Optical fiber cantilever beam temperature sensor based on metal coating

A technology of temperature sensor and metal coating, applied in thermometers, thermometers, instruments and other directions with physical/chemical changes, can solve the problems of decreased measurement accuracy, severe thermal deflection of bimetallic films, etc., to improve detection accuracy, small size, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

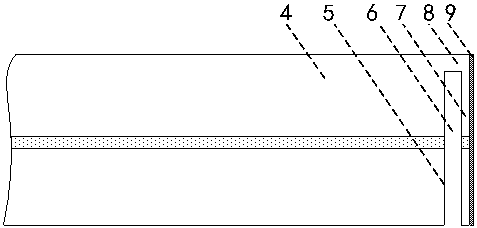

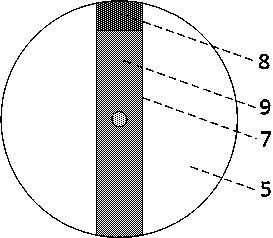

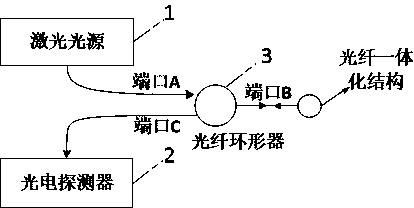

[0017] Figure 1-3 Among them, an optical fiber cantilever temperature sensor based on metal coating, including laser light source 1, photodetector 2, optical fiber circulator 3, optical fiber 4, optical fiber end face 5, Fabry-Perot cavity 6, optical fiber cantilever 7, The fixed end 8 and the metal film 9; the optical fiber cantilever 7 is located on the optical fiber end face 5, and is connected to the optical fiber end face 5 through the fixed end 8 on the edge of the optical fiber end face 5, and the optical fiber cantilever 7 and the optical fiber end face 5 form a Fabry -Perot cavity 6, forming an optical fiber integrated structure; the length of the optical fiber cantilever 7 is 90 μm-110 μm, the width of the cantilever is 20 μm-30 μm, and the thickness of the cantilever is 2 μm-5 μm. The optical fiber cantilever 7 adopts optical micromachining Process production, the preferred process is a femtosecond laser process; the metal film 9 is coated on the outer surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com