Manufacturing device integrating drying, grinding and powder selecting

A technology for production equipment and powder selection, applied in the fields of grinding, drying and powder selection production equipment, can solve the problems of large area of production system, complex production process and high equipment cost, achieve protection of grinding body, shorten process route, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

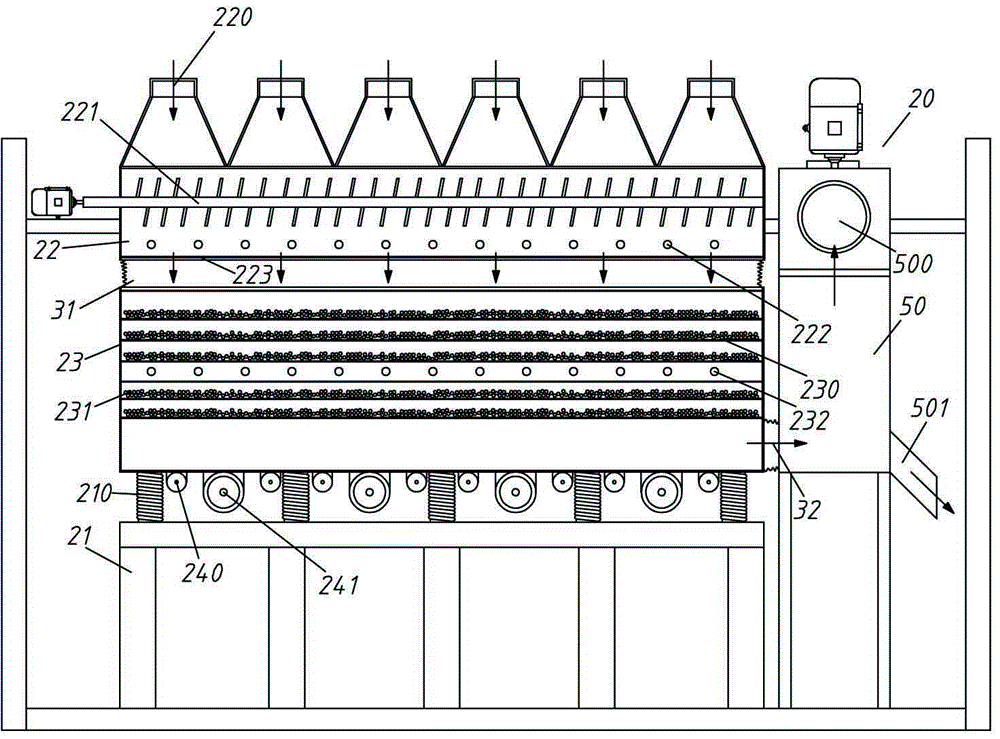

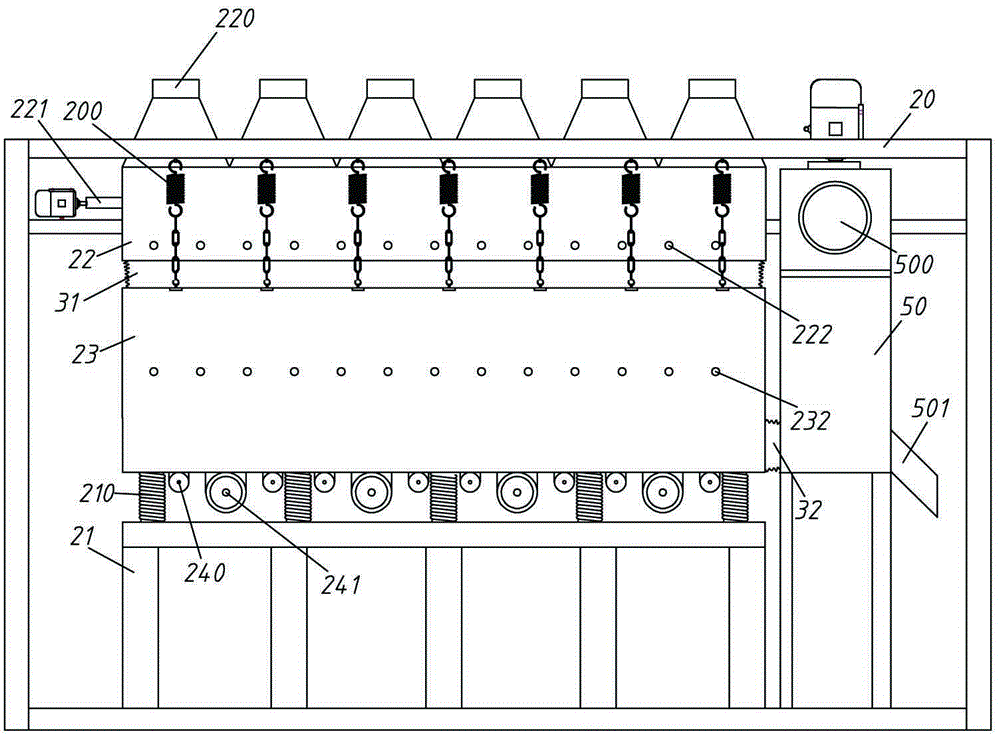

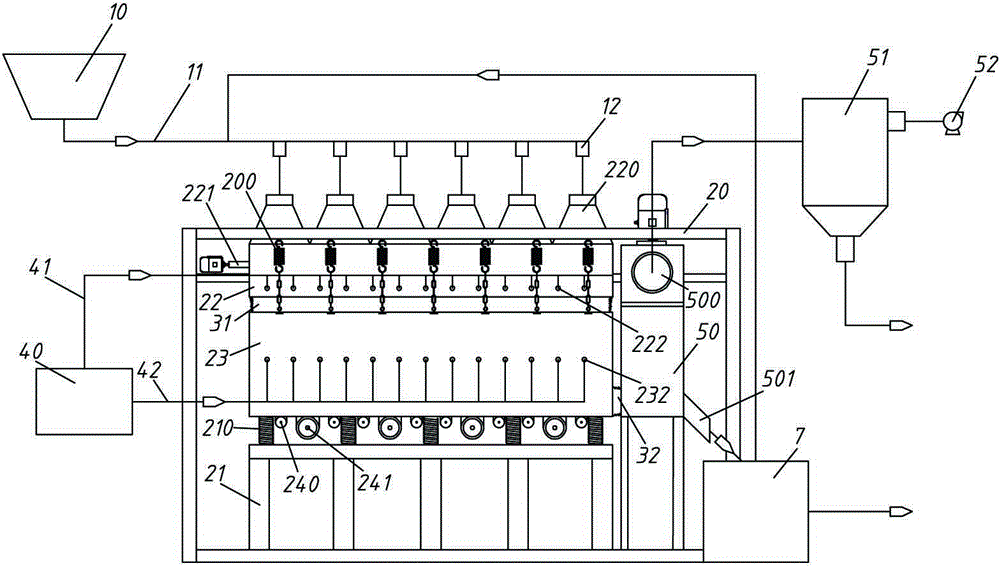

[0025] refer to figure 1 , figure 2 , image 3 and Figure 4 , an integrated production equipment of drying, grinding and powder selection, comprising a feeding system, a drying and grinding system connected with the feeding system, and a powder selection system connected with the drying and grinding system. The feeding system includes a silo 10 and a conveying mechanism 11 connected to the silo 10 , and several feeding metering devices 12 are installed on the conveying mechanism 11 . The drying and grinding system includes an outer frame 20, a base 21, a drying mill box, and a high-frequency vibrator 240 and a low-frequency vibrator 241 evenly arranged at the bottom of the drying mill box. The drying mill box is divided into an upper box Body 22 and lower box body 23, wherein the upper box body 22 is fixedly connected on the outer frame 20, and the top of the upper box body 22 is provided with a number of feed hoppers 220, which can make the materials disperse into the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com