Patents

Literature

34results about How to "Less prone to warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

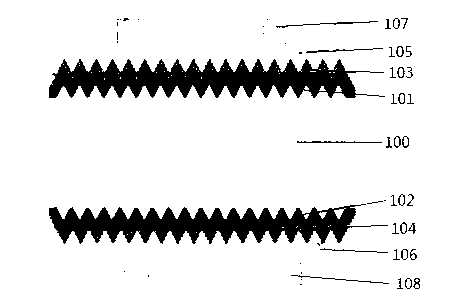

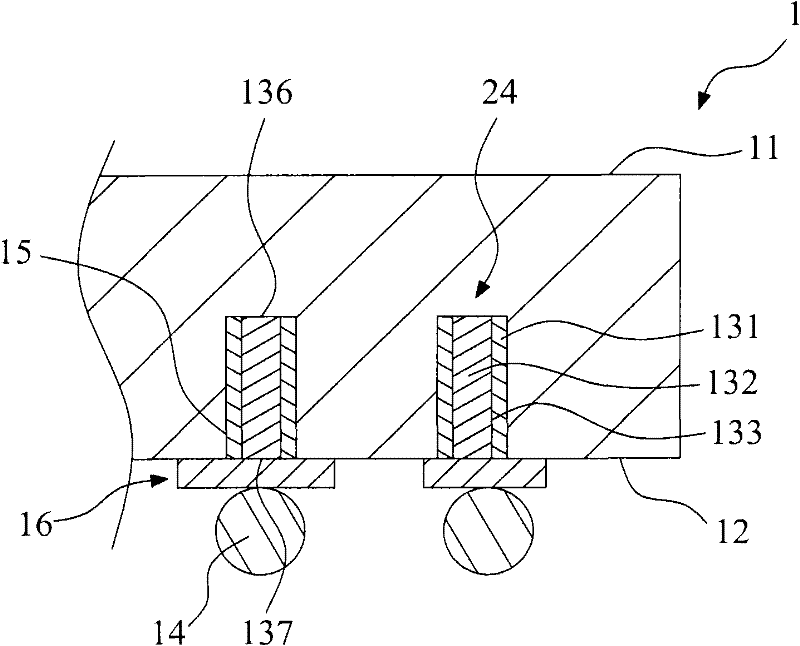

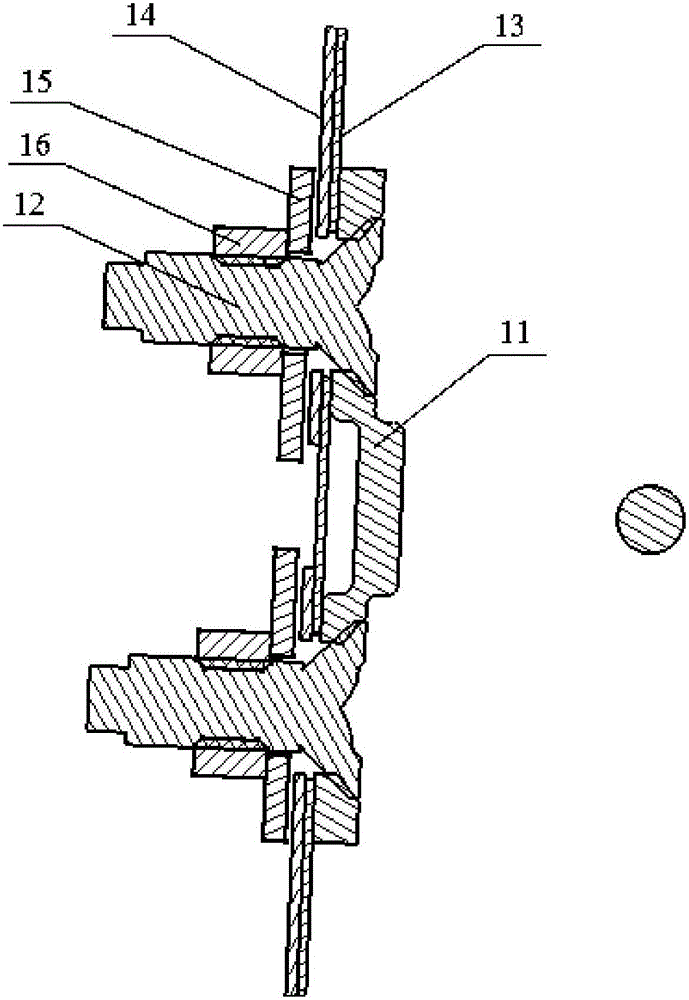

Black heterogeneous crystalline cell and manufacture method thereof

InactiveCN103000741AReduce thermal stressLess prone to warpingFinal product manufacturePhotovoltaic energy generationScreen printingTrapping

The invention discloses a black heterogeneous crystalline cell which sequentially comprises a first metal electrode, a first conductive film, a P-shaped amorphous silicon layer, a first intrinsic amorphous silicon layer, a silicon wafer, a second intrinsic amorphous silicon layer, an N-shaped amorphous silicon layer, a second conductive film and a second metal electrode. The first conductive film and the second conductive film are polycrystalline boron-doped ZnO films. The manufacture method comprises the steps of preprocessing the surface of the silicon wafer; depositing intrinsic amorphous silicon layer plating in a double-faced mode; depositing the P-shaped amorphous silicon layer from the front side, and depositing the N-shaped amorphous silicon layer from the back side; and growing the ZnO films on the front side and the back side of a cell piece and screen printing metal grid lines on the front sides and the back sides of the conductive films. The polished silicon wafer with the smooth surface is adopted, and light trapping is achieved through pyramid structures of the ZnO films, so that a light trapping structure and surface passivation of the cell can be achieved maximally and respectively, and photoelectric converting efficiency of the cell is improved.

