Patents

Literature

46 results about "Thermal deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

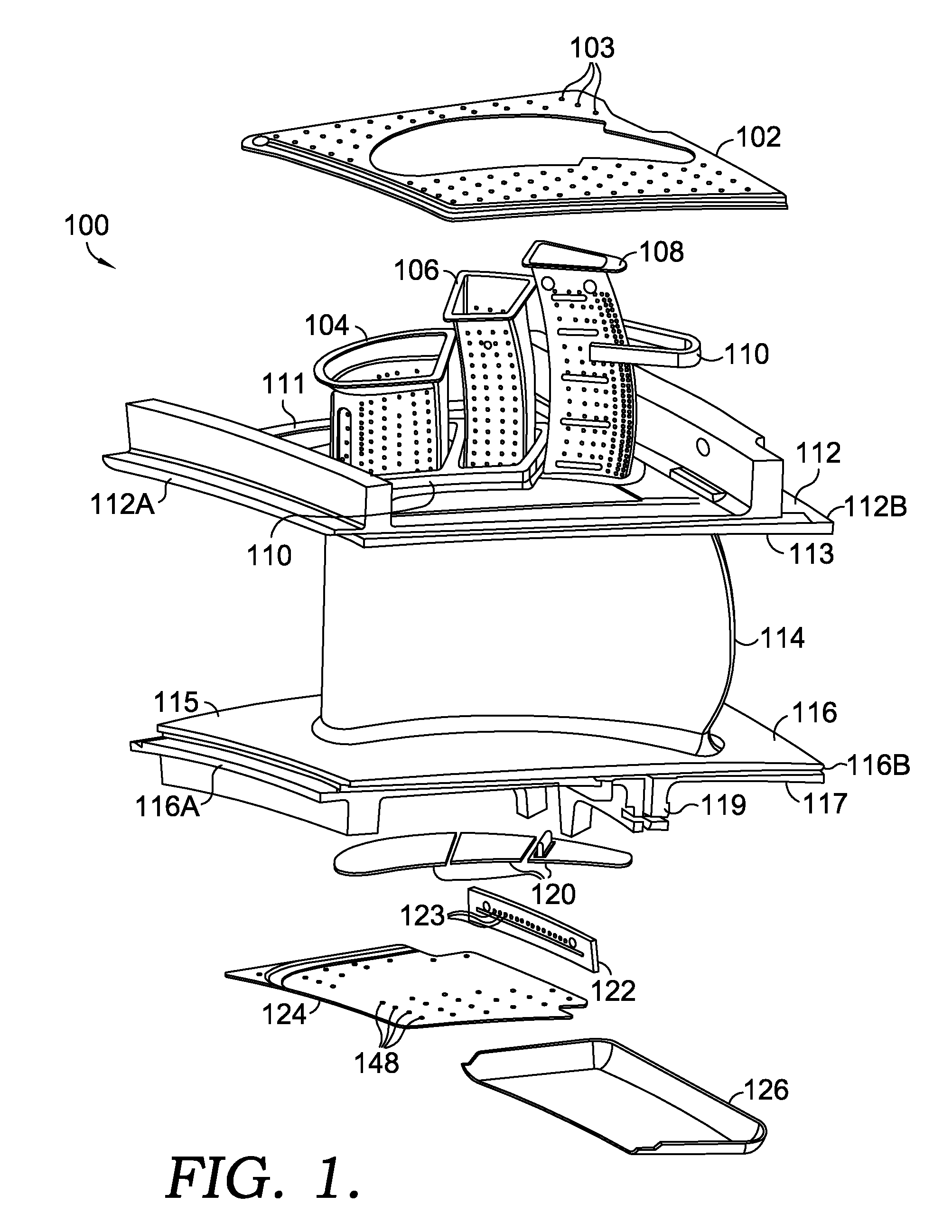

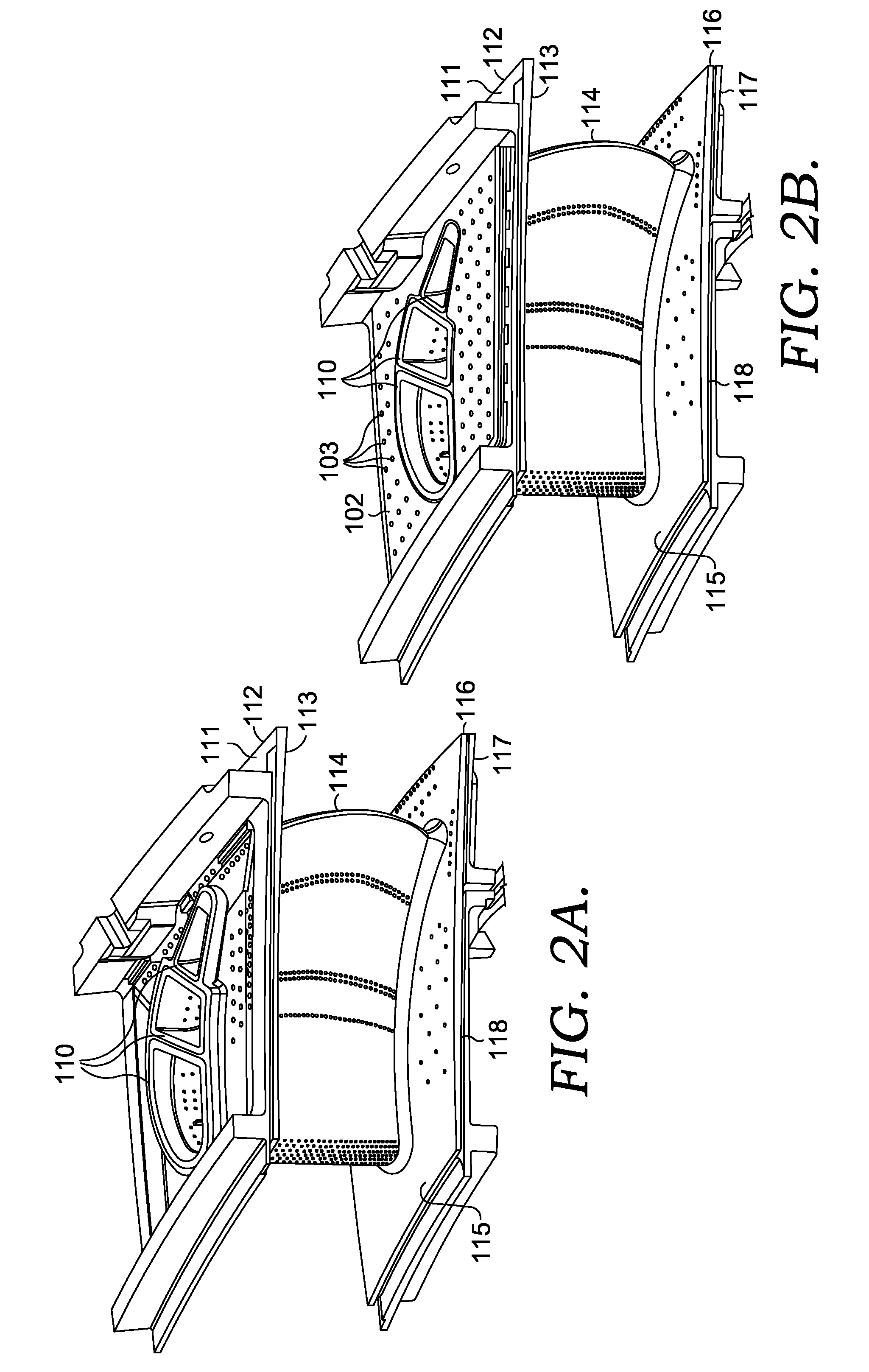

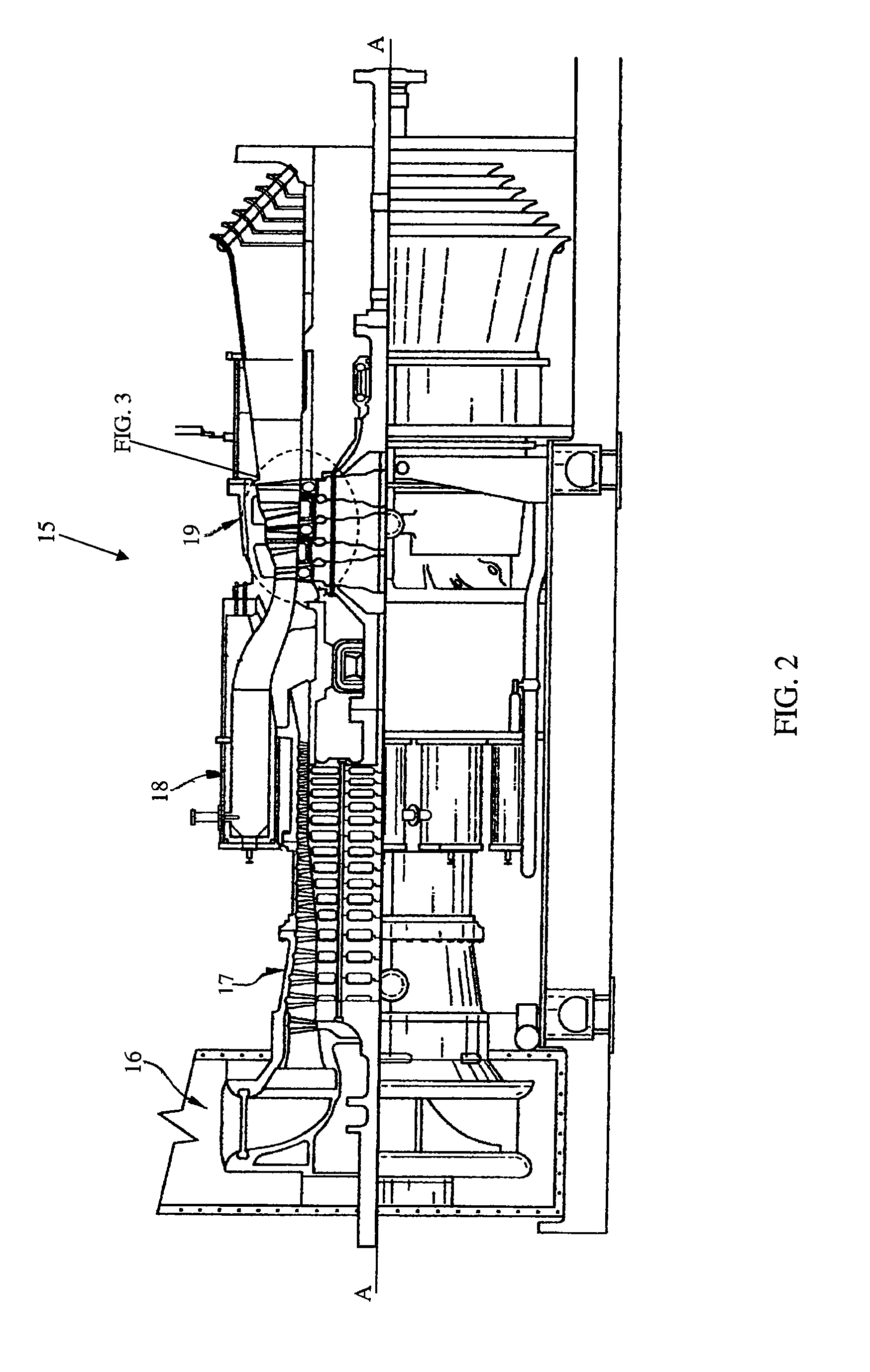

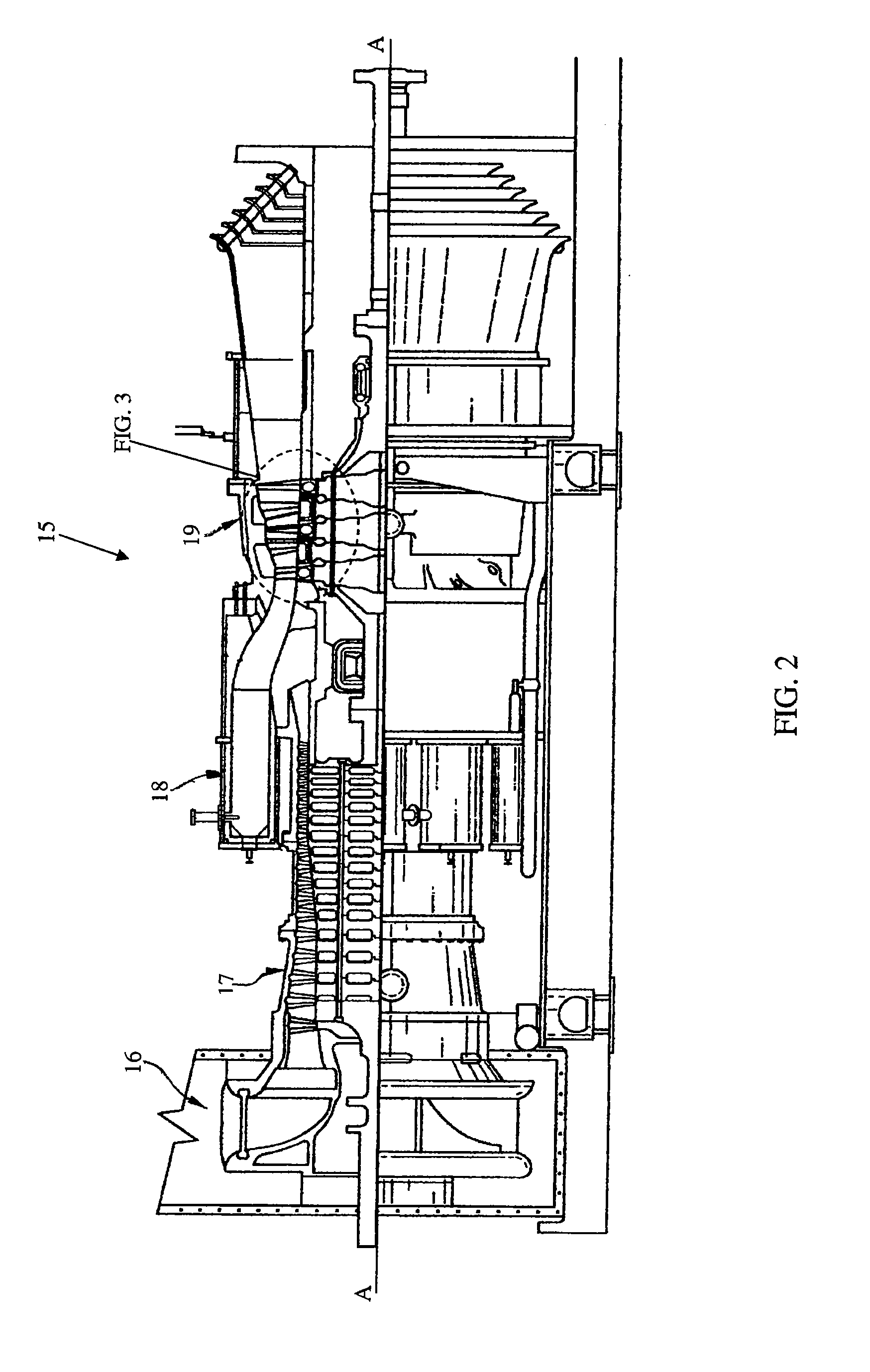

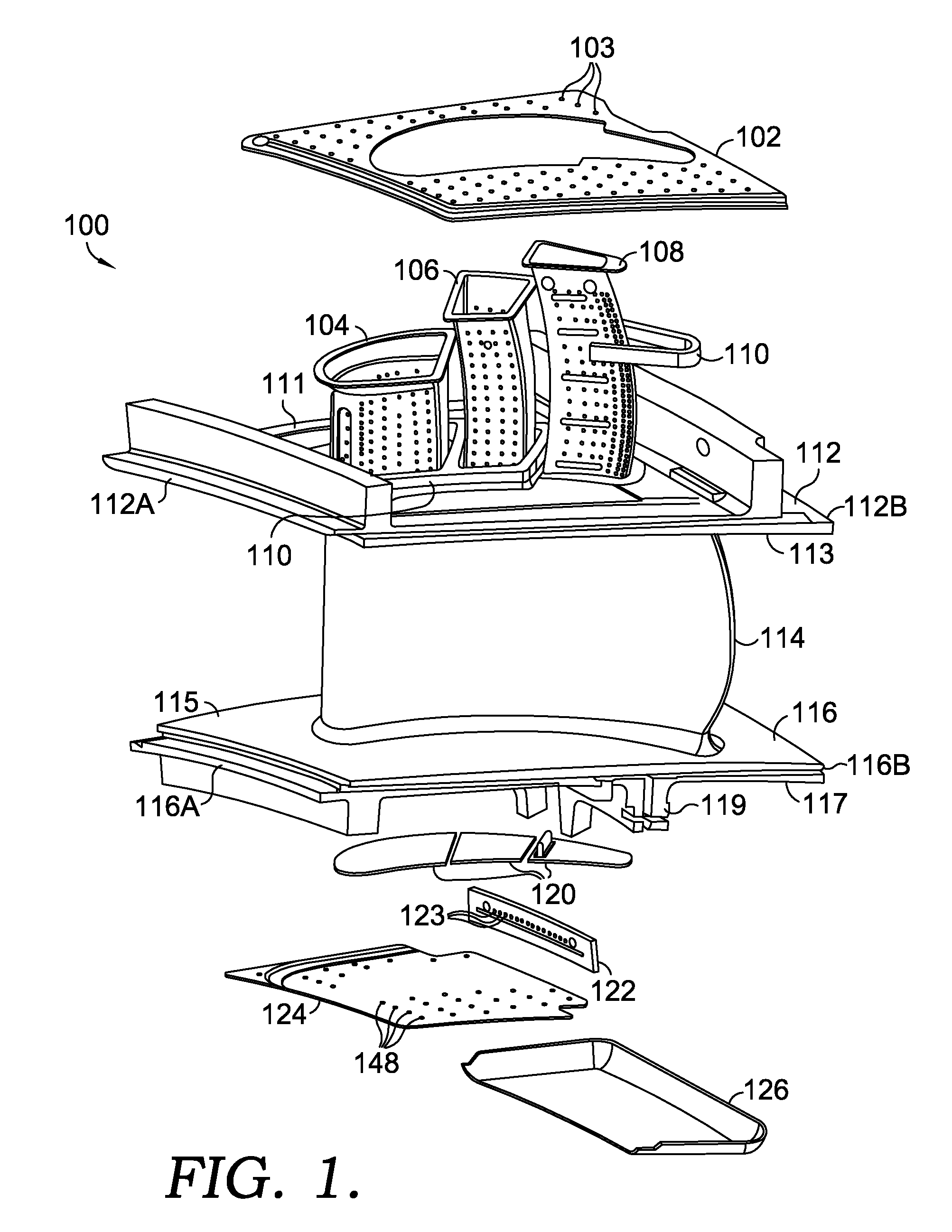

Cooled gas turbine vane assembly

ActiveUS20100129196A1Increased thermal deflectionReduce stiffnessPump componentsEngine fuctionsTrailing edgeGas turbines

A gas turbine vane to improve vane performance by addressing known failure mechanisms. A cooling circuit to the trailing edge of a vane airfoil is fed from the outer diameter platform, which prevents failure due to an oxidized and eroded airfoil trailing edge. The gas turbine includes an outer diameter platform, a hollow airfoil and an inner diameter platform with a plurality of cooling tubes extending radially through the airfoil. The cooling tubes are open at the outer diameter end and closed with covers at the inner diameter end. The inner diameter platform is also cooled and includes a meterplate for a portion of the cooling passageway and includes an undercut to improve thermal deflections of the inner diameter platform.

Owner:H2 IP UK LTD

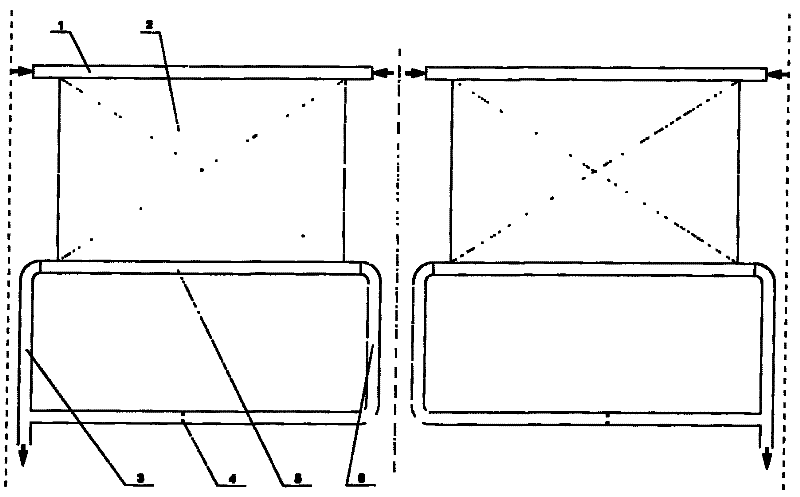

Insulated door assembly with low thermal deflection

InactiveUS6226958B1Increase and decrease viscosityViscosity modifierNatural patternsThree-dimensional effectsCompression moldingShell molding

Compression molded pigmented door skins fabricated by compression molding a pigmented, curable, unsaturated polyester sheet molding compound containing a co-curable unsaturated monomer, a low profile additive, and a microvoid-reducing thermoplastic polymer, exhibit uniform stainability while maintaining a low linear thermal coefficient of expansion. Such door skins are suitable for preparing wood grain textured exterior insulated doors which exhibit minimal thermal deflection when exposed to interior / exterior temperature differentials, even at eight foot door heights. The doors may be stained without first applying a seal coat.

