Warm air cushion

A warm air and cushion body technology, applied in the field of warm air cushions, can solve problems such as failure to achieve satisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

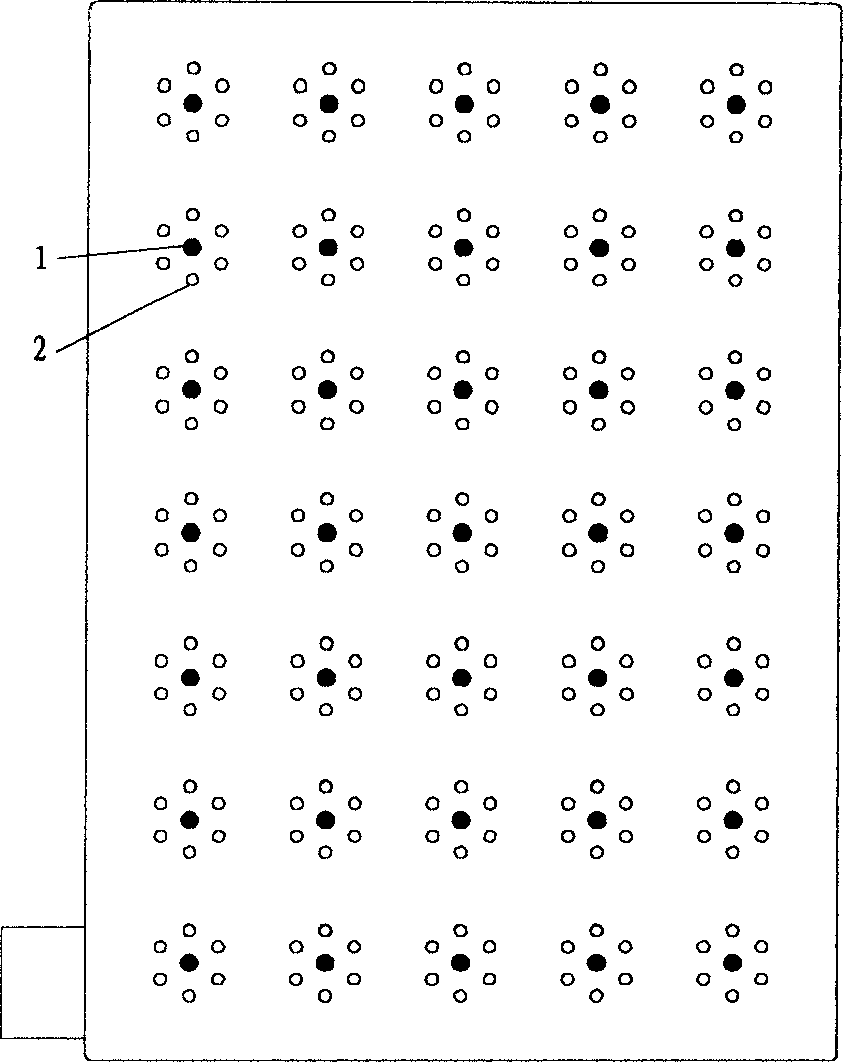

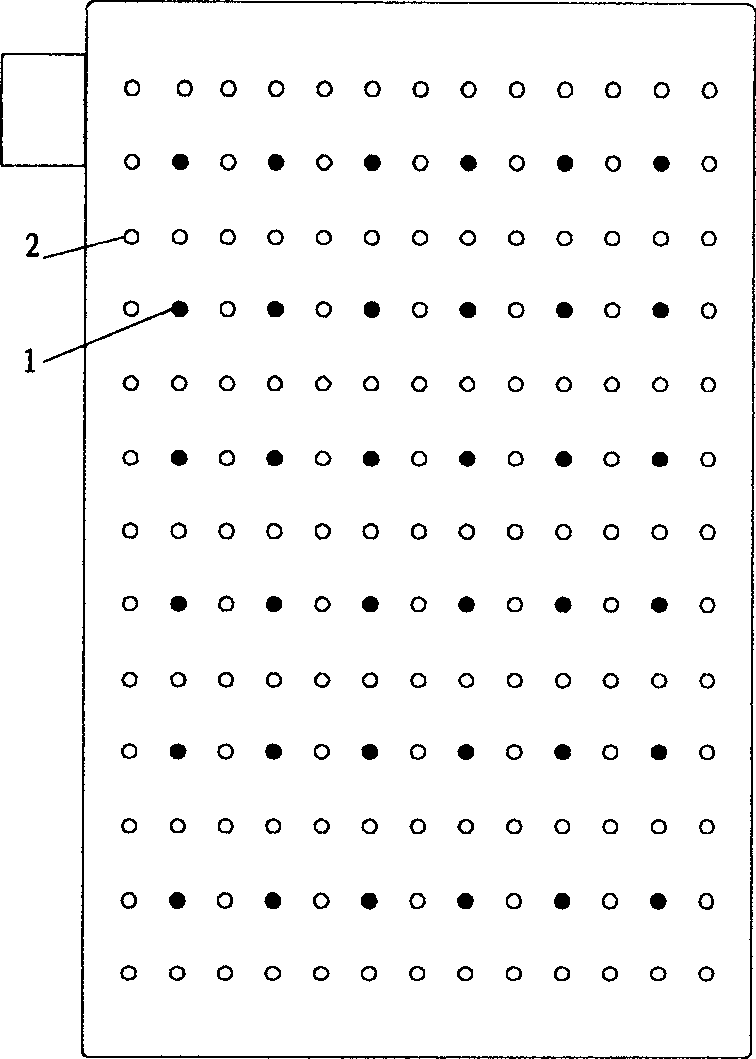

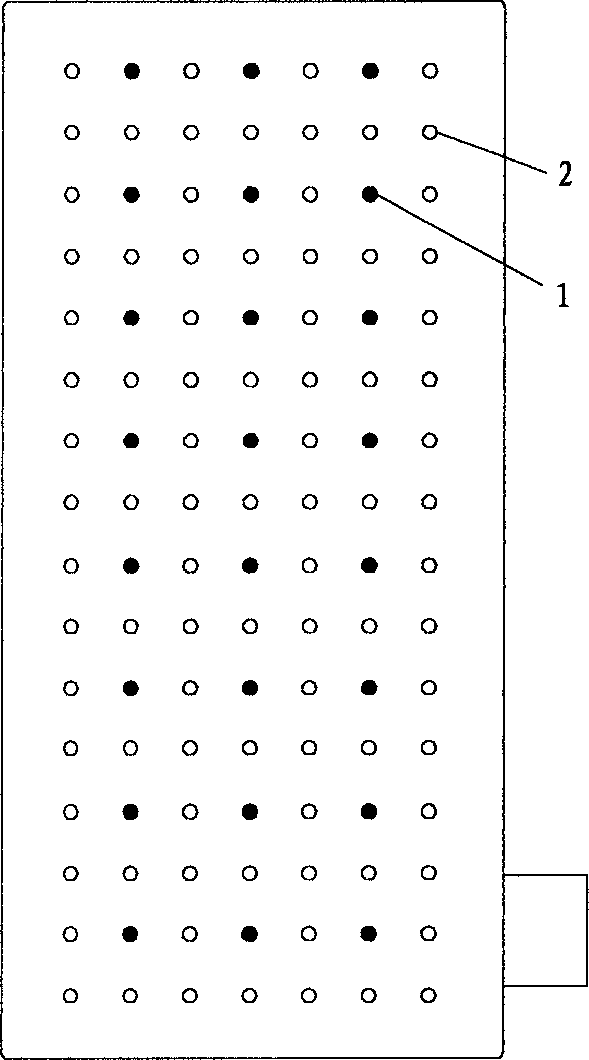

[0010] Figure 1 to Figure 14 The number and arrangement of the air holes on the upper layer and the lower layer of the warm air cushion shown are the same, corresponding to each other, and the relative positions, sizes and shapes of the corresponding air holes are consistent.

[0011] Cut two pieces of fabric, 1900 mm in length and 1350 mm in width, align and stack the two pieces of fabric, temporarily fix the edges, and determine the punching parameters in the next step. The small holes are circular, with a diameter of 3 mm, arranged vertically and horizontally, and 7 rows vertically Row spacing is 240 mm, horizontal 5 columns, column spacing is 225 mm, 35 small holes are determined as riveting eyes 1; 6 air holes 2 are respectively determined at the vertices of the regular hexagon with riveting eye 1 as the center. 2 is circular, with a diameter of 2 mm and an area of 3.14 square millimeters. The distance from the air hole 2 to the central riveting eye 1 is 60 mm. ×3.14≈...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com