Device and method for dewatering and drying mud under water

A drying and sludge technology, applied in the direction of dehydration/drying/concentrating sludge treatment, etc., can solve the problems of single form of mechanical dehydration equipment, inability to large-scale batch production, and direct discharge of effluent, etc., and achieve high-efficiency dehydration and drying treatment. , The effect of reducing the time required for natural drying and reducing the cost of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described below in conjunction with the drawings.

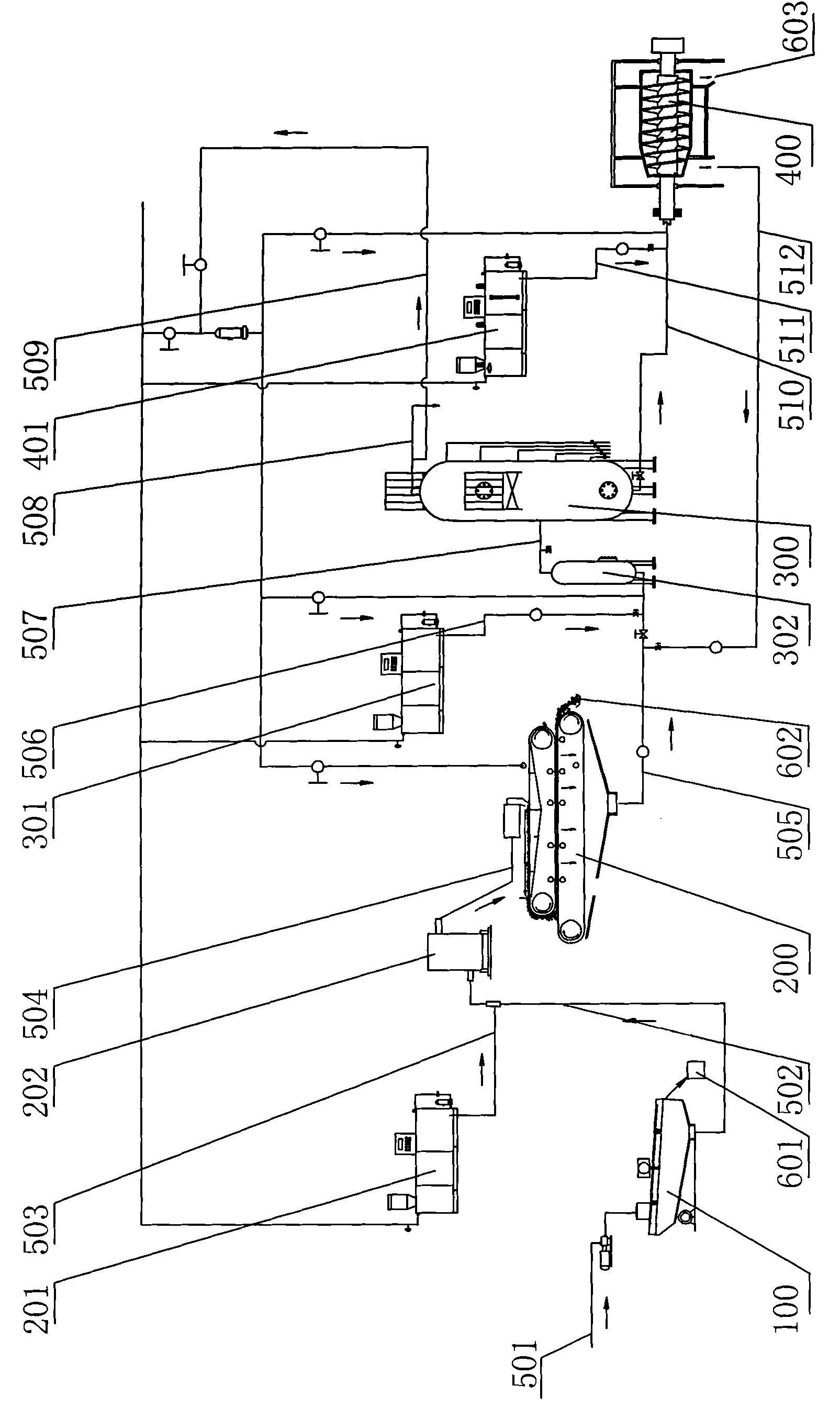

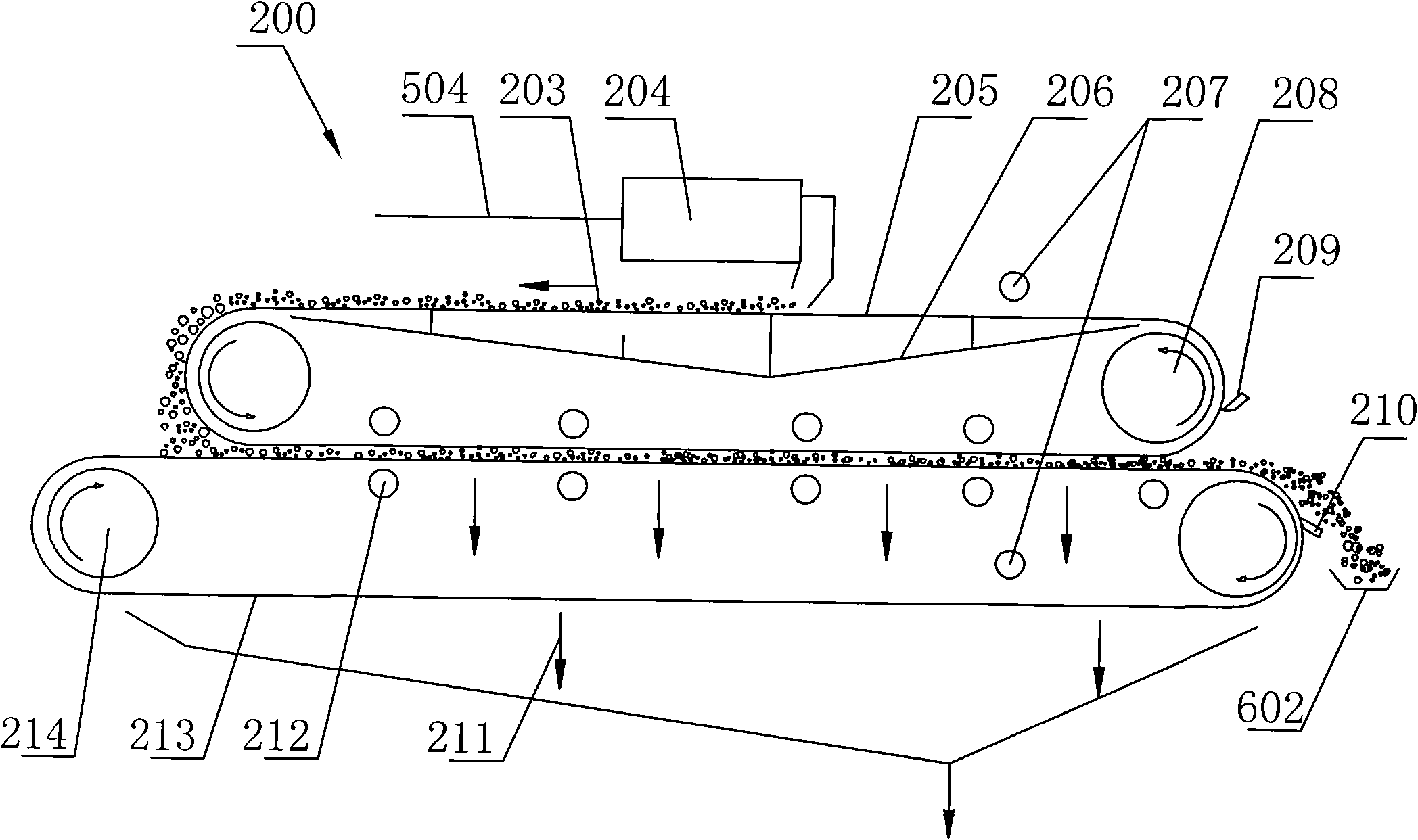

[0026] Such as figure 1 As shown, the underwater sludge dehydration and drying device of the present invention includes a vibrating screen 100, a filter press 200, a purification tower 300, and a centrifuge 400 connected in series by a pipeline and a transfer pump, wherein the filter press 200, purification The input pipeline of the tower 300 and the centrifuge 400 is provided with a flocculant addition machine, and the drain 407 of the centrifuge 400 is connected to the inlet of the purification tower 300. Reference Image 6 The method for dehydration and drying of underwater sludge according to the present invention is mainly divided into four stages for sludge treatment.