Owner:GD SOLAR

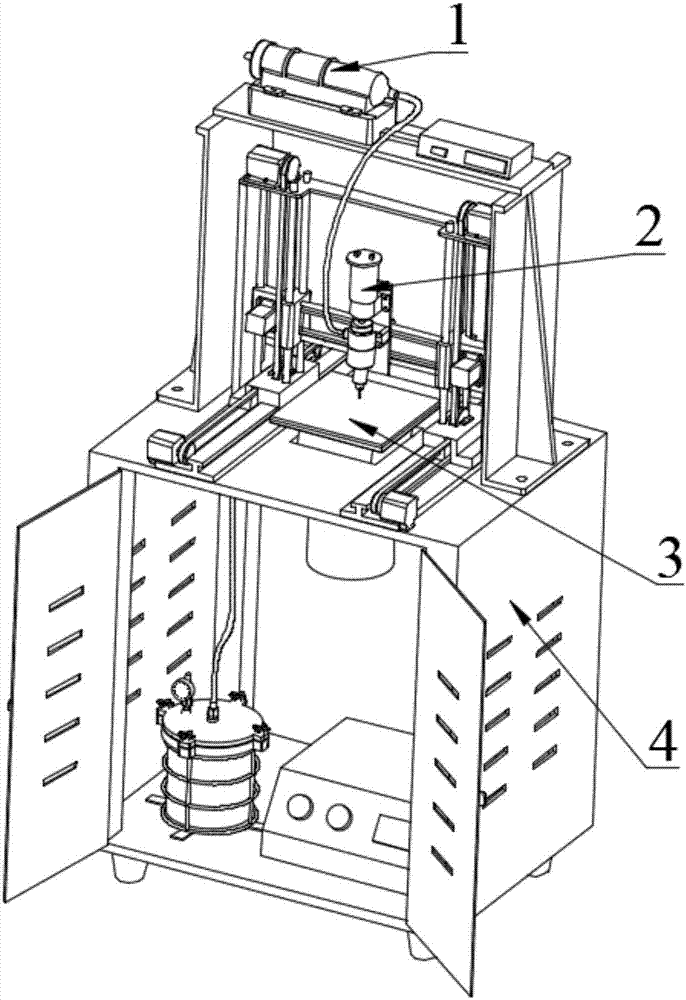

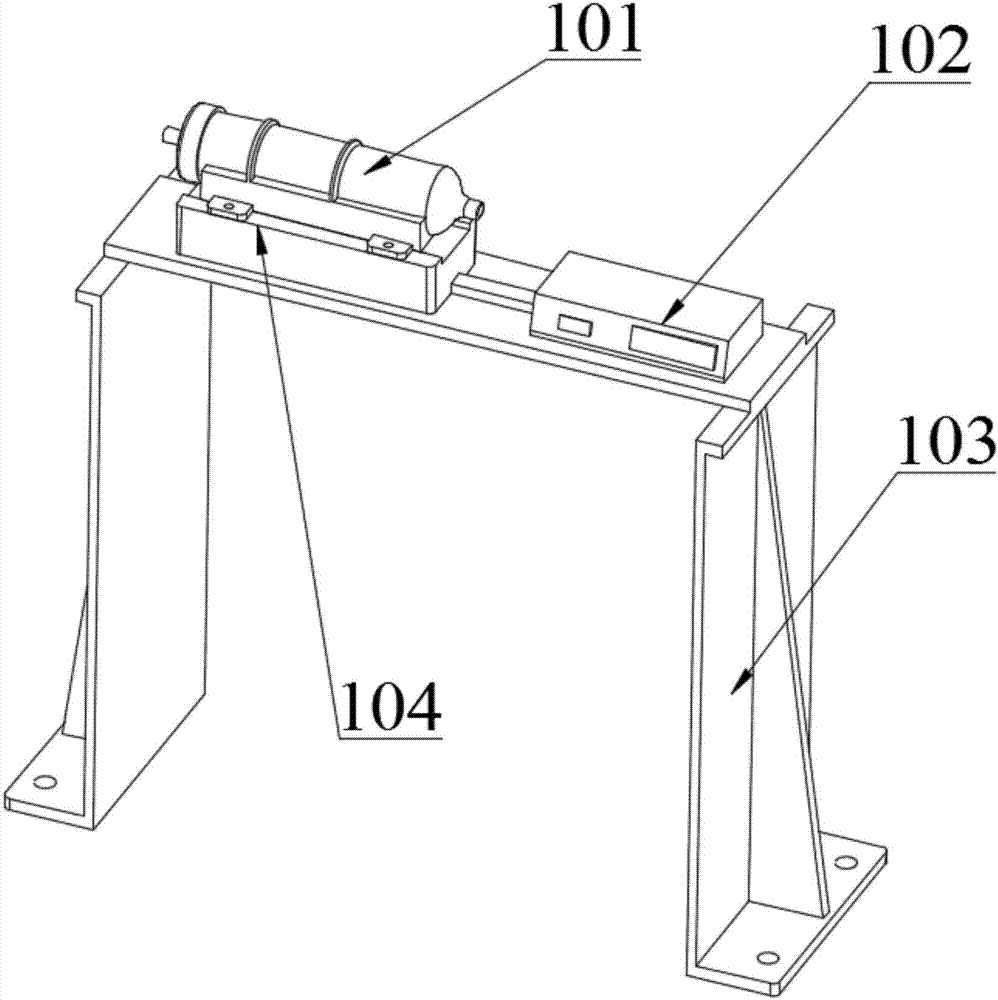

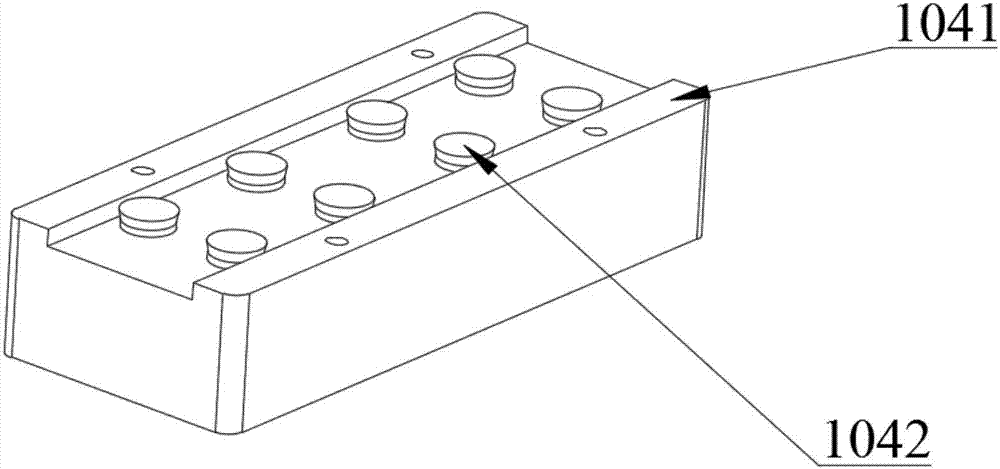

Metallic glass composite material ultrasound-assisted 3D cold printing device and method

ActiveCN107470627ALow costStrong forming abilityAdditive manufacturing apparatusTransportation and packagingGlass compositesUltrasound assisted

The invention provides a metallic glass composite material ultrasound-assisted 3D cold printing device and method, and belongs to the field of additive manufacturing. The metallic glass composite material ultrasound-assisted 3D cold printing device comprises an ultrasonic vibration material cylinder, a three-axis cold printing device, an ultrasonic vibration base plate and a base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device, the 3D cold printing technology, the ultrasonic vibration technology and the superfine-particle reinforced metal matrix composite material technology are combined, the ultrasonic vibration material cylinder is fixedly arranged on the base machine box, the three-axis cold printing device is fixedly arranged on the base machine box, and the ultrasonic vibration base plate is fixedly arranged on the base machine box. According to the metallic glass composite material ultrasound-assisted 3D cold printing device and method, superfine reinforced particles are added to a metallic particle solution, so that the mechanical property of a material is enhanced; the distribution uniformity of the superfine particles in the metallic particle solution is improved by the use of ultrasonic vibration; and a three-dimensional metallic glass composite material part is directly formed through the 3D cold printing technology, the forming speed is high, the part strength is high, the density is uniform, the cost is low, and no special requirements for the working environment exist.

Owner:JILIN UNIV

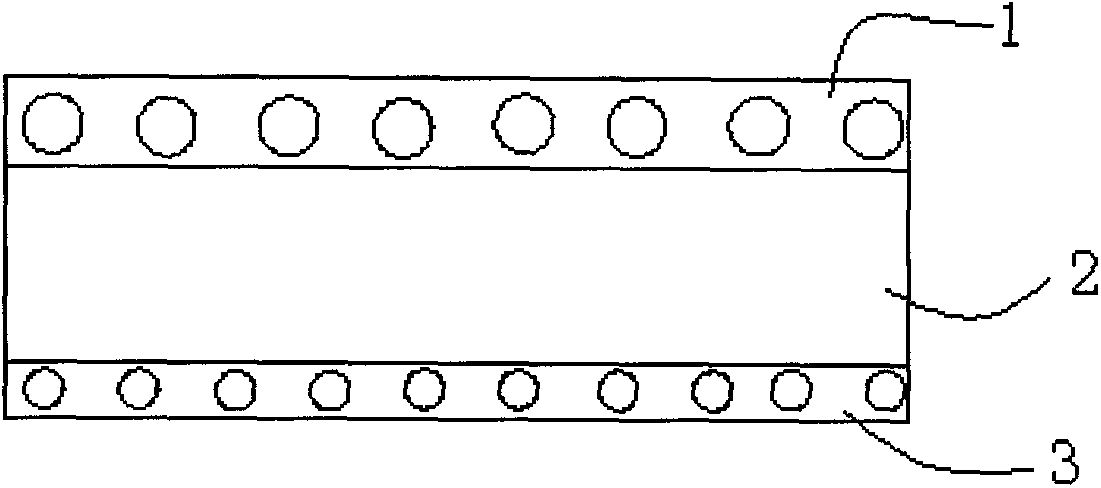

Two-way stretching light diffusion film and preparation method thereof

ActiveCN103529501ADimensionally stableHigh light transmittanceDiffusing elementsNon-linear opticsConvex structureAntistatic agent

The invention provides a two-way stretching light diffusion film. The two-way stretching light diffusion film is characterized by comprising a diffusion layer, a supporting layer and an anti-adhesion layer, wherein the diffusion layer covers the upper surface of the supporting layer; the anti-adhesion layer covers the lower surface of the supporting layer; the supporting layer is made of PET (polyethylene glycol terephthalate); the diffusion layer consists of PET, an anti-static agent and glass beads; the anti-adhesion layer consists of PET, silicon dioxide particles and an anti-static agent. A manufacturing method comprises the following steps of (A) preparing diffusion master particles; (B) preparing anti-adhesion master particles; (C) preparing the diffusion film: co-extrusion, longitudinal stretching and horizontal stretching. The two-way stretching light diffusion film provided by the invention has the advantages that due to no obvious concave-convex structure on the surface of the light diffusion film, no damage is caused to a prismatic lens and other components of a backlight module.

