Standard sample used for detecting specific thermal deflection property and its preparation method

A standard sample and specific bending technology, which is applied in the field of standard samples for testing specific bending performance and its preparation, can solve the problems of instrument calibration, data comparison, difficulty in ensuring measurement accuracy, influence of normal operation of testing equipment, and equipment that cannot be tested Calibration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

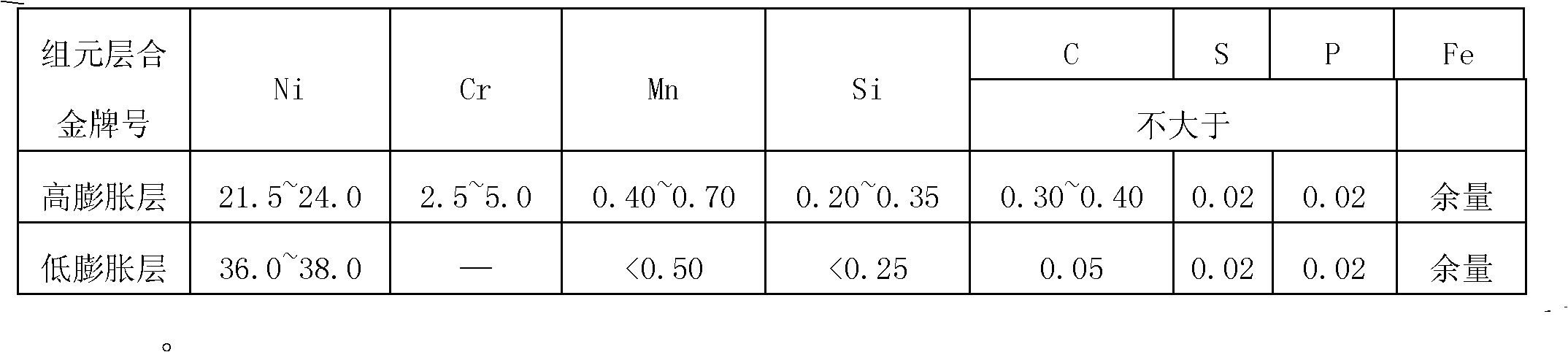

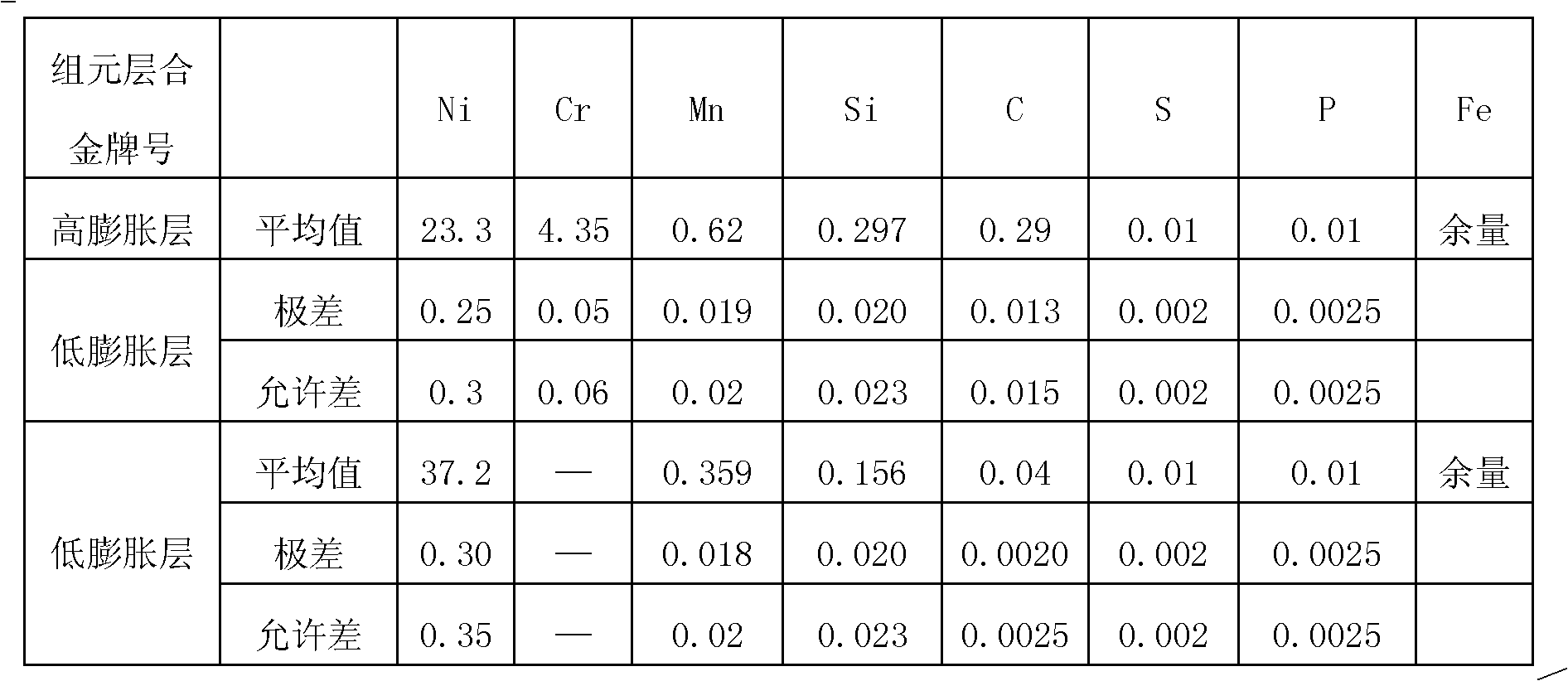

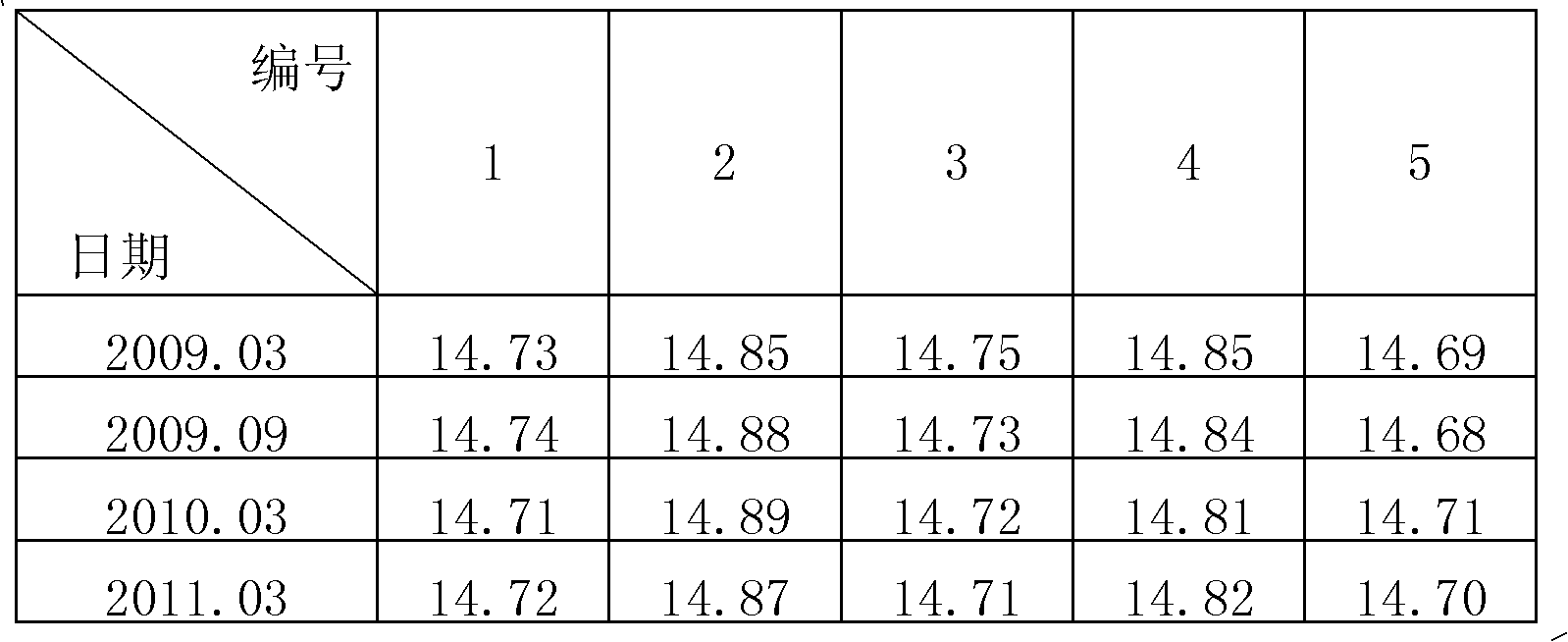

[0070] The materials with the following chemical composition are smelted by vacuum induction furnace technology to smelt hot bimetal, and cast into steel ingots after smelting. The chemical composition of the high expansion layer is Ni: 23.3; Cr: 4.35; Mn: 0.62; Si: 0.297; C: 0.316; S: 0.013; Impurities within; the chemical composition of the low expansion layer is Ni: 37.2; Mn: 0.359; Si: 0.156; C: 0.036; S: 0.013; P: 0.016; impurities inside.

[0071] A homogeneity test was performed on the ingot. The billet is heated to 1100-1200°C. After the billet is heated, the billet is forged when it reaches the forging temperature. The billet specification is φ50mm*200~300mm round bar.

[0072] The hot-rolled slab surface is not allowed to have defects with a depth exceeding 1mm (such as cracks, scars, severely oxidized skin, dents, warped skin, etc.), and the slab is required to be straight.

[0073] The billets are soaked and released from the furnace. After descaling, they...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com