Owner:THERMA TRU HLDG

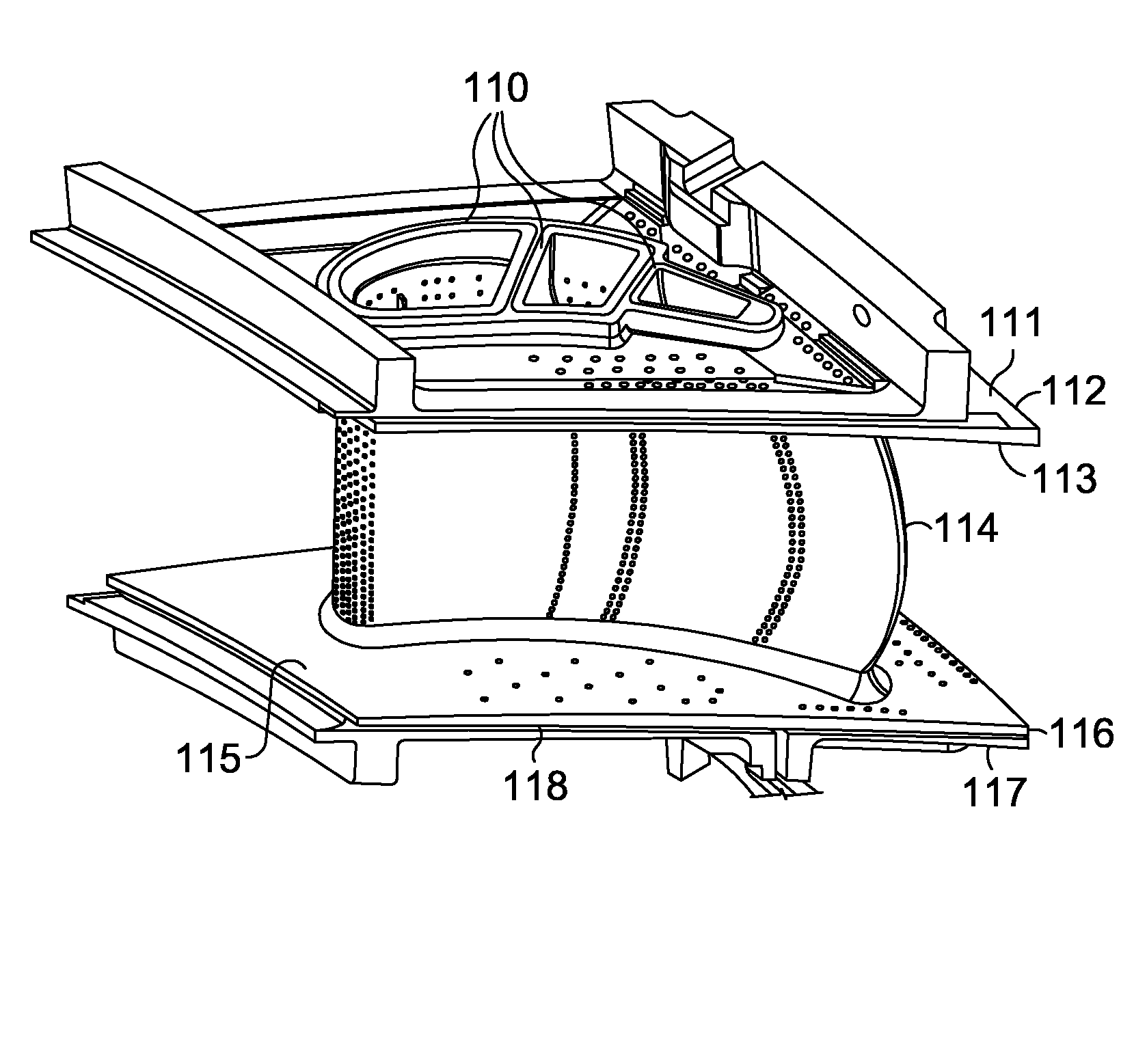

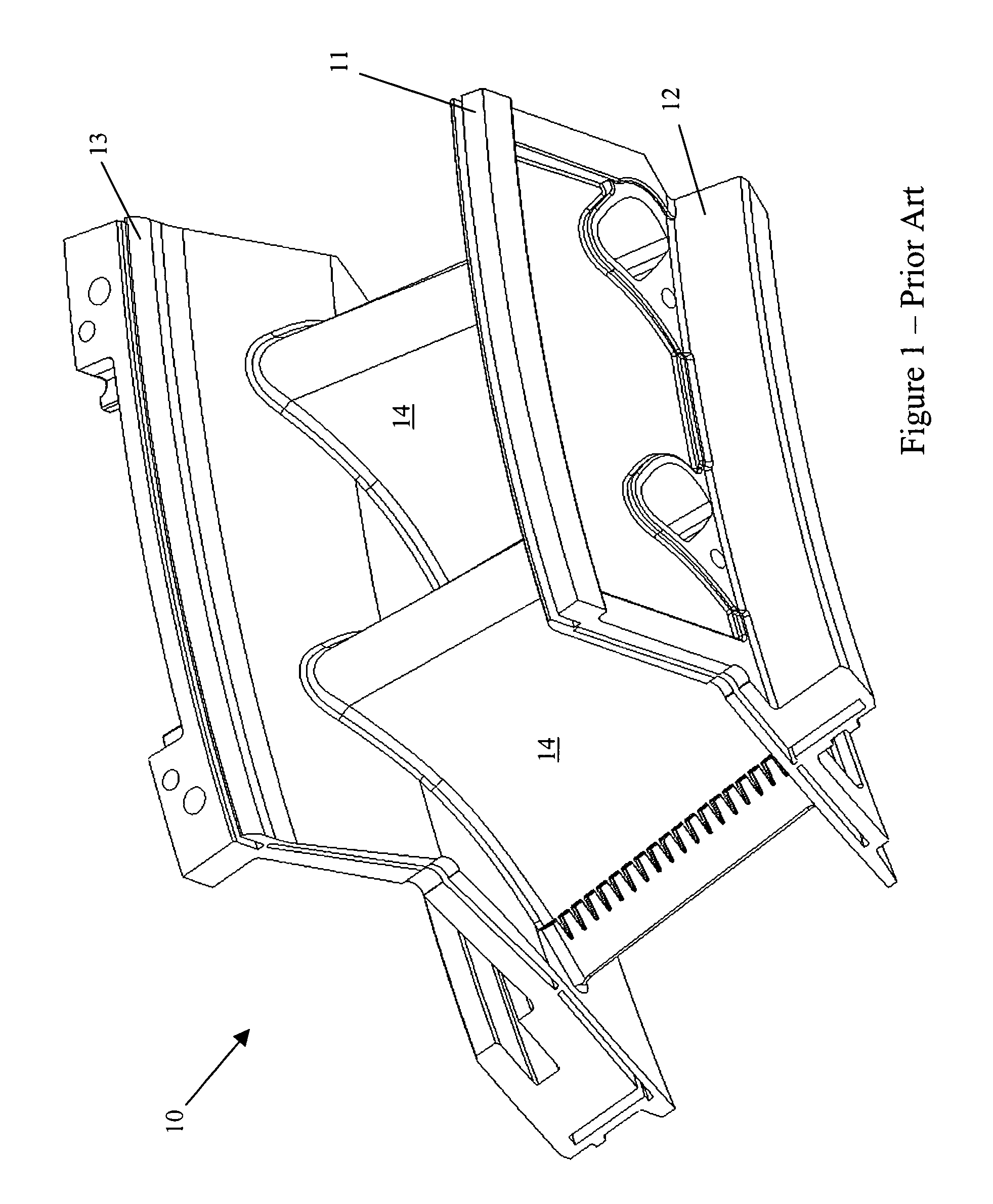

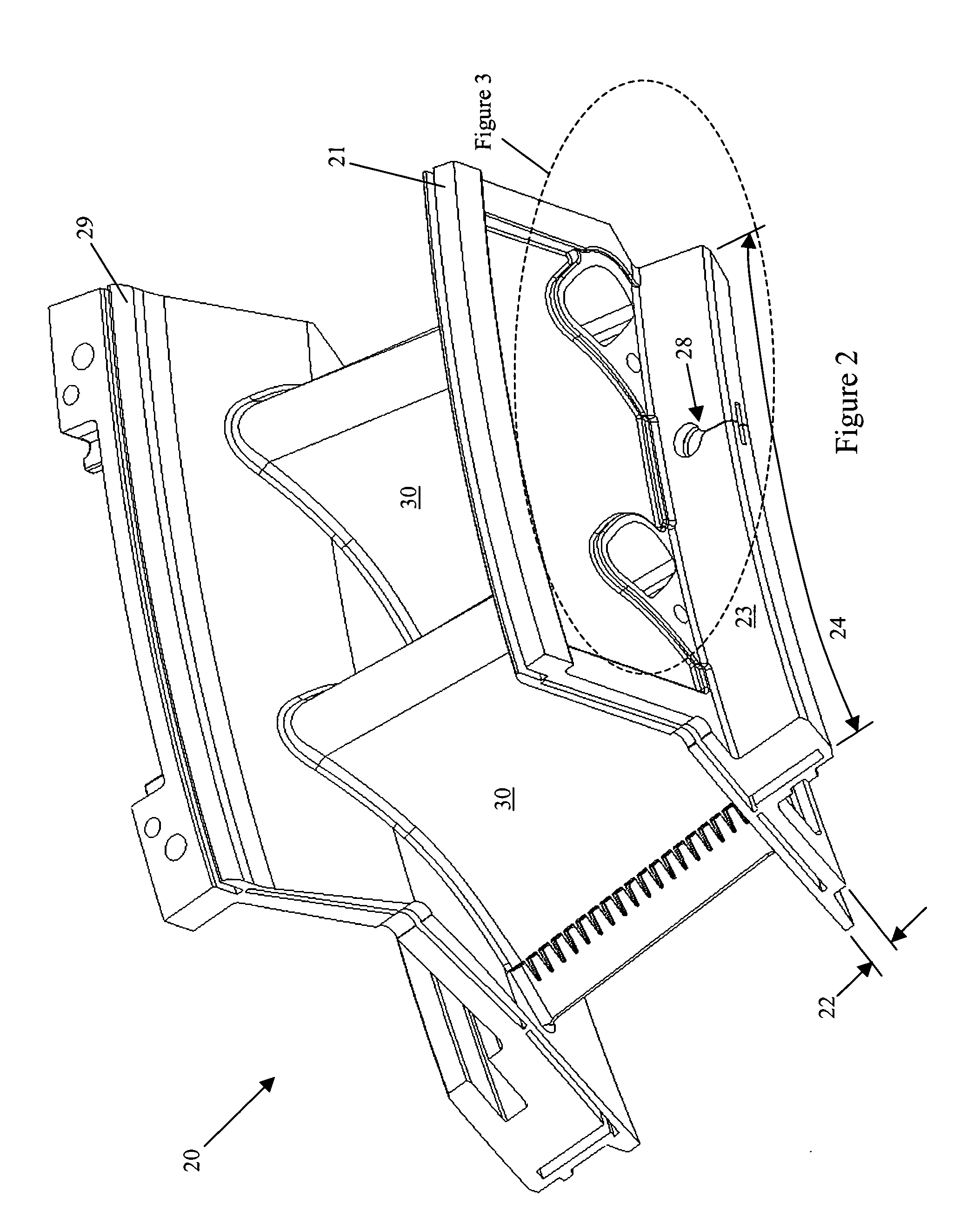

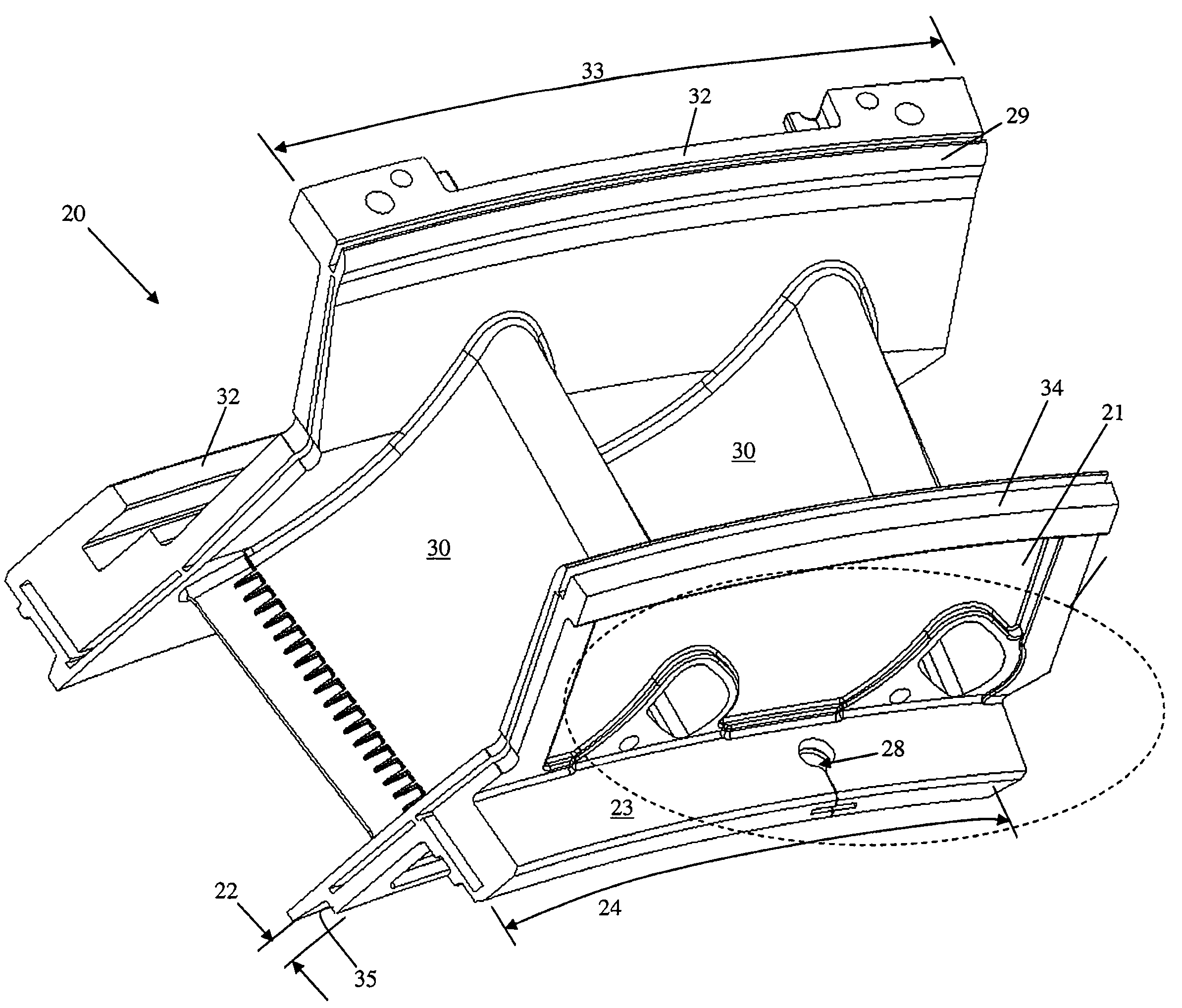

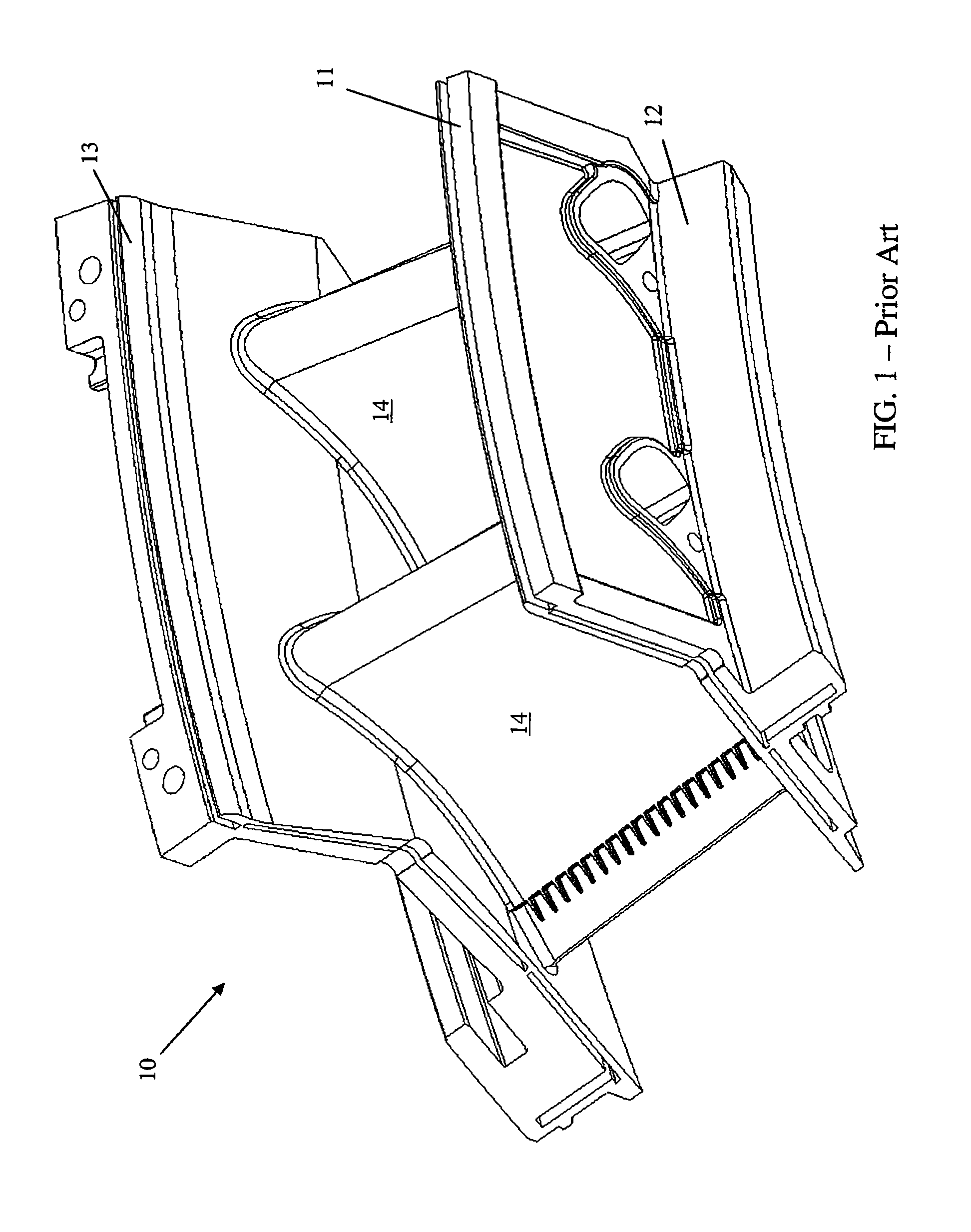

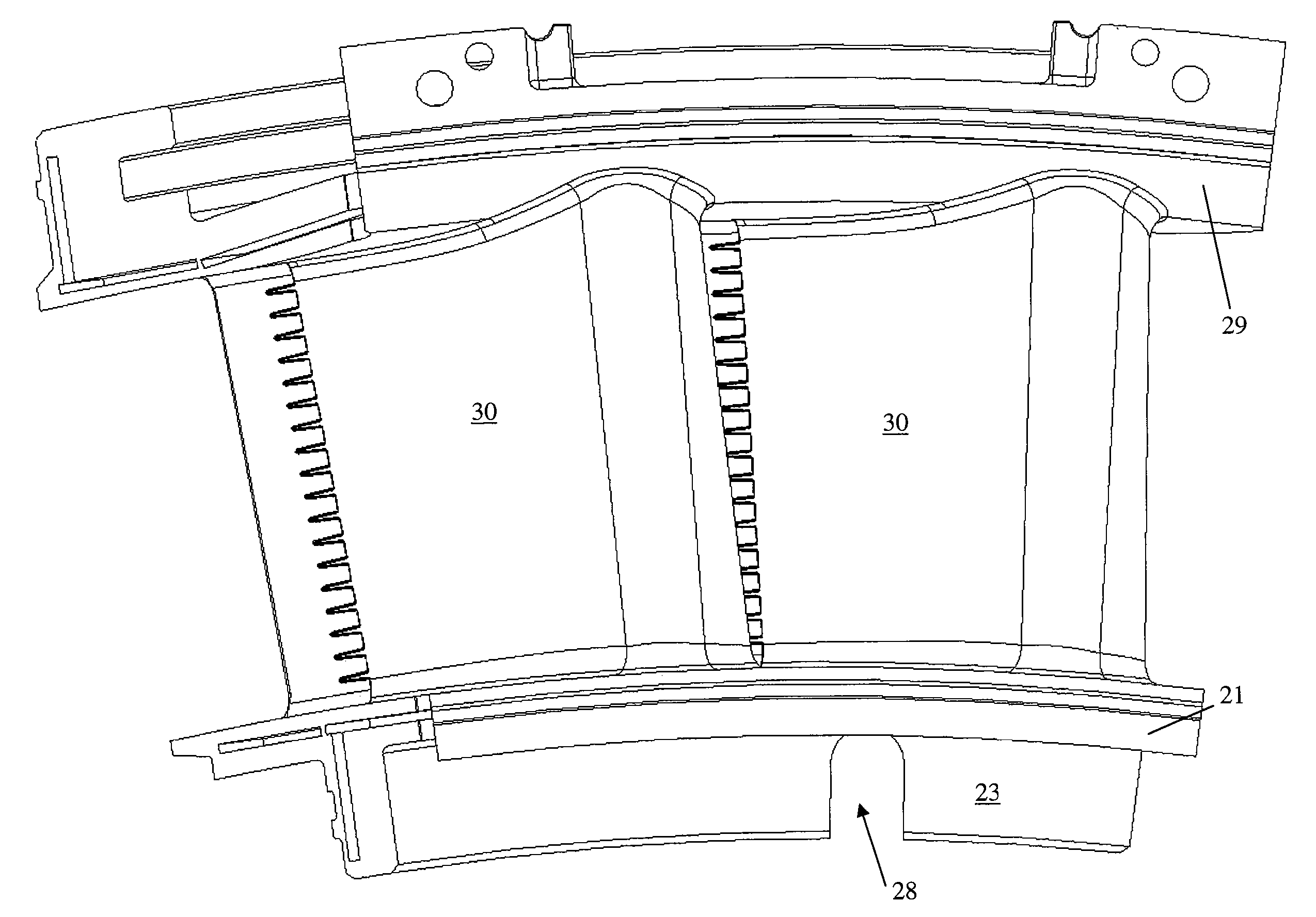

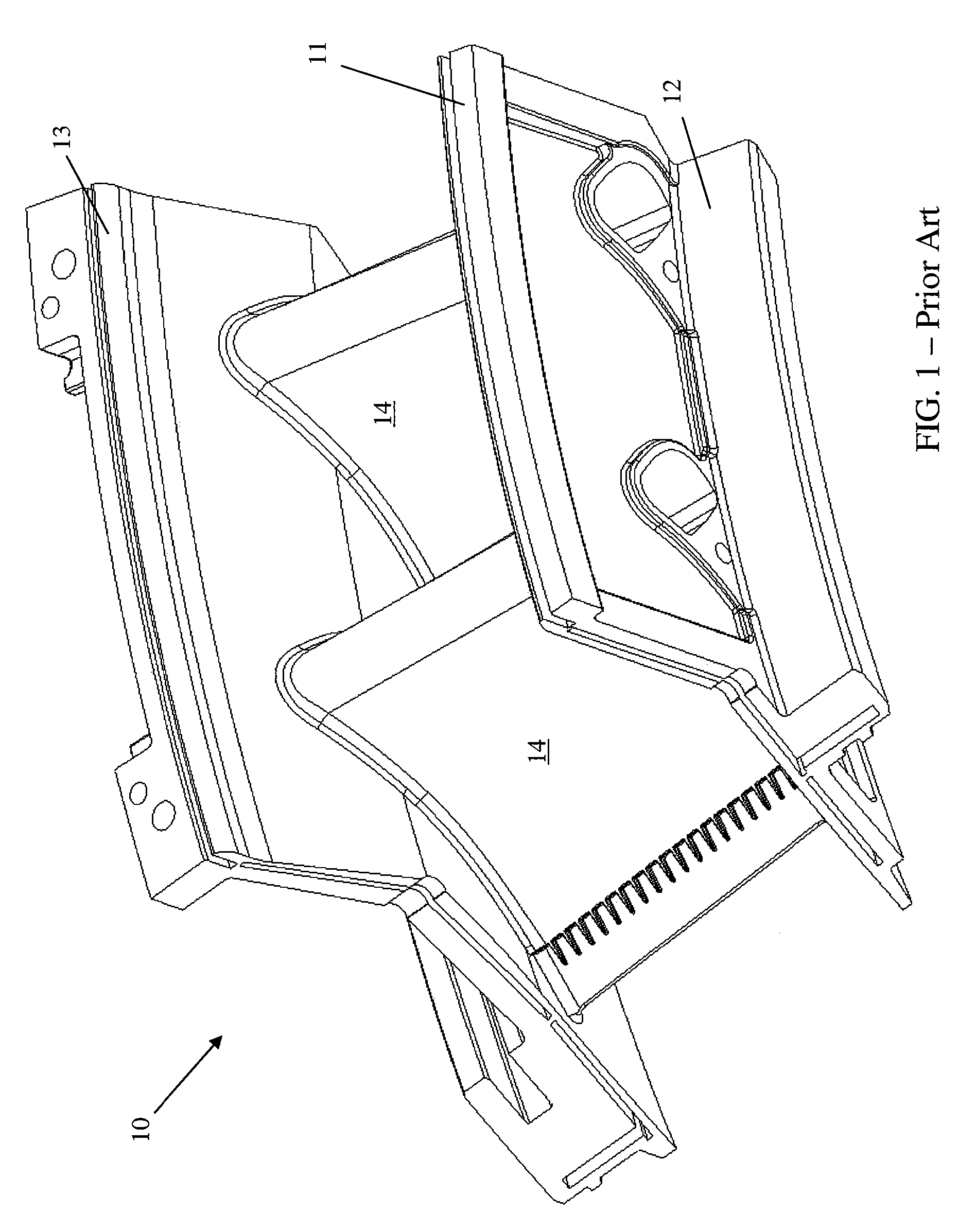

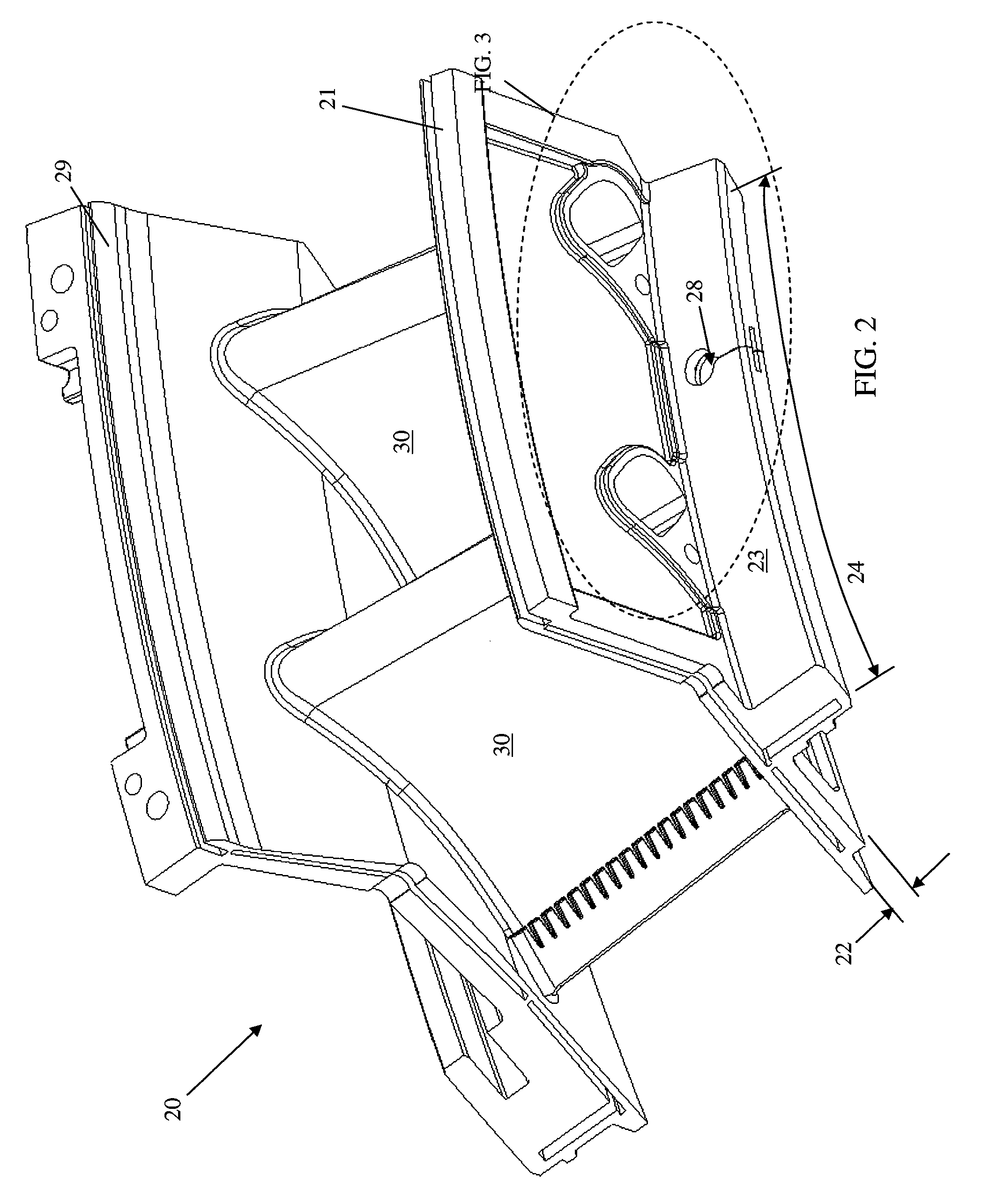

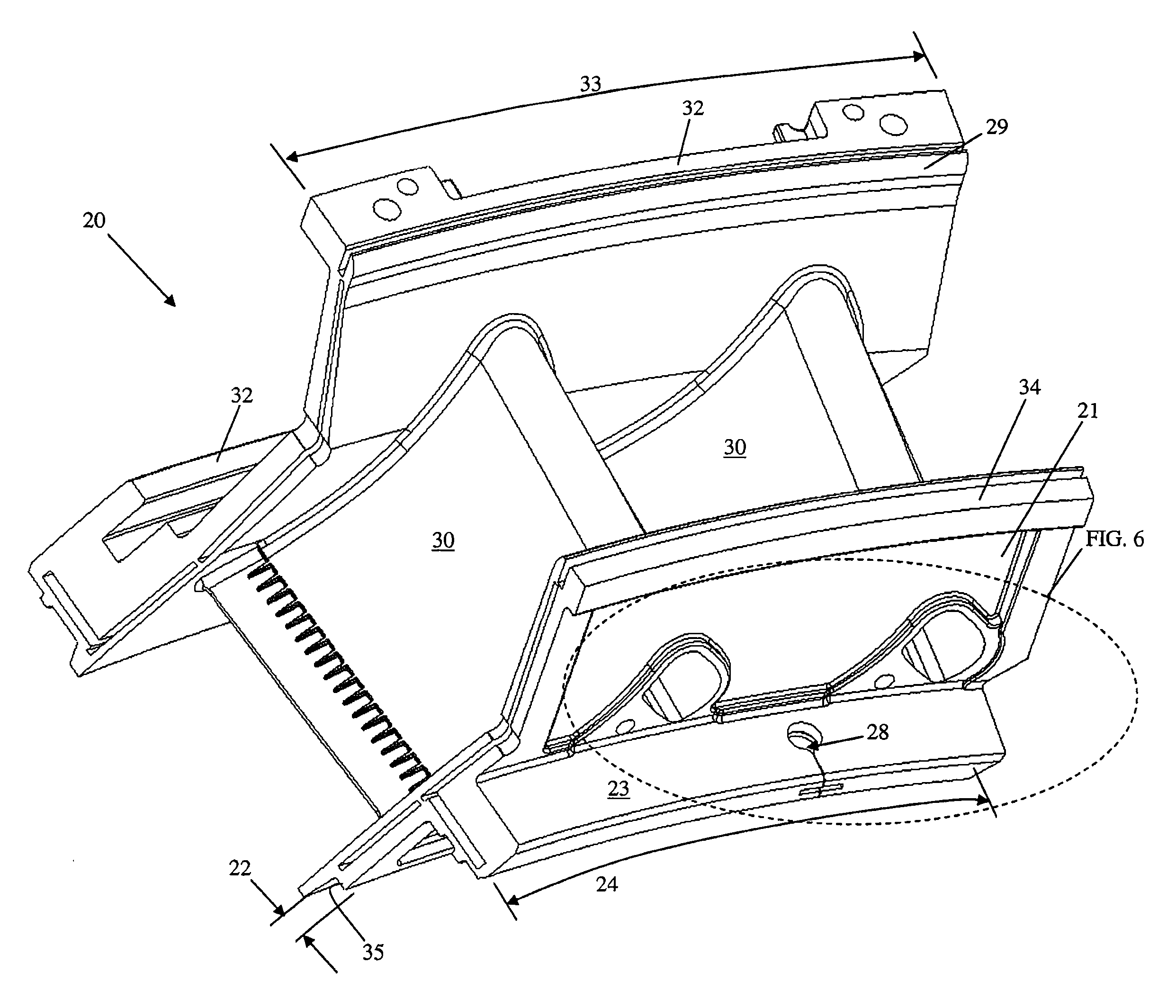

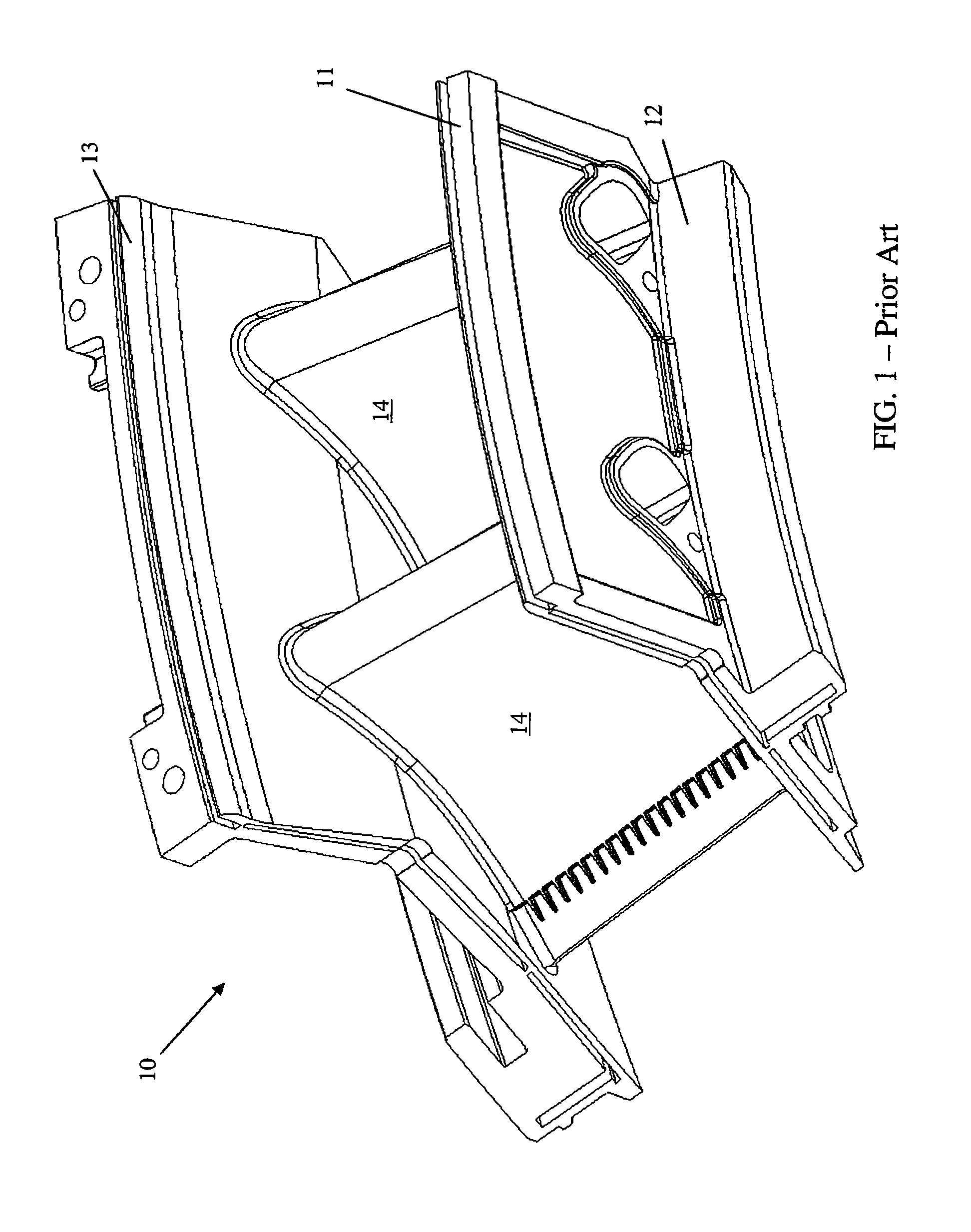

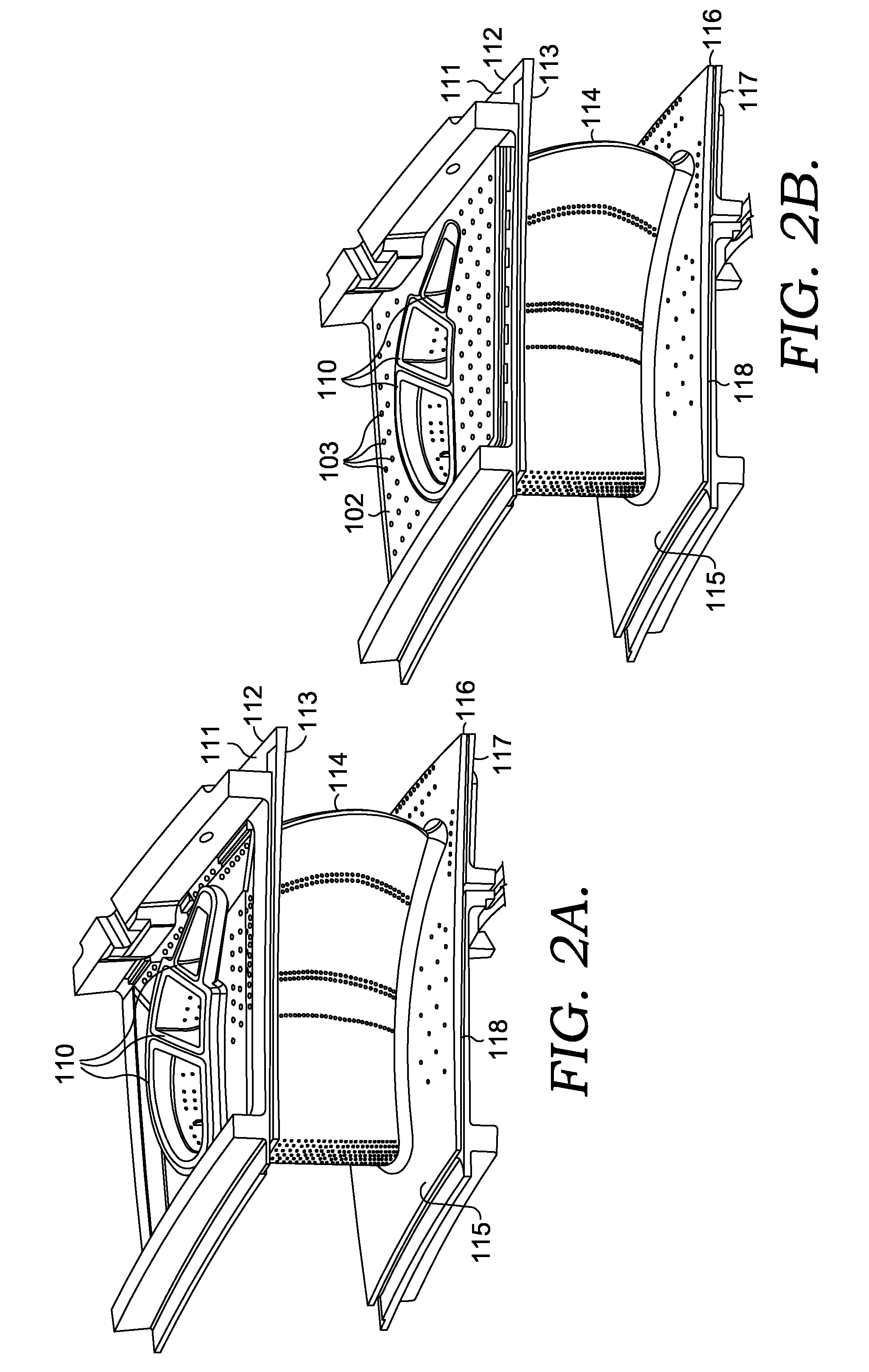

Vane platform rail configuration for reduced airfoil stress

ActiveUS20060013685A1Lower thermally induced stressImproved component durabilityPump componentsEngine fuctionsEngineeringGas turbines

A vane assembly for a gas turbine engine is disclosed having lower thermally induced stresses resulting in improved component durability. The stresses in the vane assembly airfoils are lowered by increasing the flexibility of the vane platform and reducing their resistance to thermal deflection. This is accomplished by placing an opening along the vane assembly rail that reduces the effective stiffness of the platform, thereby lowering the operating stresses in the airfoils of the vane assembly. A removable seal is then placed in the opening in order to prevent undesired leakages, while maintaining the benefit of the increased platform flexibility.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Insulated door assembly with low thermal deflection

InactiveUS6740279B2Improve insulation performanceImprove rigidityNatural patternsSpecial ornamental structuresCompression moldingShell molding

Owner:TTTECH

Insulated door assembly with low theraml deflection

InactiveUS20010001356A1Improve insulation performanceImprove rigidityNatural patternsSpecial ornamental structuresCompression moldingShell molding

Compression molded pigmented door skins fabricated by compression molding a pigmented, curable, unsaturated polyester sheet molding compound containing a co-curable unsaturated monomer, a low profile additive, and a microvoid-reducing thermoplastic polymer, exhibit uniform stainability while maintaining a low linear thermal coefficient of expansion. Such door skins are suitable for preparing wood grain textured exterior insulated doors which exhibit minimal thermal deflection when exposed to interior / exterior temperature differentials, even at eight foot door heights. The doors may be stained without first applying a seal coat.

Owner:TTTECH

Vane platform rail configuration for reduced airfoil stress

ActiveUS7293957B2Reduce stressReduced resistance to thermal deflectionPump componentsEngine fuctionsEngineeringGas turbines

A vane assembly for a gas turbine engine is disclosed having lower thermally induced stresses resulting in improved component durability. The stresses in the vane assembly airfoils are lowered by increasing the flexibility of the vane platform and reducing its resistance to thermal deflection. This is accomplished by placing an opening along the innermost vane assembly rail that reduces the effective stiffness of the platform, thereby lowering the operating stresses in the airfoils of the vane assembly. A removable seal is then placed in the opening in order to prevent undesired leakages, while maintaining the benefit of the increased platform flexibility.

Owner:ANSALDO ENERGIA SWITZERLAND AG

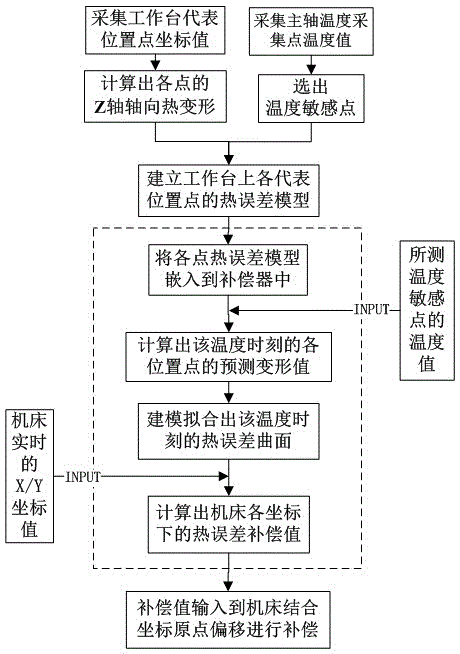

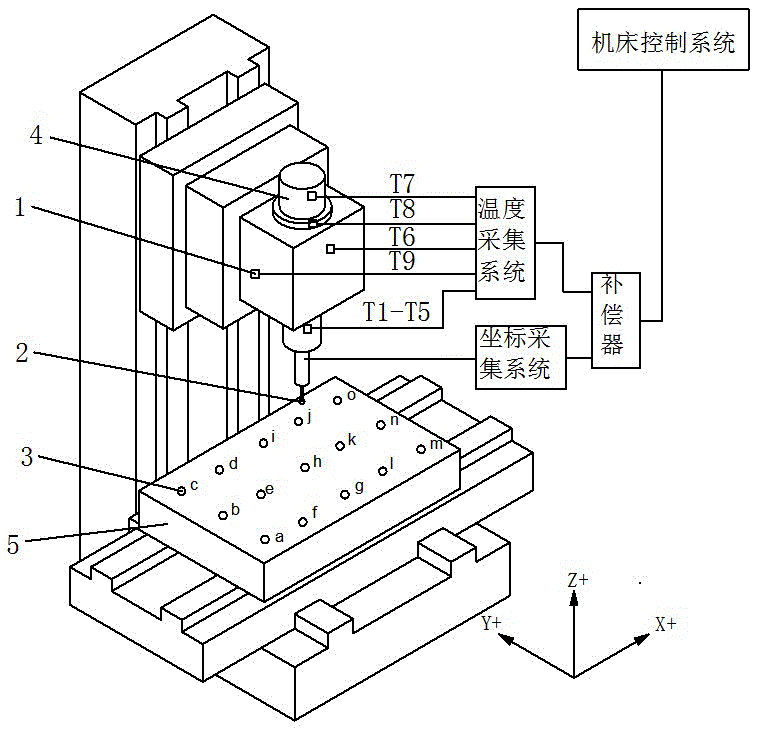

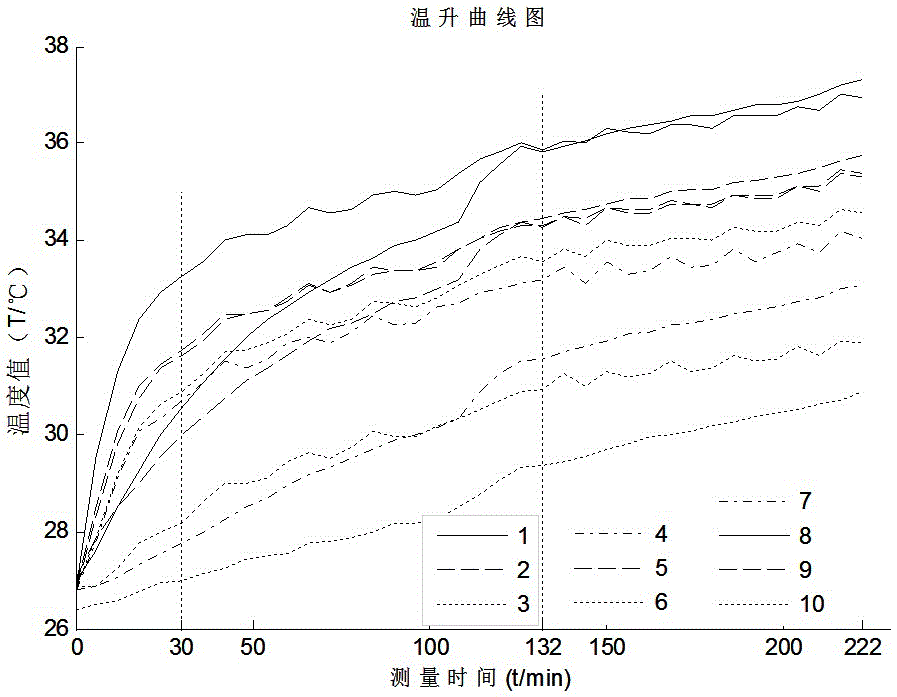

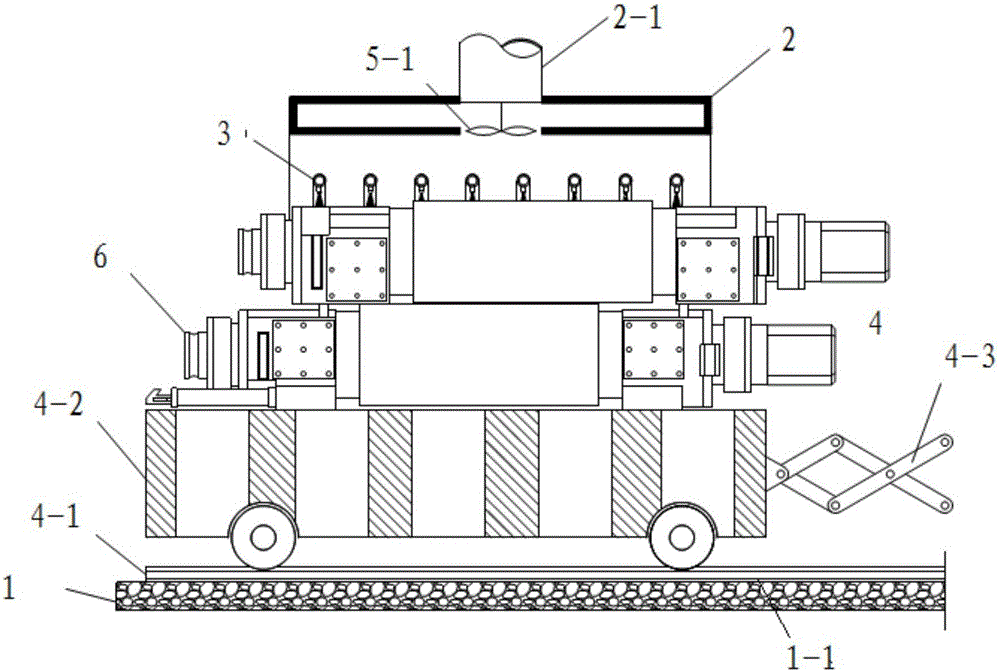

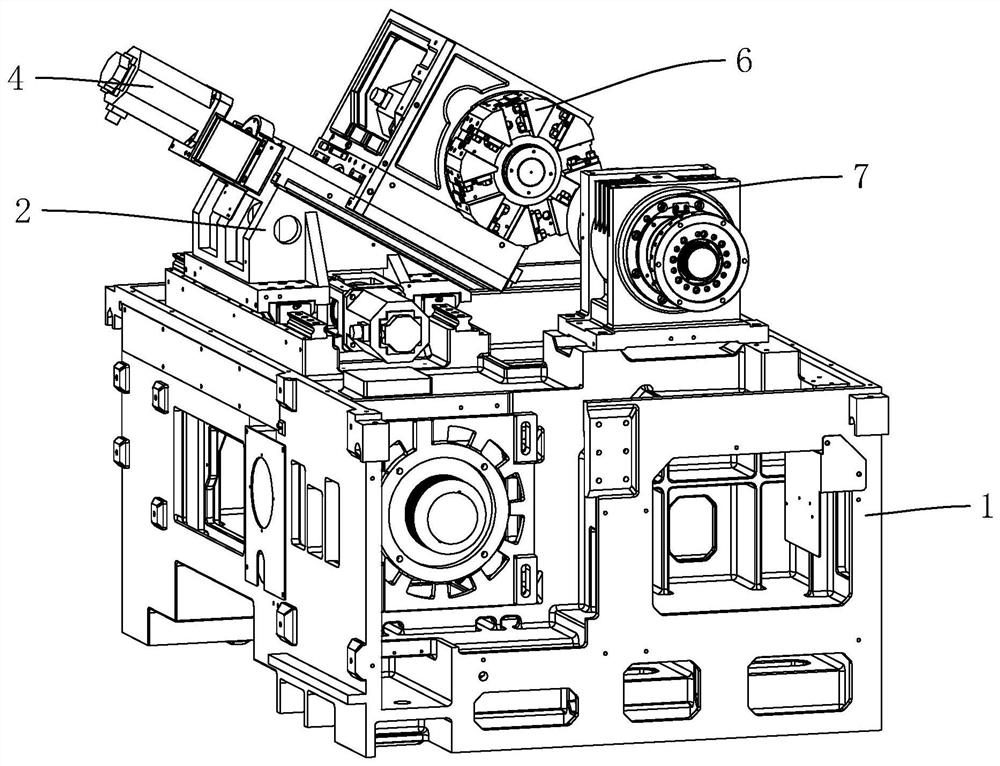

Method for curved surface thermal-error compensation of whole workbench of precise numerical-controlled machine tool

ActiveCN105700473AGuaranteed authenticityFunction increaseProgramme controlComputer controlNumerical controlSimulation

The invention relates to a method for curved surface thermal-error compensation of the whole workbench of a precise numerical-controlled machine tool. The method includes acquiring the temperature information of key positions of main shafts of the machine tool and Z-axis coordinate information of representative position point of a workbench, screening temperature sensitive points, establishing a thermal-error model of all measuring points in a workbench scope, embedding the established thermal-error model of all measuring points in a compensator, calculating a predicted thermal deflection of all measuring points at the current temperature and current moment, carrying out curved surface modeling for predicted thermal deflection of all measuring points at the current temperature and current moment, establishing a whole workbench curved surface thermal-error compensation model, calculating the thermal error compensation value of the machine tool at the coordinate position, inputting the obtained compensation value to the machine tool, and realizing Z-axis axial thermal error real-time compensation in the whole workbench scope of the machine tool by combining true origin offset. Modeling and predicting Z-axis axial thermal error of the whole workbench scope are carried out, so that accurate Z-axis axial thermal error compensation value in the whole workbench scope is obtained.

