Polyurethane foaming plastic with improved heat flexibility and production thereof

A foamed plastics, polyurethane technology, applied in the field of polyurethane foamed plastics, can solve problems such as not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0143] An isocyanate-reactive composition was prepared consisting of the materials listed in Table 1, the amounts of which are expressed in parts by weight. These isocyanate reactive components were then reacted with ISOCYANATE B in an amount such that the isocyanate index was 110 using Cannon HE-120 RIM equipment. The reaction mixture was added to an aluminum plate mold heated at 60-77°C. The properties of the moldings are shown in Table 2.

[0144] Material

[0145] determination

[0146] These examples illustrate the simple addition, without modification, of blown soybean oil to a polyurethane-making reaction mixture treated by the RIM process, which confers no appreciable benefit on the physical properties of the polyurethane foam, However, it does not adversely affect the physical properties of the foam. Since the system is more expensive by excluding the more expensive materials in the isocyanate-reactive components, there is no savings in the cost...

Embodiment 10-18

[0148] An isocyanate-reactive composition was prepared consisting of the materials listed in Table 3, the amounts of which are expressed in parts by weight. Then, using Cannon HE-120 RIM equipment, these isocyanate-reactive components were reacted with ISOCYANATE B, and the amount of ISOCYANATE B was used to make the isocyanate index 110. The reaction mixture was added to an aluminum plate mold. The properties of the moldings are shown in Table 4.

[0149] Material

[0150] determination

[0151] These examples illustrate systems employing varying amounts of blown soybean oil to replace a portion of the more expensive polyols in the polyurethane-making reaction mixture. As can be seen from these tables, the physical properties of the polyurethane foam are not adversely affected when blown soybean oil is substituted for up to about 30% by weight of the polyol. Since there is no detrimental effect on the physical properties of the foam when an inexpensive ...