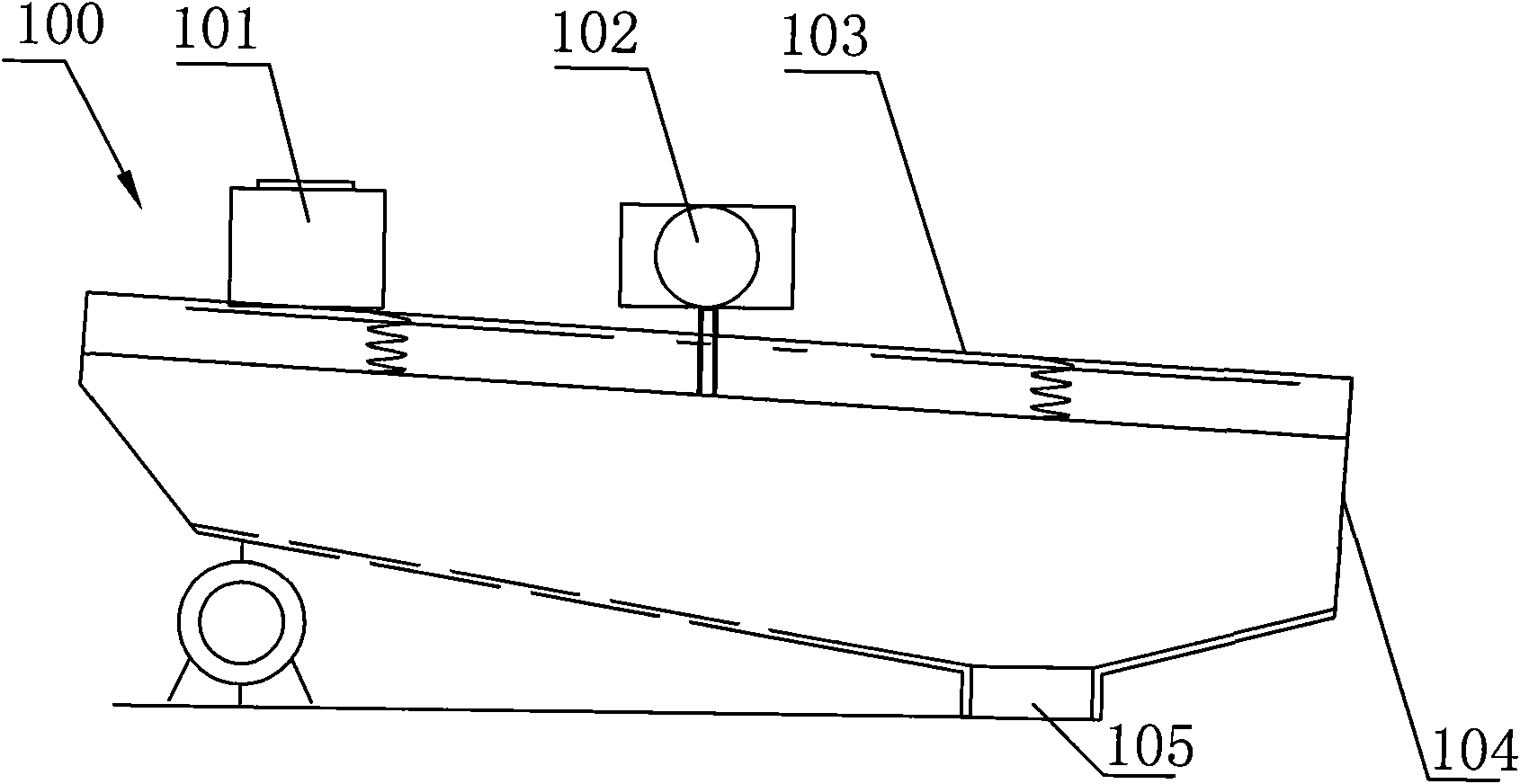

[0027] The first level: pretreatment of muddy sewage. The vibrating screen 100 is selected as the pretreatment equipment of muddy sewage. In the dredging and dredging projects of rivers and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com