Owner:NINGBO DXC NEW MATERIAL TECH

Glass for information recording media substrate, glass substrate for magnetic disk and magnetic disk

InactiveCN101417861ANot easy to peel offInhibited DiffusionWeather resistanceCondensed matter physics

To provide a glass for an information recording media substrate, which is excellent in weather resistance. A glass for an information recording media substrate, which comprises, as represented by mol % based on oxide, from 61 to 66% of SiO2, from 11.5 to 17% of Al2O3, from 8 to 16% of Li2O, from 2 to 8% of Na2O, from 2.5 to 8% of K2O, from 0 to 6% of MgO, from 0 to 4% of TiO2 and from 0 to 3% of ZrO2, provided that Al2O3+MgO+TiO2 is at least 12%, and Li2O+Na2O+K2O is from 16 to 23%, wherein in a case of where B2O3 is contained, its content is less than 1%. The above glass for an information recording media substrate, wherein when the glass is left under steam atmosphere at 120 DEG C. at 0.2 MPa for 20 hours, and the amount of Li, the amount of Na and the amount of K, which precipitate on a surface of the glass are represented as CLi, CNa and CK respectively, CNa is at most 0.7 nmol / cm2, and CLi+CNa+CK is at most 3.5 nmol / cm2.

Owner:ASAHI GLASS CO LTD

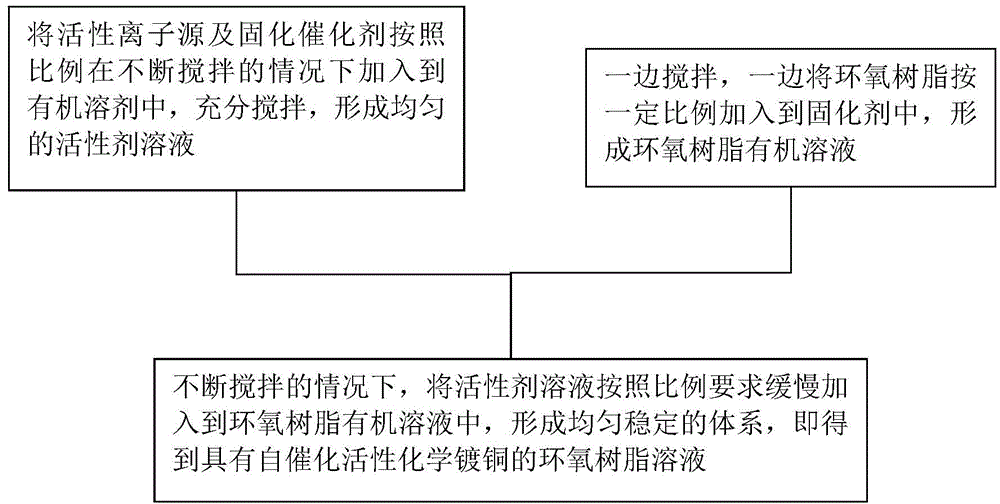

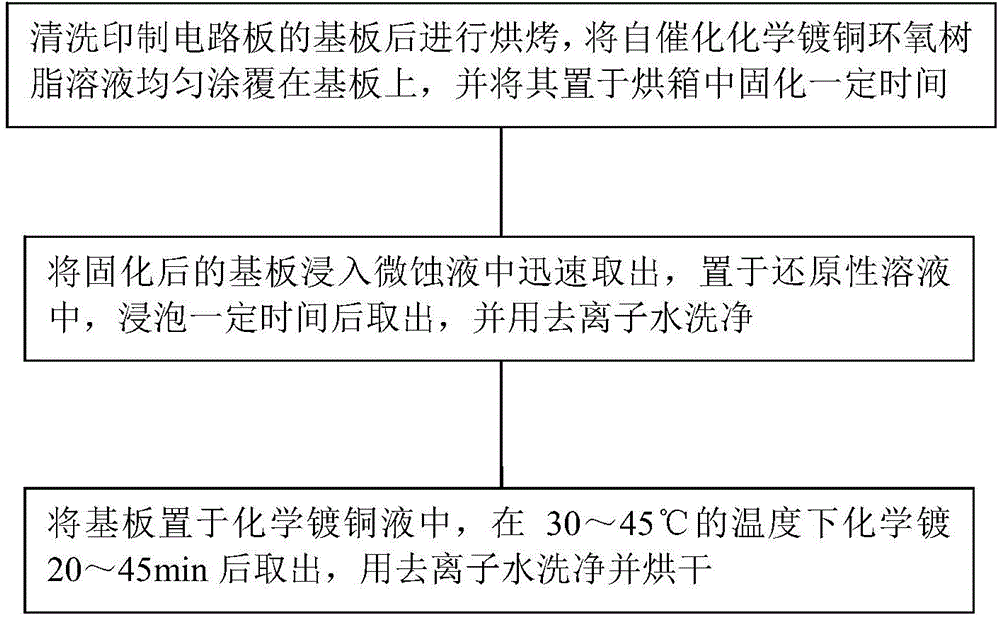

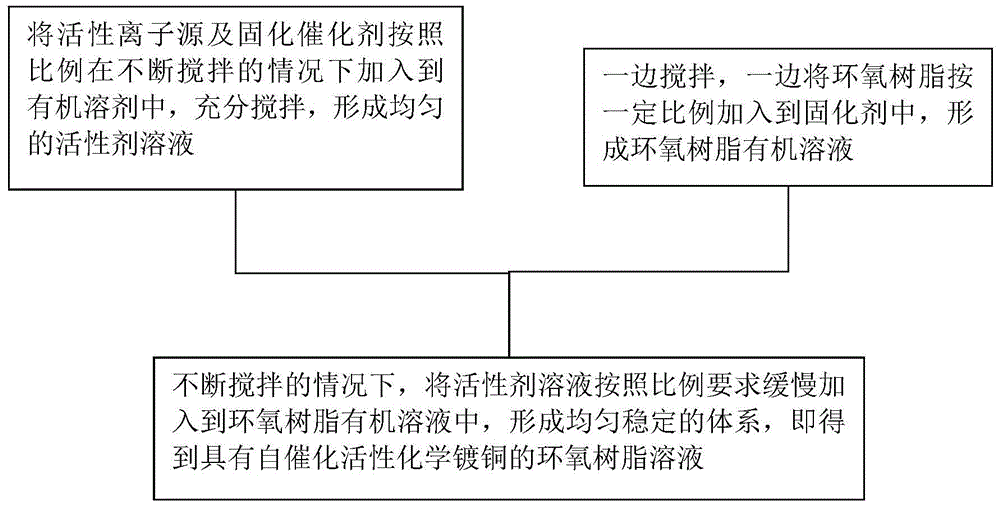

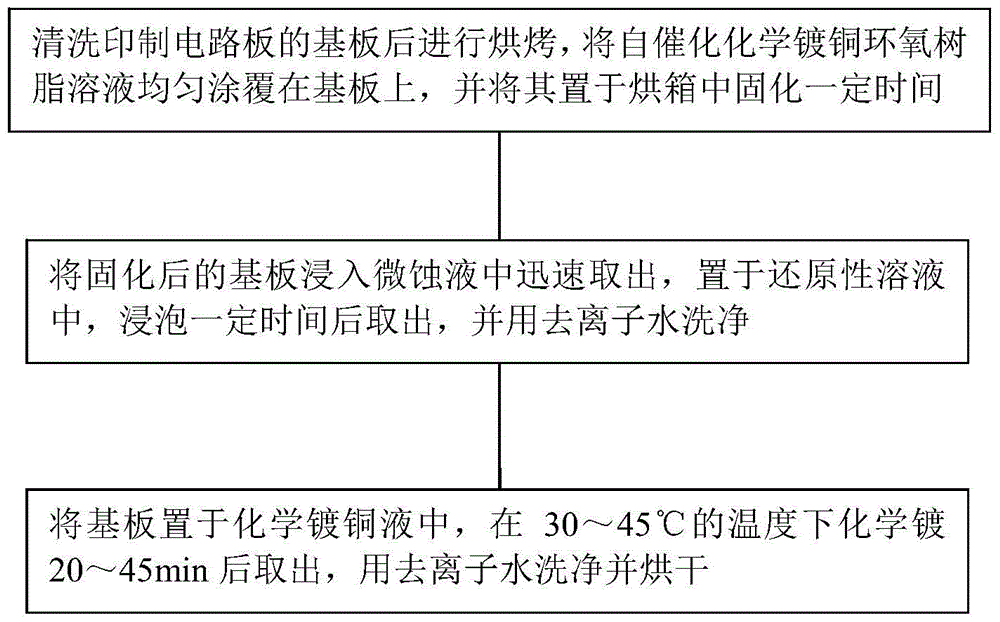

Compounding method of epoxy resin solution with autocatalysis chemical copper plating activity and chemical copper plating method

InactiveCN104789949AImprove stabilityEvenly distributedLiquid/solution decomposition chemical coatingEpoxyChemical plating

The invention relates to a compounding method of an epoxy resin solution with autocatalysis chemical copper plating activity and a chemical copper plating method, and belongs to the technical field of material surface treatment. The compounding method comprises the following steps: adding an activity ion source to an organic solvent under the circumstance of unceasingly stirring, adding a given number of curing catalysts, and sufficiently stirring the activity ion source, the organic solvent and the curing catalysts so as to form a uniform active agent solution; adding epoxy resins to a curing agent according to a certain proportion in a stirring manner so as to form an epoxy resin organic solution; unceasingly stirring the epoxy resin organic solution, and besides, slowly adding the active agent solution to the epoxy resin organic solution so as to form a uniform stable system, namely obtaining a chemical copper plating epoxy resin solution with autocatalysis activity; enabling a compounded resin solution to form a uniform coating on a basal board of a printed circuit board by a casting method or a silk screen printing method, and performing the procedures of solidification, microetch, reduction, chemical plating and the like so as to obtain a plating piece with a bright pink copper plating layer. Through performance test, the copper layer-resin binding force and the electrical conductivity of samples are excellent, and the compounding method and the chemical copper plating method are suitable for a chemical copper plating technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