Owner:HEFEI UNIV OF TECH

Vane platform rail configuration for reduced airfoil stress

ActiveUS7229245B2Reduce stressIncrease flexibilityPump componentsEngine fuctionsEngineeringGas turbines

A vane assembly for a gas turbine engine is disclosed having lower thermally induced stresses resulting in improved component durability. The stresses in the vane assembly airfoils are lowered by increasing the flexibility of the vane platform and reducing their resistance to thermal deflection. This is accomplished by placing an opening along the vane assembly rail that reduces the effective stiffness of the platform, thereby lowering the operating stresses in the airfoils of the vane assembly. A removable seal is then placed in the opening in order to prevent undesired leakages, while maintaining the benefit of the increased platform flexibility.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Vane platform rail configuration for reduced airfoil stress

ActiveUS20070166154A1Lower thermally induced stressImproved component durabilityPump componentsEngine fuctionsEngineeringGas turbines

A vane assembly for a gas turbine engine is disclosed having lower thermally induced stresses resulting in improved component durability. The stresses in the vane assembly airfoils are lowered by increasing the flexibility of the vane platform and reducing its resistance to thermal deflection. This is accomplished by placing an opening along the innermost vane assembly rail that reduces the effective stiffness of the platform, thereby lowering the operating stresses in the airfoils of the vane assembly. A removable seal is then placed in the opening in order to prevent undesired leakages, while maintaining the benefit of the increased platform flexibility.

Owner:ANSALDO ENERGIA SWITZERLAND AG

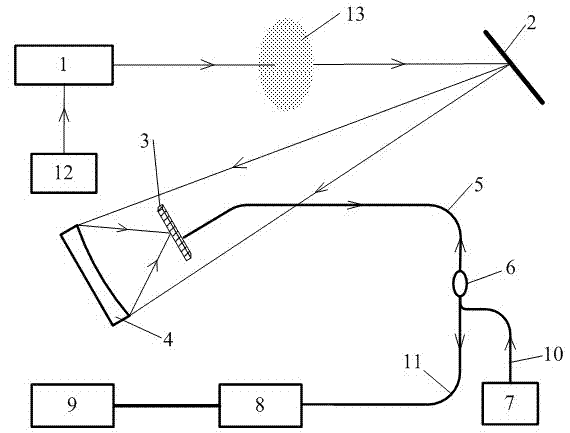

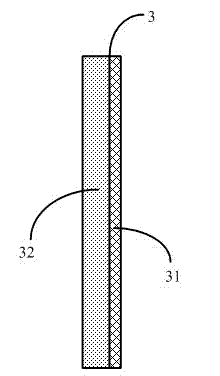

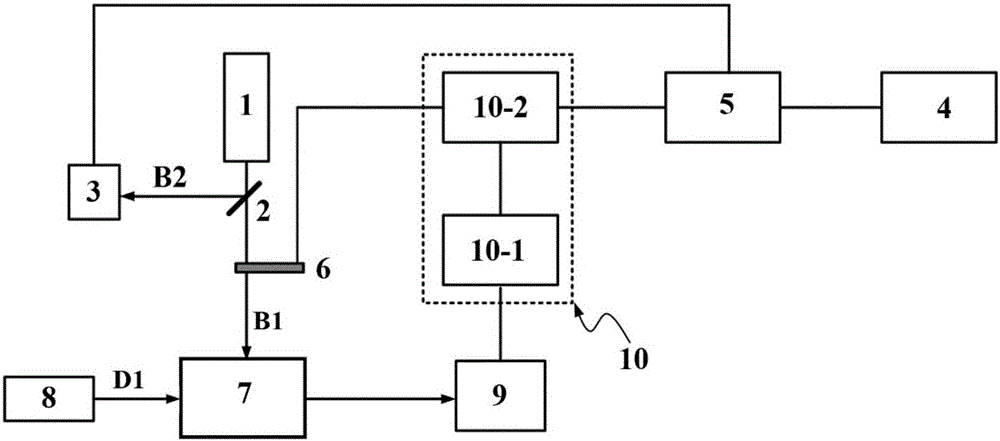

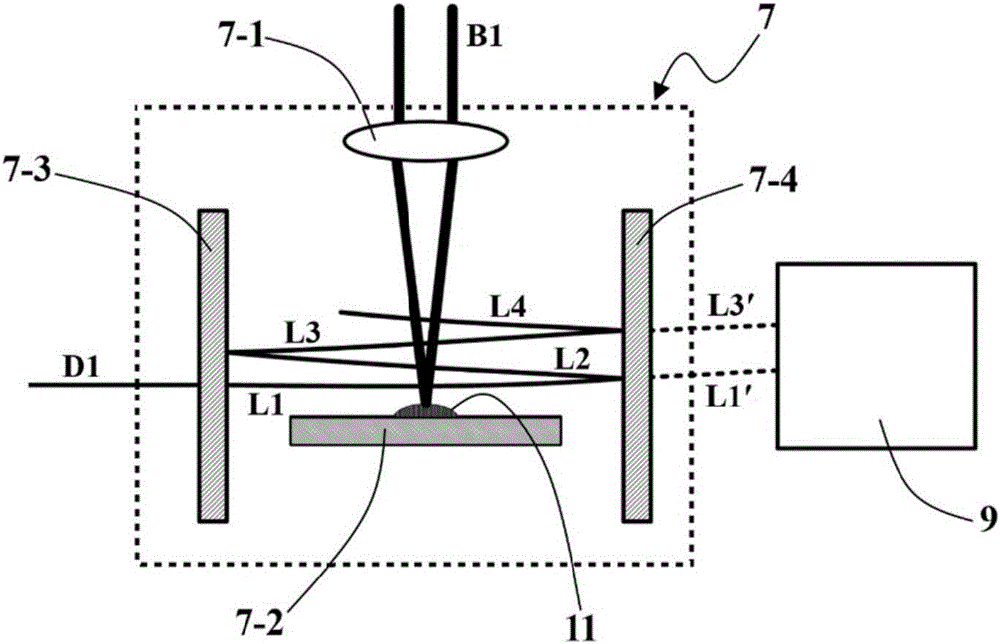

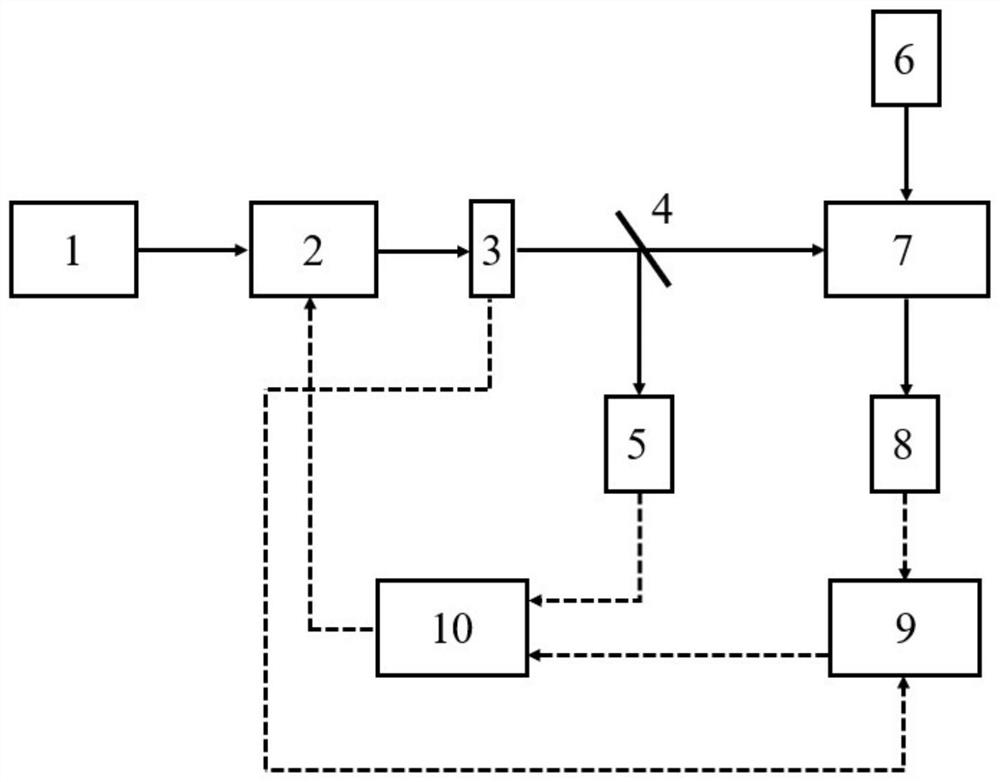

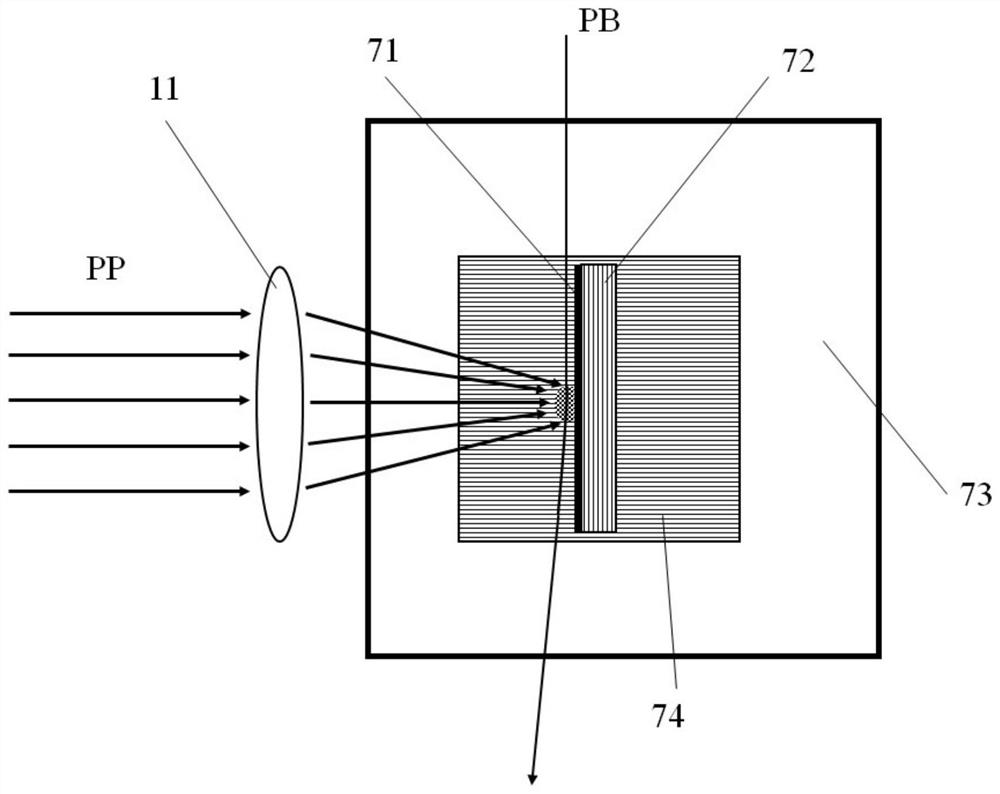

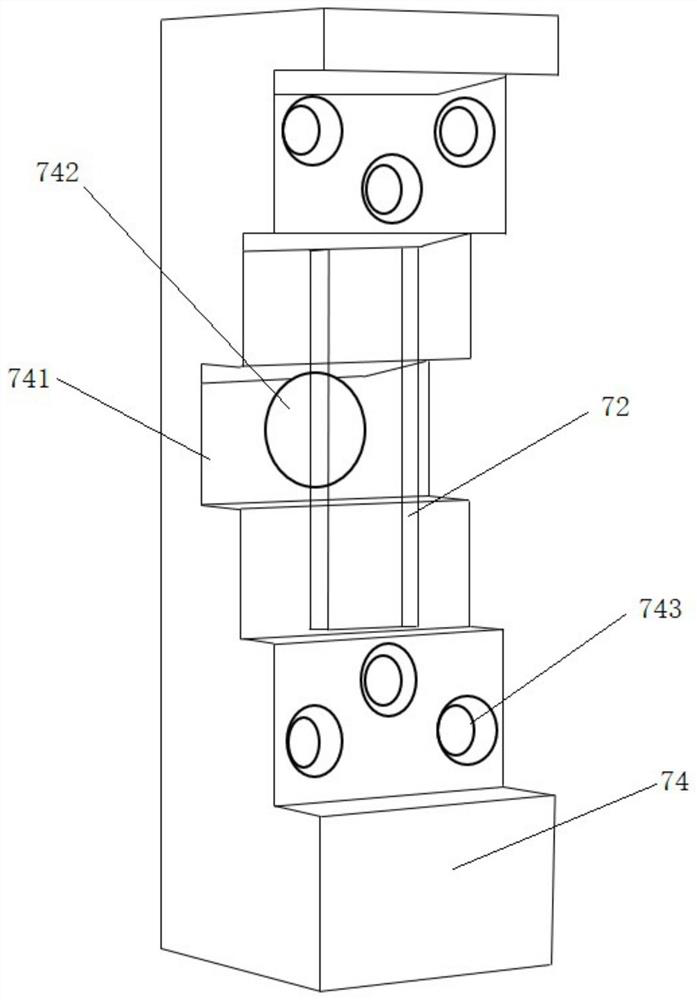

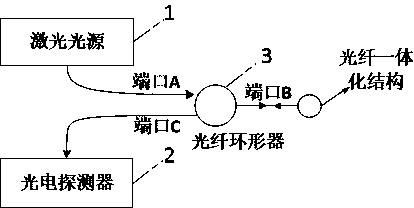

Surface microstructure silicon cantilever enhancement type optical-thermal spectrum trace gas detection method and device

ActiveCN102590112AImprove absorption rateAchieving Broad Spectrum Detection RequirementsColor/spectral properties measurementsResonance amplitudeOptical fiber coupler

The invention relates to a surface microstructure silicon cantilever enhancement type optical-thermal spectrum trace gas detection method and device. The device comprises a tunable laser, a reflective object, a surface microstructure silicon cantilever, a concave mirror, an optical fiber, an optical fiber coupler, a continuous laser, a laser controller, an optical detector, a signal processing system and the like. Modulated light emitted from the tunable laser is reflected on the concave mirror by the reflective object after passing through the gas to be detected, the received reflective light on the concave mirror is focused on a silicon surface of the cantilever beam. After the optical energy is absorbed by the cantilever beam, the optical-thermal deflection occurs to generate resonance. If the gas concentration is higher, the optical intensity absorbed by the gas is larger, and if the optical energy absorbed by the cantilever beam is smaller and the resonance amplitude is smaller. A length adjustable Fabry-Perot cavity is formed by an optical fiber end surface and a metal surface of the cantilever beam, the amplitude of the cantilever beam is demodulated to obtain gas absorption spectrum, furthermore the concentration of the detected trace gas is obtained. The device has the advantages of cheap price, small size, simple structure, convenience in use, strong flexibility, high detection sensitivity, and field work capacity and can be widely used in remotely detecting the components and concentration of a variety of or multi-component trace gas.