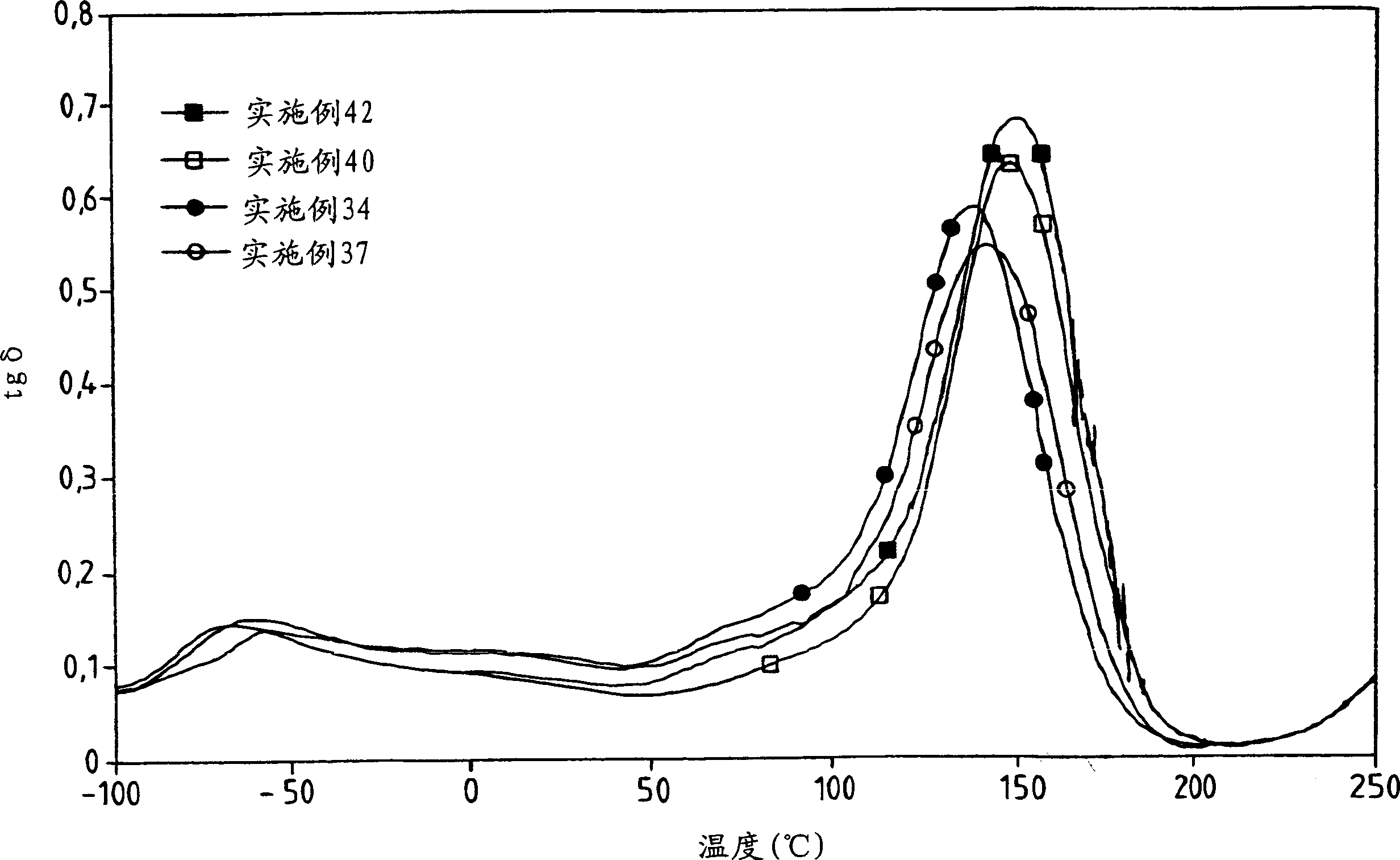

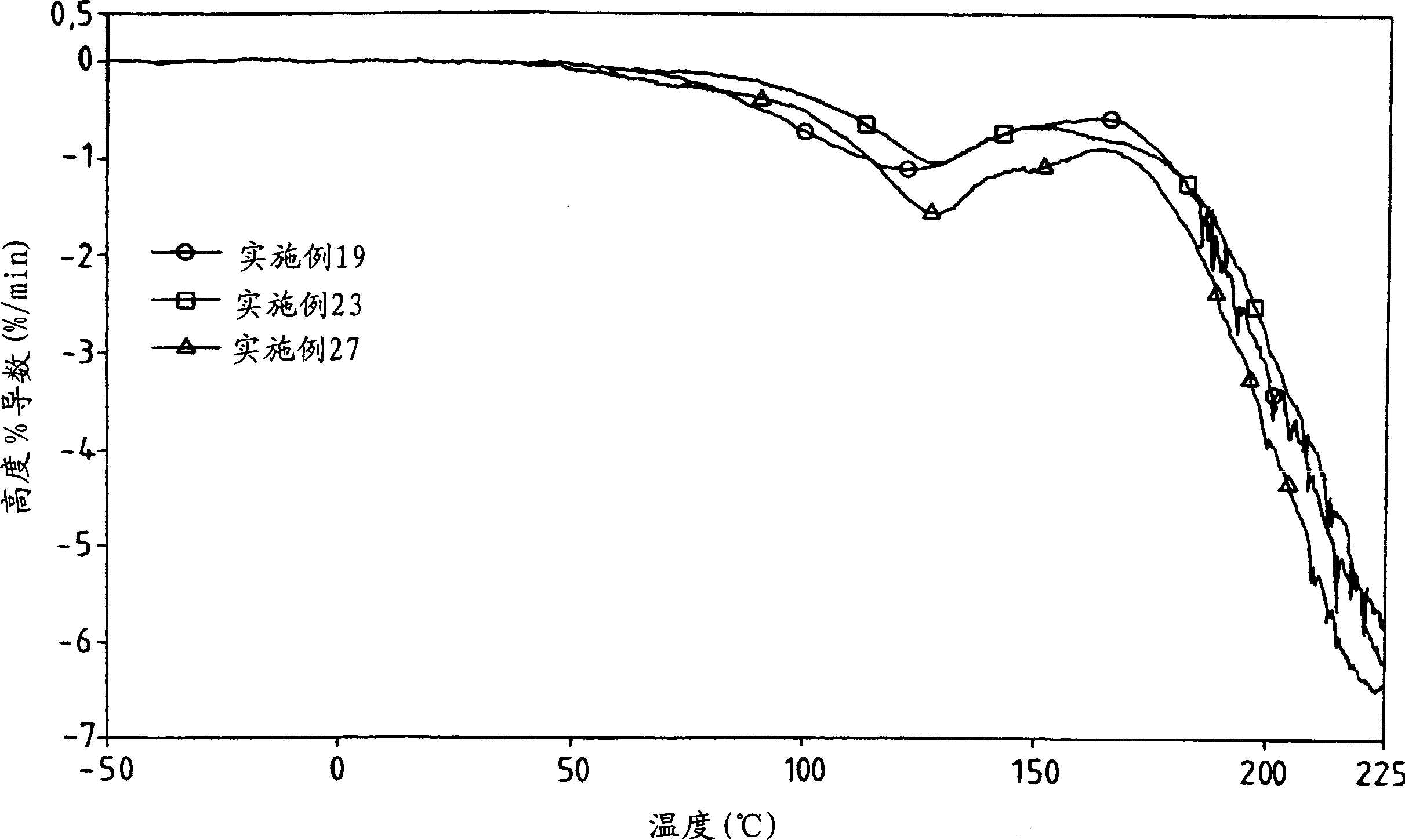

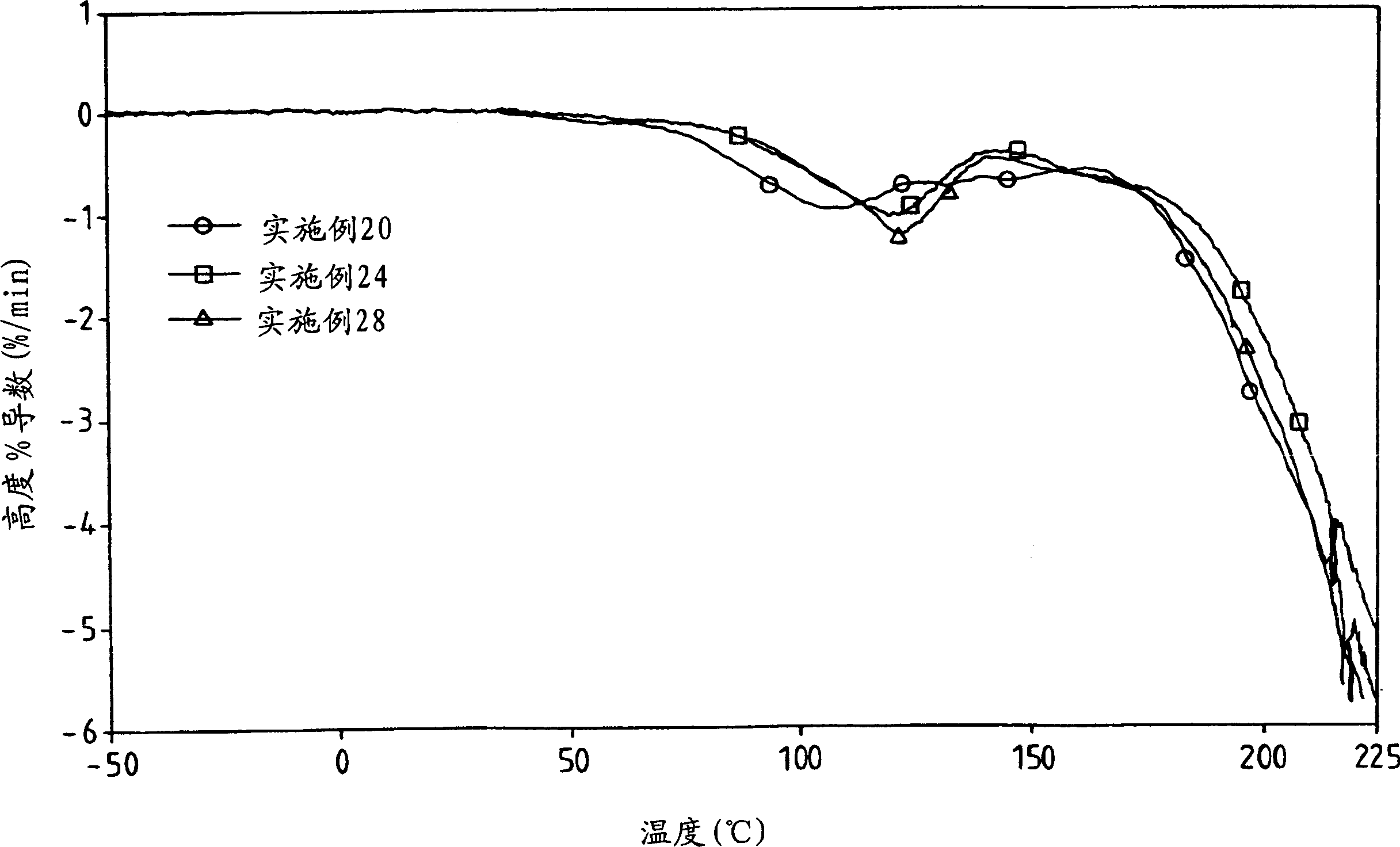

Embodiment 19-30

[0153] An isocyanate-reactive composition was prepared consisting of the materials listed in Table 5, the amounts of which are expressed in parts by weight. Then use Cannon HE-120 RIM equipment to make these isocyanate-reactive components react with ISOCYANATE A. The amount of ISOCYANATE A makes the isocyanate index 110. The reaction mixture was added to an aluminum plate mold. The properties of the moldings are shown in Table 6.

[0154] Material

PD

PE

SF

PU

CB

PA

LA

CA

BA

Example 19

55

45

3

6

0.2

--

3

4

0.7

Example 20

55

45

3

6

0.2

--

3

4

0.7

Example 21

55

45

3

6

0.2

--

3

4

0.7

Example 22

55

45

3

6

0.2

--

3

4

0.7

Example 23

55

33

3

6

0.2

12

3

4

0.7

Example 24

55 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com