Arrangement method of tower-type boiler high-temperature reheater container system

A layout method and tower boiler technology, applied in the field of energy and power, can solve problems such as safety accidents and over-temperature, and achieve the effect of reducing the hidden danger of over-temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

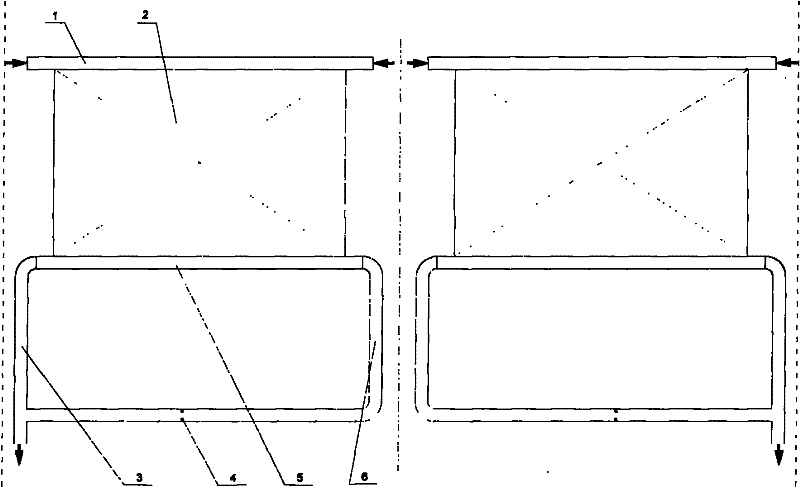

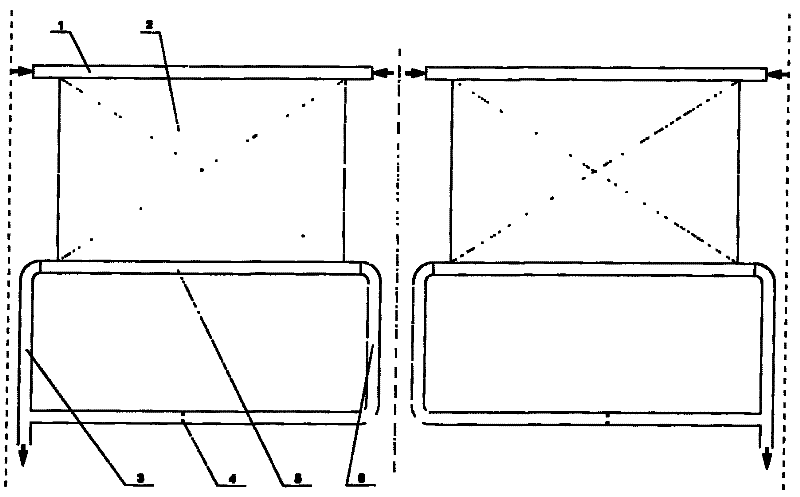

[0012] The layout method of the high-temperature reheater header system of a tower boiler according to the present invention is shown in the accompanying drawings, mainly consisting of a high-temperature reheater inlet header 1, a high-temperature reheater tube group 2, and a high-temperature reheater outlet header The steam guide pipe 3 is led out from the wall side, the outlet header 5 of the high temperature reheater is formed, and the outlet header of the high temperature reheater is drawn out from the steam guide pipe 6 near the center of the boiler. A resistance device 4 is installed in the steam guide pipe 6 drawn from the outlet header of the high-temperature reheater near the boiler center line. The resistance device includes pipe fittings with obvious resistance characteristics such as throttle rings, throttle pipe sections, and regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com