Owner:CHONGQING UNIV

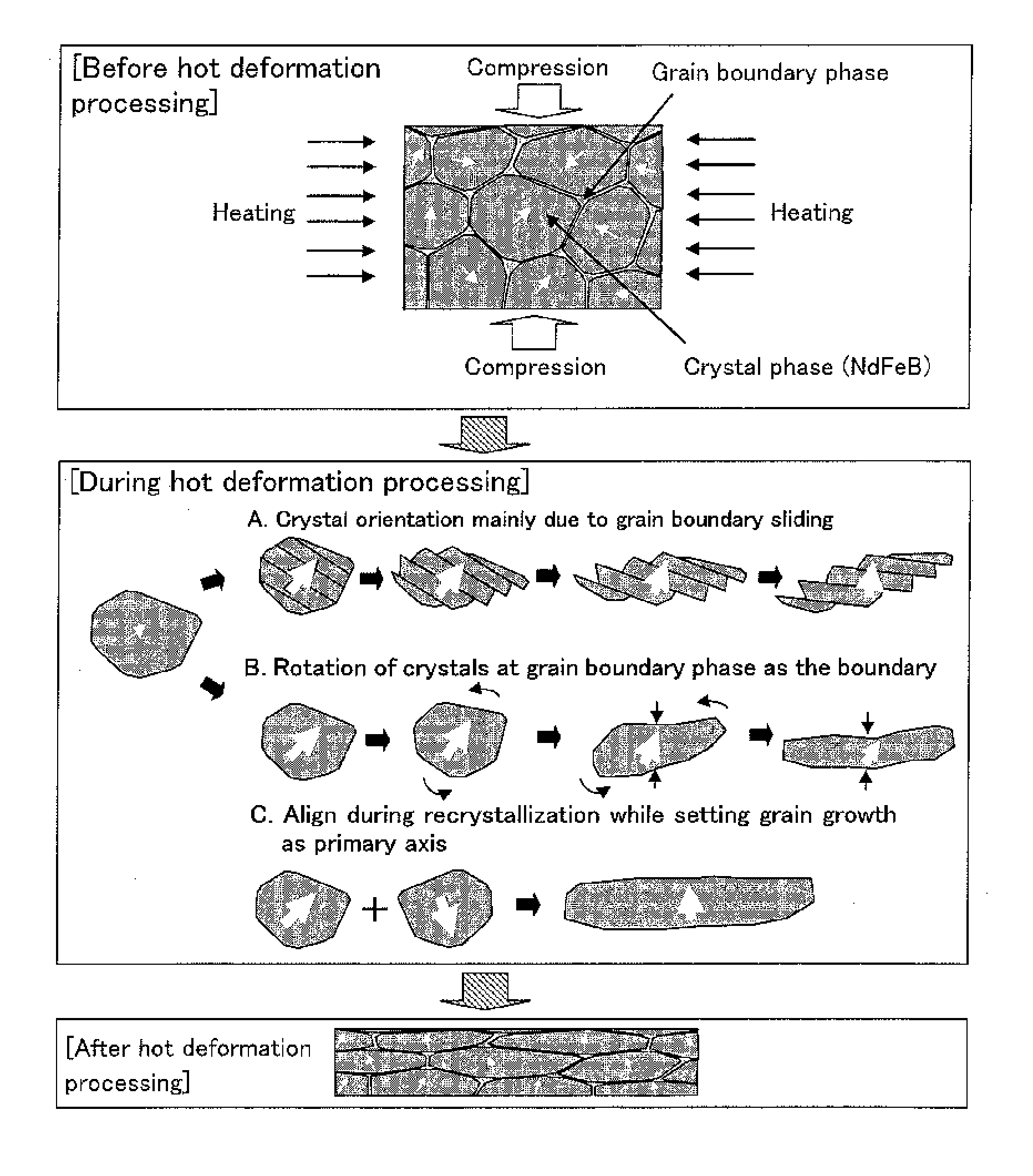

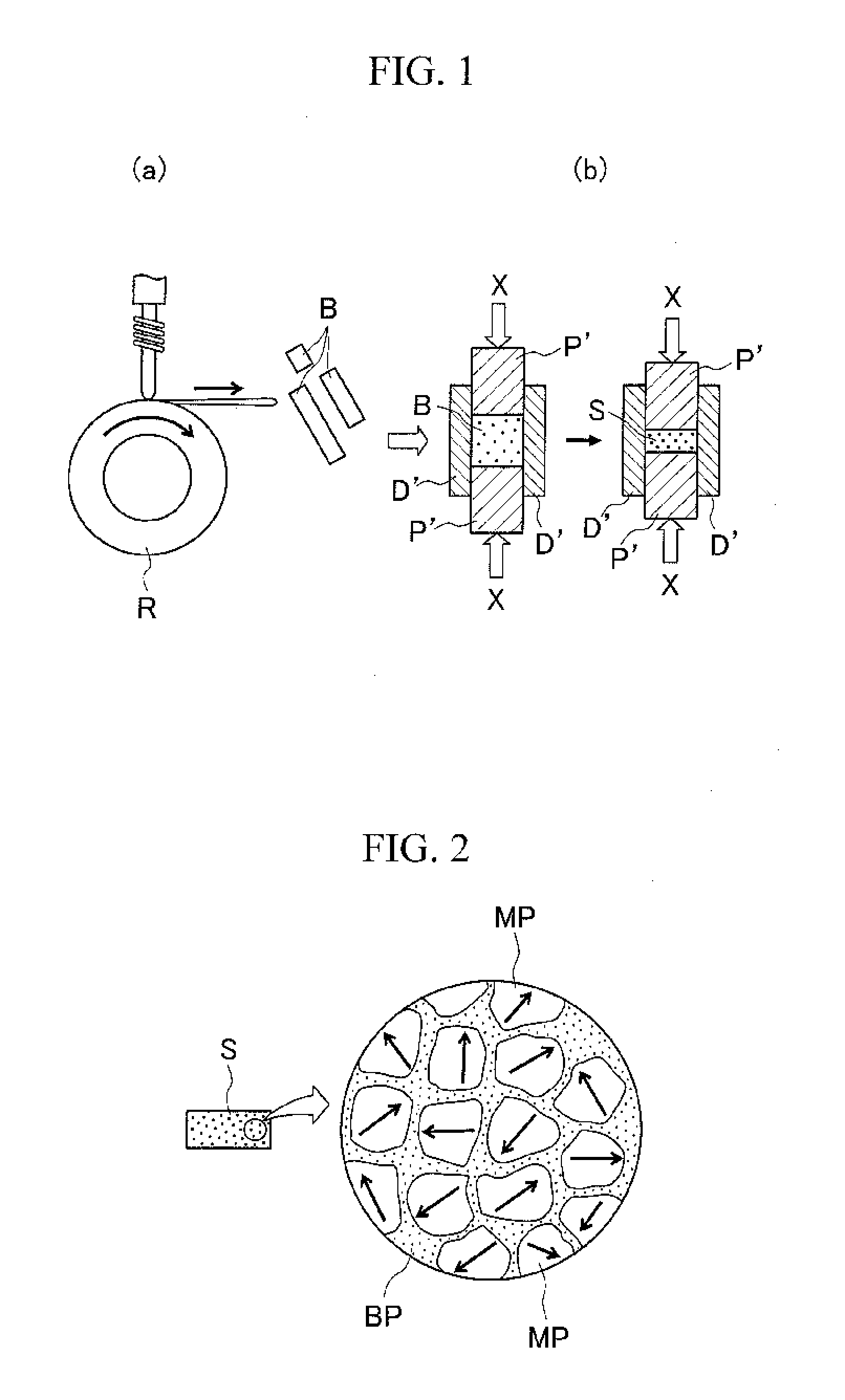

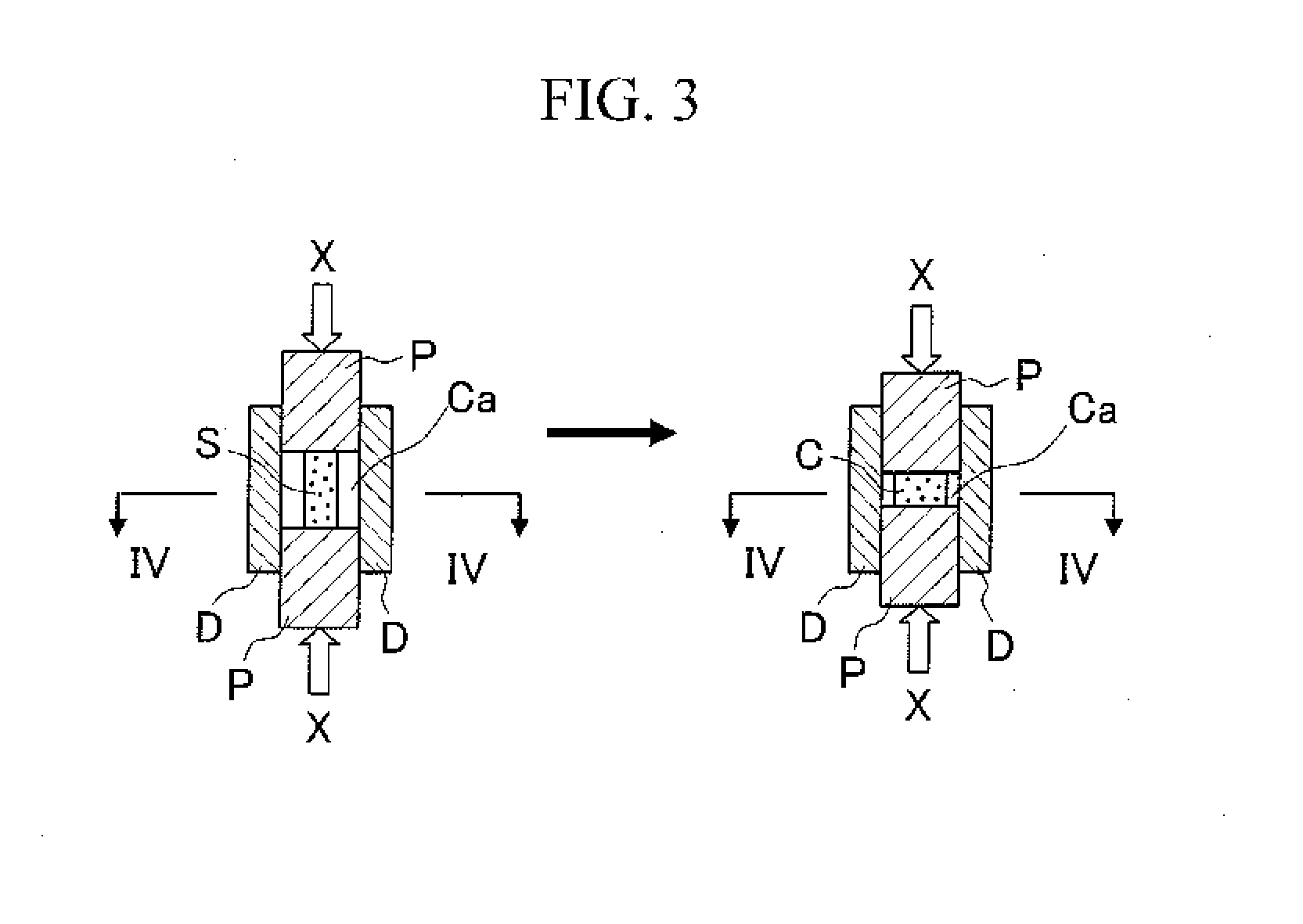

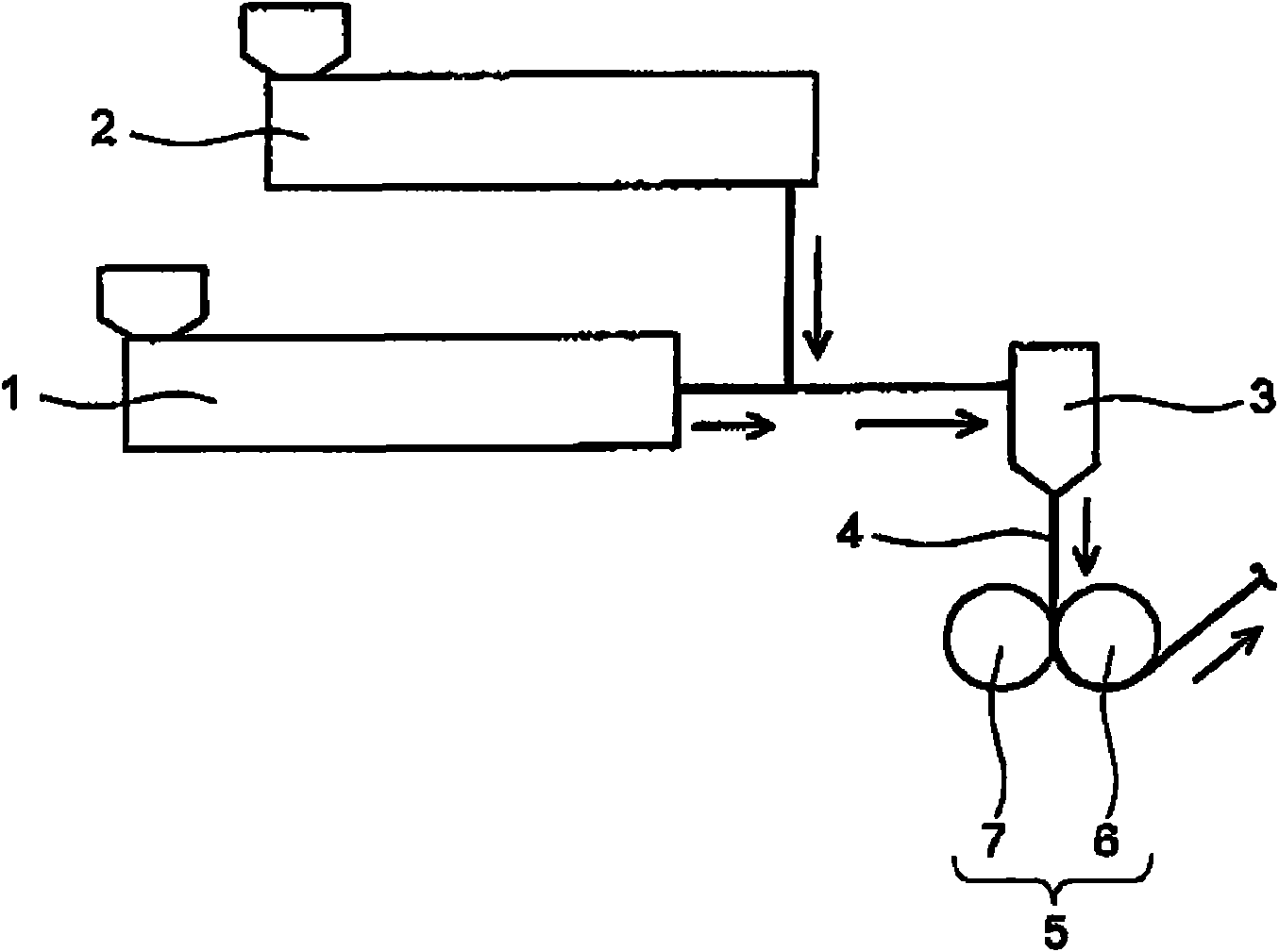

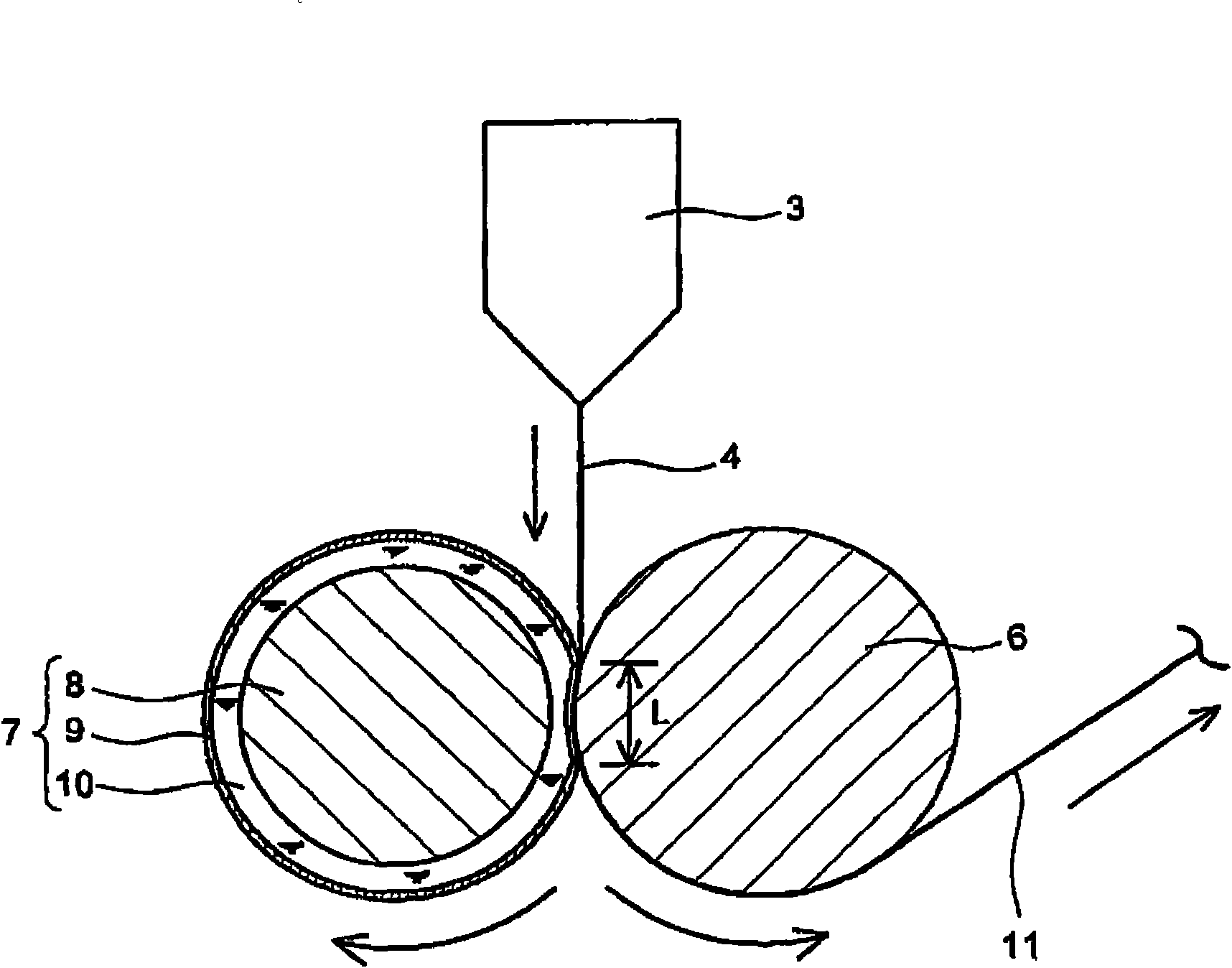

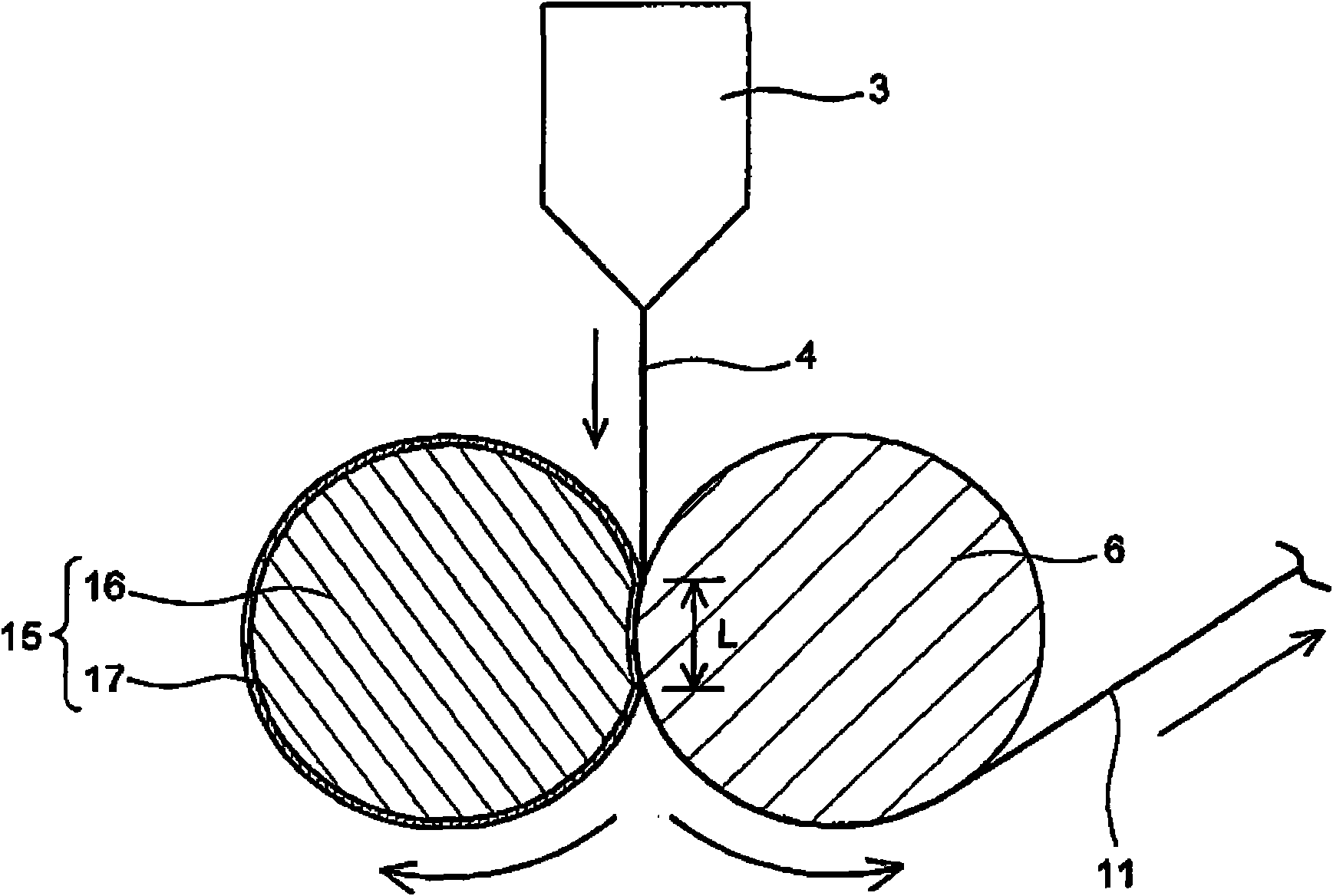

Manufacturing method for rare-earth magnet

ActiveUS20150279559A1Good orientationExcellent magnetic propertiesTransportation and packagingMetal-working apparatusRare-earth magnetMaterials science

Provided is a method for manufacturing a rare-earth magnet capable of manufacturing a rare-earth magnet with high degree of orientation by sufficient plastic deformation while suppressing cracks at the side faces of a compact that is plastic-deformed during the hot deformation processing. The method includes a step of preparing a compact S, preparing a plastic processing mold including a die D in which a cavity Ca is provided, and punches P that are slidable in the cavity Ca, the cavity Ca having a cross section that is larger in cross-sectional dimensions than a cross section of the compact S that is orthogonal to a pressing direction by the punches P; and a step of placing the compact S in the cavity Ca and performing hot deformation processing, thus manufacturing an orientational magnet C. Let that W1 denotes a length of a short side of the cross section of the cavity Ca and t1 denotes a length of a side of the cross section of the compact S that is placed in the cavity Ca, the side corresponding to the short side of the cavity Ca, t1 / W1 is within a range of 0.55 to 0.85, and from some stage during the hot deformation processing, a part of the compact S is constrained at a side face of the cavity Ca so that deformation of the compact is suppressed, but another part of the compact is in a non-constraint state.

