Horizontal type spiral settling and filtering centrifuge

A horizontal screw and centrifuge technology, used in centrifuges, centrifuges with rotating drums, etc., can solve the problem of high moisture content of solid materials, inability to thicken and remove fine particles, inability to settle and filter, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

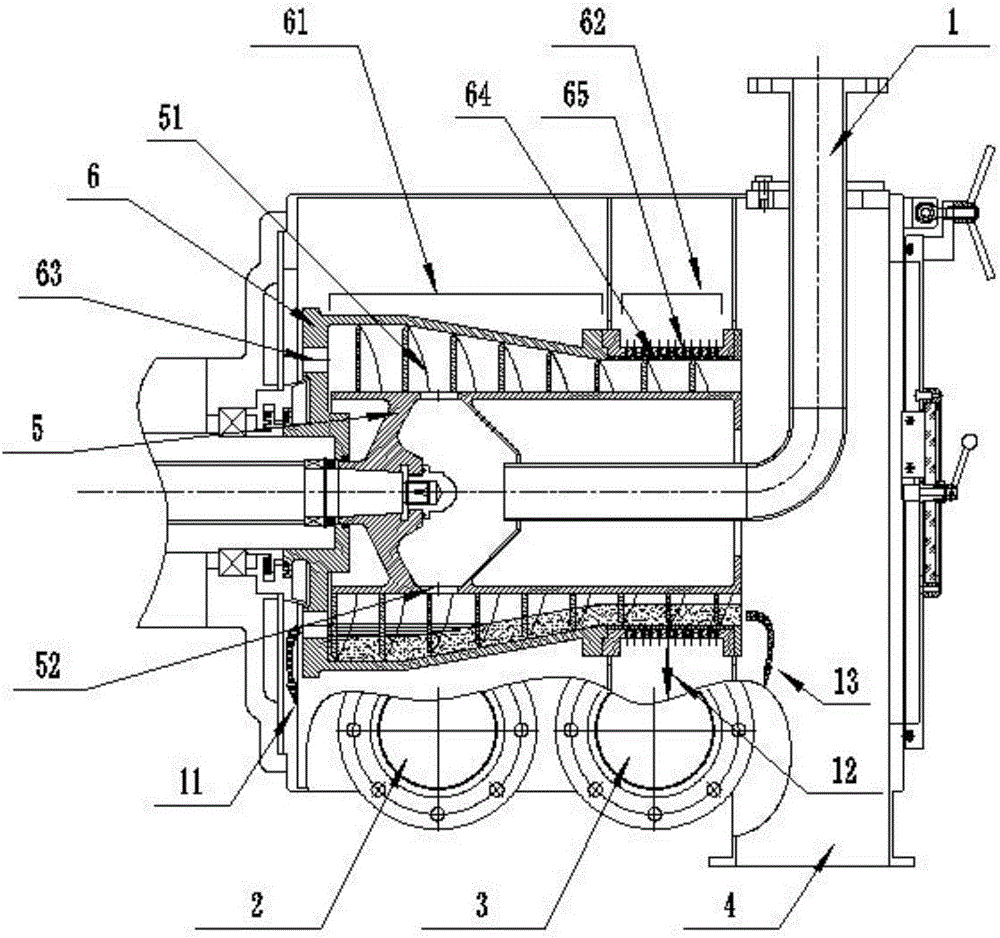

[0012] Such as figure 1 As shown, the horizontal spiral sedimentation filter centrifuge of the present invention includes a casing, and the casing is provided with a feed pipe 1, an overflow drain pipe 2, a filter drain pipe 3 and a solid outlet 4, and in the casing An inner drum 5 and an outer drum 6 are provided, and the inner drum 5 is provided with a spiral blade 51 and at least one outlet 52, and the outer drum 6 includes a sedimentation concentration zone 61 and a filtration zone 62; the sedimentation concentration zone 61 The outer diameter of the sedimentation concentration zone 61 is larger than the filter zone 62, and the front end of the sedimentation concentration zone 61 is a conical surface connected to the filter zone 62; the sedimentation concentration zone 61 is provided with a concentrated overflow port 63, and the peripheral wall of the filter zone 62 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com