Cold section steam multi-stage utilization system for enhancing industrial steam supply capacity of once-through boiler

A once-through boiler and steam technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as boiler reheater overheating, extraction volume constraints, etc., to increase steam supply, reduce power generation coal consumption, and reduce overheating Warm Risk Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

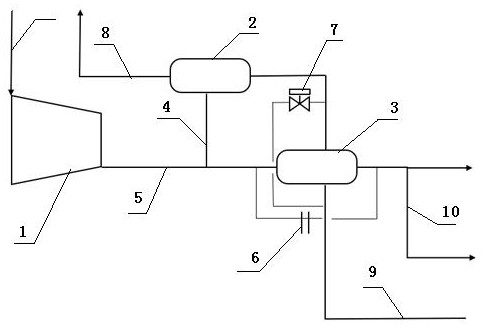

[0018] A cold section steam multi-stage utilization system that enhances the industrial steam supply capacity of once-through boilers. Its composition includes: a steam turbine high-pressure cylinder 1, a high-pressure heater 2 and a ladder heat exchanger 3. The steam turbine high-pressure cylinder passes through a high-pressure steam extraction pipeline. 4 is connected with the high-pressure heater, and the high-pressure cylinder of the steam turbine is connected with the step heat exchanger through the steam pipeline 5, and the flow regulating orifice plate 6 is installed on the steam pipeline, and the step heat exchange The water heater is connected in parallel to the flow regulating orifice, and the feed water at the outlet of the high-pressure heater passes through the bypass isolation valve 7 and then enters the ladder heat exchanger, and the ladder heat exchanger is also connected in parallel with a bypass pipe. And a bypass isolation valve is installed on the bypass pip...

Embodiment 2

[0020] According to the cold section steam multi-stage utilization system for enhancing the industrial steam supply capacity of once-through boilers described in Embodiment 1, the high-pressure heater is connected to the boiler feed water pipeline 8, and the step heat exchanger is respectively connected to the feed water pipeline 9 and to The boiler reheater original pipeline 10 is connected.

Embodiment 3

[0022] According to the cold section steam multi-stage utilization system for enhancing the industrial steam supply capacity of once-through boilers described in embodiment 1 or 2, the cold re-steam of the high-pressure cylinder of the steam turbine enters the steam pipeline, and part of the heat of the cold re-steam passes through the ladder heat exchanger Exchanging heat with the feed water, the heat-exchanged feed water is output as boiler feed water; the feed water at the outlet of the high-pressure heater passes through the water inlet isolation valve and then enters the heat recovery heat exchanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com