Planar fiber vertical structure flooring base material and production process thereof

A vertical structure and plane technology, applied in the direction of wood processing equipment, floors, manufacturing tools, etc., can solve the problems of carcinogenicity of human chemical poisoning, large amount of adhesive, bending and deformation of the floor, etc., so as to reduce the probability of deformation and smooth the floor The effect of high degree and improvement of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

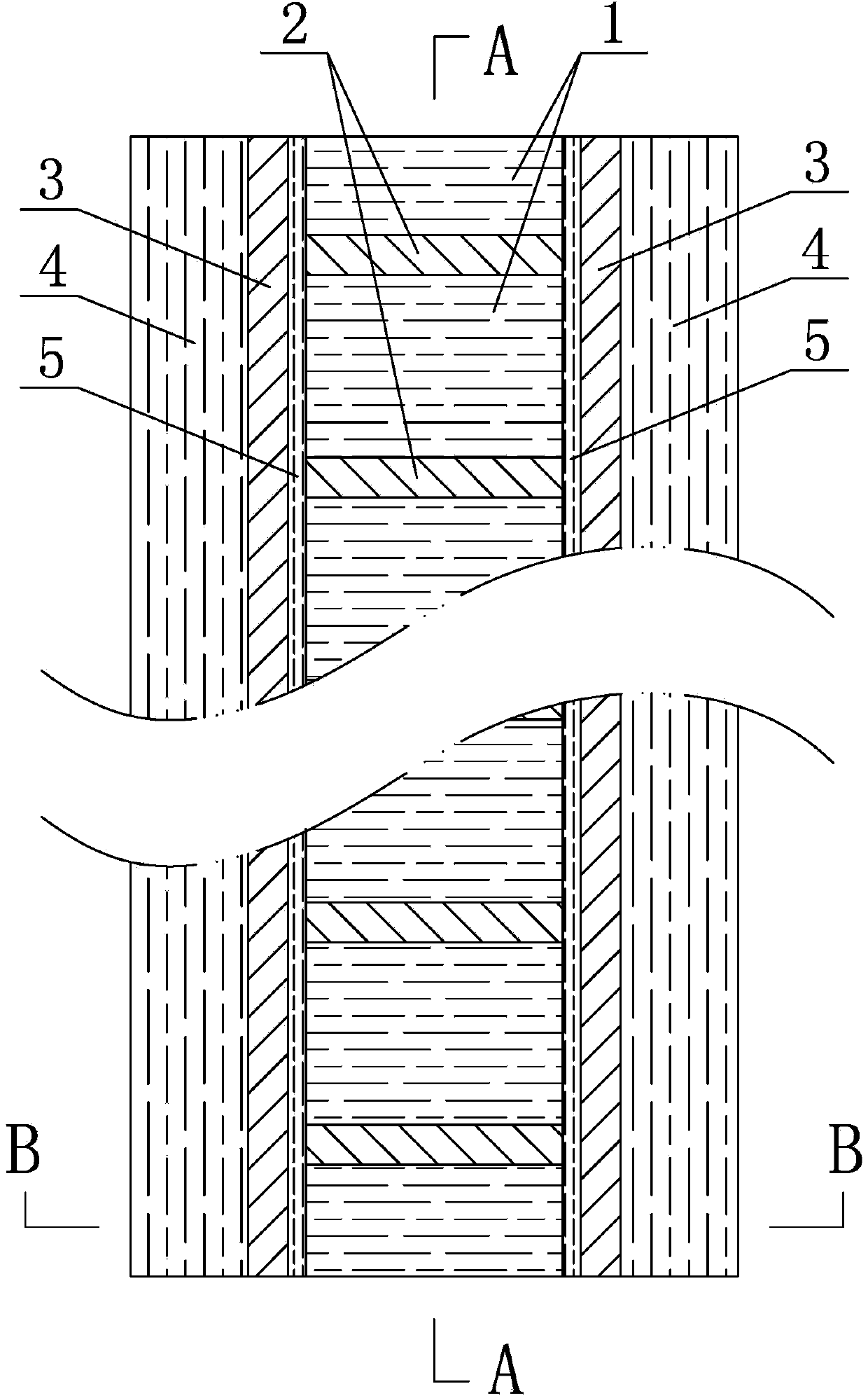

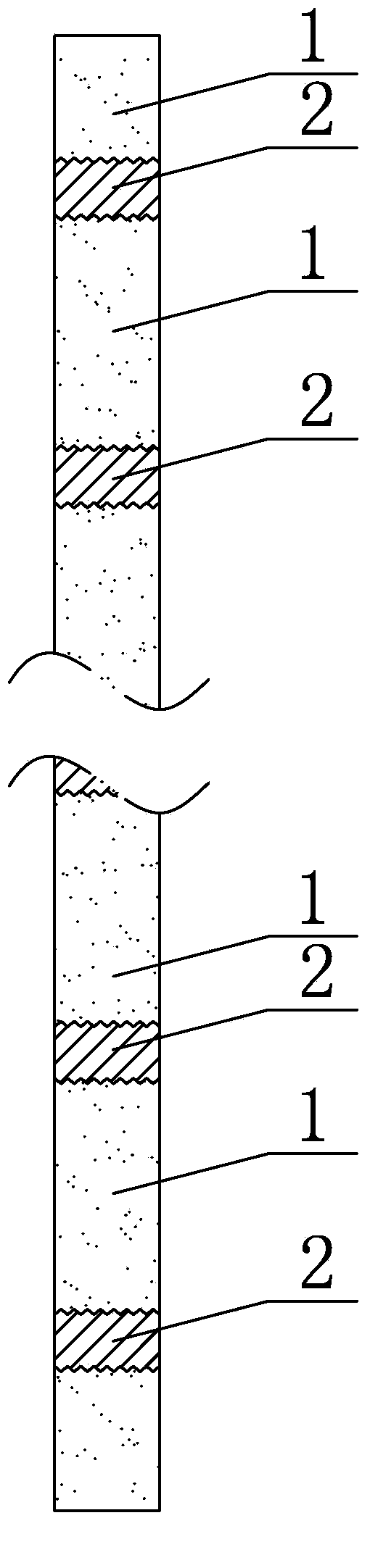

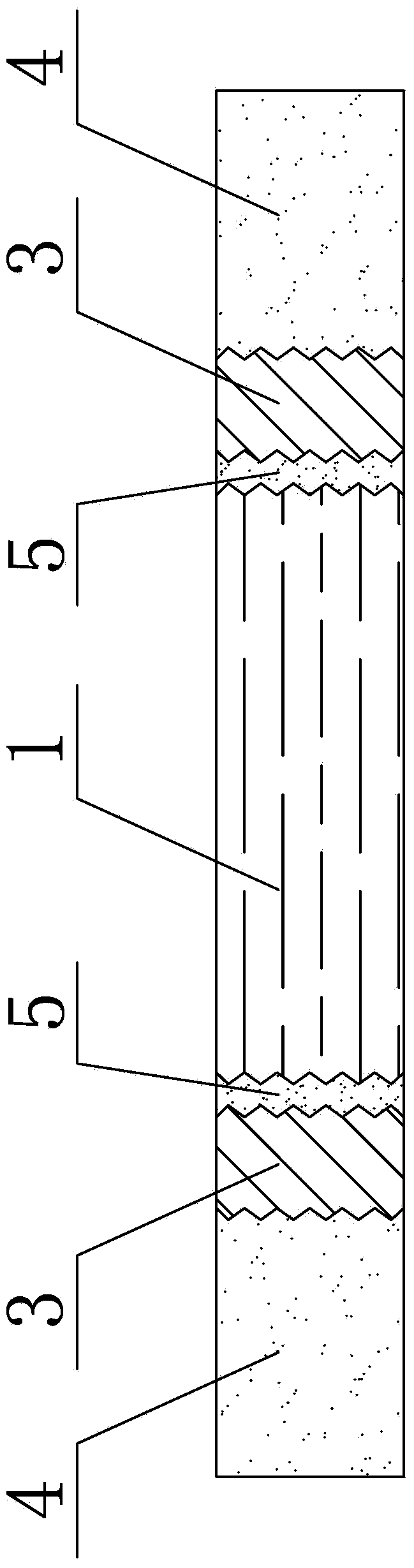

[0027] Embodiment 1: as Figure 1-Figure 3 As shown, the floor base material of this embodiment is a single-layer plane composite structure, including a central board, and two side boards located on both sides of the central board and spliced with it as a whole; the central board and the side boards are located on the same plane , the fiber direction of the two side panels is the same as the length direction of the floor substrate, the fibers of the center panel and the fibers of the side panels are located in the same plane, and the fiber directions are perpendicular to each other; the "vertical anisotropic combination" is carried out on the same horizontal plane, The internal stress in the vertical and horizontal directions of the plate is controlled, and the probability of deformation of the plate is reduced.

[0028] The central board is spliced by several wooden middle boards 1 and some transverse bamboo strips 2 at intervals. The wooden middle board 1 and the transve...

Embodiment 2

[0037] Embodiment 2: as Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that the upper and lower surfaces of the integral body of the central plate and the side plates are each covered with a layer of wood veneer 6 (which can be a fast-growing rotary-cut wood veneer, It can also be decorative sliced wood veneer).

[0038] The production process adds step S5 on the basis of the production process in Example 1: sand the board obtained in step S4 on both sides, and coat it with a formaldehyde-free adhesive, and then cover it with fast-growing rotary-cut wood veneer or decorative planing Wooden veneer 6, and put it into a heat press machine to heat press the veneer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com