A 3D additive printing machine

A printing machine and 3D technology, applied in the field of additive manufacturing, can solve the problems of inability to increase the thickness of additive manufacturing, uneven penetration of printing ink on the screen, and inability to accurately overlay printing ink, achieving fast response time and adjustment speed. Fast, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

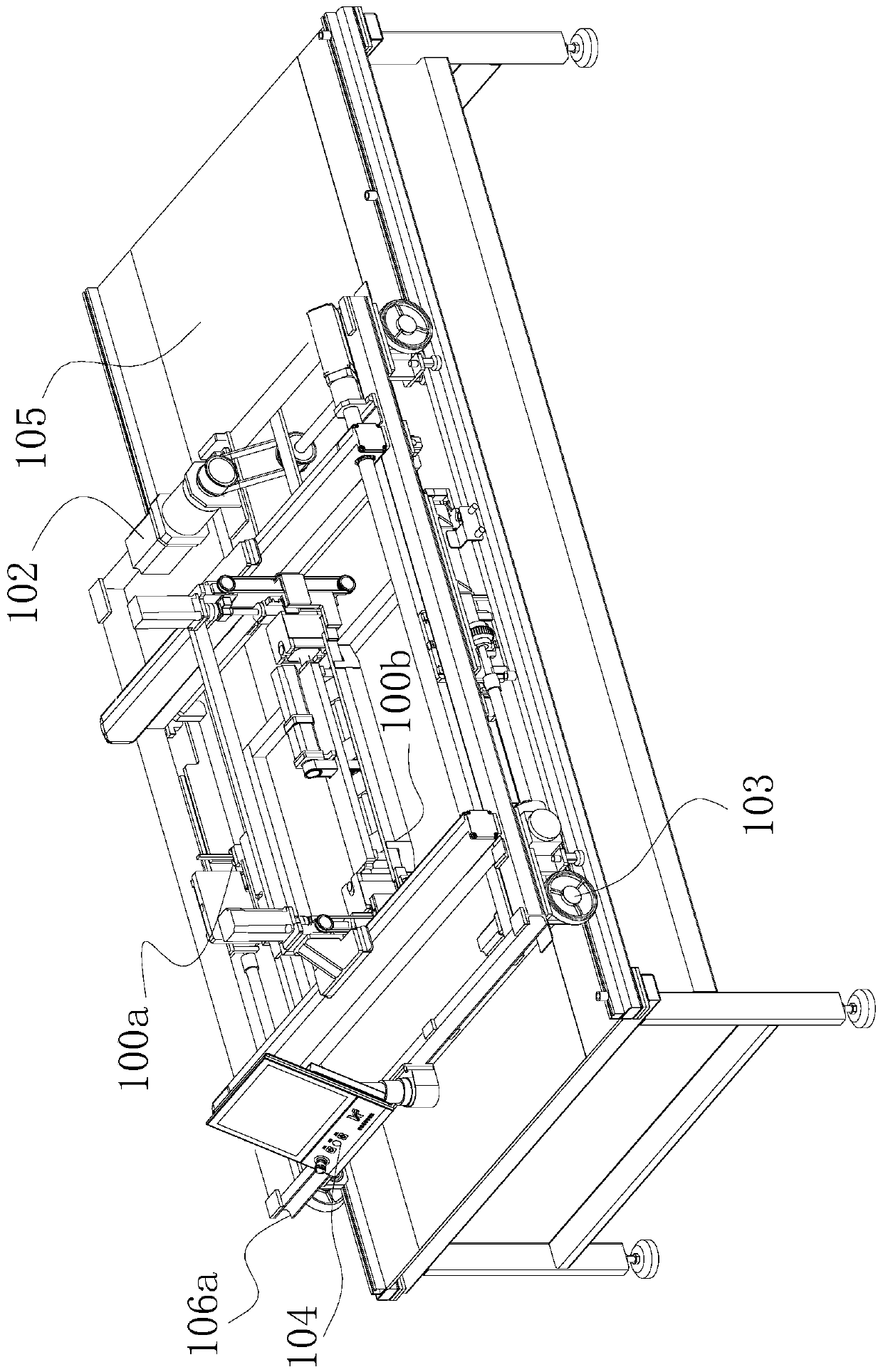

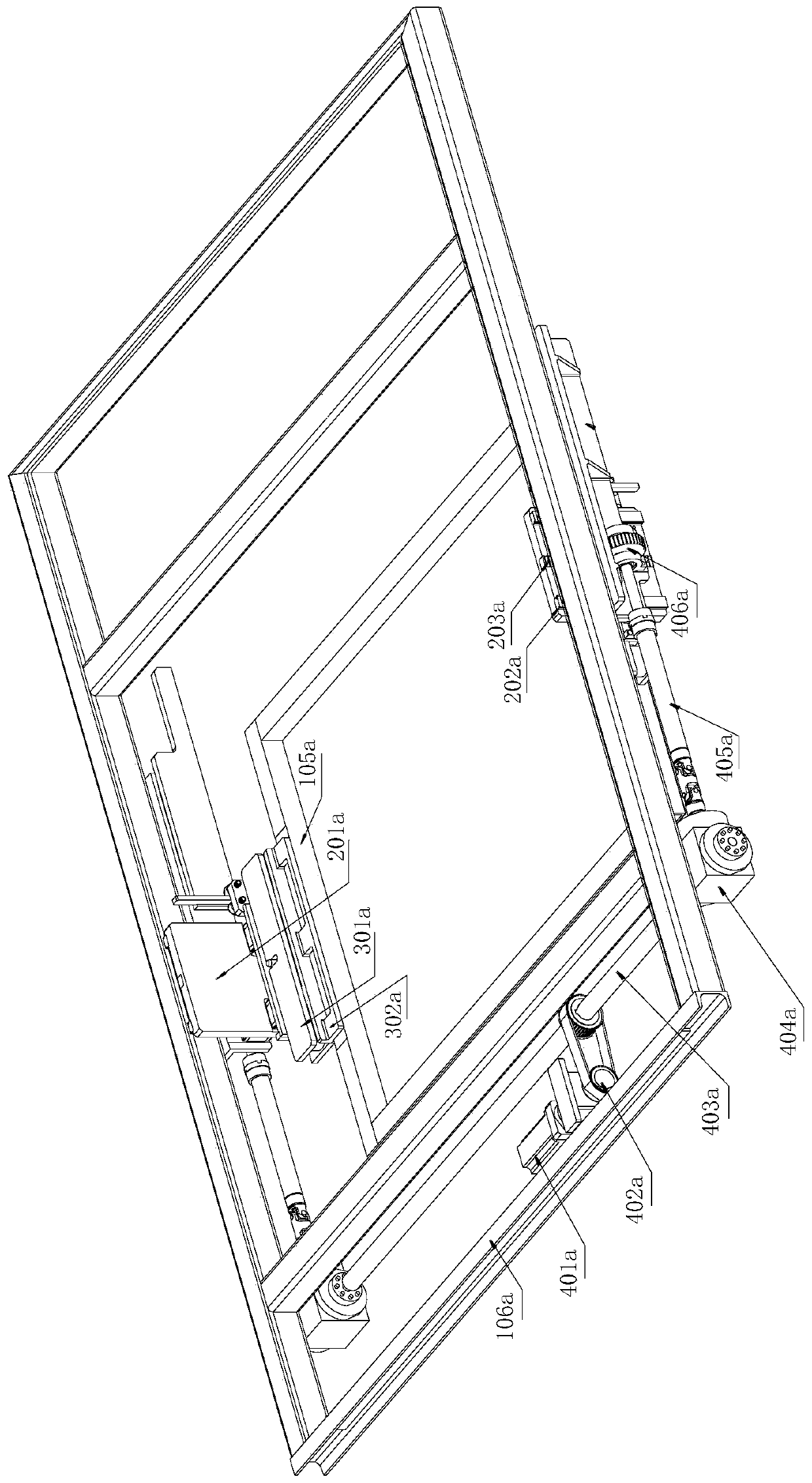

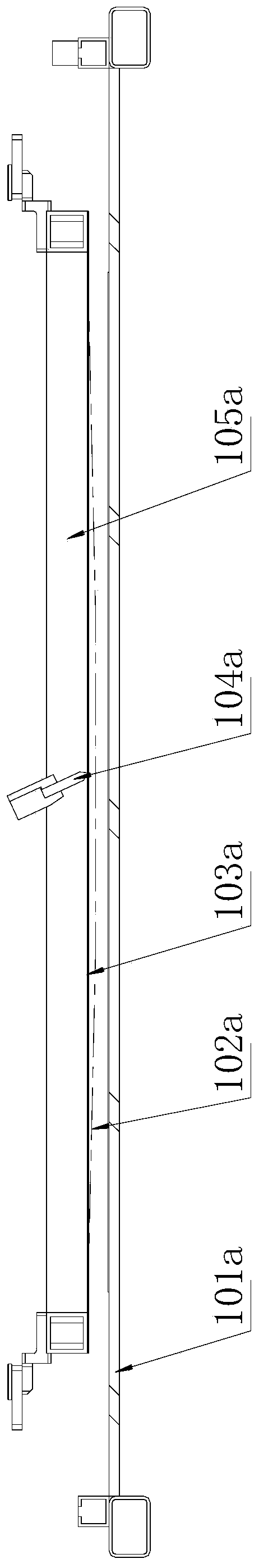

[0065] First of all, the 3D additive printing machine referred to in this case refers to the mechanical equipment that achieves additive manufacturing through innovation of existing screen printing. The 3D additive printing machine includes a frame, a walking device, a printing mechanism and a control device. The general printing process The frame transports the printing equipment to the top of the printing label through the walking device. The printing label is usually clothing fabric and shoe fabric. Print patterns on the surface of the printing label fabric, then remove the printing mechanism, and then dry it with drying equipment. Then print again on the pattern as needed, and then print again; until the set thickness of additive manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com