Spark plug

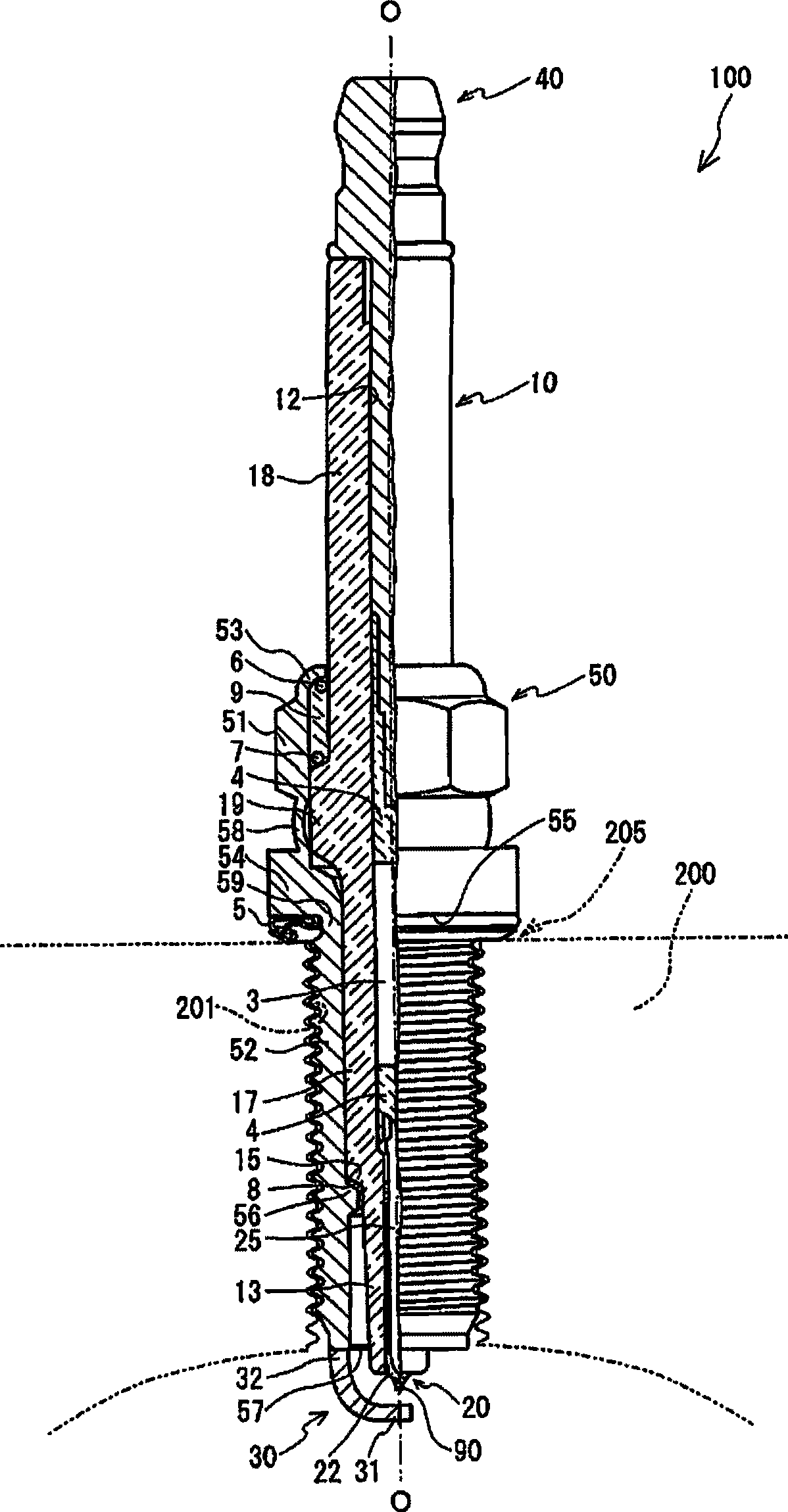

A spark plug and center electrode technology, applied in the field of spark plugs, can solve the problems of reducing the bonding ability of the electrode tip, insufficient heat dissipation performance of the fusion joint, and reduced heat dissipation performance, and achieve the effect of preventing loss or even falling off, preventing oxidation, preventing cracking or deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

