Mounting structure and method for reducing thermal deflection of tool tower crane

A technology of installation structure and thermal displacement, which is applied in the direction of positioning device, metal processing machinery parts, clamping, etc., can solve the problems such as the reduction of workpiece accuracy, achieve high processing accuracy, reduce errors, and avoid the effects of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-4 The application is described in further detail.

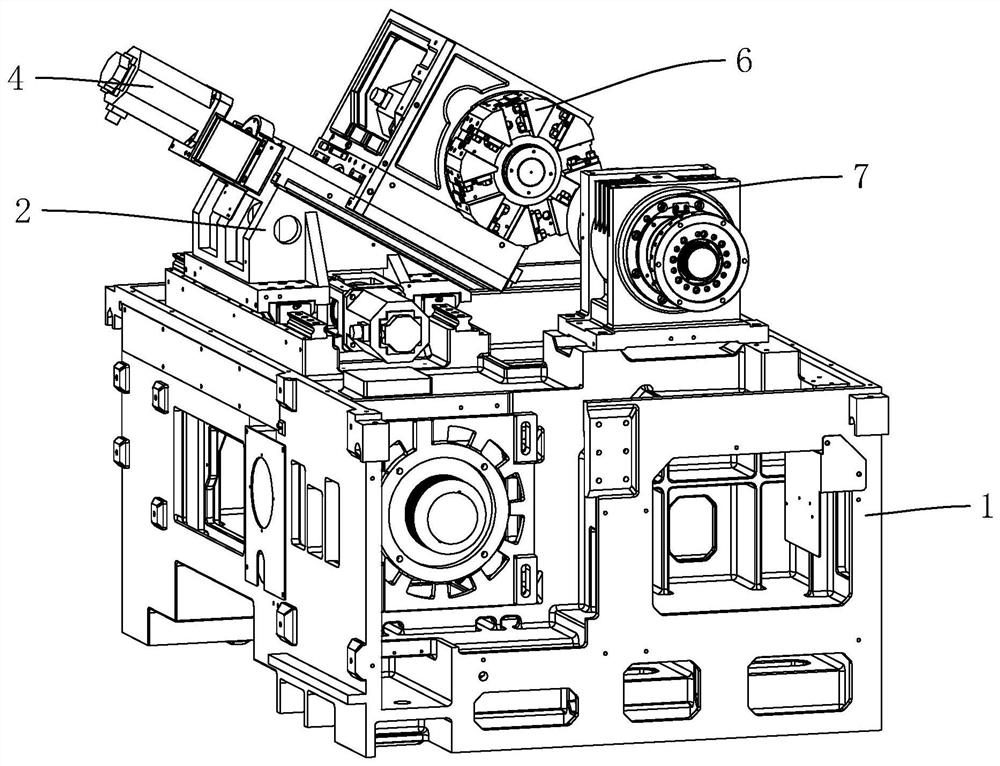

[0038] The embodiment of the present application discloses an installation structure for reducing the thermal displacement of the turret machine, such as figure 1 As shown, including the bed 1, a guide rail is arranged on the bed 1, and a mounting frame 2 is slidably connected to the guide rail, and a screw nut mechanism for controlling the sliding of the mounting frame 2 is also arranged on the bed 1. The screw nut mechanism The impact on the overall machine tool is small, and the lead screw of the screw nut mechanism can be pre-stretched or not pre-stretched.