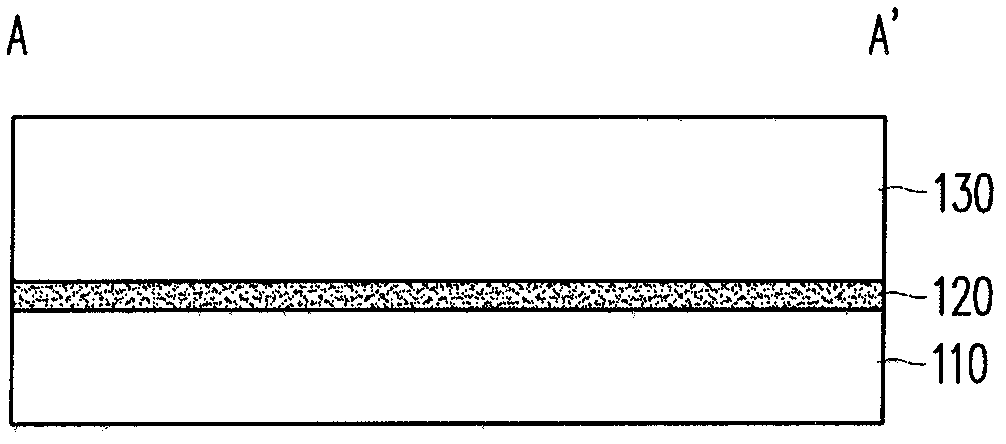

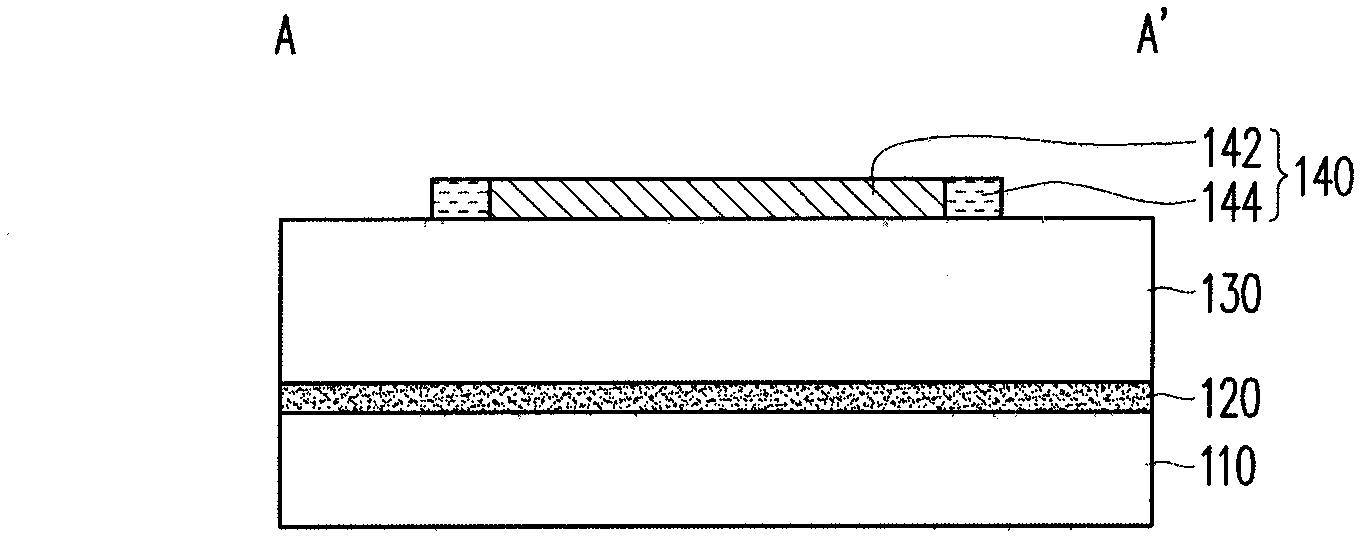

Flexible electronic component and manufacturing method thereof

ActiveCN102280371AImprove manufacturing yieldEasy to removeStatic indicating devicesSemiconductor/solid-state device detailsInterface layerContact type

The invention discloses a pliable electronic component and a manufacturing method thereof. The manufacturing method comprises the following steps of attaching a pliable substrate on a hard substrate through a weak-force interface layer; forming multiple array-arranged electronic components on the pliable substrate; dividing the hard substrate into multiple sub-substrate each provided with an electronic component; performing non-contact type cutting on the electronic components along at least a part of the functional part of each electronic component so as to form a first cutting channel between the functional part of each electronic component and a quasi part of the electronic component; performing contact type cutting on the pliable substrate and the weak-force interface layer along the first cutting channel so as to form a second cutting channel between the pliable substrate and the weak-force interface layer, wherein, the second cutting channel makes the sub-substrate part exposed; and removing the functional part and the pliable substrate located below the functional part from the sub-substrate. The method provided in the invention improves the manufacture good product rate of the pliable electronic component.

Owner:AU OPTRONICS CORP

Low-cost Keruing timber degreasing method

InactiveCN102218762AImprove convenienceIncrease usageWood impregnation detailsOrganic solventFresh water

The invention provides a low-cost Keruing timber degreasing method, which comprises the steps as follows: Keruing timbers are arranged into a steaming vat; then fresh water is filled in the steaming vat and heated so that the internal temperature of the Keruing timbers can reach a target temperature; then heating is stopped and the surfaces of the Keruing timbers are cleaned after natural cooling; then the Keruing timbers are discharged out of the vat and are processed into blank materials and dried so that the grease in the blank materials can be volatilized and seeped; after the grease is seeped, the surfaces of the Keruing timbers are wiped by organic solvent to dissolve and remove the grease; then the Keruing timbers are piled until the surfaces of the Keruing timbers are dry to remove the surface grease grains and finally achieve the purpose of degreasing. The low-cost Keruing timber degreasing method is simple to operate, has low cost, can not pollute environment and has obvious degreasing effect. The degreased Keruing is hard to warp and crack, etc. Moreover, the paint adhesion of products is strong; the excellence and occupation coefficient of the Keruing timbers are greatly improved.

