Apparatus and method for defect detection of steel structure on the basis of eddy-current heating deflection spectroscopy

A defect detection and eddy current heating technology, applied in optical testing flaws/defects, color/spectral characteristic measurement, phase influence characteristic measurement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

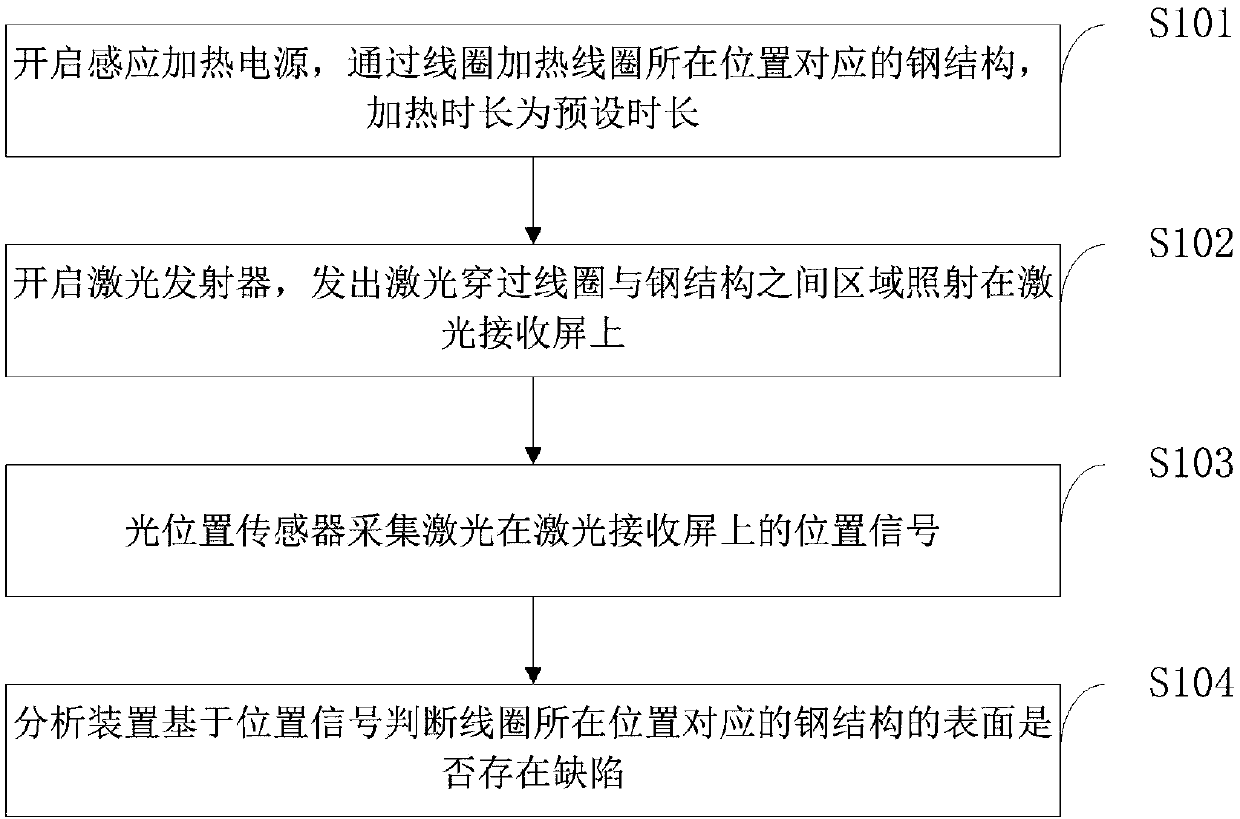

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

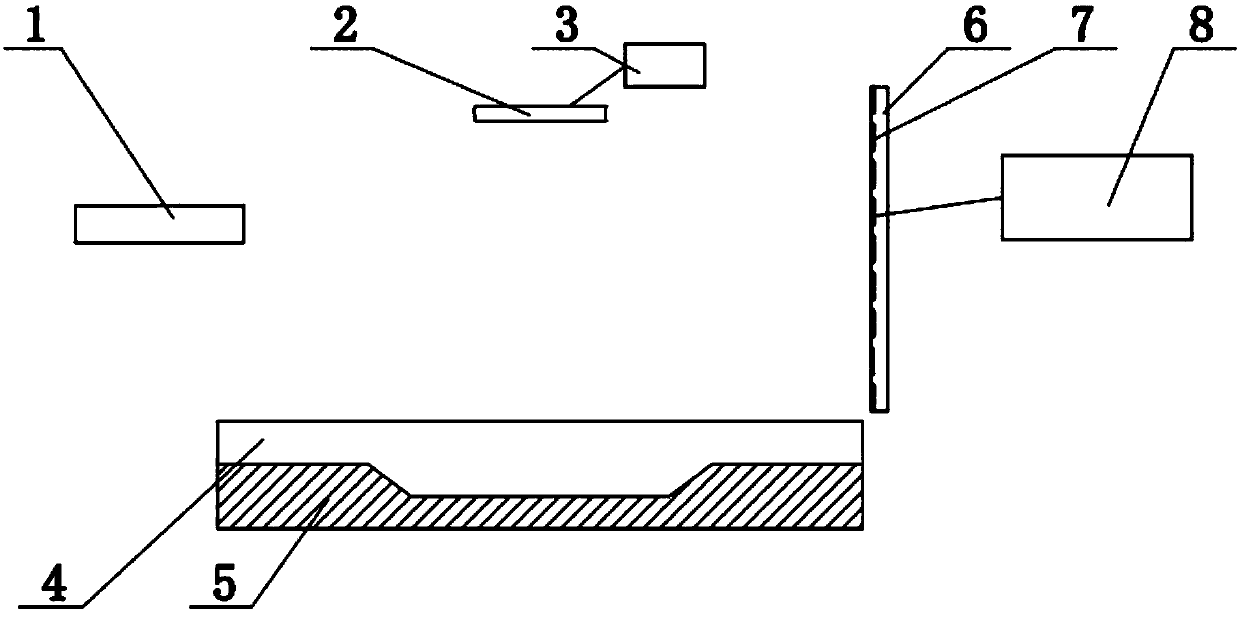

[0040] like figure 1 As shown, it is a structural schematic diagram of a steel structure 5 defect detection device based on eddy current heating deflection spectrum disclosed in the present invention, including an induction heating power supply 3, a coil 2, a laser transmitter 1, a laser receiving screen 6, an optical position sensor 7 and Analysis device 8, wherein:

[0041] The induction heating power supply 3 is connected to the coil 2;

[0042] The coil 2 is arranged at a preset distance from the surface of the protective layer 4 of the steel structure 5;

[0043] The laser transmitter 1 and the laser receiving screen 6 are respectively arranged on both sides of the area between the coil 2 and the surface of the protective layer 4, and the laser transmitter 1 faces the laser receiving screen 6;

[0044] A light position sensor 7 is laid on the laser re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com