Step type continuous-dehydrating anti-deviating conveyor

An anti-deviation, stepped technology, applied in the direction of conveyors, conveyor objects, dryers, etc., can solve the problems of easy deviation, uneven drying, imperviousness, etc., to enhance the guiding and restraining effect and avoid material Adhesive, ensure uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

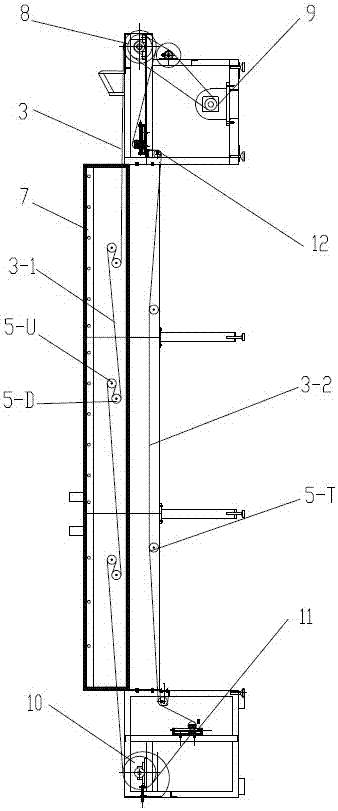

[0019] The stepped continuous dehydration anti-deviation conveyor of this embodiment is as follows: figure 1 As shown, the two ends of the frame of the tunnel-type drying tunnel 7 are respectively equipped with a driving wheel 8 and a driven wheel 10 driven by a motor 9 through a belt transmission, and a driving end tensioning device 12 is placed on one side of the driving wheel 8, and a driving end tensioning device 12 is placed on one side of the driven wheel 10. Install the driven end tensioner 11. The conveyor belt 3 of high temperature resistant material surrounds the driving wheel 8, the tensioning device 12 at the driving end, the tensioning device 11 at the driven end, and the driven wheel 10, forming the feeding section 3-1 through the drying tunnel and the return journey under the drying tunnel Section 3-2 constitutes a complete loop.

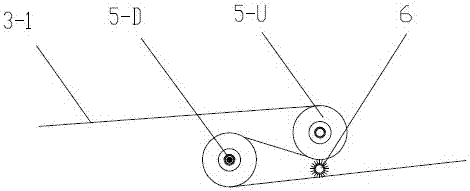

[0020] The feeding section 3-1 has three Z-shaped bends distributed at intervals, and each Z-shaped bend is formed by the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com