Owner:GUANGDONG YIHUA TIMBER IND

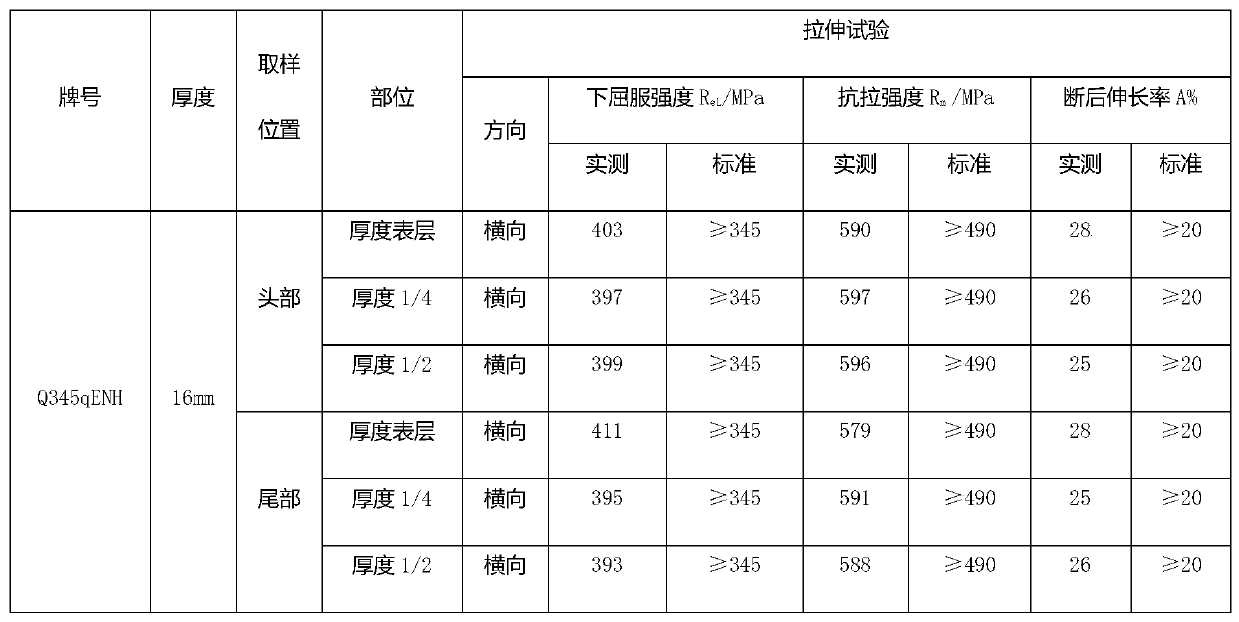

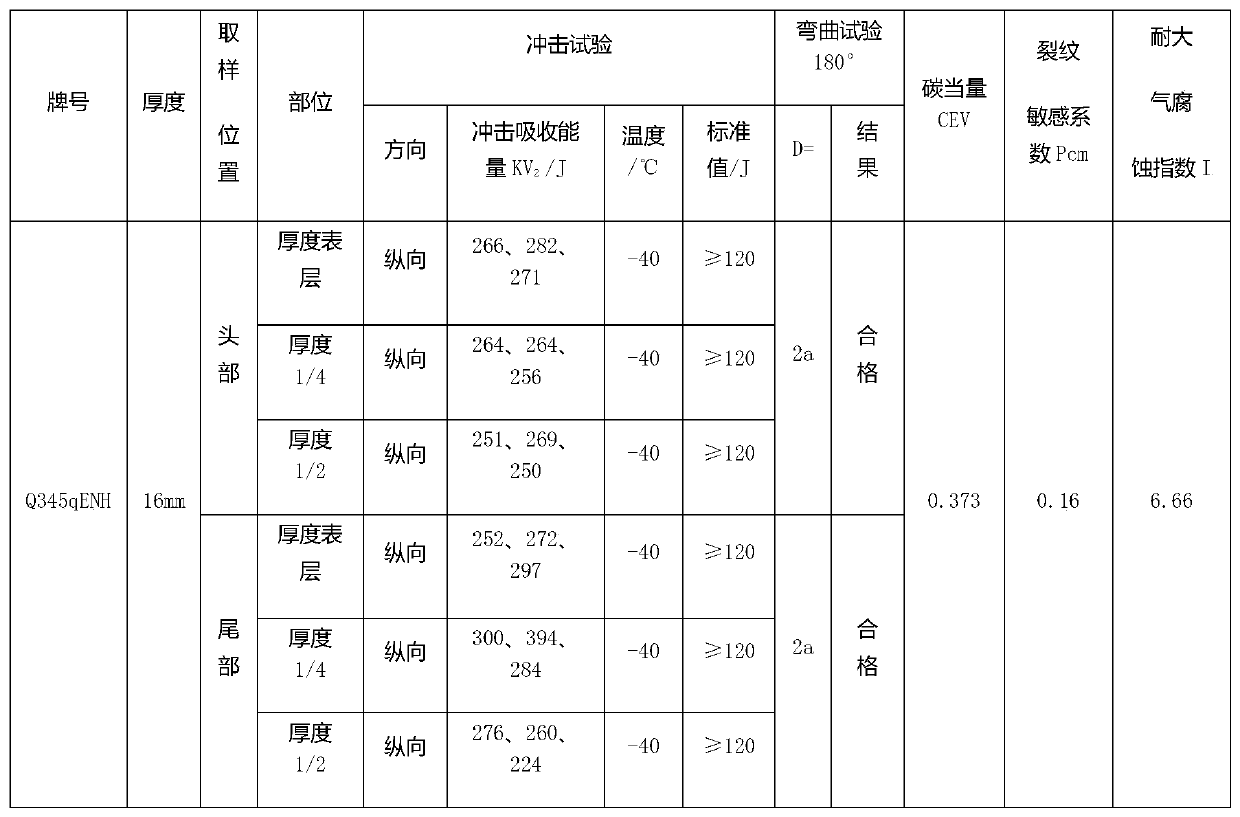

Q345qENH weather-resistant bridge steel plate with thickness smaller than or equal to 50 mm and production method thereof

InactiveCN110565011AReduce carbon equivalentReduce crack sensitivity factorProcess efficiency improvementHeating timeCrack resistance

The invention discloses a Q345qENH weather-resistant bridge steel plate with the thickness smaller than or equal to 50 mm. The Q345qENH weather-resistant bridge steel plate comprises the chemical compositions including C, Si, Mn, P, S, Als, V, Ti, Cr, Ni, Nb, Cu, N, B, H and the balance Fe and residual elements. According to the Q345qENH weather-resistant bridge steel plate, the contents of elements such as B, N, H, Ti and S are controlled, so that the carbon equivalent and the crack sensitivity coefficient of the steel plate are greatly reduced, and the welding performance and the welding crack resistance of the steel plate are improved. The corrosion resistance index can be greatly increased, and the atmospheric corrosion resistance of the steel plate is improved. Phased control over theheating temperature and the heating time is beneficial to control over hot cracks, meanwhile, a billet is uniformly burned thoroughly, and deformation is facilitated. Matching of comprehensive properties such as tensile properties, low-temperature impact performance, cold bending performance and failure impact performance of the steel plate can be achieved. It is ensured that the shape of the steel plate is straight in the subsequent cutting process, and the plate shape problems such as rebound, warpage and distortion are not prone to being caused.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

