solved.

Owner:HUNAN ZHENGZHONG PHARMA MACHINERY

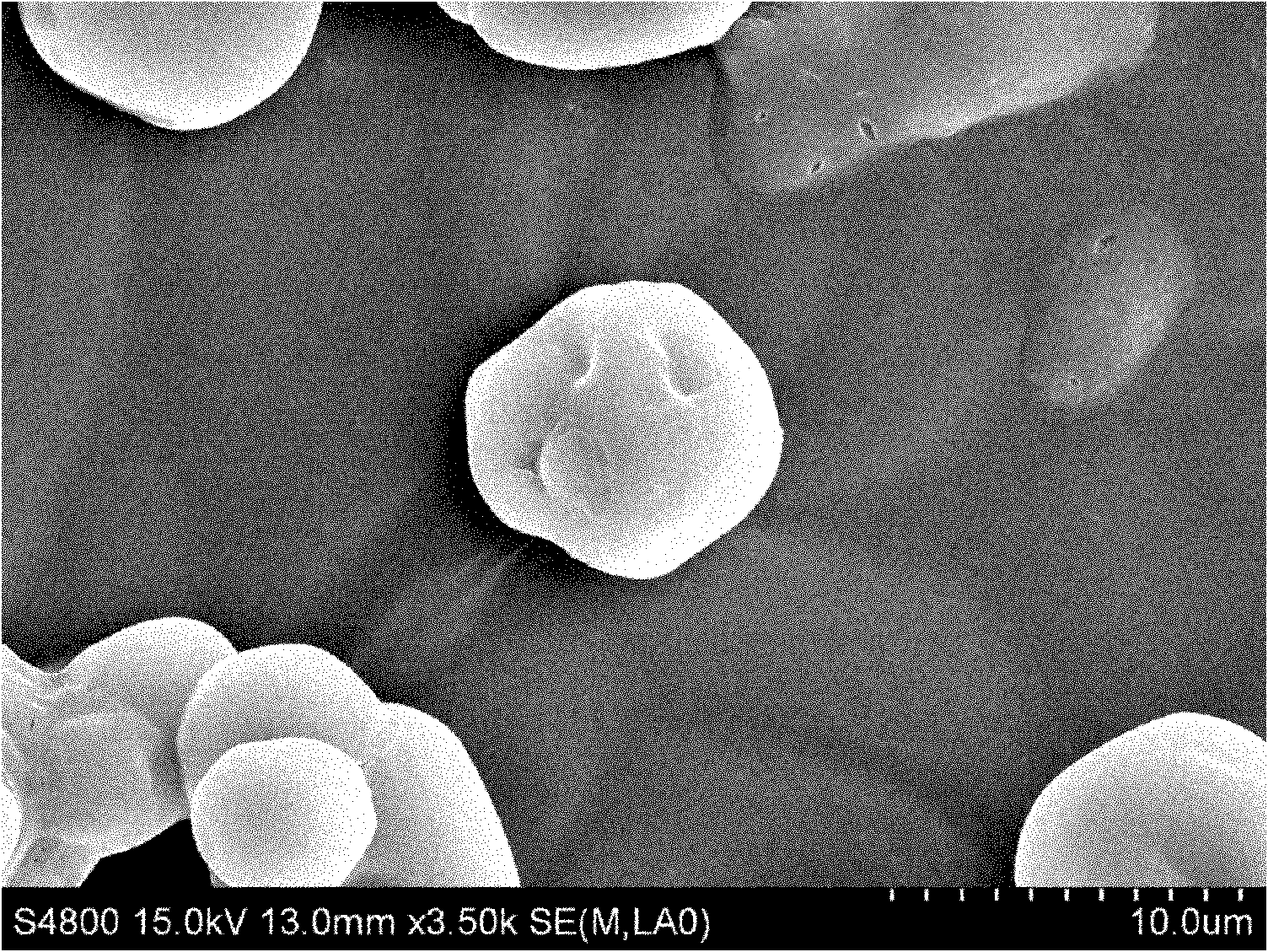

Crystallization method of aluminium fluoride

InactiveCN1830793AHigh bulk densityGood for dehydration and dryingAluminium fluoridesAluminum fluorideWater of crystallization

A process for crystallizing aluminum fluoride from the resultant aluminum fluoride solution includes such steps as crystallizing at 130-200 deg.C under 3-5 atom, filtering, washing, and drying. It has high volume weight.