Owner:TOYOTA JIDOSHA KK

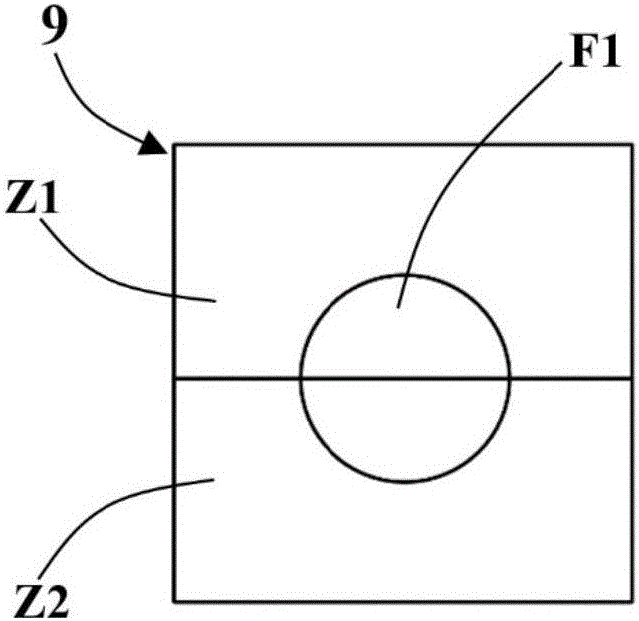

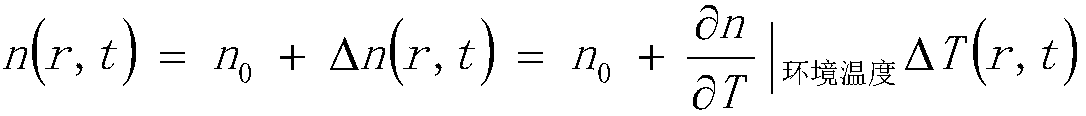

Photo-thermal deflection spectrum detection device and detection method

ActiveCN105737982AIncrease deflection angleHigh detection sensitivityRadiation pyrometrySpectrum investigationCollection analysisSpectroscopy

The invention discloses a photo-thermal deflection spectrum detection device and detection method. The detection device mainly comprises a pump laser, a detection laser, a detection cavity, an optical position detector and devices for signal modulation, amplification and collection analysis. The method comprises steps of irradiating the pump light to a film to be detected during the detection, forming a refractive index gradient in a medium in the proximity after the film to be detected absorbs the pump light and produces a heating effect, irradiating the detection light to an area having refractive index gradient above the film to be detected, and using an optical position detector to detect the light deflection amount after the light passes through the area. The detection device of the invention is provided with two parallel reflectors on the detection optical path inside the detection cavity, the detection light which is deflected inside the detection cavity is oscillated between two reflectors, and the detection light repeatedly passes through the medium area having the refractive index gradient, which enables the detection light to increase the deflection angle and improve the sensitivity of the photothermal deflection spectroscopy.

Owner:安徽中科春谷激光产业技术研究院有限公司

Cooled gas turbine vane assembly

ActiveUS8142137B2Increase flexibilityControl flowPropellersRotary propellersTrailing edgeGas turbines

A gas turbine vane to improve vane performance by addressing known failure mechanisms. A cooling circuit to the trailing edge of a vane airfoil is fed from the outer diameter platform, which prevents failure due to an oxidized and eroded airfoil trailing edge. The gas turbine includes an outer diameter platform, a hollow airfoil and an inner diameter platform with a plurality of cooling tubes extending radially through the airfoil. The cooling tubes are open at the outer diameter end and closed with covers at the inner diameter end. The inner diameter platform is also cooled and includes a meterplate for a portion of the cooling passageway and includes an undercut to improve thermal deflections of the inner diameter platform.

Owner:H2 IP UK LTD

Light conducting plate

The invention provides a light conducting plate composed of extrusion resin boards, wherein heat distortion is difficult to occur even if it is used in thin and large picture of backlight. The light conducting plate is composed of extrusion resin boards with the thickness of 0.1-2.0mm, the extrusion resin boards are placed in a thermal environment of 120 DEG C for 0.5 hours, and both the contraction percentage S1 (%) of the extrusion direction of the extrusion resin and the contraction percentage S2 (%) of the broad width direction of the extrusion resin board are 0-5%. Preferably the in-planedelay value of the extrusion resin board is below 200nm.

Owner:SUMITOMO CHEM CO LTD

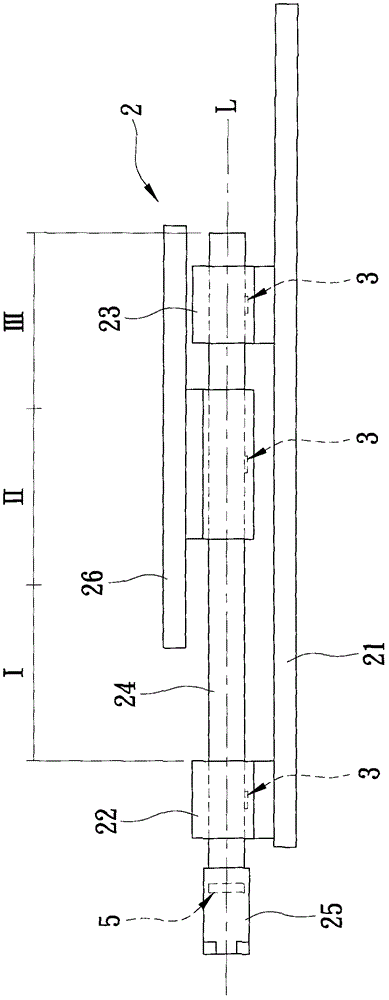

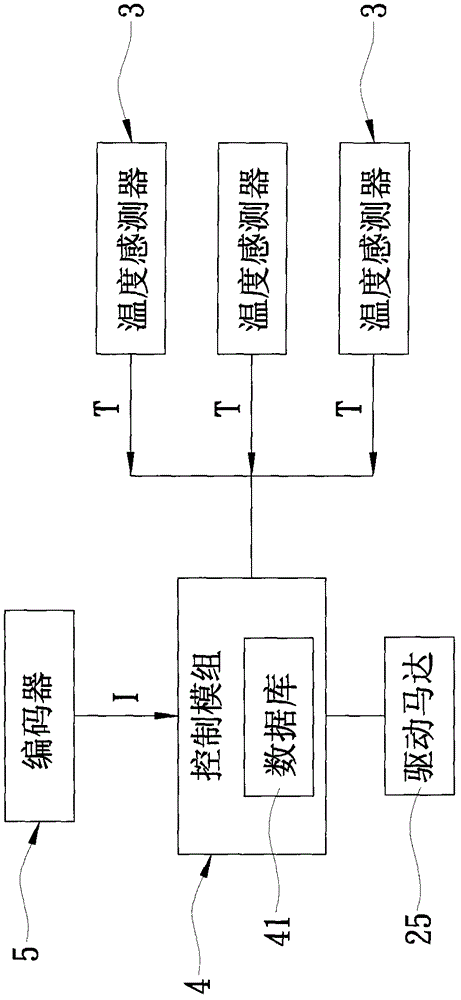

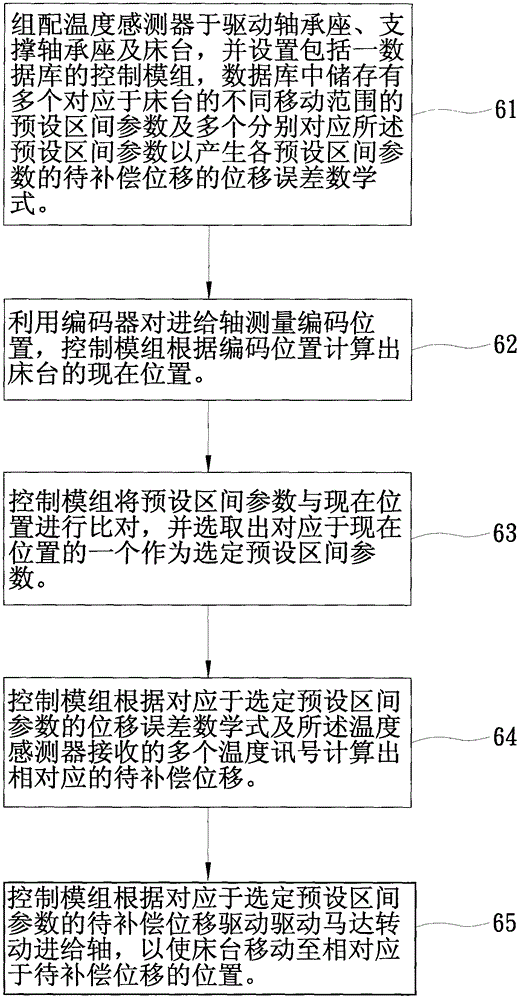

Feed shaft thermal deflection compensating method of comprehensive machining machine

ActiveCN102794671AThermal Displacement Error CorrectionAccurate responseAutomatic control devicesFeeding apparatusElectricityEngineering

The invention discloses a feed shaft thermal deflection compensating method of a comprehensive machining machine. The compensating method is applied to a comprehensive machining machine which comprises a feed shaft and a platform installed on the feed shaft. The compensating method comprises the following steps: assembling a plurality of temperature sensors on the comprehensive machining machine; arranging a control module which is electrically connected with the temperature sensors and comprises a databank, wherein a plurality of preset region parameters corresponding to different movement ranges, and a plurality of displacement error mathematic expressions (corresponding to the preset region parameters) of displacement to be compensated, are stored inside the databank; measuring the feed shaft according to an encoder so as to calculate out the position of the platform by virtue of the control module and selecting one preset region parameter corresponding to the position; subsequently calculating out the displacement to be compensated according to the displacement error mathematic expressions and a plurality of received temperature signals; and moving the platform to a corresponding position, thereby reducing the error caused by the thermal deflection.

Owner:PRECISION MACHINERY RES & DEV CENT

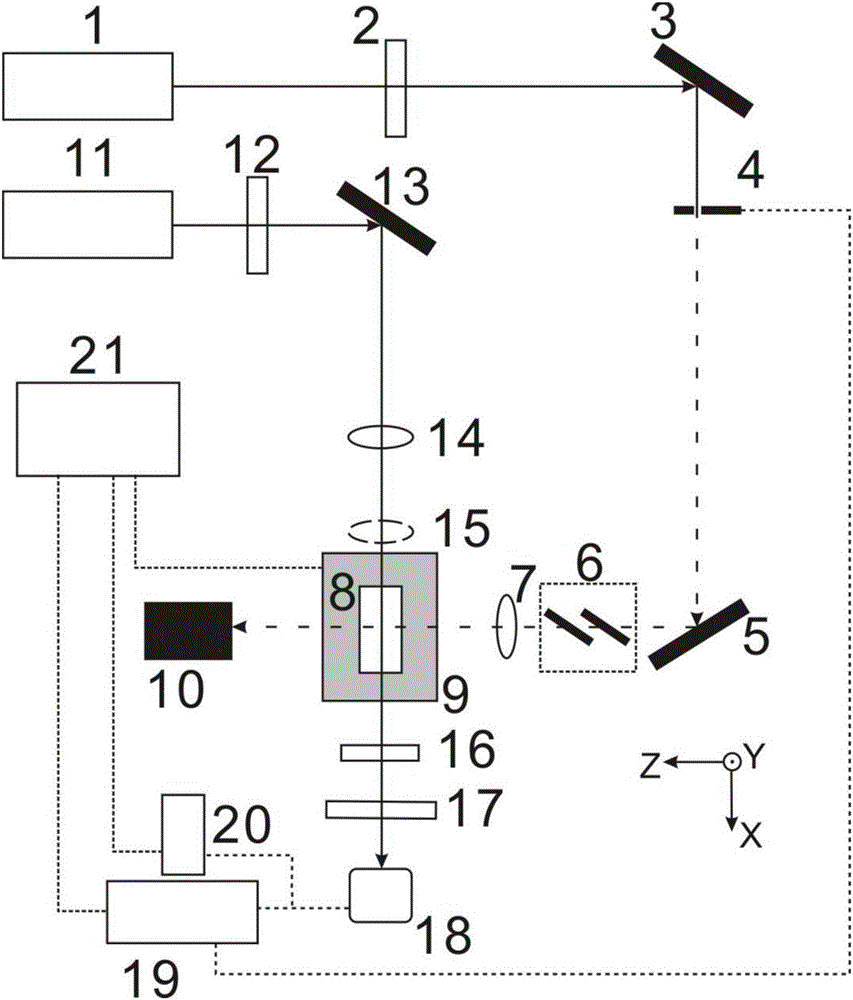

Measurement device and method for three-dimensional photo-thermal absorption of optical material

ActiveCN106248585AAvoid errorsReduce mistakesMaterial analysis by optical meansElectrical resistance and conductanceMeasurement device

The invention discloses a measurement device and a measurement method for three-dimensional photo-thermal absorption of an optical material. The device is of a transverse type structure; the material is subjected to three-dimensional photo-thermal absorption measurement by using a thermal lens technology, so that an error caused by the fact that a light spot irradiates the edge of a detector or the outside of the detector during measurement with a photo-thermal deflection technology is avoided, and a favorable tool is supplied to the research on the characteristics of the material and damage to the material; according to the method, by means of the photo-thermal deflection technology, a resistance heating calibrator is indirectly used for calibrating thermal lens absorption measurement, so that an error caused by a difference between materials during calibration of different types of samples in the thermal lens absorption measurement is avoided; meanwhile, when a parameter product between a system and the material is calculated, a thermal lens signal point to be measured and a known absorption rate point are the same point, so that the error is reduced. The device is simple, convenient to adjust and high in sensitivity.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

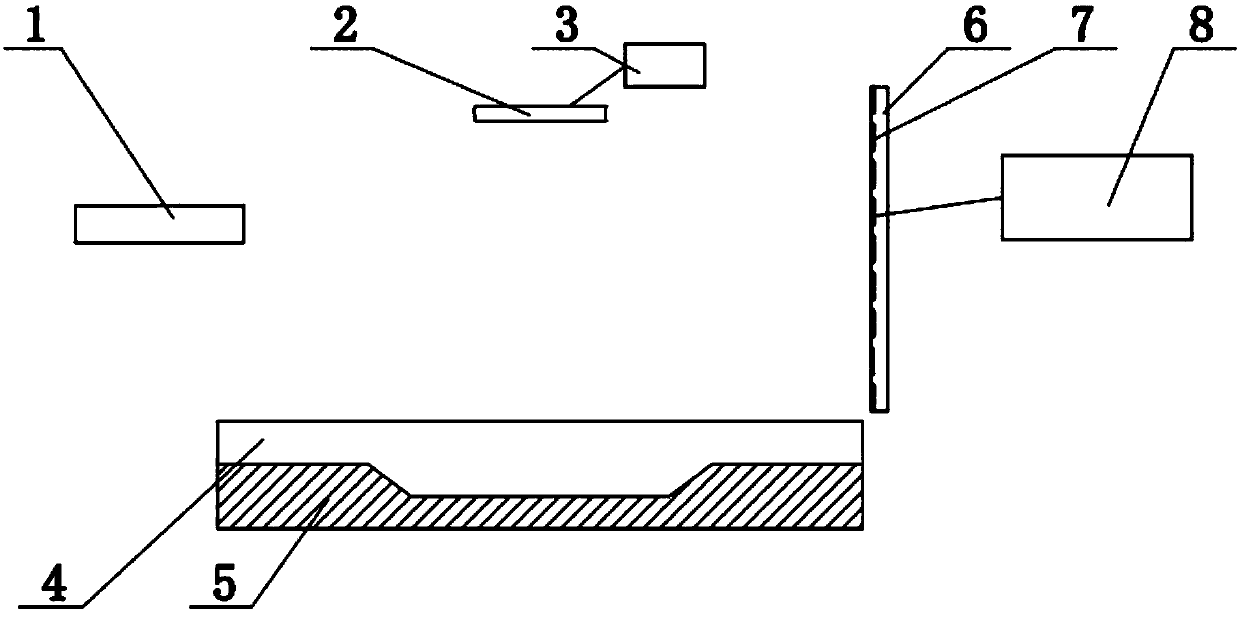

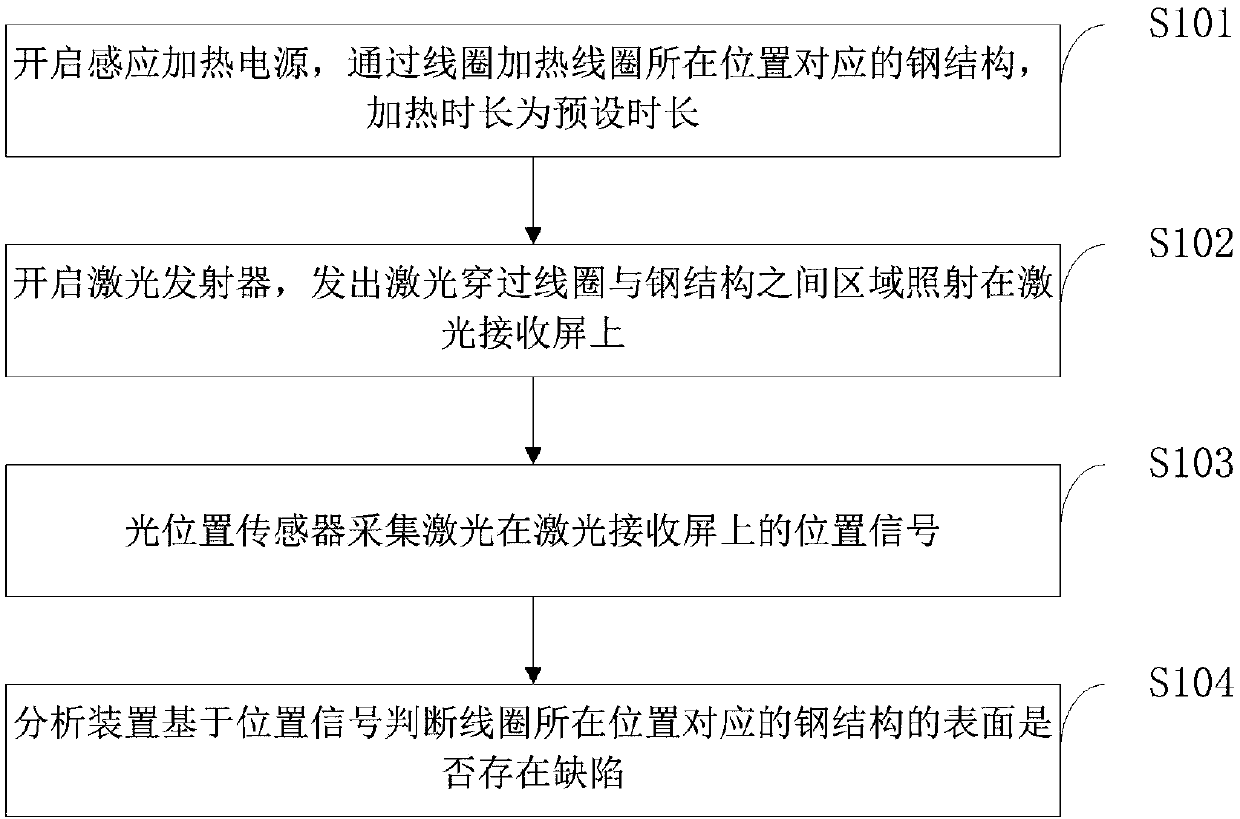

Apparatus and method for defect detection of steel structure on the basis of eddy-current heating deflection spectroscopy

InactiveCN107607614AReduce heating powerSmall temperature changePhase-affecting property measurementsOptically investigating flaws/contaminationLaser transmitterSpectroscopy

The invention provides an apparatus for defect detection of steel structure on the basis of eddy-current heating deflection spectroscopy. The apparatus includes: an induction heating power supply, a coil, a laser emitter, a laser receiving screen, a plurality of laser position sensors and an analyzer. The induction heating power supply is connected to the coil. The coil is arranged at a preset distance from a protective layer surface of a steel structure. The laser emitter and the laser receiving screen are respectively arranged at two sides of a zone between the coil and the protective layersurface. The laser emitter is faced to the laser receiving screen. The laser position sensors are paved on the laser receiving screen. The laser receiving screen is connected to the analyzer. In the apparatus, by means of difference of temperature changes between a defect position and a non-defect position on the steel structure under eddy-current heating, defect detection on the surface of the steel structure inside the protective layer can be completed without damage on the steel structure and the protective layer thereon. Meanwhile, because photo-thermal deflection effect is very sensitive,even a small temperature change can be detected, thus reducing eddy-current heating powder and greatly reducing weight and energy consumption of the apparatus.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Photo-thermal deflection spectrum testing device with wide wavelength coverage

PendingCN113109282AMeet the needs of high-sensitivity detectionSimple structureColor/spectral properties measurementsBeam splitterEngineering

The invention discloses a photo-thermal deflection spectrum testing device with wide wavelength coverage. The photo-thermal deflection spectrum testing device comprises a pump light source, a monochromator, an optical chopper and a beam splitter which are sequentially arranged along a light path, a photoelectric detector is arranged on a reflection light path of the beam splitter, and an absorption cell is arranged on a transmission light path of the beam splitter; the signal output end of the photoelectric detector is connected with the computer; a detection light source and a position sensitive detector are respectively arranged on two side surfaces, vertical to a transmission light path of the beam splitter, of the absorption cell; the signal output end of the position sensitive detector is sequentially connected with a lock-in amplifier and a computer; the absorption cell is used for accommodating a heat-conducting medium, and a sample table is fixed at the bottom and is used for fixing a to-be-detected film; a focusing lens is arranged between the absorption cell and the beam splitter, and the pump light transmitting through the beam splitter enters the absorption cell through the focusing lens; and the pump light source adopts a laser-driven broadband light source and is used for emitting pump light of 170-2100 nm. According to the invention, the test requirements from a narrow-band-gap material to a wide-band-gap material can be met at the same time.

Owner:ZHEJIANG UNIV

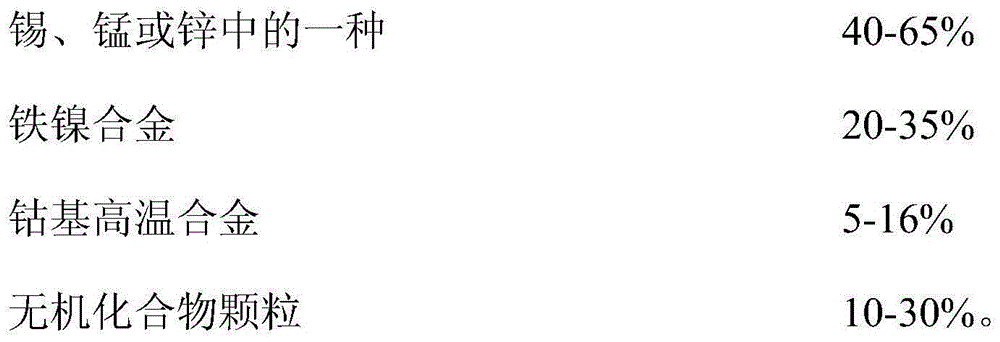

Thermal bimetal material

The invention provides a thermal bimetal material which comprises the following ingredients in percentage by weight: 40-65% of one of tin, manganese and zinc, 20-35% of iron-nickel alloy, 5-16% of cobalt-based high temperature alloy and 10-30% of inorganic compound particles. The thermal bimetal material provided by the invention has the advantages that the production cost of the thermal bimetal material is reduced, economic benefits are increased, the quality is higher, the electrical resistivity reaches 175 Omega.m, the highest specific thermal deflection rate is 32.5 / DEG C and the thermal bimetal material can replace the conventional high-sensitivity thermal bimetal material.