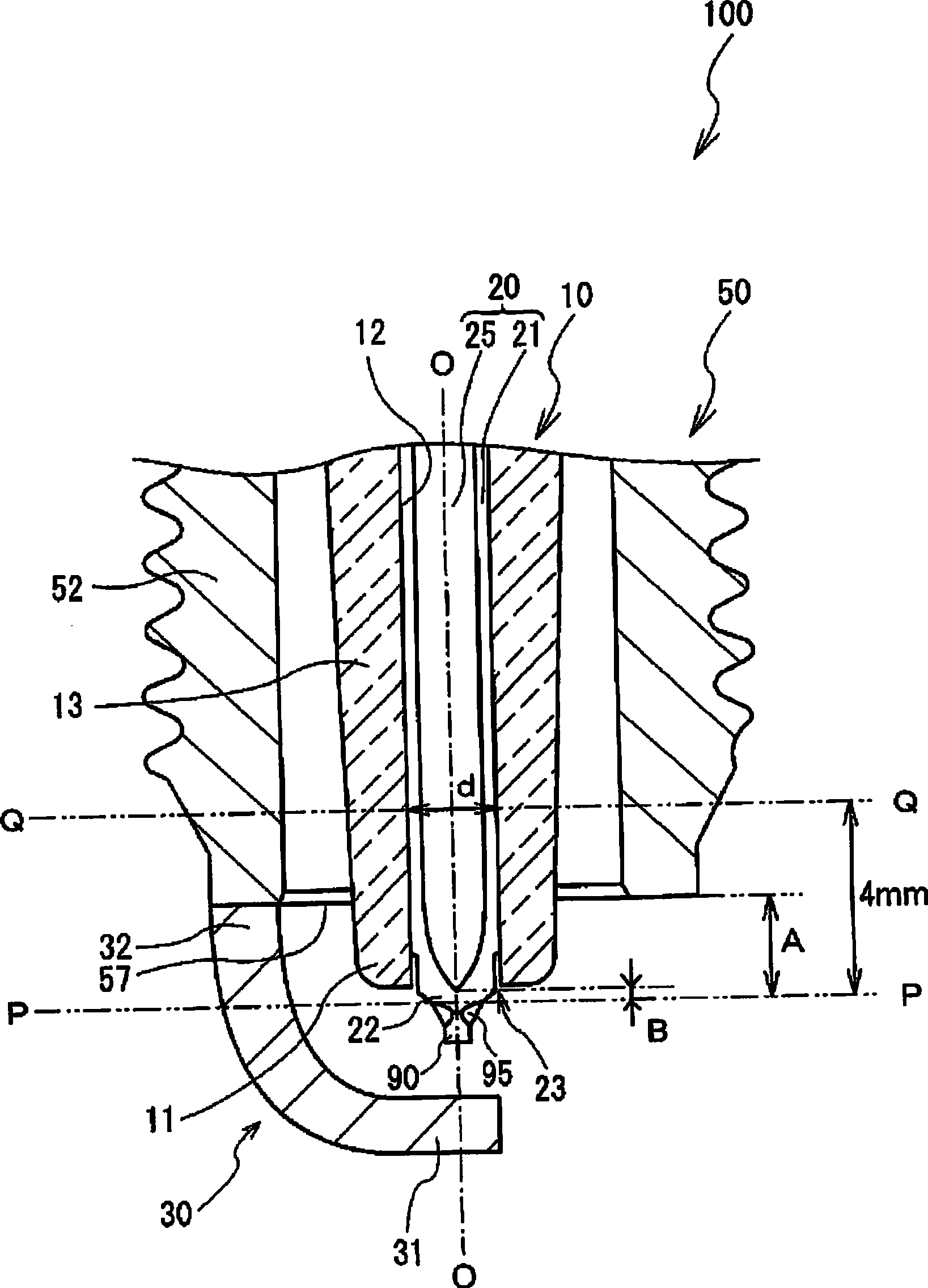

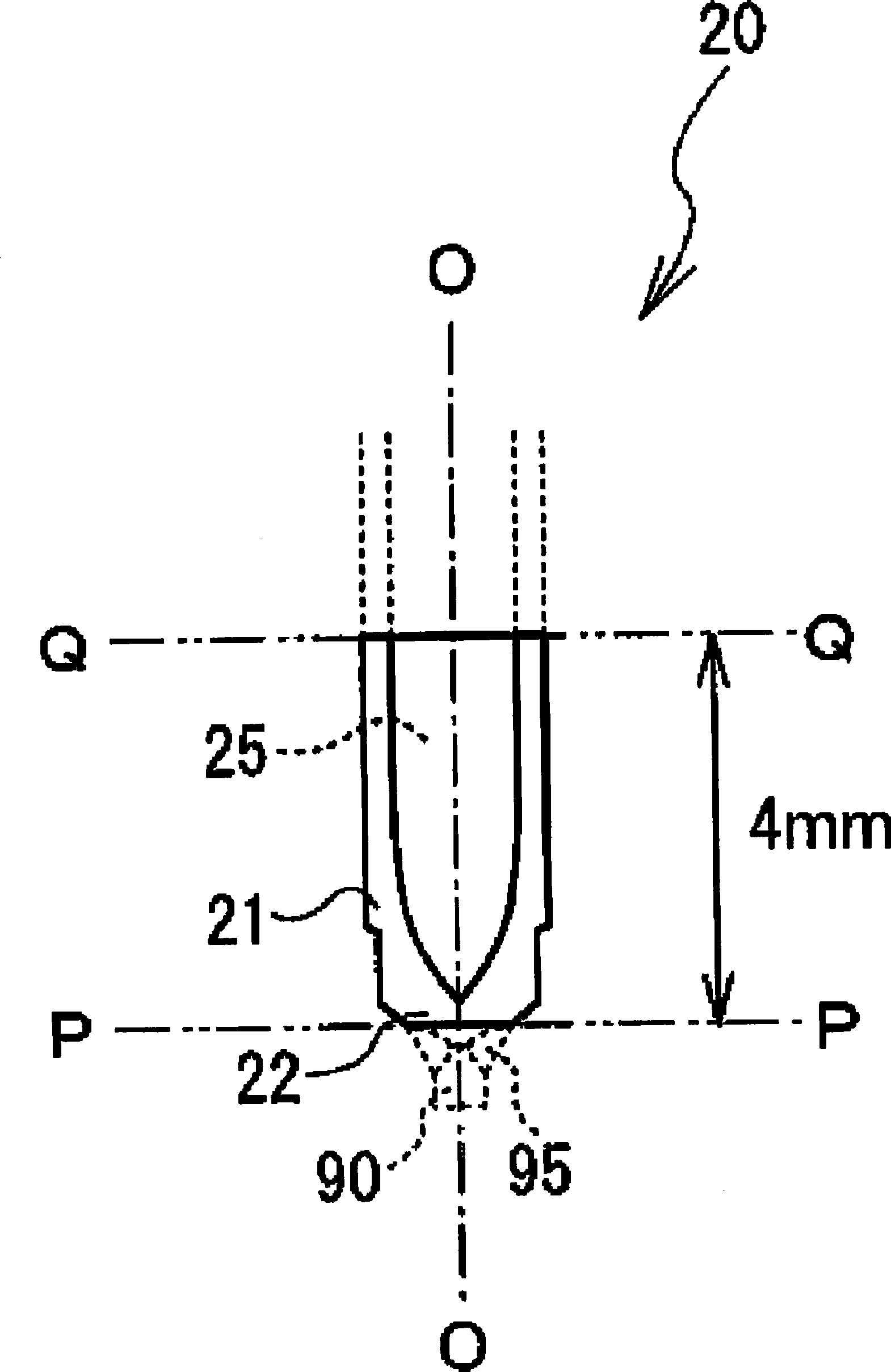

[0058] First, an evaluation test was conducted to examine the relationship between the volume of the core member 25 and the heat dissipation performance of the center electrode 20 . Such as Figure 5 As shown, three kinds of center electrodes were produced, which differed in the volume of the core member included in the region from the base end of the fusion joint to the position 4 mm from the base end of the fusion joint toward the base end side, and Spark plug samples 1, 2 and 3 respectively employing these center electrodes were prepared. The center electrode of Sample 1 was produced while adjusting the size and shape of the electrode base member and the core member which had not been subjected to extrusion molding so that the ratio of the volume Vb of the core member to the volume Va+Vb of the center electrode in the above-mentioned part Vb / (Va+Vb) was set to 0.16. Also, the center electrode of sample 2 was produced so that the ratio Vb / (Va+Vb) was set to 0.28, and the c...

Embodiment 2

[0061] Next, an evaluation test was performed on the relationship between the outer diameter d of the center electrode 20 at a position 4 mm from the base end of the fusion bonded portion 95 and the heat dissipation performance of the center electrode 20 . Several center electrodes were prepared with different outer diameters d ranging from 1.5 mm to 2.6 mm. The number of each center electrode is twelve. Samples of spark plugs using each type of center electrode were produced. Thereafter, each sample was installed in an engine, and an endurance test was performed in which the rotational speed was maintained at 6000 rpm for 700 hours using a 2.5-liter 6-cylinder gasoline engine. After that, the occurrence rate of pits (abrasion or chipping) in the fusion bonded portion of each sample was examined. Here, the dimples represent a state in which the volume of the fused joint is reduced after the durability test, which is determined by measuring the volume of the fused joint befor...

Embodiment 3

[0064] Next, an evaluation test was performed to examine the influence of temperature on the occurrence rate of craters in the fusion bonded portion 95 . In this evaluation test, a sample of the center electrode combined with an electrode tip was prepared, and one thousand cycles were performed, each of which included: heating and melting the junction at a predetermined temperature for two minutes; and then allowing the sample to naturally cool for one minute. In this test, 10 samples were prepared for each evaluation temperature. The state of the melted junction of each sample that had been heated was confirmed, and the crater occurrence rate for each evaluation temperature was calculated from the number of samples in which craters were observed. As a result, the graph shows the relationship between the pit occurrence rate and the heating temperature (see Figure 8 ).

[0065] Such as Figure 8 As shown, it was confirmed that the higher the temperature of the fusion joint,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com