Owner:DO FLUORIDE CHEM CO LTD

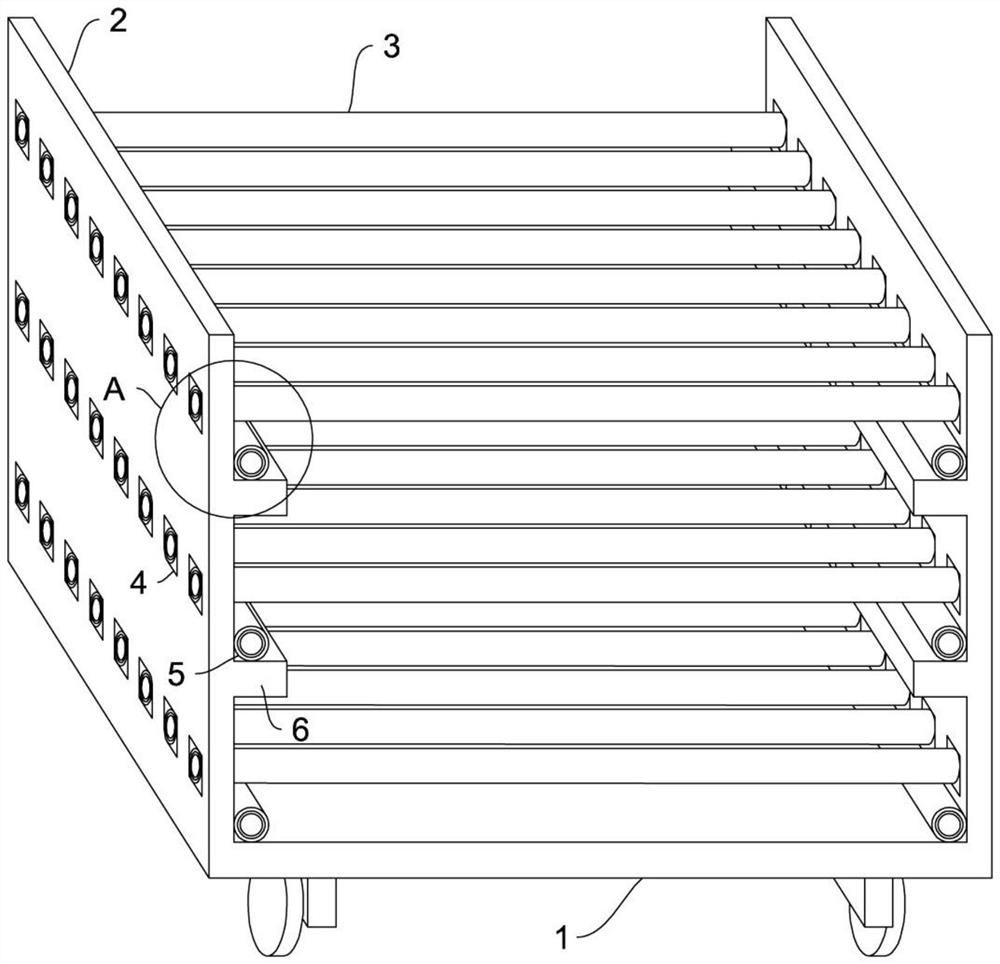

Box type efficient cloth dehydration device

InactiveCN106676791AEven heat distributionReduce stretchTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsDrive motorElectric heating

