Apparatus and method for manufacturing photosensitive laminate

A laminated body, photosensitive technology, applied in lamination devices, chemical instruments and methods, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

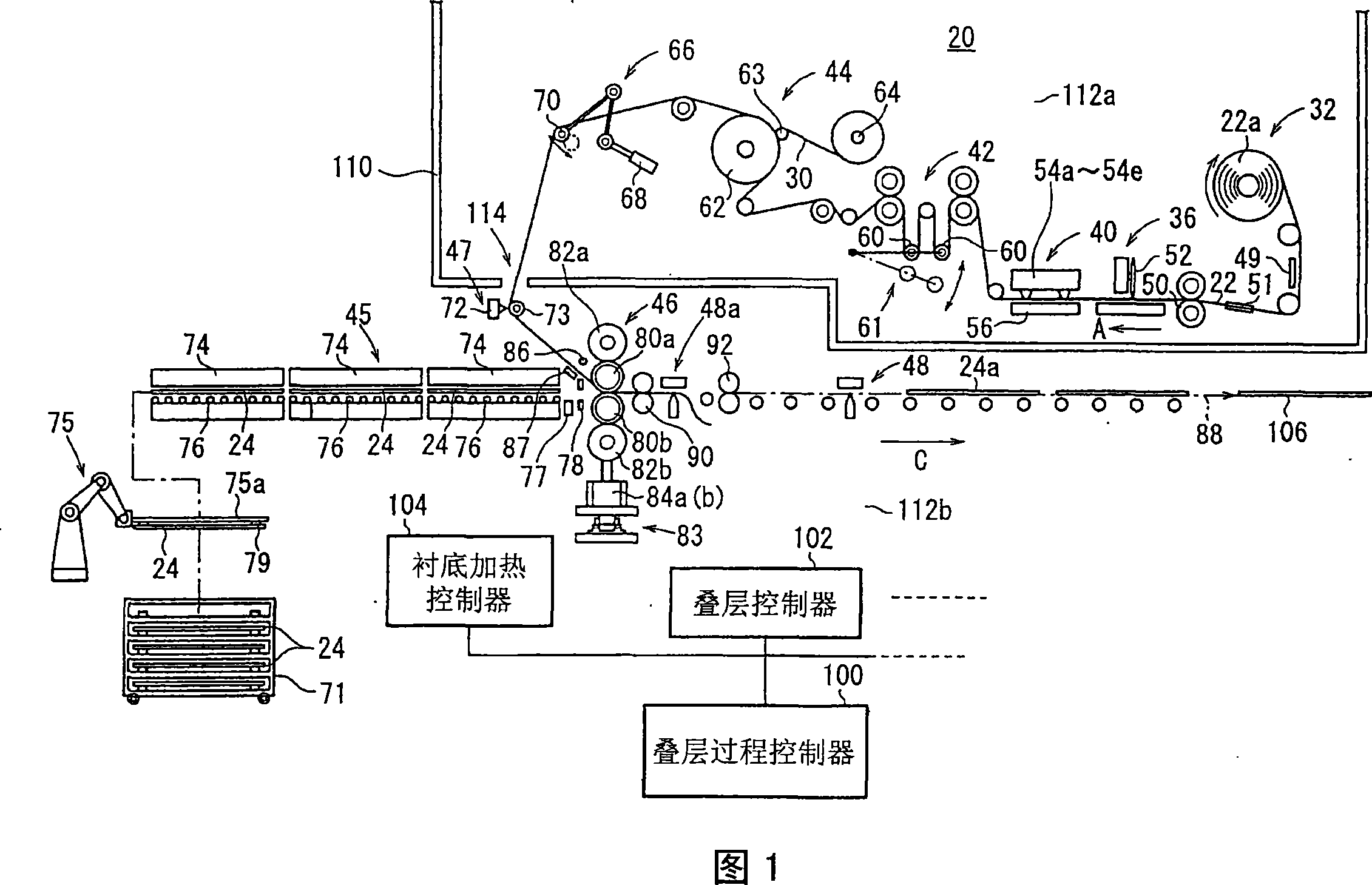

[0069] Fig. 1 shows a schematic side view of an apparatus 20 for manufacturing a photosensitive laminate according to a first embodiment of the present invention. In the process of manufacturing liquid crystal or organic EL color filters, manufacturing apparatus 20 operates to thermally transfer photosensitive resin layer 28 (described later) of elongated photosensitive sheet 22 to glass substrate 24 .

