A kind of eva film for encapsulating solar photovoltaic modules and preparation method thereof

A solar photovoltaic and module technology, applied in adhesives, electrical components, semiconductor devices, etc., can solve the problems of limited reduction in thermal shrinkage of EVA film internal stress, increased raw material and energy consumption, and inability to achieve results. Simple in-line tempering, reduced stretching effect, low thermal shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Prepare materials

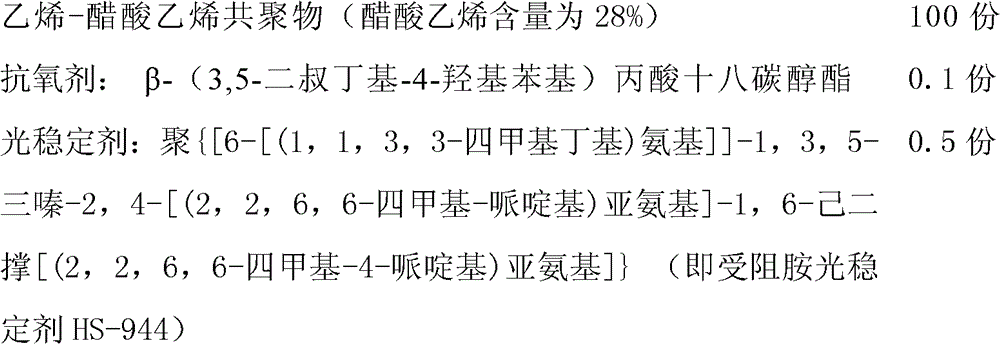

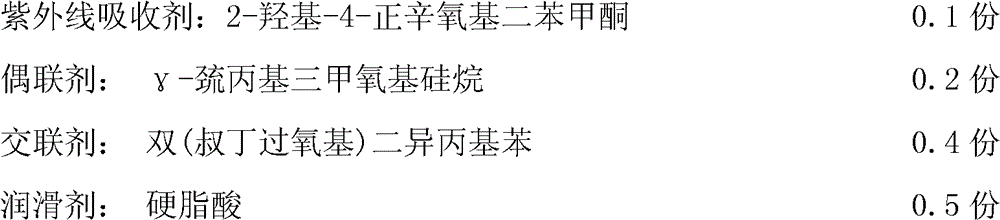

[0033] Prepare materials according to the following weight ratio:

[0034]

[0035]

[0036] 2. Mixed material

[0037] Firstly, add all the coupling agent and crosslinking agent in the raw materials into the ethylene-vinyl acetate copolymer according to the above weight ratio, and mix evenly to obtain a primary mixture; secondly, add the antioxidant and light stabilizer in the above raw materials and ultraviolet absorber are all added to the primary mixture, and mixed uniformly to obtain a secondary mixture; finally, the lubricant in the above-mentioned preparation materials is added to the secondary mixture, and the mixture is uniformly prepared;

[0038] 3. Preparation of EVA film

[0039] The prepared mixture is sent to the feeding box of the extruder, and through the heating of the extruder barrel and the rotation of the screw, the mixture is heated, melted and kneaded in the extruder to form a melt; the screw will melt The body is c...

Embodiment 2

[0045] In addition to preparing materials, prepare materials according to the following weight ratio:

[0046]

[0047]

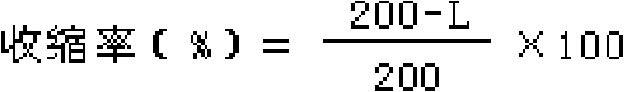

[0048] In the step of preparing the EVA film, the extruder barrel heating temperature is 80°C, the temperature of the mold is 85°C, and the speed of the production line is 3.5 m / min, all the other are the same as in Example 1, and the thickness of the prepared EVA film is It is 0.5mm and the shrinkage rate is 2.8%.

Embodiment 3

[0050] In addition to preparing materials, prepare materials according to the following weight ratio:

[0051]

[0052] In the step of preparing the EVA film, the extruder barrel heating temperature is 85°C, except that the temperature of the mold is 85°C, all the other are the same as in Example 1, the thickness of the prepared EVA film is 0.30mm, and the shrinkage rate is 2.0mm. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com