Stainless-steel high-speed drill bit

A stainless steel, high-speed technology, used in wood drilling tools, wood processing appliances, wood turning tools, etc., can solve the problems of unsmooth cutting and short service life of stainless steel high-speed drills, and achieve smooth chip removal and unbreakable cutting. Accumulation and anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

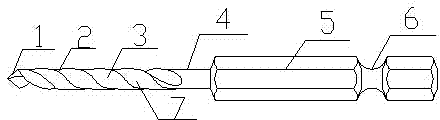

[0017] Reference numerals: 1, main cutter, 2, S-shaped cutter, 3, cutting groove, 4, drill body, 5, drill shank, 6, positioning groove, 7, front end of drill

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0019] The structure of the special drilling drill bit for wood of the present invention is as figure 1 As shown, a stainless steel high-speed drill bit is formed by connecting two parts of a drill handle 5 and a drill body. The two parts of the drill body 4 are integrally formed on the same axis. This structure can not only realize two-stage drilling, one-time forming, smooth cutting surface of the drill hole, but also ensure the stability of the structure of the drill body.

[0020] A main cutting tool 1 and an S-shaped cutting tool 2 are arranged on the front end portion 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com