Owner:WUXI QINGYANG MACHINERY MFG

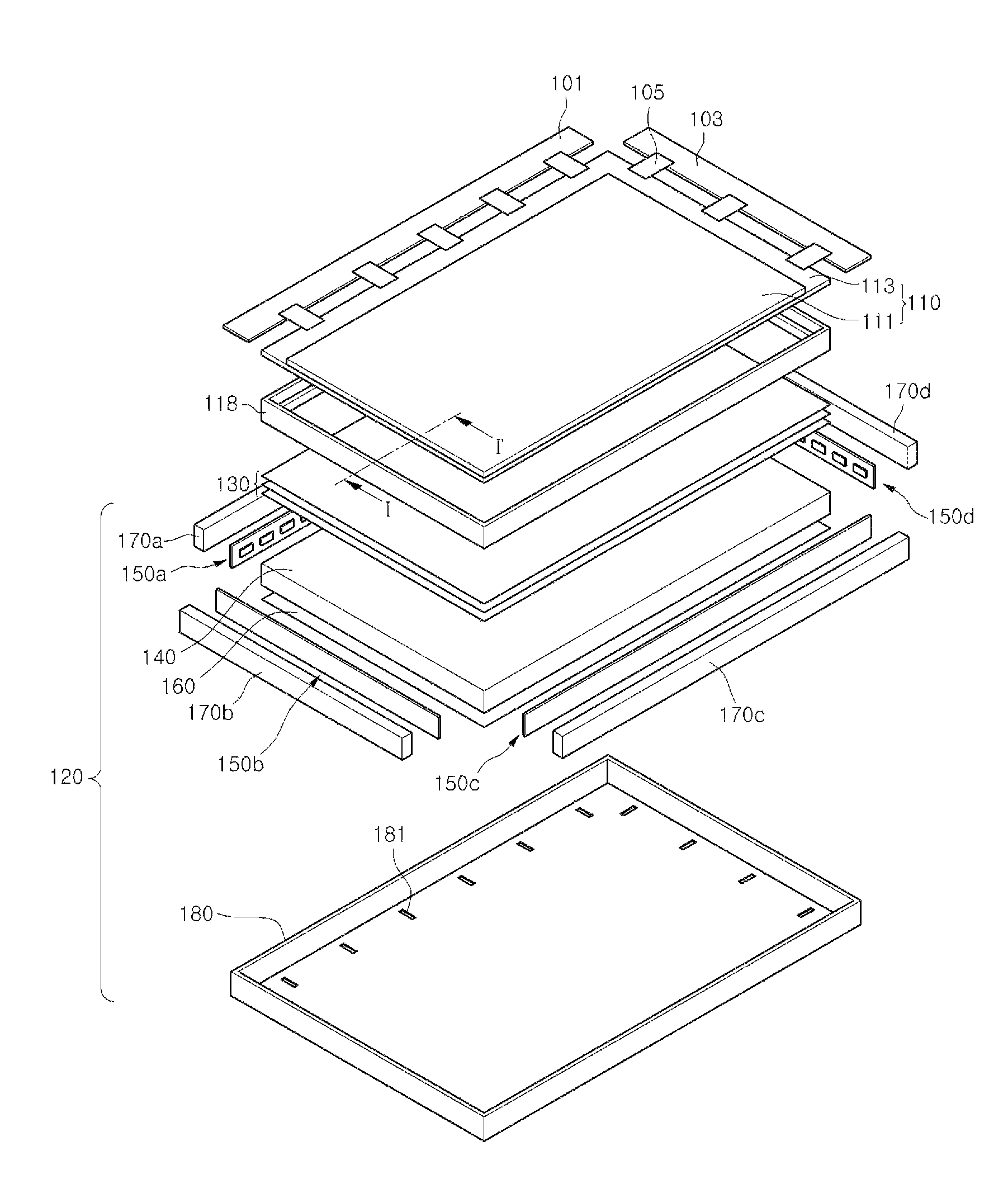

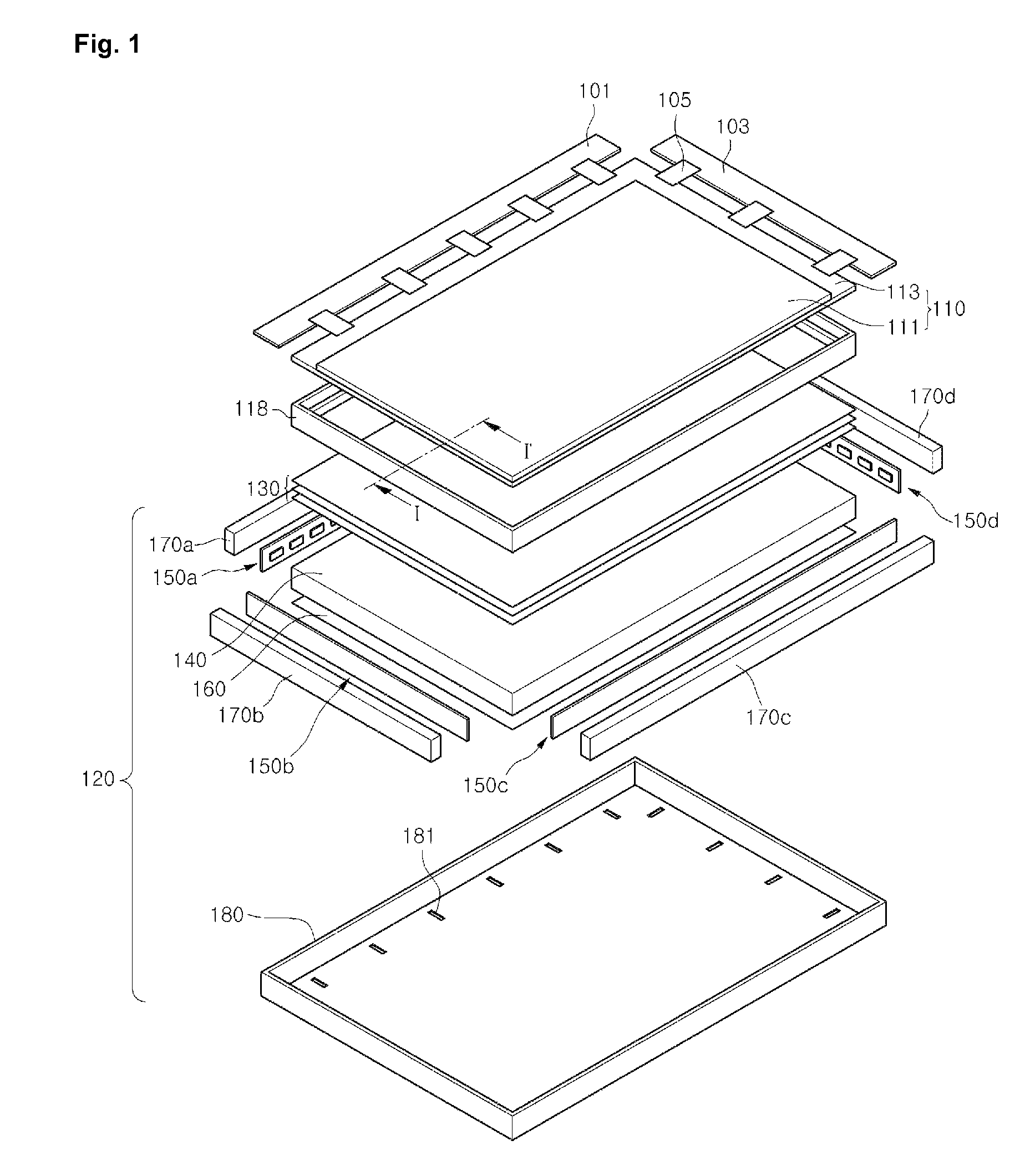

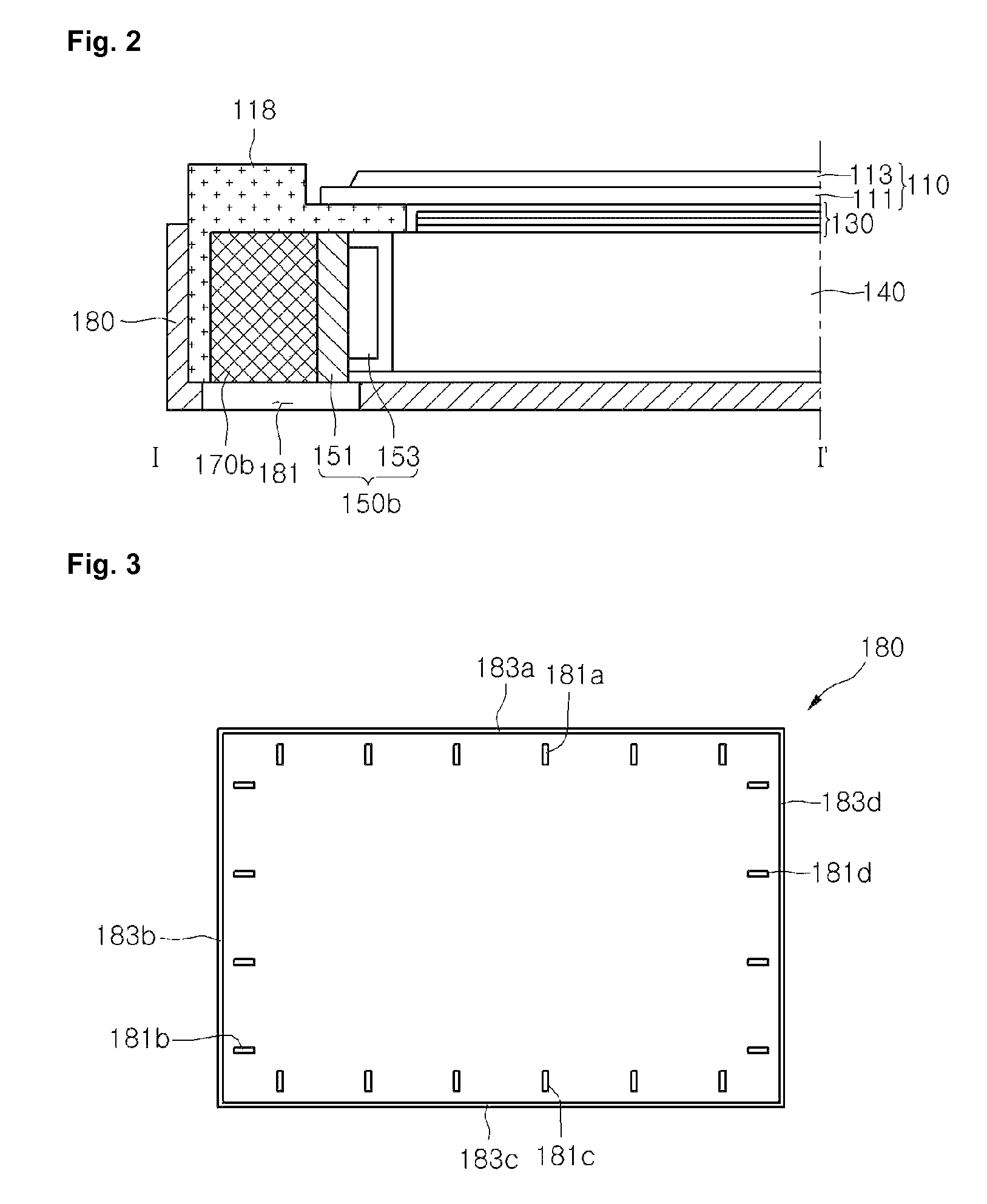

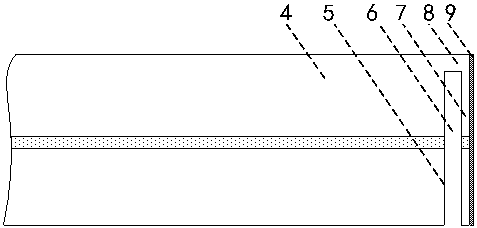

Backlight unit comprising a plurality of slits formed on a bottom surface of at least one edge of a bottom cover and liquid crystal display device having the same

ActiveUS9019443B2Improve display qualityReduce thermal deformationMechanical apparatusLight guides for lighting systemsLiquid-crystal displayPrinted circuit board

A backlight unit adapted to prevent light leakage and damage of its internal components due to a thermal deformation is disclosed.The backlight unit includes: a bottom cover with an opened upper surface; a printed-circuit-board disposed on at least one inner side surface of the bottom cover; a plurality of LEDs loaded on the printed-circuit-board; and a plurality of slits formed on at least one edge of the bottom cover opposite to the printed-circuit-board and configured to reduce thermal deformation of the bottom cover.

Owner:LG DISPLAY CO LTD

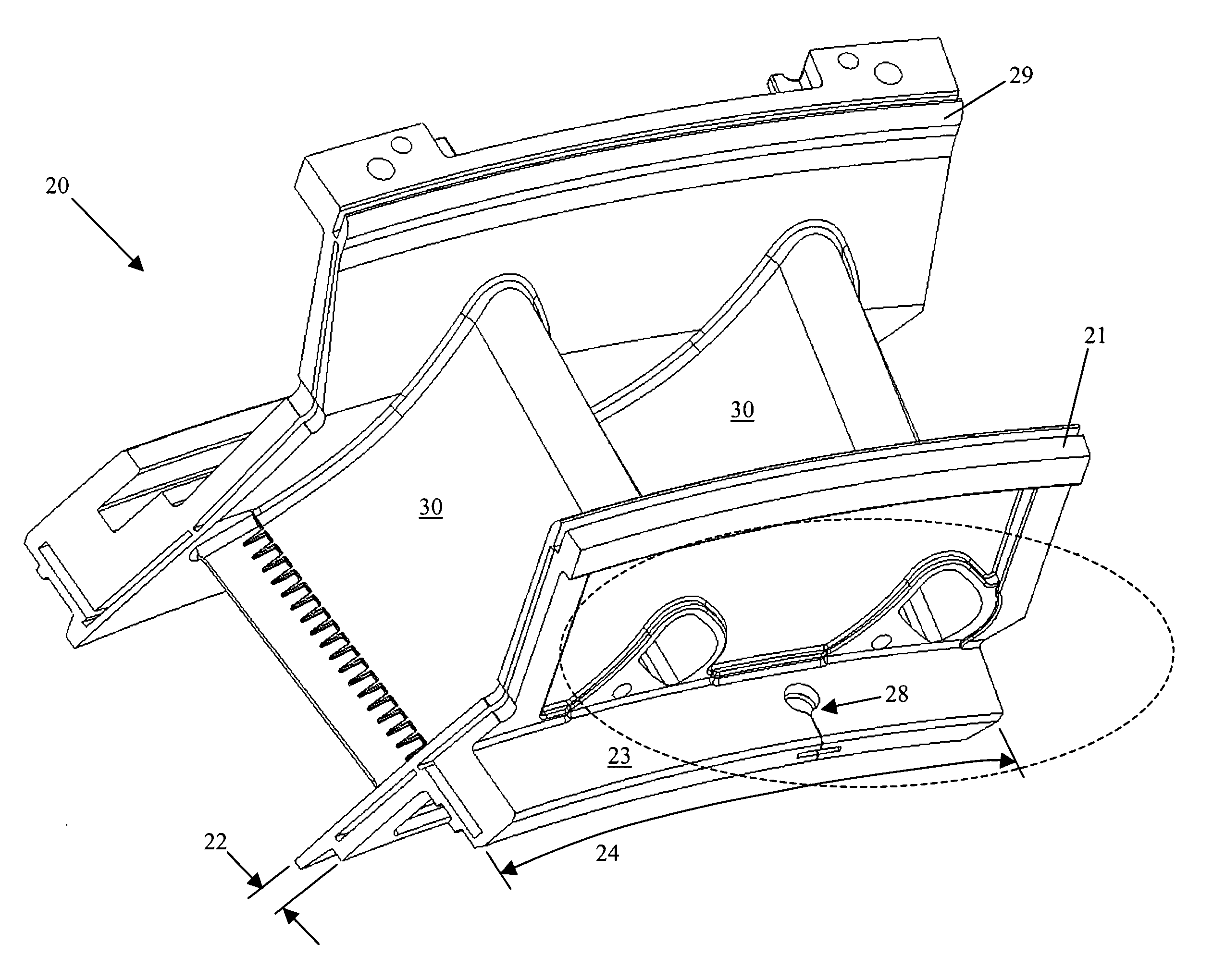

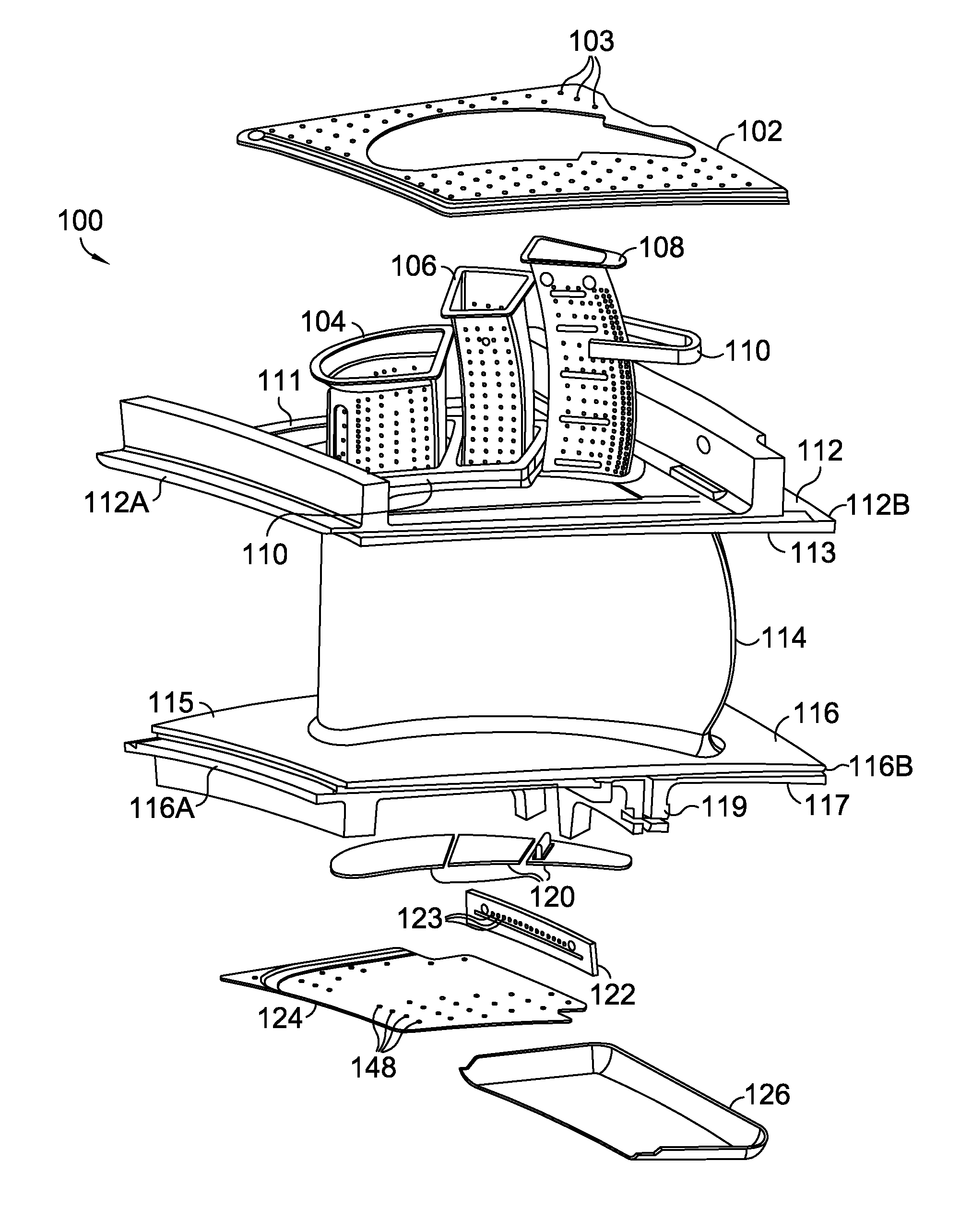

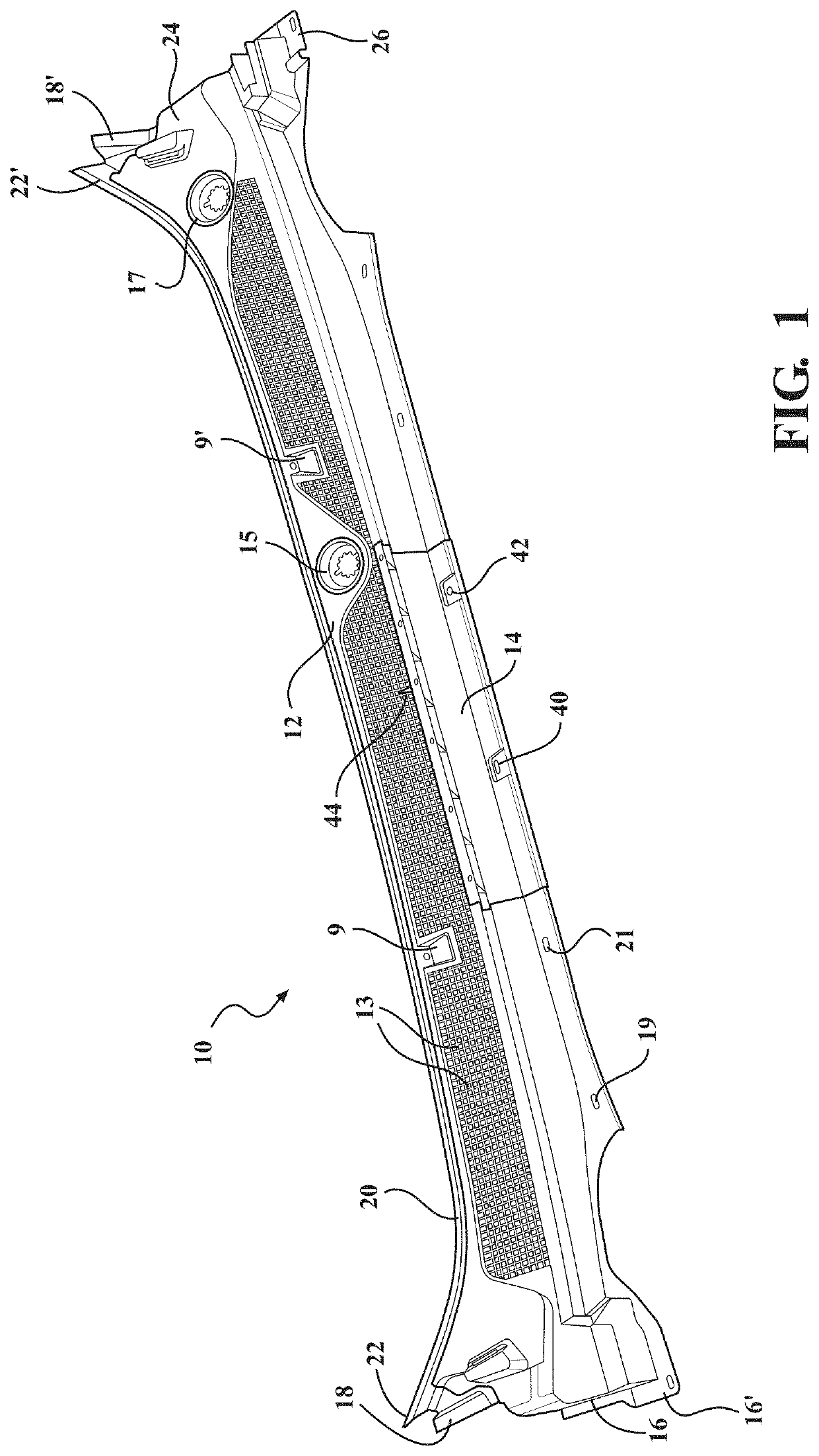

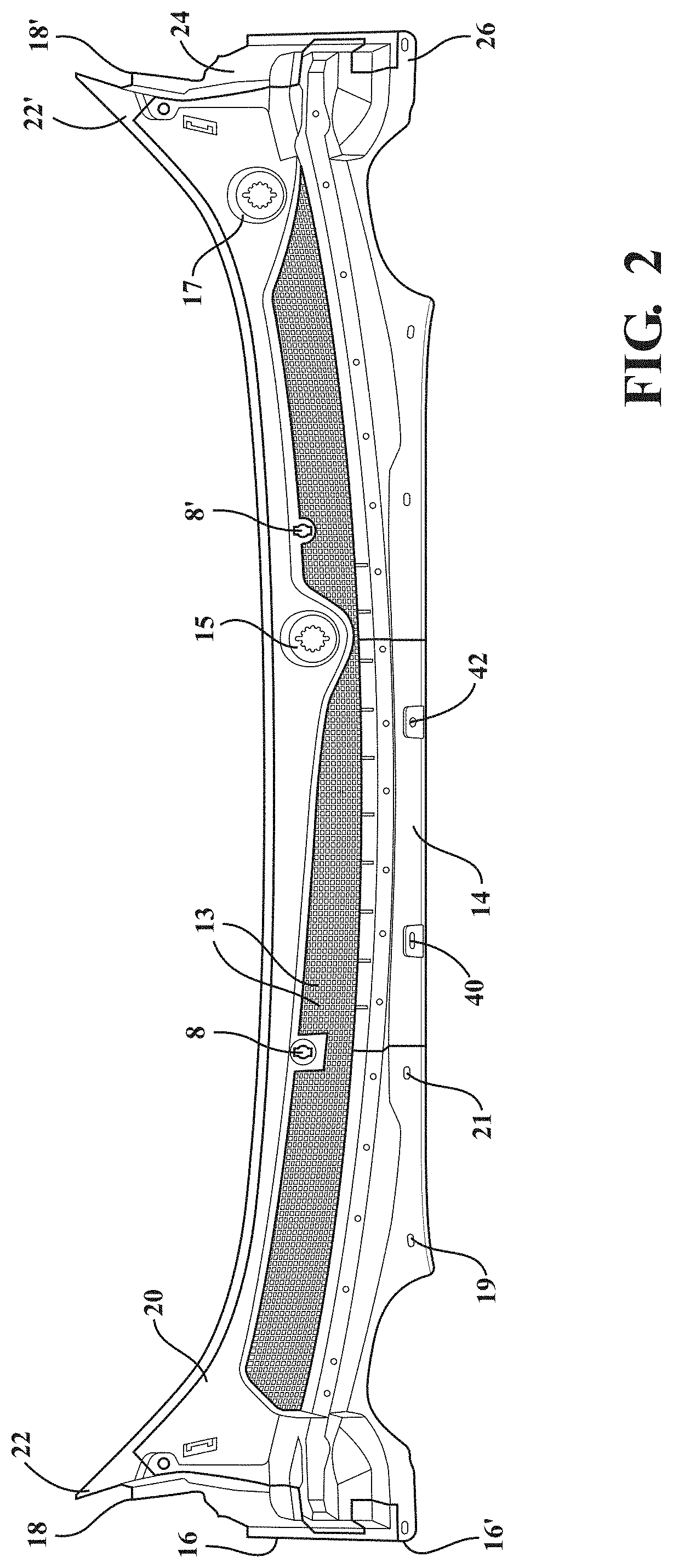

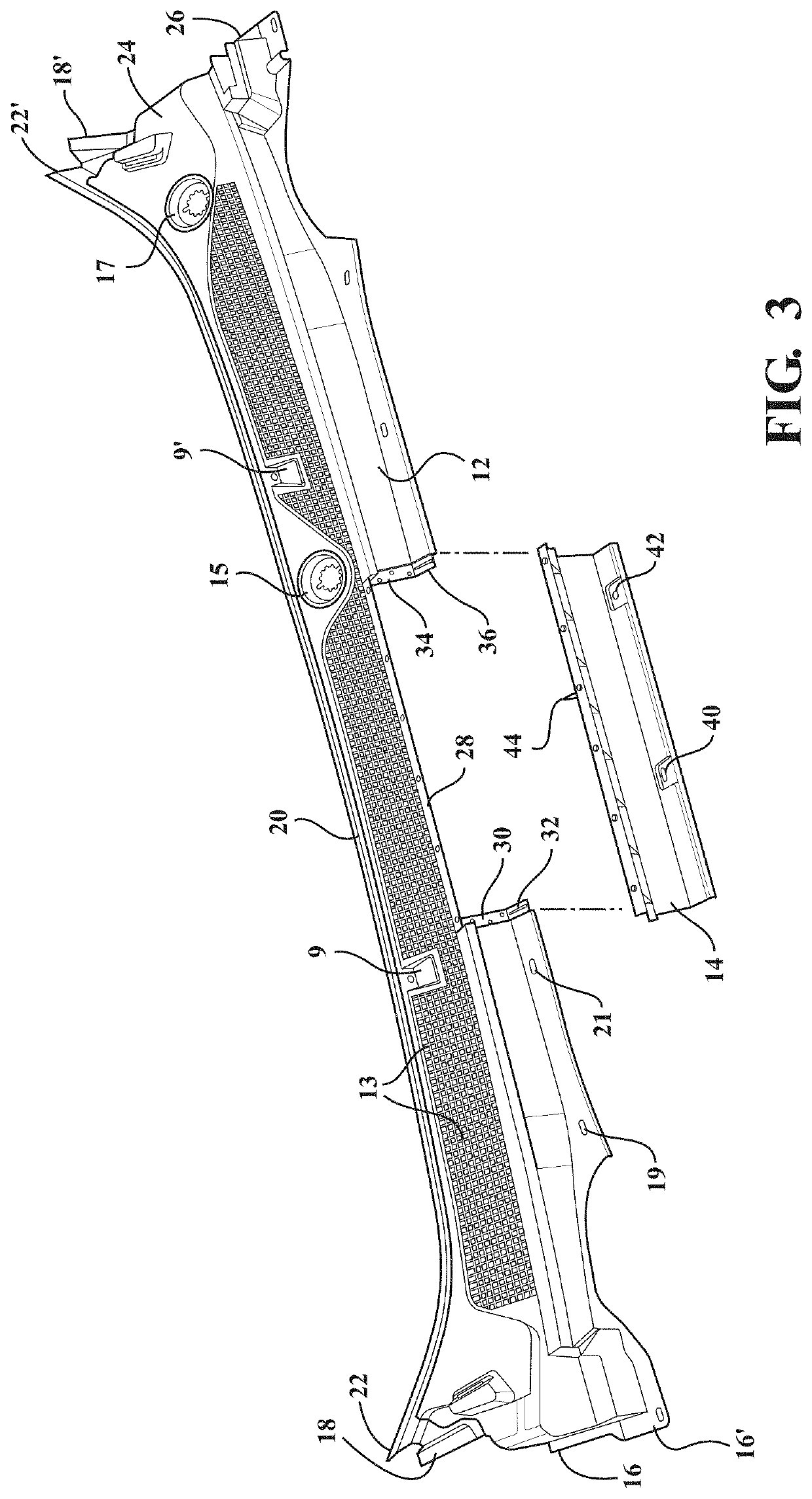

Method for producing a multi shot injection molded article incorporating a heat shield

A method and assembly for forming a multi-shot panel for a vehicle including the steps of providing a mold and forming therein a main body of the panel from a first rigid material, the step of forming the main body further including forming a multi-sided recess. The rigid material is transferred to a second reconfiguration of the mold for forming thereupon at least one second softer material. The panel is then transferred to a third reconfiguration of the mold for forming the heat deflecting shield. Alternative, a two shot injection molded panel can be removed from the mold and a previously formed heat deflecting shield can be attached along edges of the main body defining the multi-sided recess. In either variant, locking features are designed into the interface geometry between the heat deflecting shield and rigid main body.