The invention discloses a box type efficient cloth dehydration device which comprises a box. A left conveying roller and a right conveying roller are arranged on the left side and the right side in the box respectively, air inlet pipes are rotatably arranged in the middle of the front ends of the left conveying roller and the right conveying roller, front ends of the two air inlet pipes are communicated with conveying pipes through connecting bends, the other ends of the two conveying pipes are connected to air outlets of air blowers, spiral electric heating wires are arranged on the inner sides of the left conveying roller and the right conveying roller in the air inlet pipes, the front ends and the rear ends of the left conveying roller and the right conveying roller are further provided with a plurality of blades, rotating shafts are fixedly arranged in the middle of the rear ends of the left conveying roller and the right conveying roller, the rear ends of the two rotating shafts are provided with a left pulley and a right pulley respectively, driving belts are wound around the left pulley and the right pulley, and the rear end of the rotating shaft at the rear end of the right conveying roller is further connected with a driving motor. The box type efficient cloth dehydration device can be used for drying and dehydration during cloth processing and is high in working efficiency, small in environmental pollution and favorable for popularization and application.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

A medical instrument disinfection device

ActiveCN110935051BGood for dehydration and dryingSave manpower and material resourcesLavatory sanitoryChemicalsElectric machineryApparatus instruments

The invention discloses a medical instrument disinfection device, which comprises a frame, a waste liquid recovery box is arranged on the right side of the bottom end of the frame, a drying assembly and an adjusting assembly are arranged in the frame, A stirring assembly is provided on the left side of the bottom end. The stirring assembly includes a first motor fixedly installed on the left side of the upper end of the waste liquid recovery tank. The end of the first motor is power-connected with a first rotating shaft extending up and down. The lower end of a rotating shaft is fixedly connected with a first pulley, and the first pulley is rotatably connected with a second pulley through a belt, and a second rotating shaft extending up and down is fixedly installed at the center of the second pulley. When the device is working, the stirring component can fully mix and stir the disinfectant, the nozzle can fully spray and wash the instruments with the reciprocating rotation angle, and the instrument storage dish and drying assembly that can filter the liquid are convenient for dehydration and drying of the instruments, saving manpower and material resources and improving the disinfection effect Better and improve work efficiency.

