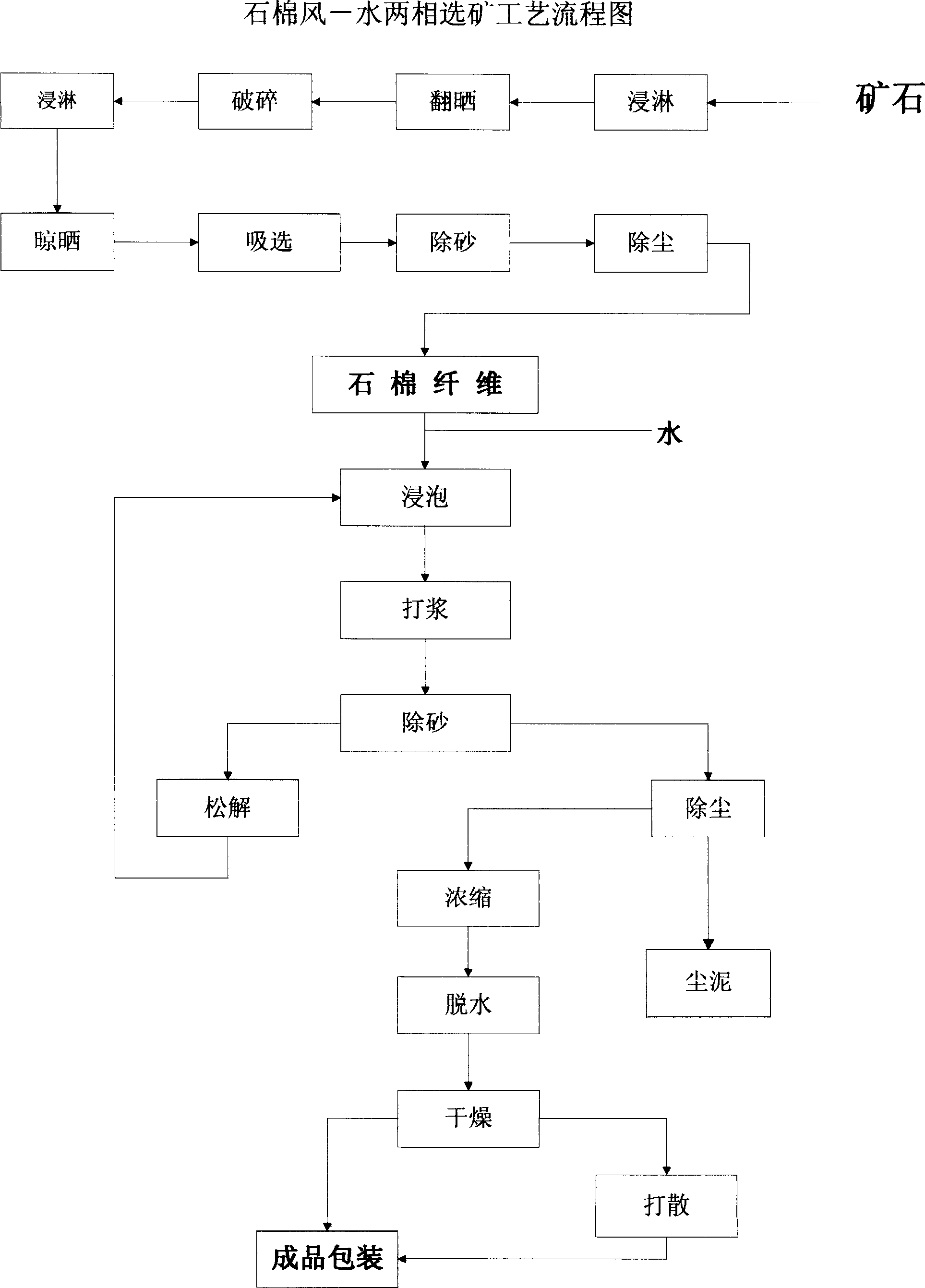

Asbestos wind-water two-phase concentrating technology

A kind of asbestos and process technology, which is applied in the field of non-metallic mineral processing, can solve the problems of asbestos loosening or insufficient opening of fibers, and difficult removal of sediment, etc., to achieve the effects of easy dust removal, convenient dehydration and drying, and good ore processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1). The raw ore used for ore preparation has a cotton content of 3.8% and a particle size of <100mm.

[0022] (2). Dipping and drying the ore twice, and vertical shaft crushing twice. Ore particle size <5mm.

[0023] (3). Carry out dry air selection, two-stage suction selection. One section adopts a vibration specific gravity separator to remove sand, and the other section uses a cylindrical sieve to remove dust, so as to obtain coarse cotton with a sand content of about 2% and a dust content of 32%.

[0024] (4). Soak the rough and refined cotton in the soaking tank for 24 hours, then enter the high-speed beater, and beat for 10 minutes to make the concentration 40%.

[0025] (5). Dilute the pulp to 5-10%, and then use a subsidence hydraulic desander to remove sand.

[0026] (6). Pour the ore slurry evenly into the belt shaker dust collector to remove dust, and go through two stages of dust removal operations.

[0027] (7). Dehydrate the concentrated pulp with a m...

Embodiment 2

[0029] (1). The ore to be processed is tailings with a grade of 2.3% and a particle size of <4mm.

[0030] (2) Carry out dry winnowing, two-stage suction selection, one-stage adopts vibratory specific gravity separator to remove sand, and one-stage uses cylinder sieve to remove dust, obtain coarse cotton, quality is sandy 2.3%, dusty 35%.

[0031] (3). Soak coarse and refined cotton for 20 hours, beat for 15 minutes, and the concentration is 40%.

[0032] (4). Dilute the pulp concentration to 5%, and then remove sand in the subsidence hydraulic desander. The tailings are ground and returned to the desander for desandering.

[0033] (5). Evenly pour the ore slurry into the belt shaker dust collector for dust removal, and go through two stages of dust removal operations.

[0034] (6). Dehydrate the concentrated pulp with a molding machine, and dry it in the sun to obtain asbestos with a sand content of 5%; a dust content of 4.5%, and a specific surface area of 110dm 2 / g, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com