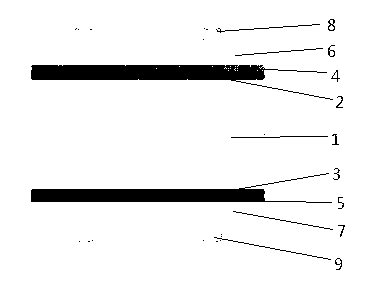

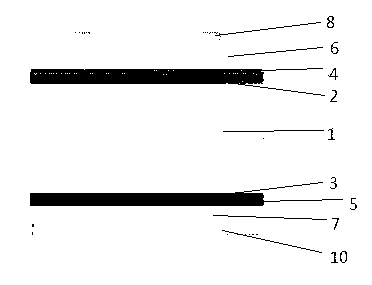

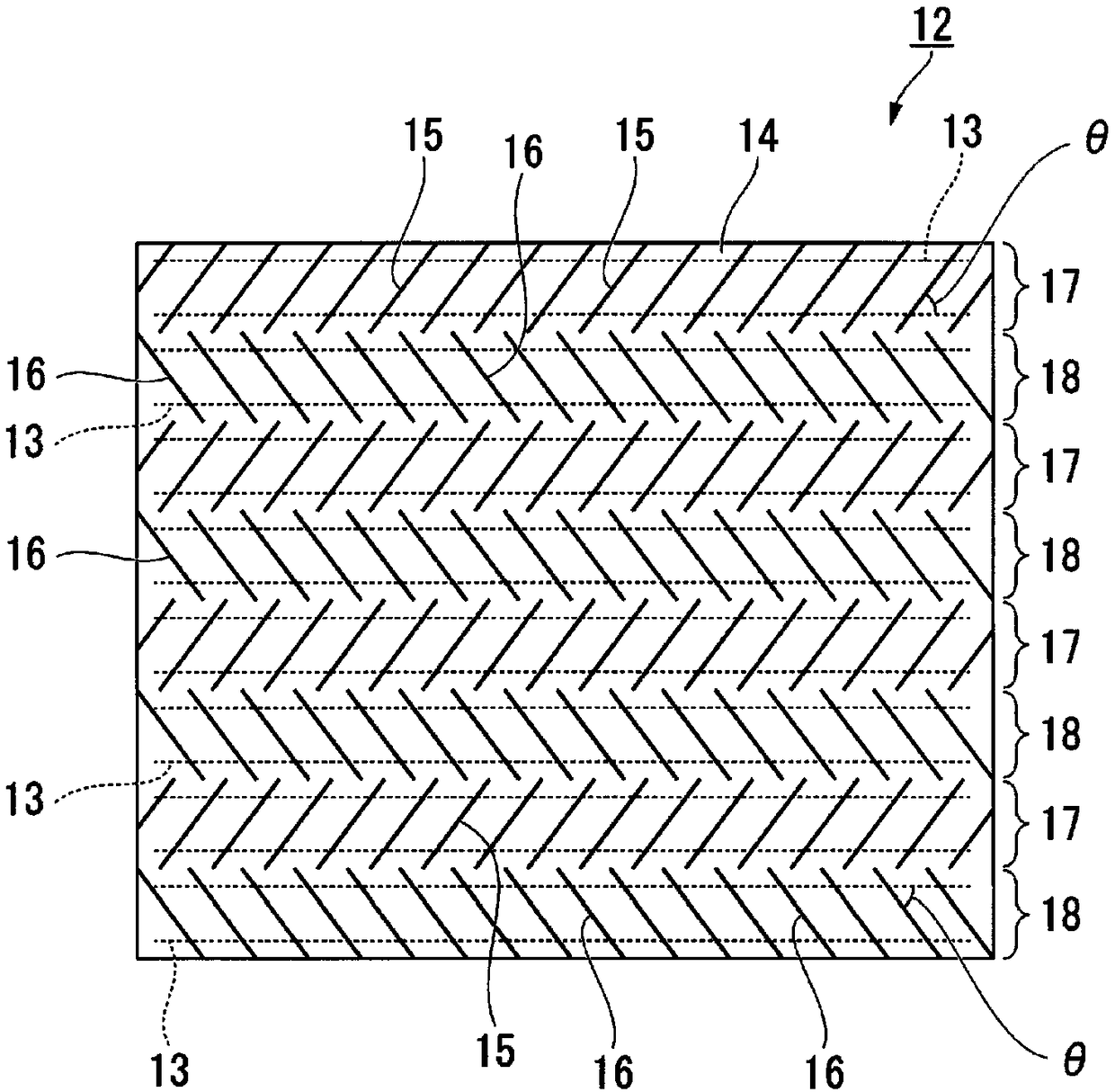

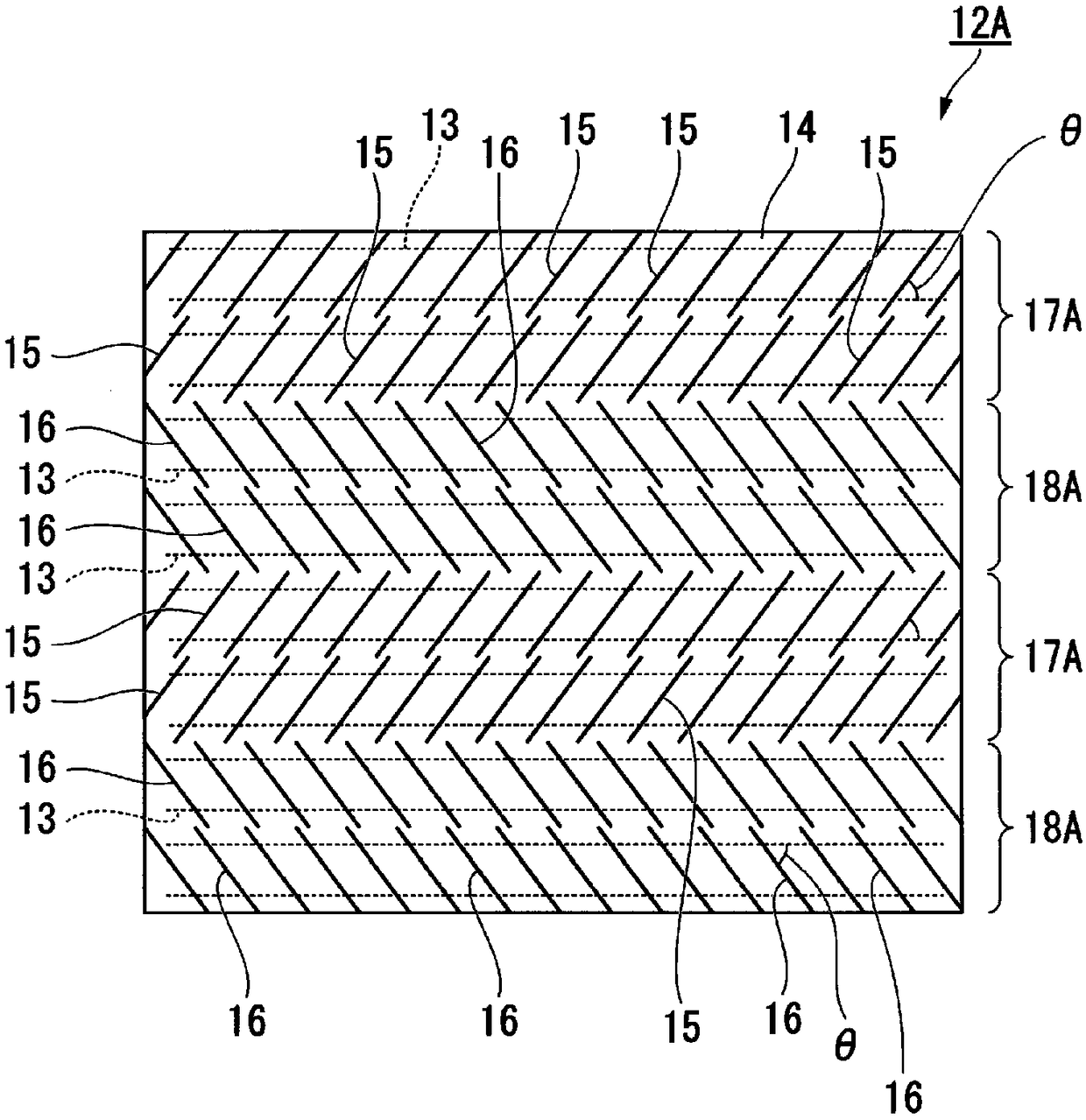

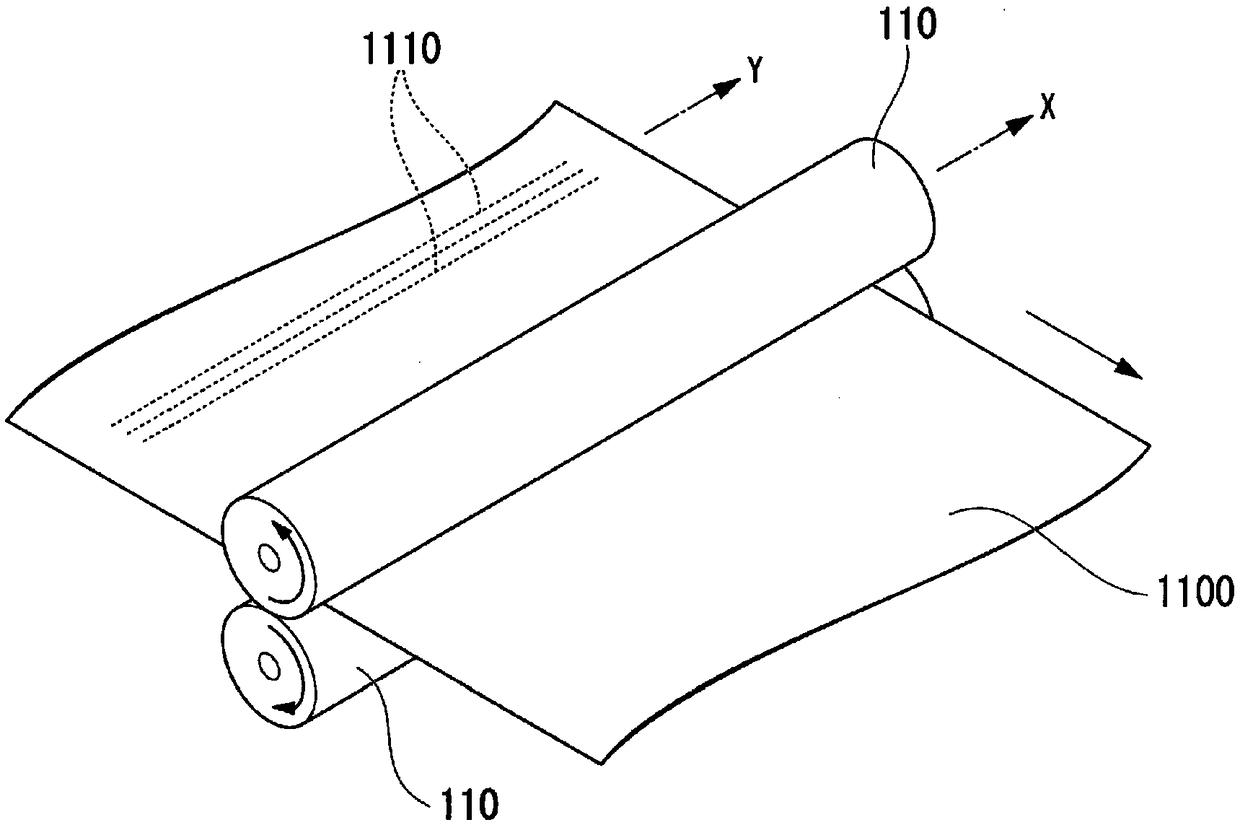

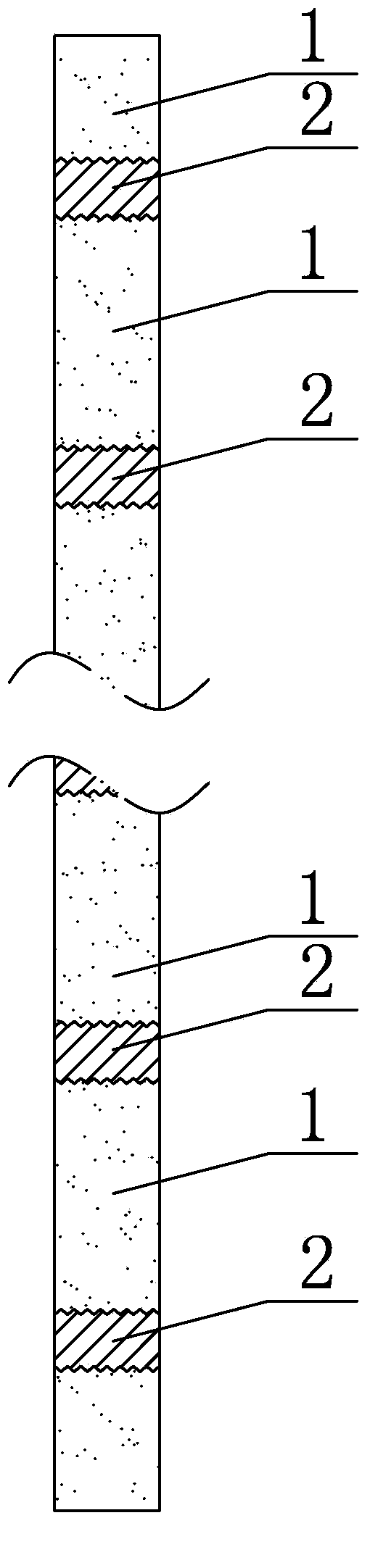

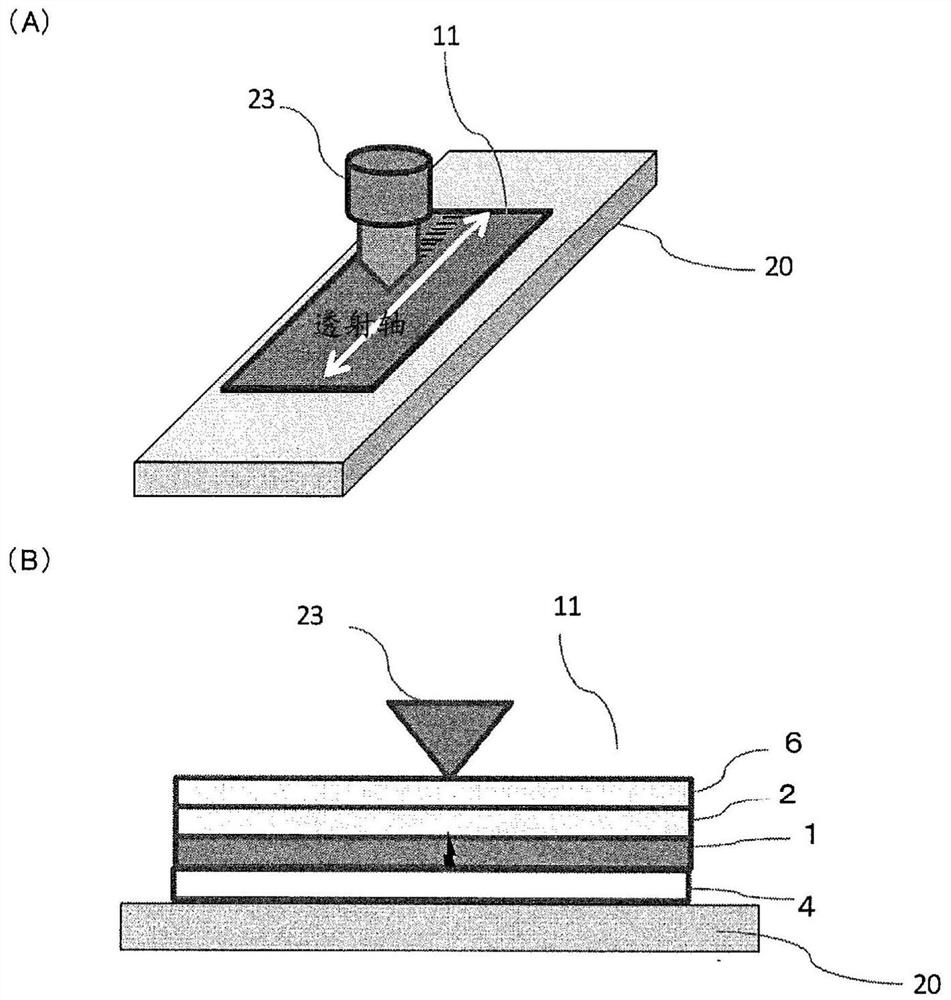

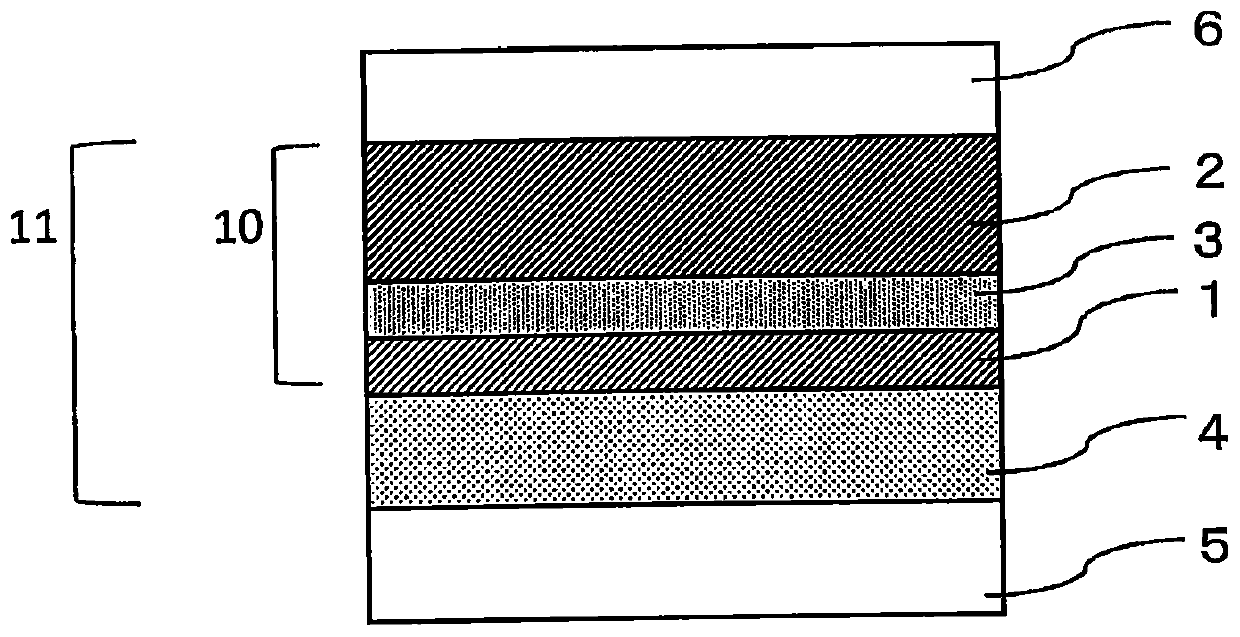

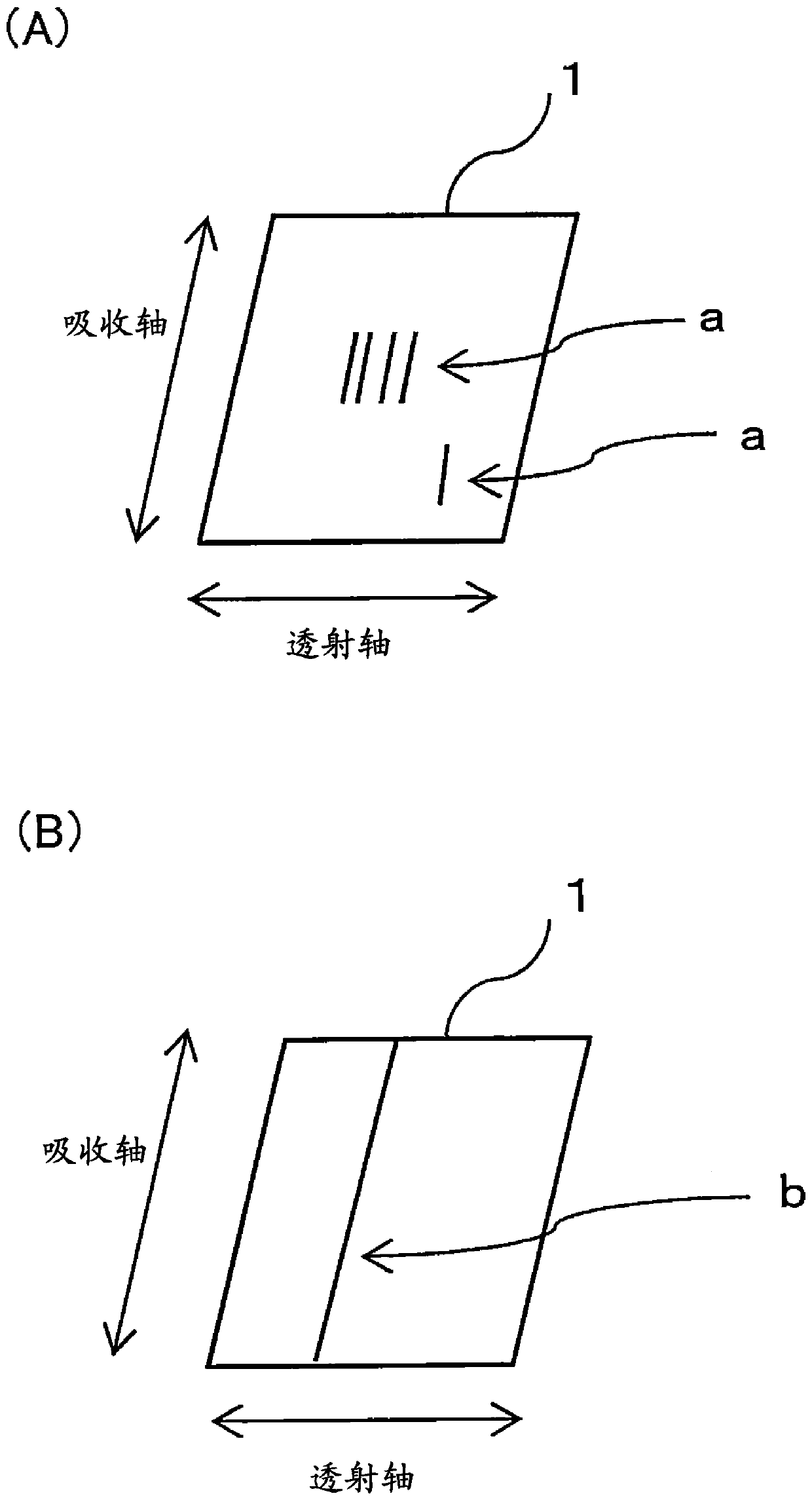

Fiber-reinforced plastic and method for producing same

ActiveCN109348708ANot prone to ups and downsLess prone to warpingFlat articlesPolymer sciencePolymer chemistry

Provided are a fiber-reinforced plastic producing method capable of easily producing a fiber-reinforced plastic in which swelling and warpage are less likely to occur and of which excellent mechanicalcharacteristics