Owner:U S FARATHANE LLC

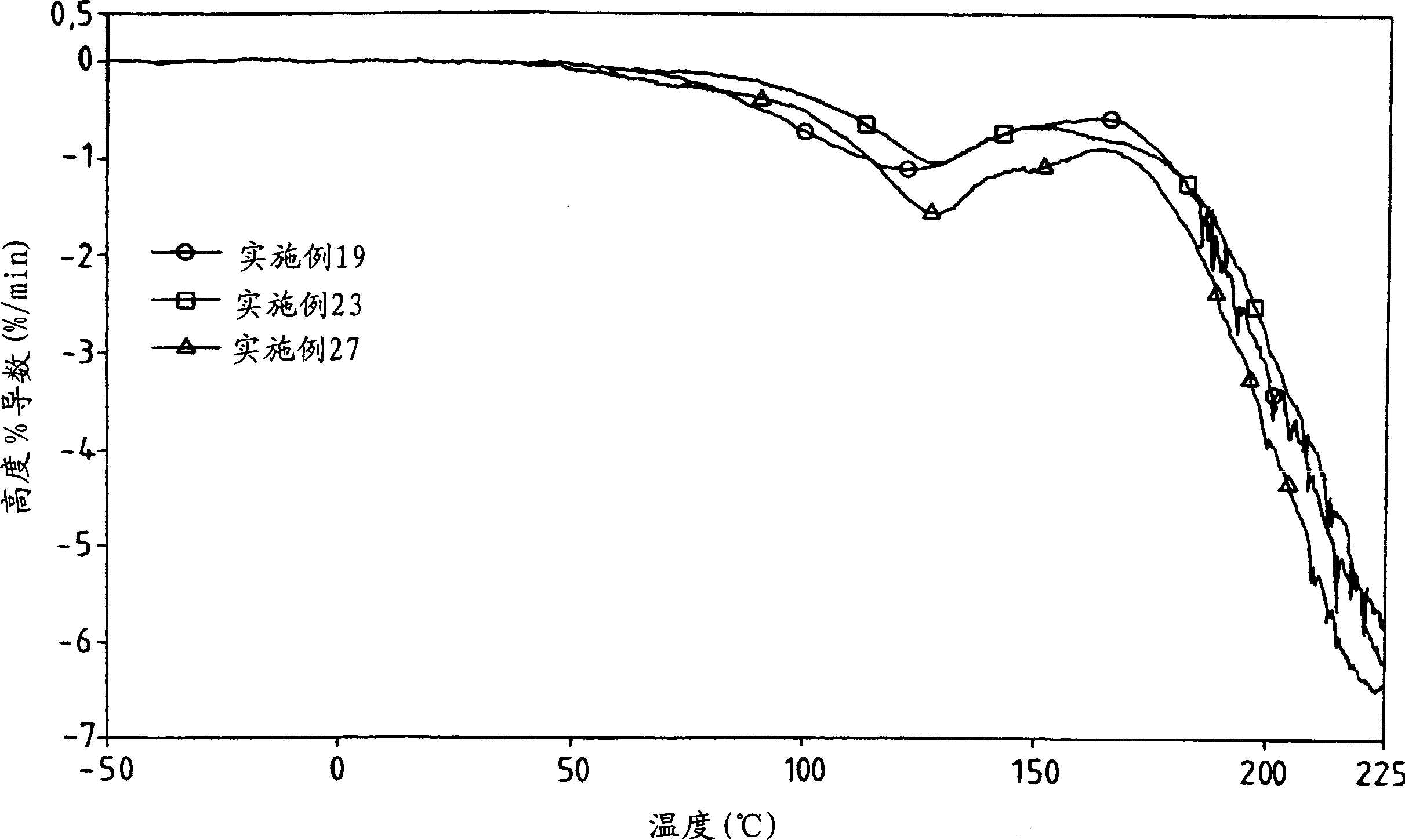

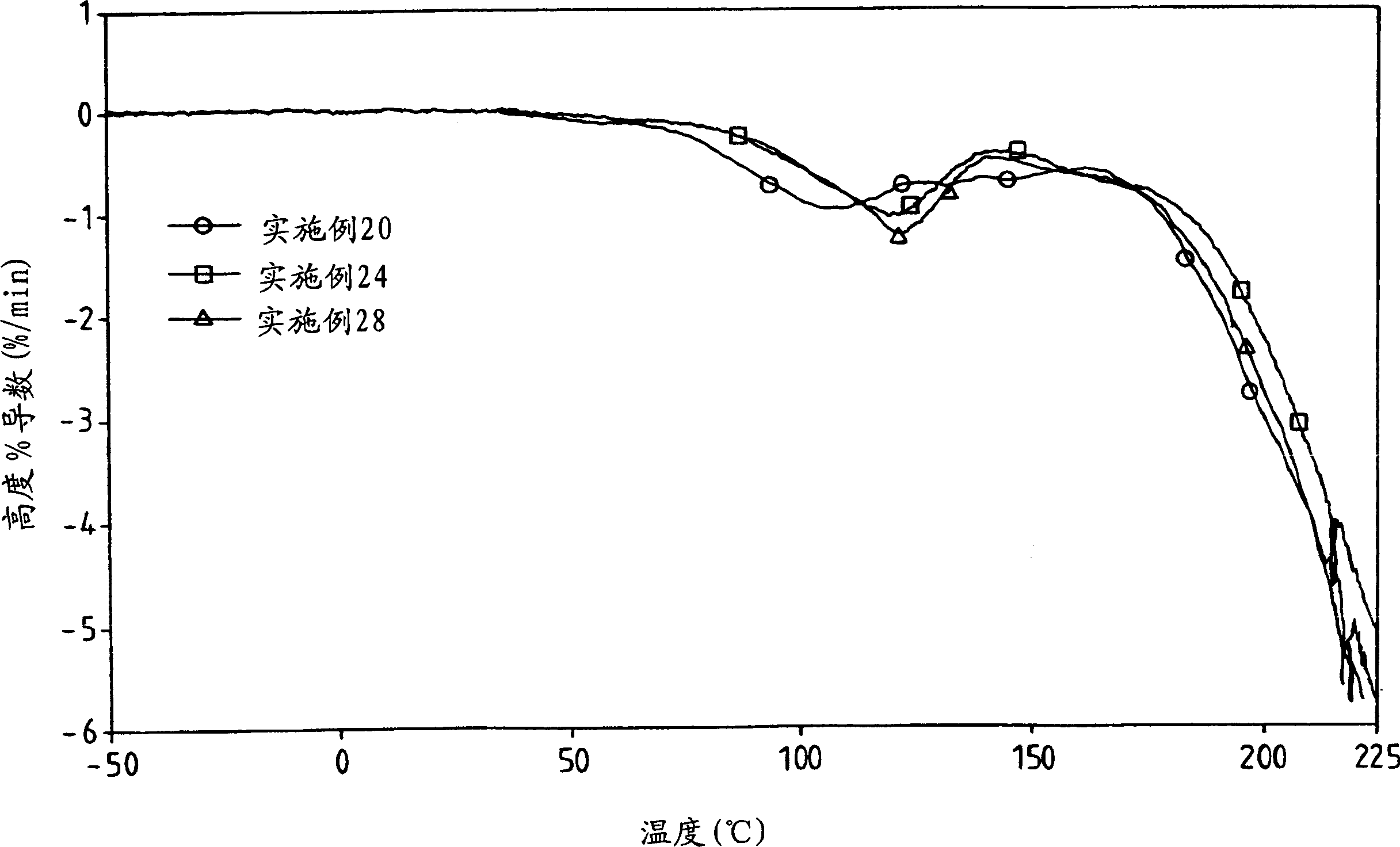

Standard sample used for detecting specific thermal deflection property and its preparation method

InactiveCN103207204BImprove accuracyHigh measurement accuracyPreparing sample for investigationMaterial thermal analysisIngotVacuum induction furnace

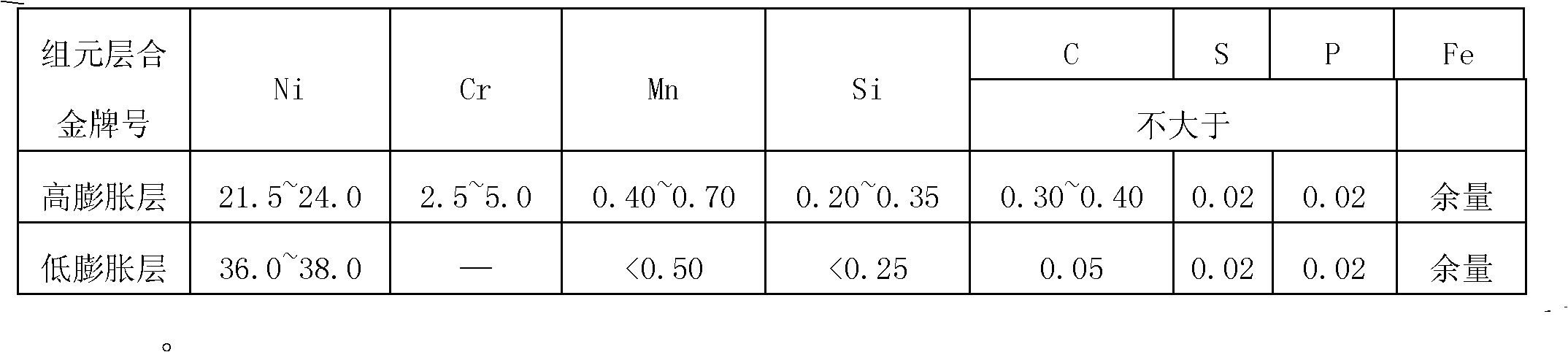

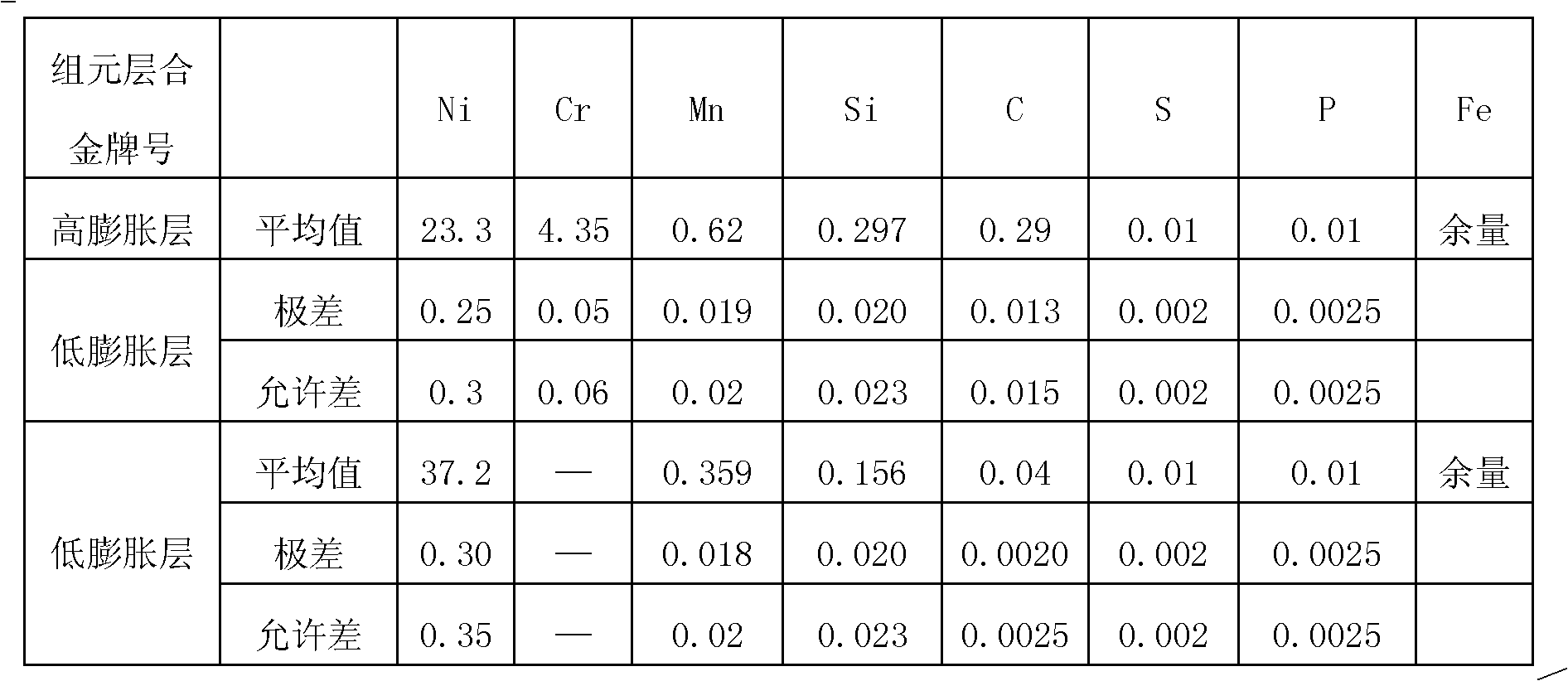

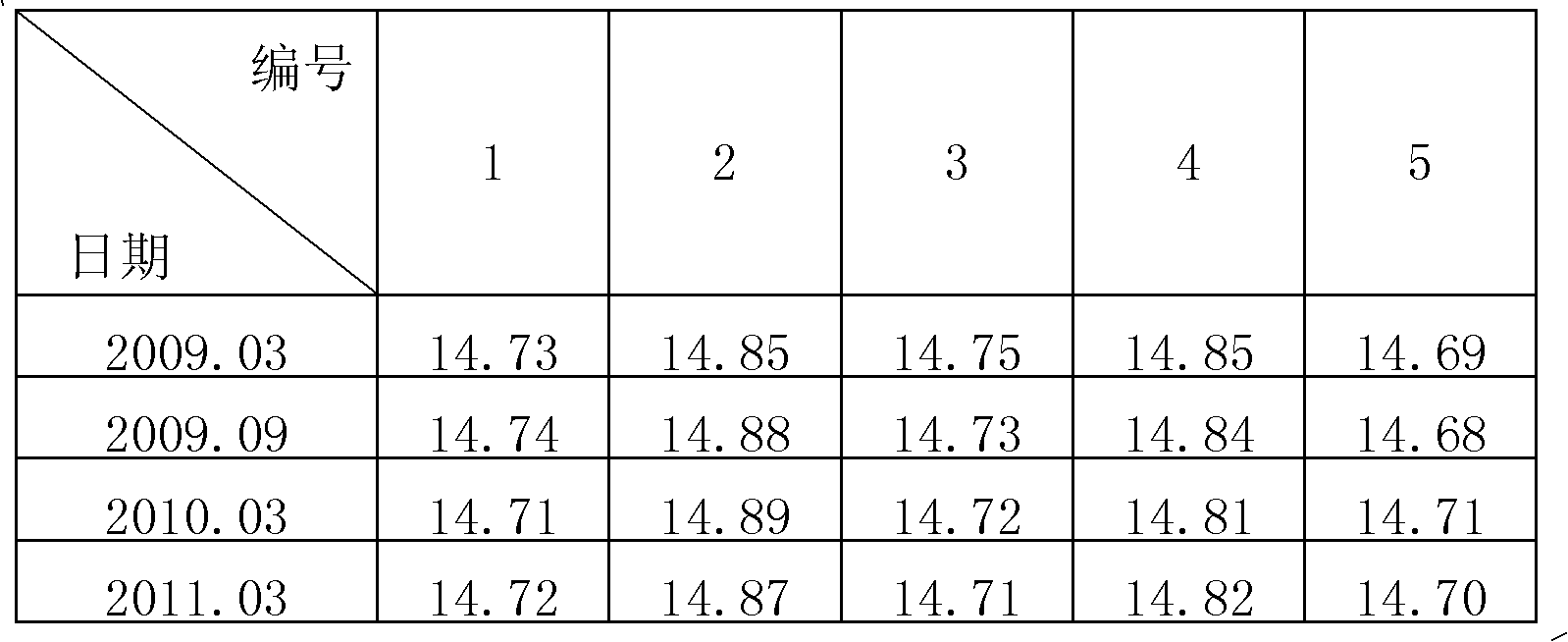

The invention relates to a standard sample used for detecting specific thermal deflection property and its preparation method. Selecting thermal bimetals as the materials, the standard sample comprises the following components by weight percent: a high expansion layer composed of 21.5-24.0 of Ni; 2.5-5.0 of Cr; 0.40-0.70 of Mn; 0.20-0.35 of Si; 0.30-0.40 of C; less than or equal to 0.02 of P; less than or equal to 0.02 of S; and a low expansion layer composed of 36.0-38.0 of Ni; less than 0.50 of Mn; less than 0.25 of Si; less than or equal to 0.05 of C; less than or equal to 0.02 of P; and less than or equal to 0.02 of S. The preparation method includes: employing a vacuum induction furnace process to smelt thermal bimetals, then casting them into an ingot, and conducting a homogeneity test; taking the central part of the ingot to perform forging and hot rolling into a bar of certain specification, then carrying out cold drawing on the bar to obtain a finished bar with certain diameter; taking a representative part from the finished bar along the rolling direction; performing finish machining to obtain the standard sample. The standard sample provided in the invention and a thermal bimetal detection device can be used together for determining the specific thermal deflection property of thermal bimetals, can effectively guarantee instrument calibration and data comparison, thus greatly improving the accuracy of evaluation test and measurement precision, and guaranteeing effective supervision of product quality.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Polyurethane foaming plastic with improved heat flexibility and production thereof

The RIM method is used to react organic polyisocyanate with an isocyanate-reactive mixture in which a large amount of bio-based polyol is present to produce rigid closed-cell polyurethane foam. Foam plastics produced using this method are characterized by improved heat sag and increased heat distortion temperature.

Owner:BAYER CORP

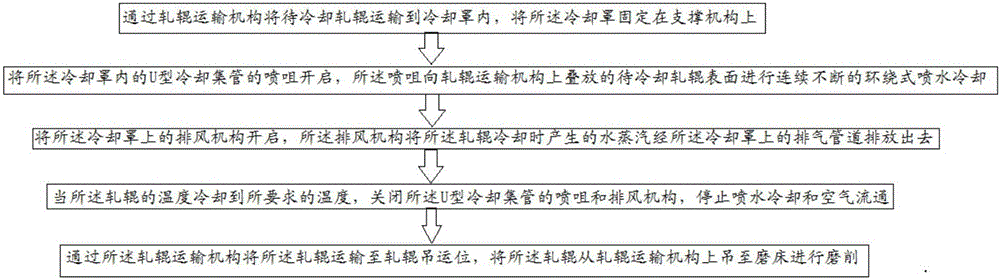

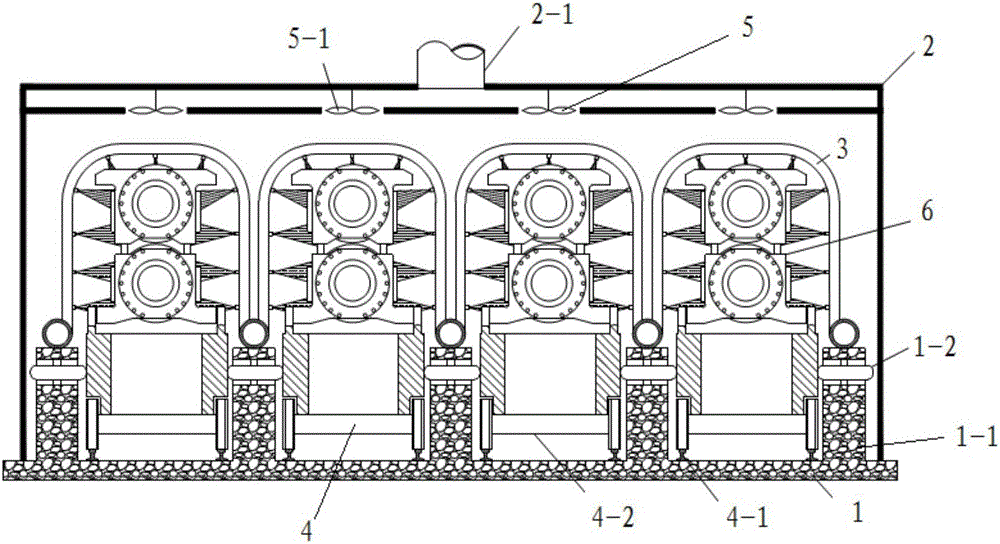

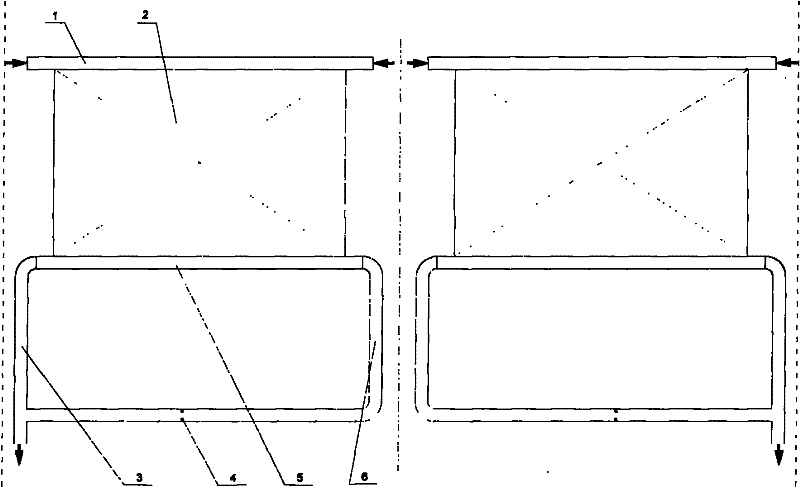

Roller cooling method and device

ActiveCN106040746ASpeed up coolingPrevent splashRollsMetal rolling arrangementsProcess systemsEngineering

The invention discloses a roller cooling method and device, and belongs to the technical field of hot rolling. The roller cooling device comprises a supporting mechanism, wherein a cooling cover is arranged on the supporting mechanism; an exhaust pipeline is arranged on the cooling cover; U-shaped cooling manifolds are arranged in the cooling cover; the U-shaped cooling manifolds are connected with the supporting mechanism; nozzles are arranged on the U-shaped cooling manifolds; roller conveying mechanisms are connected with the supporting mechanism and arranged under the U-shaped cooling manifolds; an exhaust mechanism is arranged on the cooling cover; and cooling fans are arranged above the U-shaped cooling manifolds respectively. The roller cooling method and device provided by the invention can increase the cooling velocity of a roller which is dismounted from a rolling mill, reduces influence of thermal deflection caused by uneven cooling of the roller, and thus improves the grinding accuracy of a working roller to obtain an original roller shape expected by a process system.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

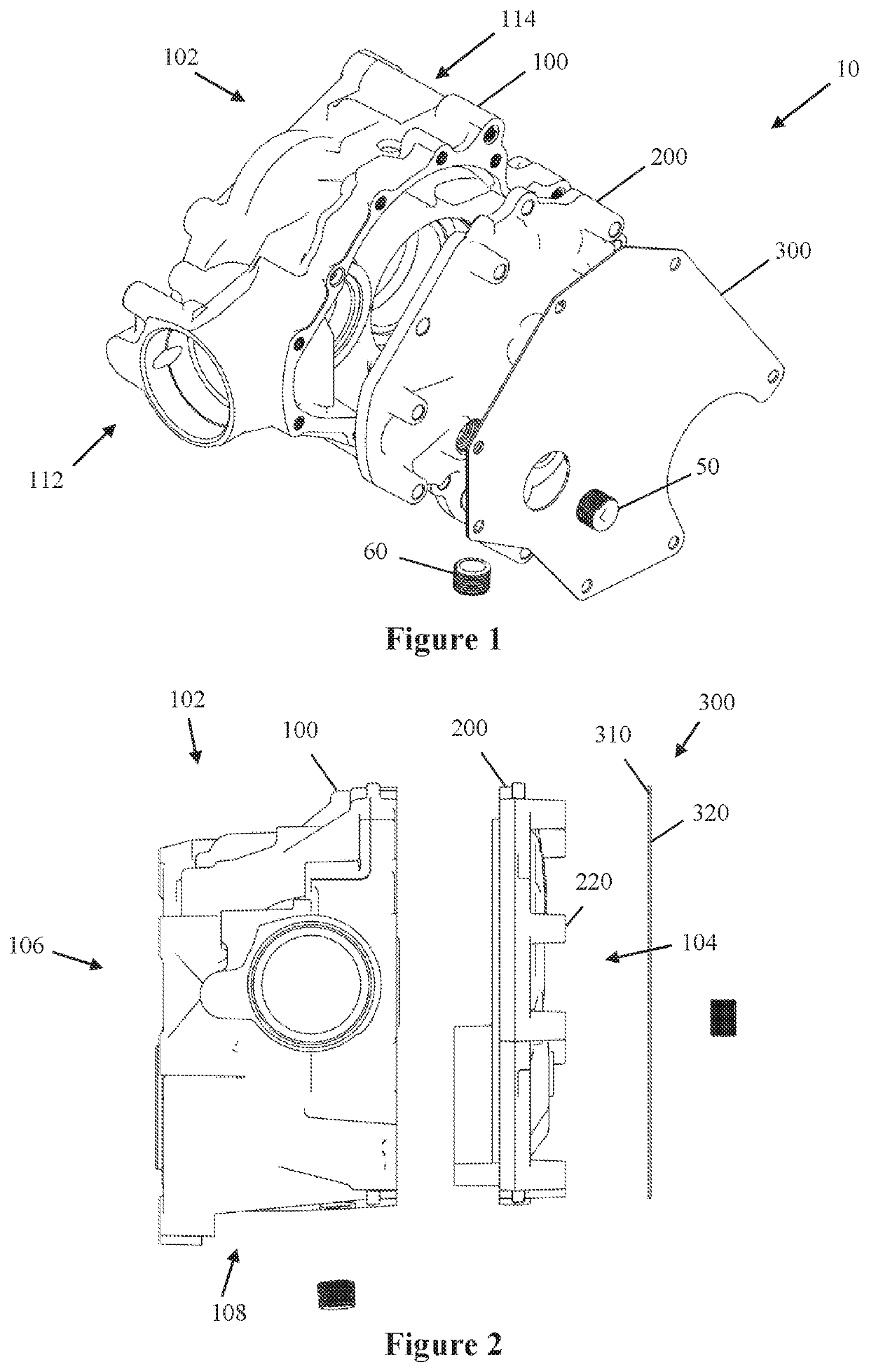

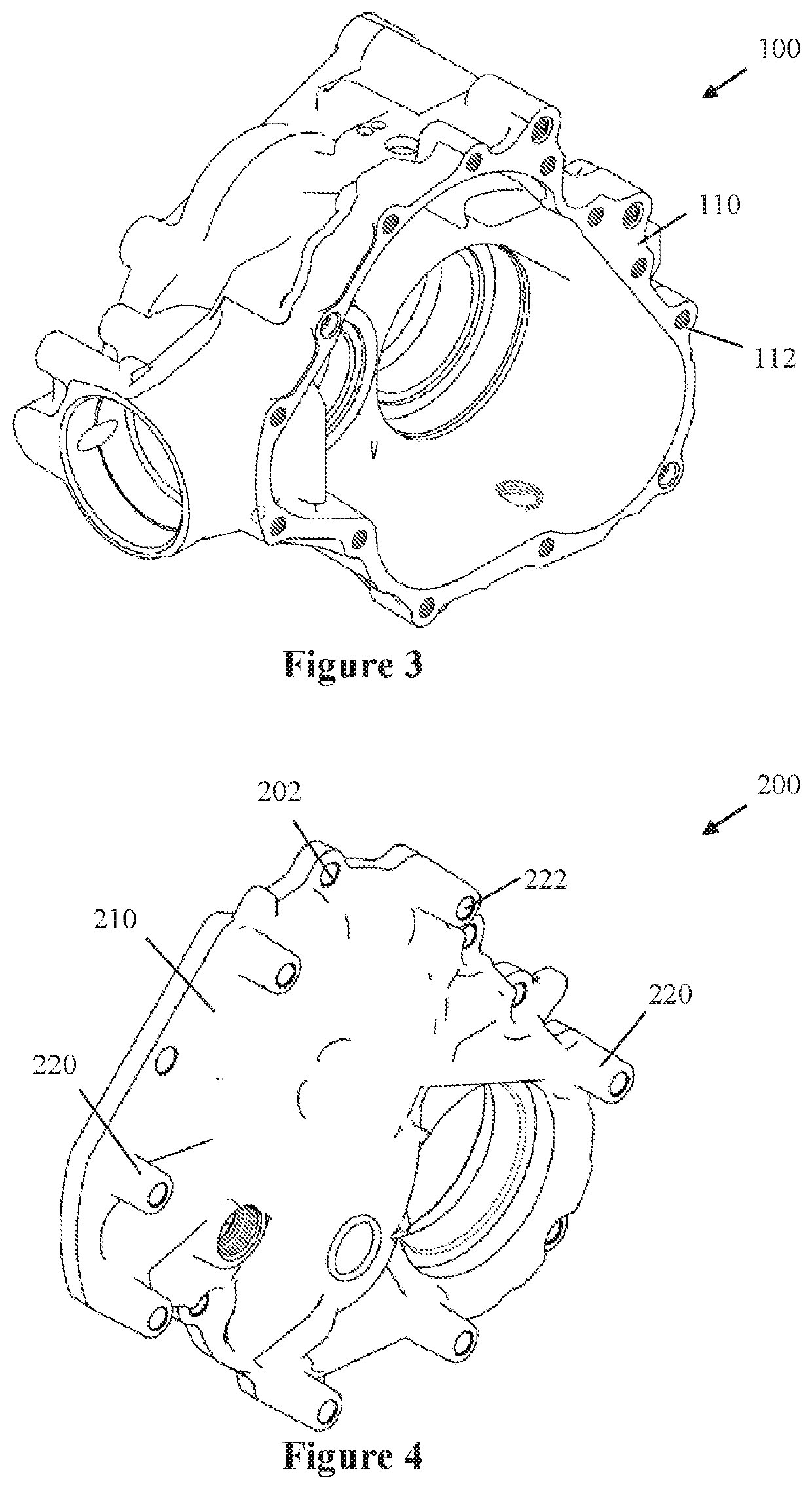

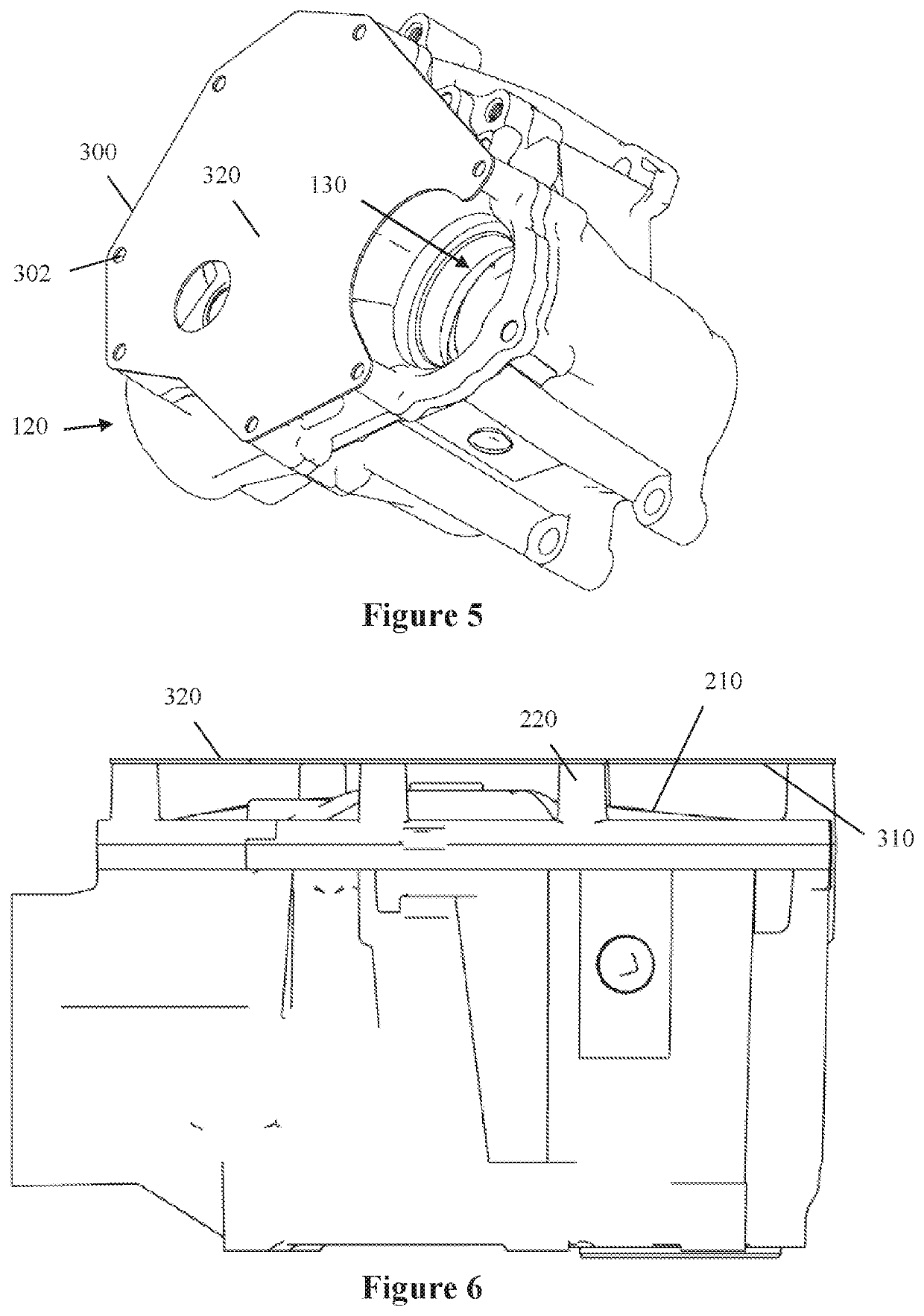

Thermal deflection apparatus

A Power Transfer Unit (PTU) has a housing with at least one side having an outer surface. One or more standoffs are provided at the at least one side of the housing and extend outward from the outer surface of the housing. A thermal deflector formed as a flat plate is attached to the standoffs at a predetermined distance from the outer surface of the housing. The flat plate deflects heat from nearby components, such as the catalytic converter and / or exhaust pipe, away from the PTU.