Owner:HEBI CITY PEOPLES HOSPITAL

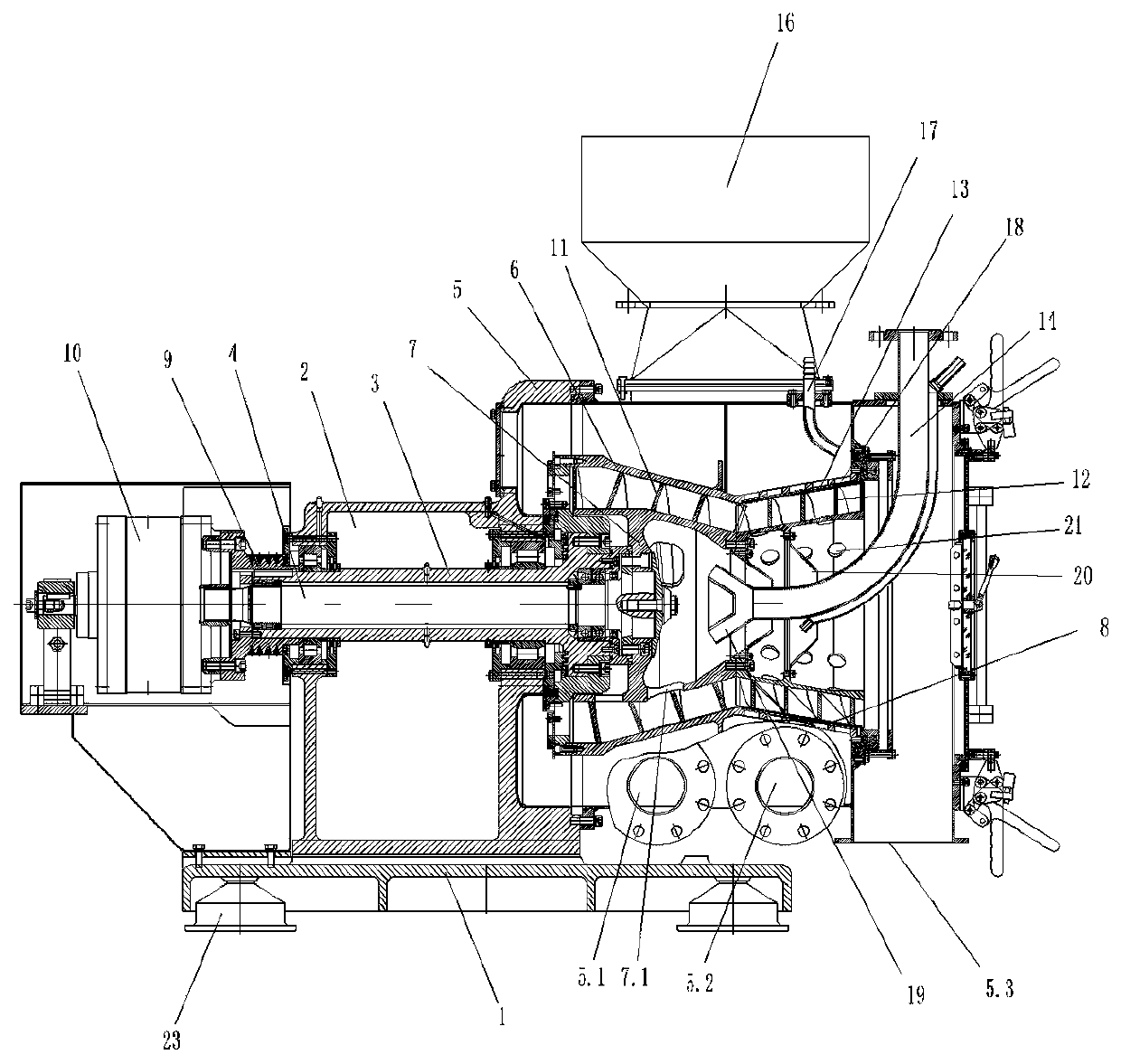

A kind of manufacturing method of powder material high temperature calcining rotary furnace furnace tube

ActiveCN109737735BGood for dehydration and dryingEvenly heatedRotary drum furnacesEngineeringNitrogen gas

The invention discloses a high-temperature roasting rotary furnace furnace-tube for a powder material. The high-temperature roasting rotary furnace furnace-tube comprises a tube body, spiral sheets and a connecting rod, which are integrated in a welding mode, wherein three connecting rod mounting holes which are used for welding and fixing the spiral sheets to position are uniformly distributed onthe tube body; three grooves used for positioning are formed in the spiral sheets; after the spiral sheets are processed and welded in sections, the connecting rods are blocked into the three groovesof the spiral sheets; the connecting rod and the spiral sheets are welded or adopt a bayonet blocking structure; the spiral sheets are blocked into the tube body; and the spiral sheets are rotated for enabling the connecting rod to align to the three mounting holes in the tube body, so that the connecting rod and the tube body are welded into an integer. Compared with the prior art, the high-temperature roasting rotary furnace furnace-tube is not liable to cause accumulation of the powder material, enables the material to be mutually dispersed, is more in turnover times, is high in heat conduction speed, and is complete in sintering; and during working, production efficiency is high, the yield is twice or more that of a conventional rotary furnace, and power consumption and nitrogen gas consumption are saved by 60% or more in comparison with those of the conventional rotary furnace.

Owner:HENGLI ELETEK

Device and method for dewatering and drying mud under water

InactiveCN101921050BAvoid processing inefficient defectsEfficient dehydration and drying treatmentSludge treatment by de-watering/drying/thickeningSmall footprintFilter press

The invention relates to a device and a method for dewatering and drying mud under water. The device comprises a filter sieve, a filter press, a purification tower and a centrifugal machine, wherein the filter sieve is connected in series with a delivery pump through a pipeline; input pipelines of the filter press, the purification tower and the centrifugal machine are provided with flocculating agent adding machines; and a water outlet of the centrifugal machine is connected to an input port of the purification tower. A plurality of water treatment equipment are selected reasonably and a complete set of device is established based on the advantages of various equipment, so that the defect of low treatment efficiency of single equipment is overcome and dewatering and drying treatment can be efficiently performed on mud under water. The device and the method have the characteristics of reducing time needed by natural drying of a mud yard, improving mud treatment efficiency, greatly lowering dredging cost and meeting the requirement of mass, batched and engineered mud treatment, along with small floor area, low energy consumption, no blocking in continuous operation, high mud yield, good mobility, convenient arrangement on a mud treatment site and the like.