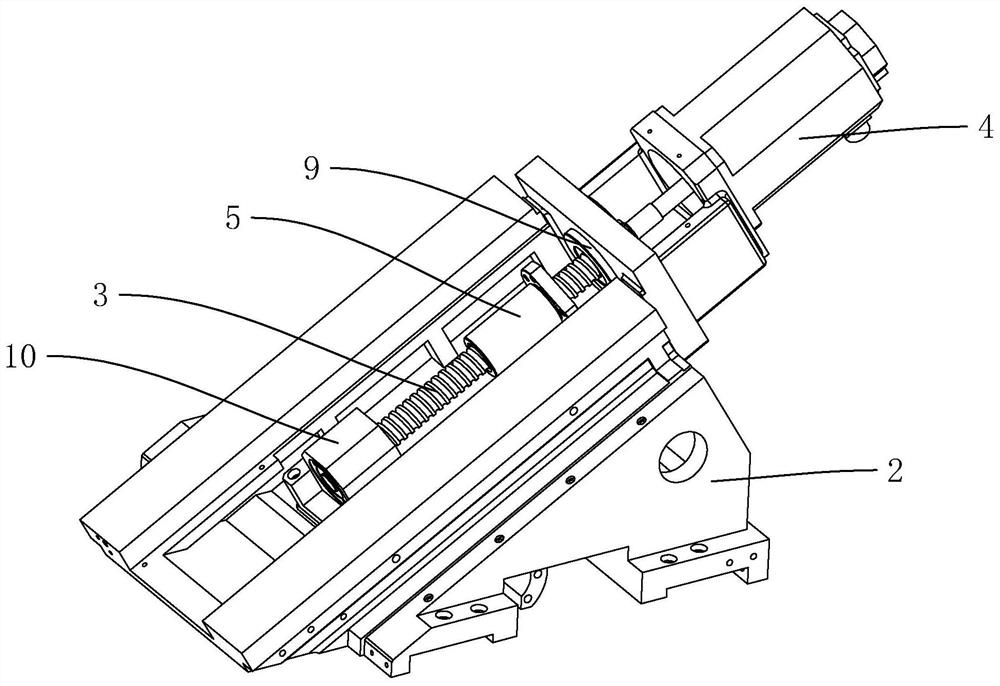

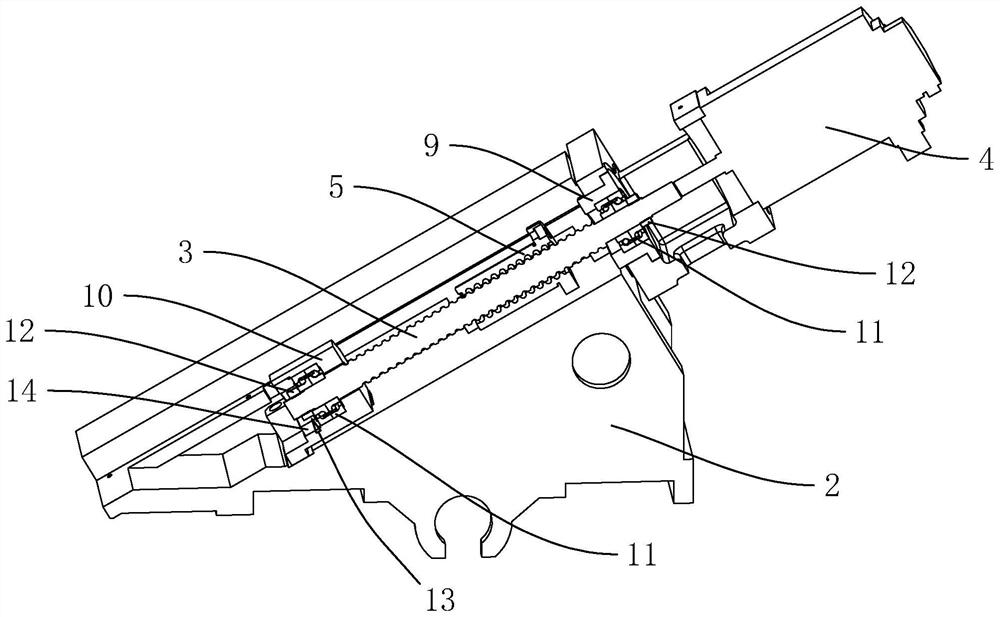

[0039] combine figure 2 and image 3 As shown, the large bearing seat 9 and the small bearing seat 10 are installed and fixed on the mounting frame 2 by bolts, and the screw rod 3 is installed on the large bearing seat 9 and the small bearing seat 10. The screw rod 3 has been pre-stretched, and the screw rod 3. Pre-stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com