Owner:RB DISTRIBUTION INC A PENNSYLVANIA CORP

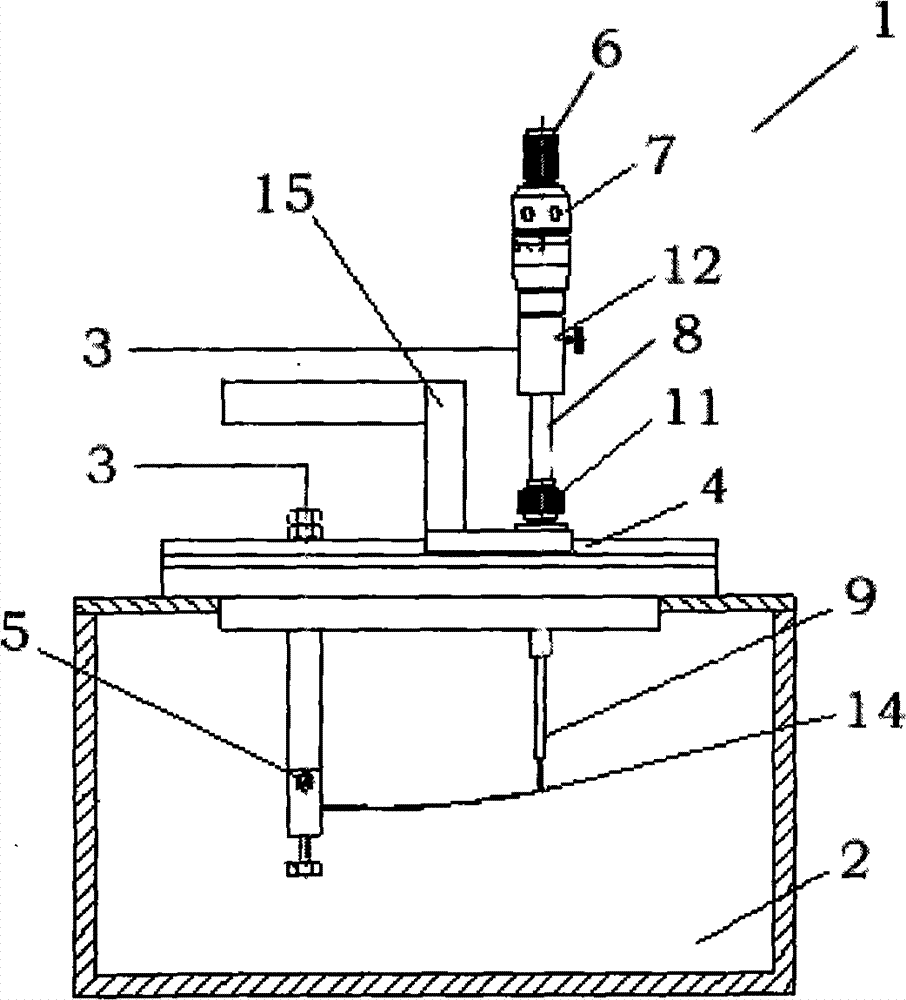

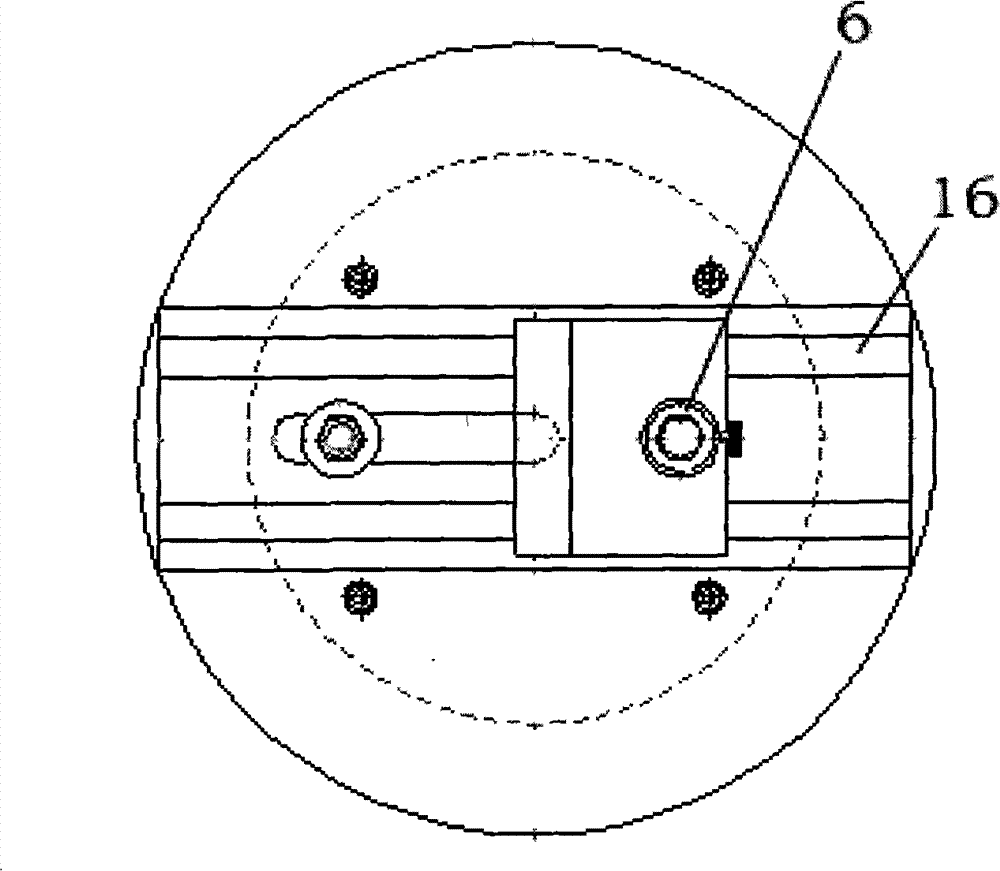

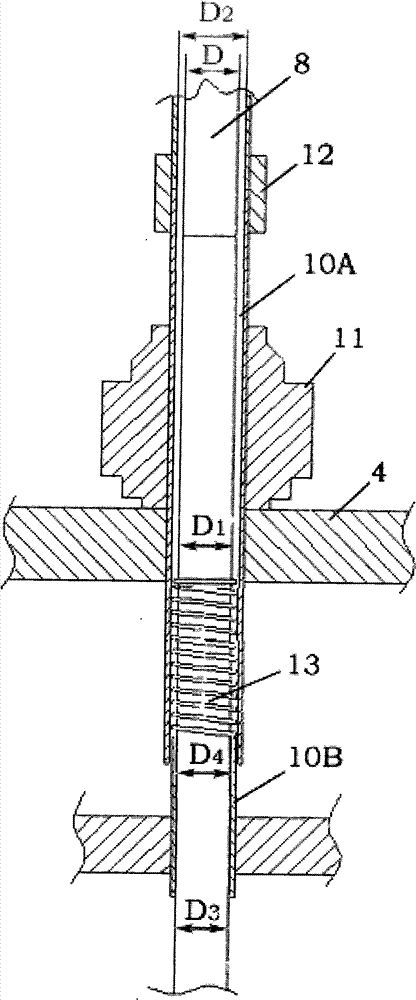

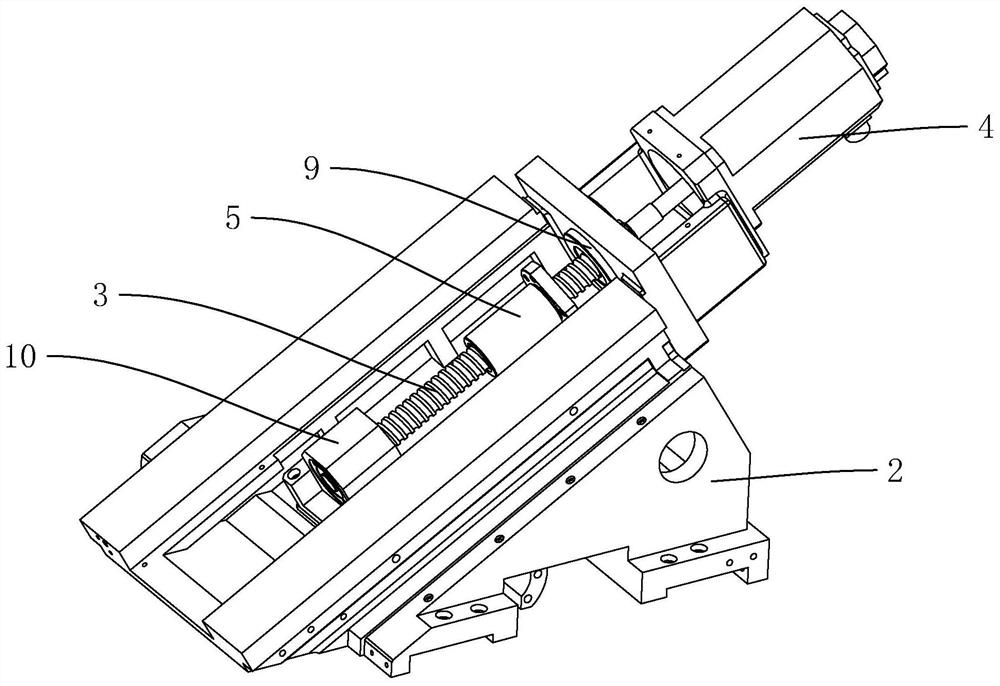

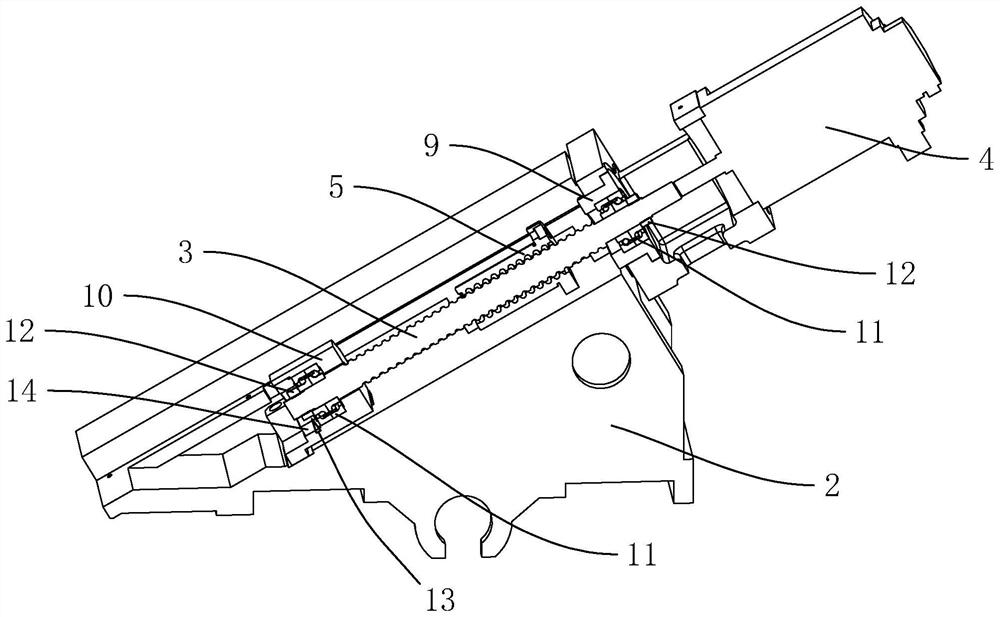

Device and method for detecting bimetallic thermo-sensitive property

InactiveCN101839872BMaterial thermal analysisMechanical solid deformation measurementsTemperature controlMicrometer

The invention discloses a device and a method for detecting bimetallic thermo-sensitive property. The device comprises a torsion measuring device, a temperature control oil tank arranged below the torsion measuring device and an electronic contact indicator connected with the torsion measuring device, wherein the torsion measuring device comprises a bracket platform, a sample holding rod (bracket) arranged on the bracket platform and submerged in the temperature control oil tank and a measuring pen capable of moving on the bracket platform; and the measuring pen comprises a micrometer head and a measuring rod which is connected with the micrometer head by a connecting block and submerged in the temperature control oil tank and contacts a sample. According to the device and the method for detecting the bimetallic thermo-sensitive property, the 'specific thermal deflection value' of a thermal bimetallic sample at the temperature of between 20 and 300 DEG C can be measured, and the maximal measurement deviation does not exceed + / - 1.0 percent, which meets precision requirements of national standard GB / T8364-1987 'Test Method for Specific Thermal Deflection of thermostat Metals'.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Arrangement method of tower-type boiler high-temperature reheater container system

The invention relates to an arrangement method of a tower-type boiler high-temperature reheater container system, which can reduce the thermal deflection among the screens of reheater effectively according to the operation characteristic of the tower-type boilers. The arrangement method comprises: arranging a resistance device in a lead-out steam guide pipe, close to the center of the boiler, of the tower-type boiler reheater outlet container, the distribution of inter-screen flow is changed by changing the difference between the lead-out flows on two sides of the reheater system outlet container so as to be matched with the distribution of inter-screen heat release difference on a smoke side to reduce inter-screen thermal deflection.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

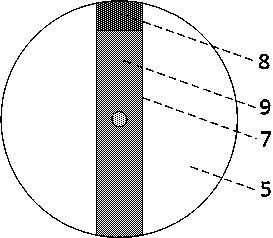

Optical fiber cantilever beam temperature sensor based on metal coating

PendingCN108195486ASimple structureReduce volumeThermometers using physical/chemical changesMetal coatingPhotovoltaic detectors

The invention discloses an optical fiber cantilever beam temperature sensor based on metal coating, which belongs to the technical field of optical fiber sensors. The optical fiber cantilever beam temperature sensor based on metal coating comprises a laser source, a photodetector, an optical fiber circulator, an optical fiber, a fixed supporting end, an optical fiber cantilever beam, a metal film,a fabry-perot cavity and an optical fiber end surface, wherein the optical fiber cantilever beam is located on the optical fiber end surface and is connected with the optical fiber end surface through the fixed supporting end at the edge of the optical fiber end surface; the optical fiber cantilever beam is parallel with the optical fiber end surface to form the fabry-perot cavity, and an opticalfiber integration structure is formed; the outer surface of the optical fiber cantilever beam is coated with the metal film, and a two-film structure is formed; the laser source is connected with theport A of the optical fiber circulator; the optical fiber cantilever beam integration structure is connected with the port B of the optical fiber circulator; and the photodetector is connected with the port C of the optical fiber circulator. The metal film is expanded and contracted under temperature influences and two-film thermal deflection effects are generated with the optical fiber cantilever beam, the optical fiber cantilever beam generates thermal deflection, the length of the fabry-perot cavity is caused to change, light signals emitted by the laser source are reflected in the fabry-perot cavity, and under fabry-perot cavity length modulation, the reflected light signals are detected, and thus, the temperature can be detected.

Owner:CHINA JILIANG UNIV

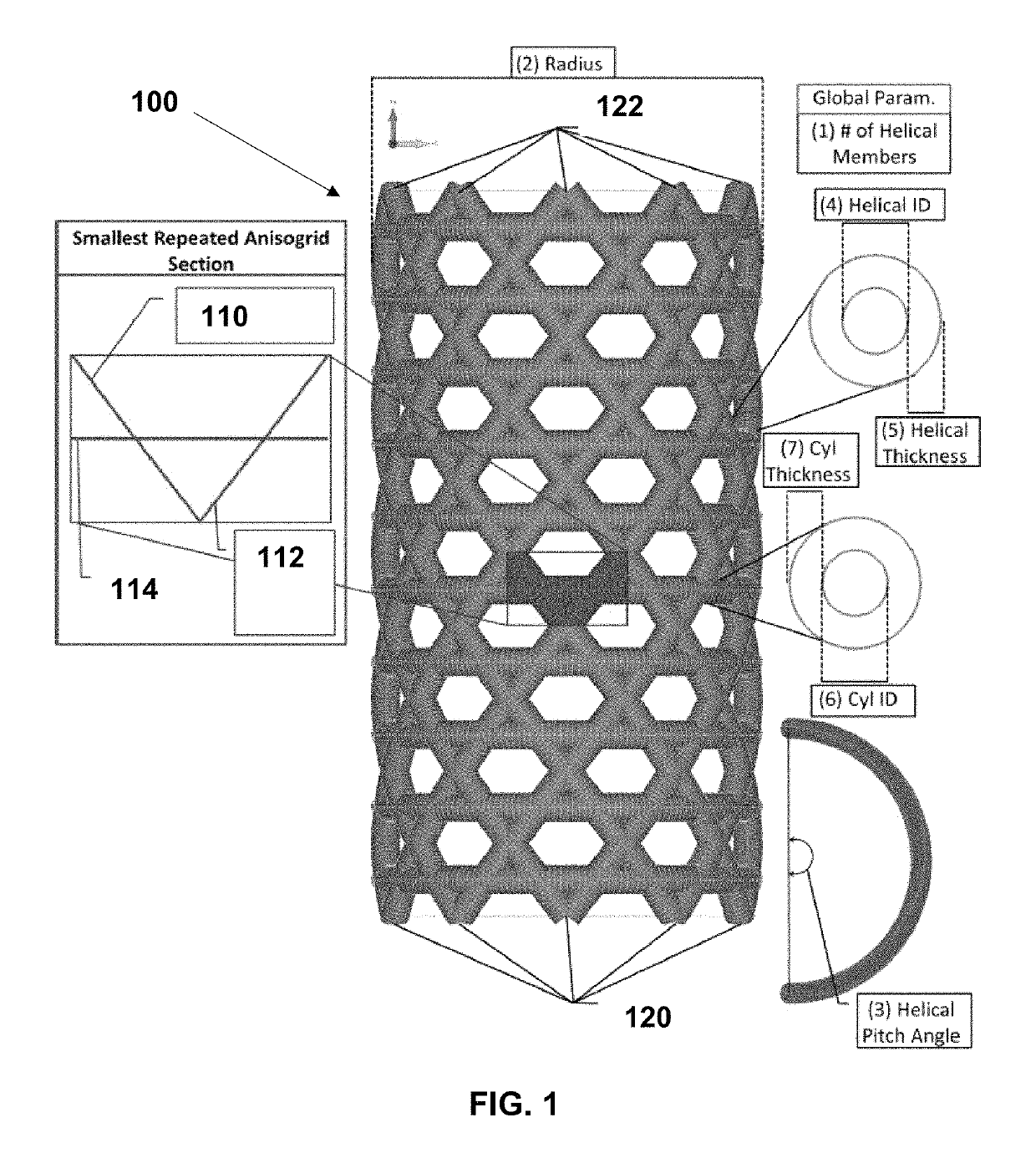

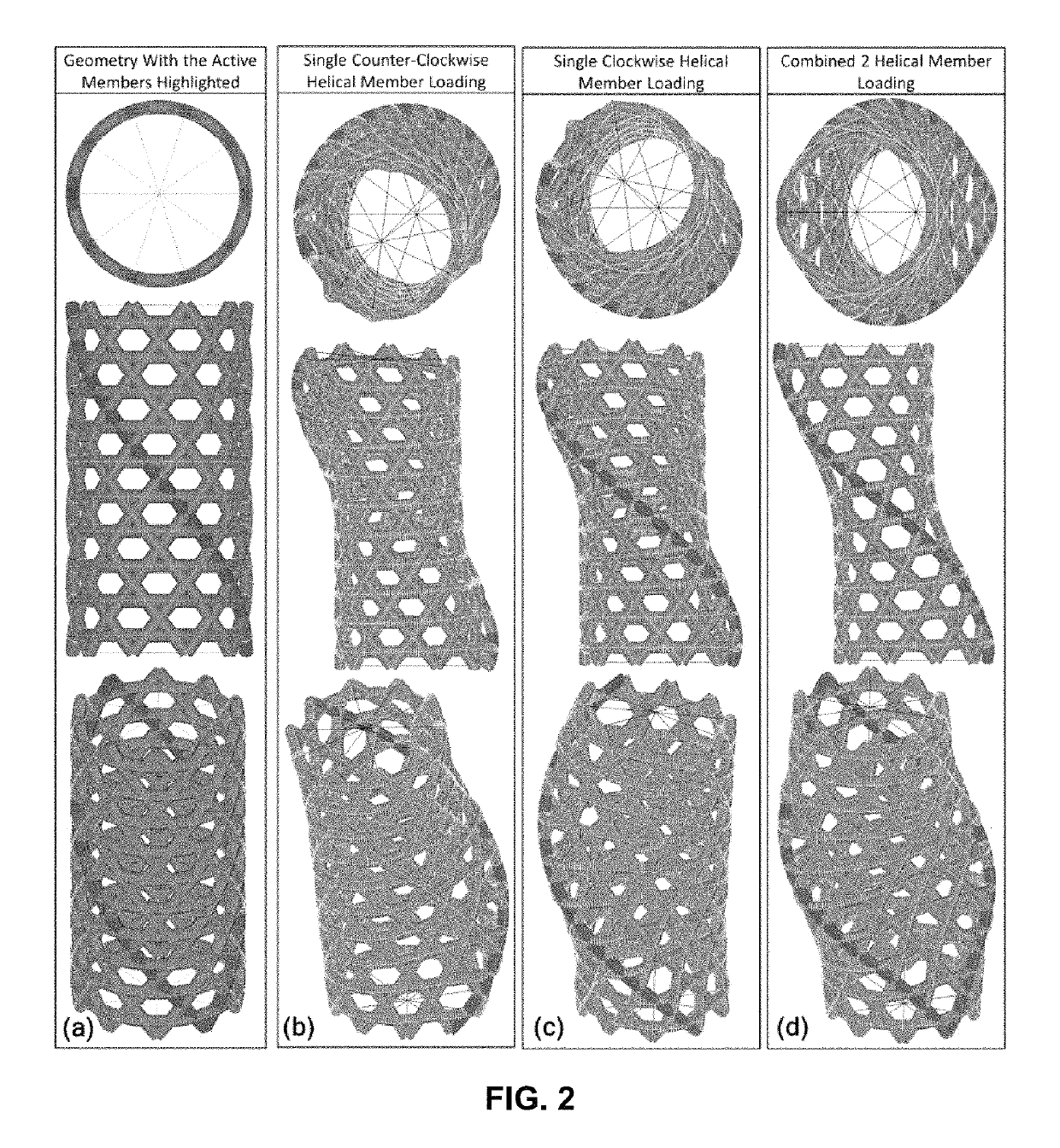

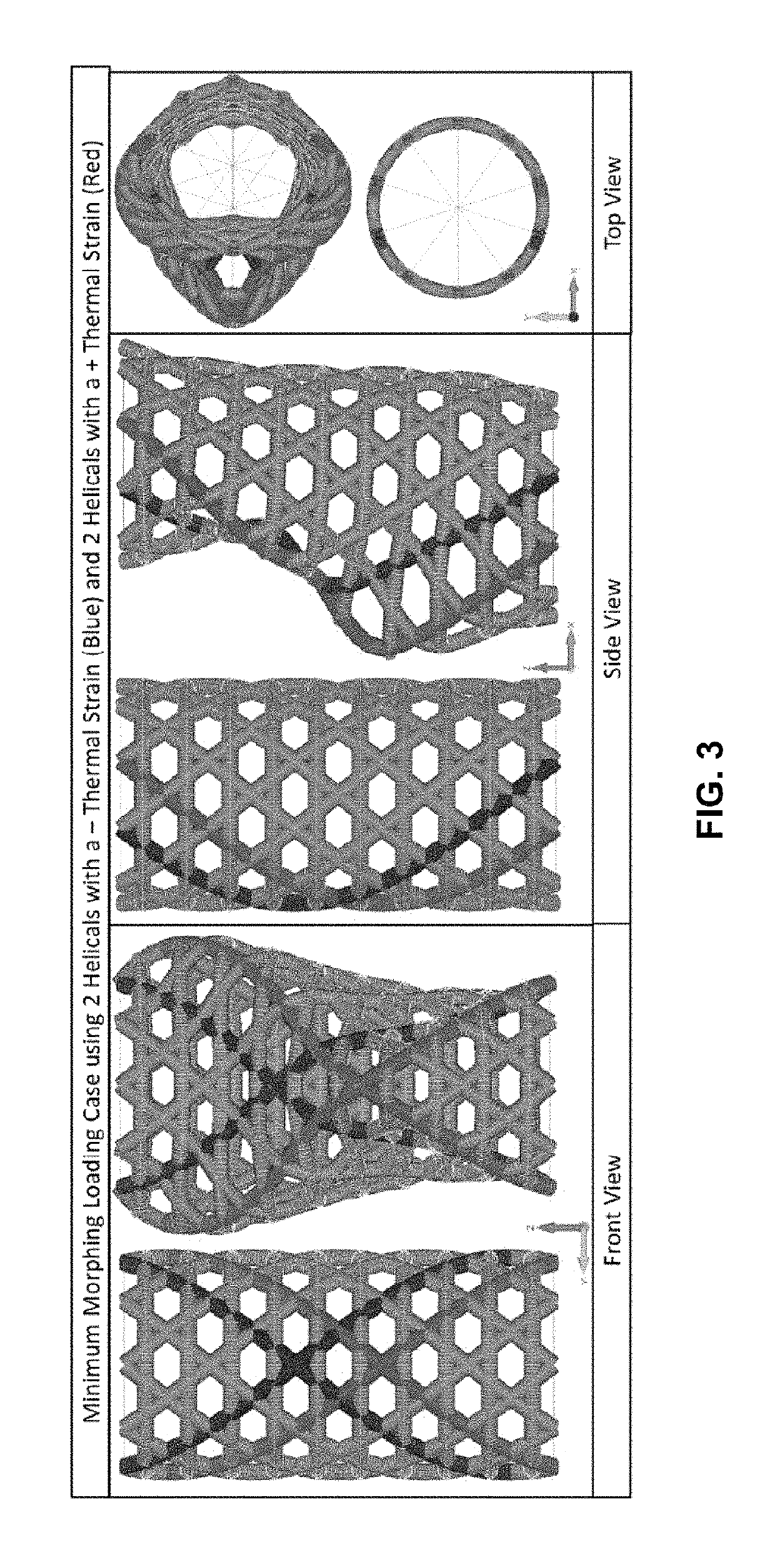

Thermal morphing anisogrid structure

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com