Owner:中国船舶重工集团公司第七〇二研究所

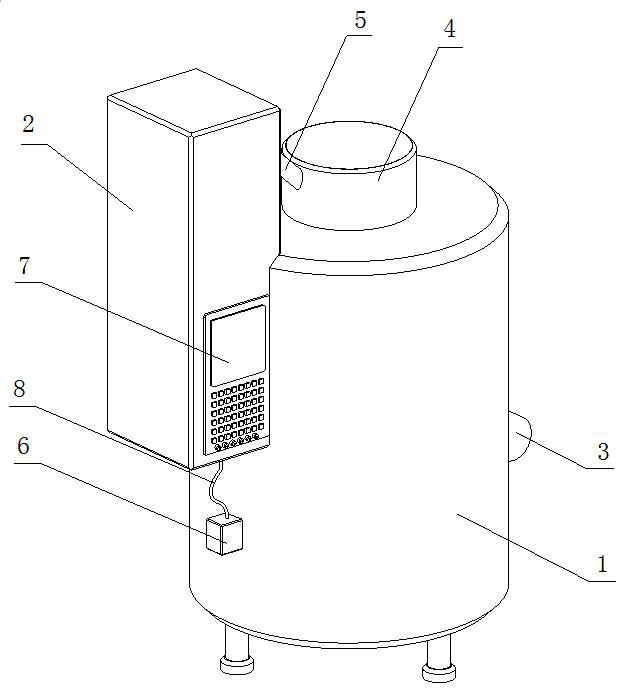

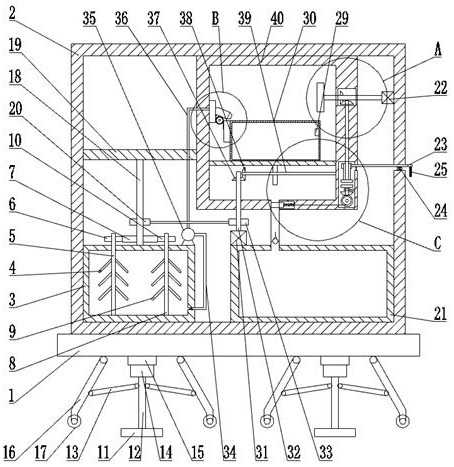

Biochar production device for laboratory

PendingCN109370626ARealize experimental teachingGood for dehydration and dryingBiofuelsSpecial form destructive distillationElectronic temperatureCarbonization

The invention discloses a biochar production device for a laboratory, and mainly relates to the field of biochar production. The biochar production device includes a pulverizing device, a pushing device, a drying device, a suction device, a rod manufacturing device and a carbonization device. The pulverizing device includes a servo motor, an elastic telescopic spindle, a crushing box and a placingframe. The drying device includes a drying box and an air blower. The rod manufacturing device includes an electric servo cylinder and a rod manufacturing barrel. The carbonization device includes acarbonization tank, an electronic temperature control box, and a waste treatment tank. The biochar production device has the advantages that students can manufacture a small amount of biochar in the laboratory and personally experience the production process of the biochar, which is helpful for the realization of experimental teaching.

Owner:BENGBU COLLEGE

Crystallization method of aluminium fluoride

InactiveCN100360412CHigh bulk densityGood for dehydration and dryingAluminium fluoridesAluminum fluorideWater of crystallization

A process for crystallizing aluminum fluoride from the resultant aluminum fluoride solution includes such steps as crystallizing at 130-200 deg.C under 3-5 atom, filtering, washing, and drying. It has high volume weight.

Owner:DO FLUORIDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com