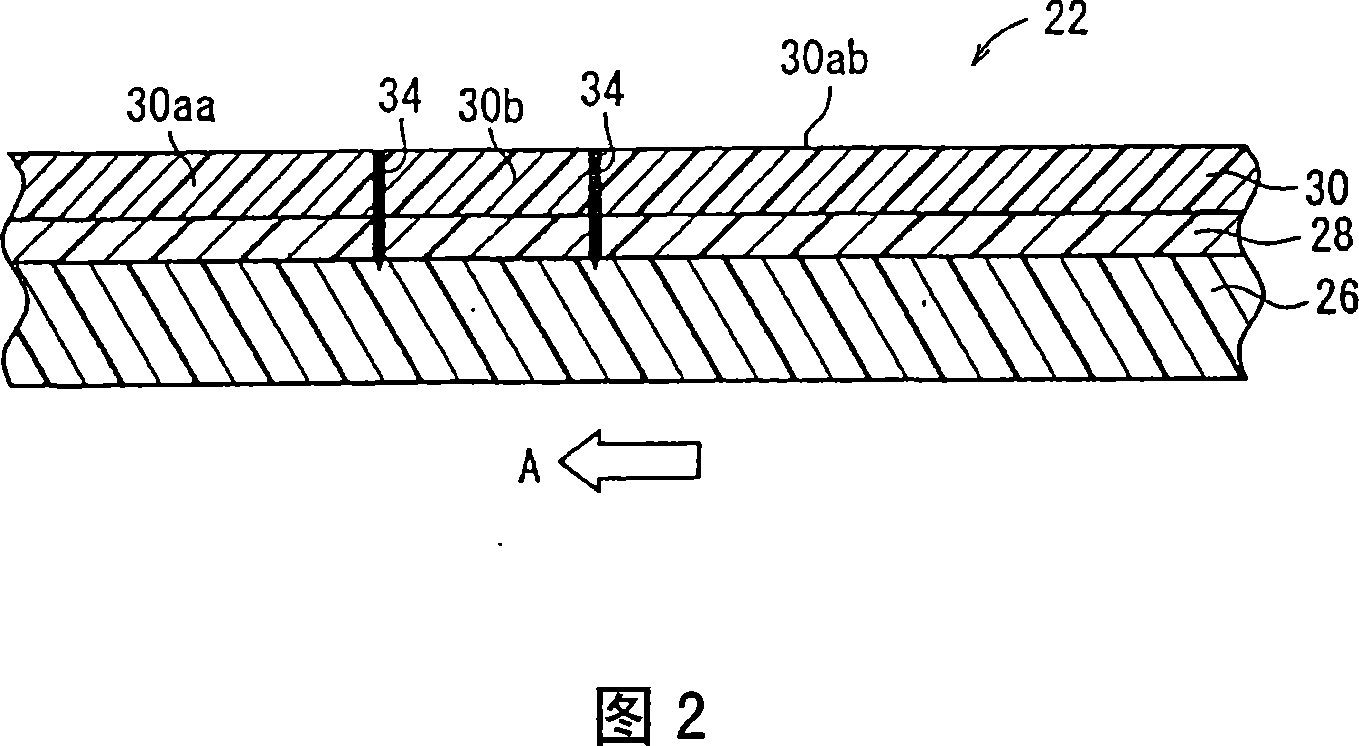

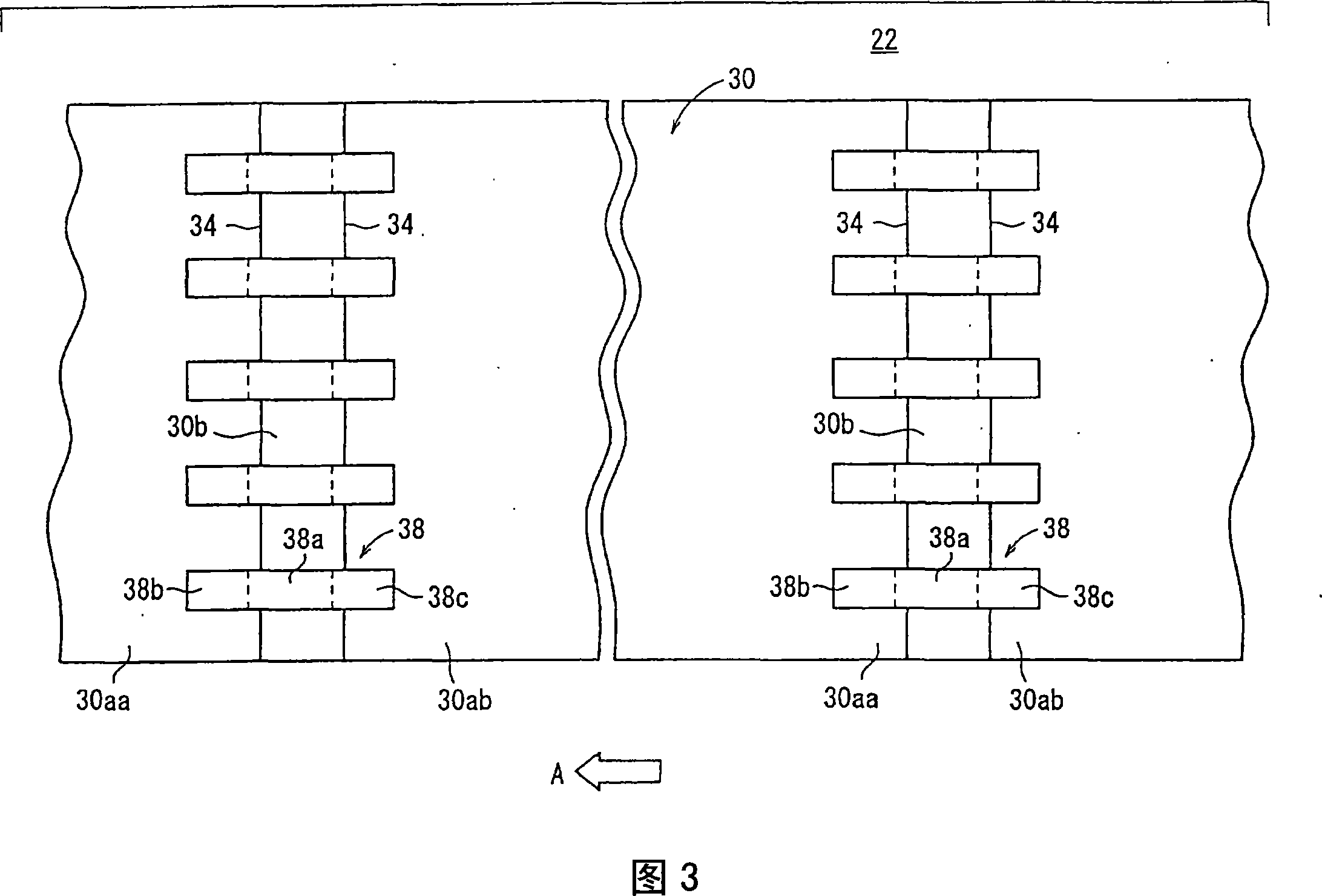

[0070] FIG. 2 shows a cross-section of a photosensitive web 22 used in the manufacturing apparatus 20. As shown in FIG. The photosensitive sheet 22 includes a laminated assembly of a flexible base film (support) 26 , a photosensitive resin layer (photosensitive material layer) 28 provided on the flexible base film 26 , and a protective film 30 provided on the photosensitive resin layer 28 .

[0071] As shown in FIG. 1, the manufacturing apparatus 20 has a pay-out mechanism 32 for accommodating a photosensitive sheet roll 22a in the form of a rolled photosensitive sheet 22 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com