and isotropy are ensured, and a fiber-reinforced plastic in which swelling and warpage are suppressed from occurring. The fiber-reinforced plastic producing method has a step for obtaining a material (A) including a prepreg base material (12) in which a region (B) (17), where reinforcing fibers (13) pulled and aligned in one direction are impregnated with a matrix resin (14) and aplurality of cuts (b) (15) are formed, and a region (C) (18), where a plurality of cuts (c) (16) are formed, are alternately formed in a direction orthogonal to a fiber axis of the reinforcing fiber(13), a step for hot-pressing the material (A) while moving the material (A) under specific conditions, and a step for cooling the pressed material (A) to obtain the fiber-reinforced plastic.

Owner:MITSUBISHI CHEM CORP

LED lamp molding printing process

ActiveCN109659419AAvoid stickingEqual amount of glueNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveEngineering

The invention relates to the technical field of LEDs, in particular to an LED lamp molding printing process. The LED lamp comprises an LED base, the LED base is provided with a plurality of cavities,and each cavity is fixed with an LED chip. The printing process comprises the following steps of: (1) designing a tape film, wherein the tape film is provided with a plurality of through holes, one surface of the tape film is coated with an adhesive layer, the adhesive is applied to the base to allow the through holes to face the cavities of the LED base; (2) injecting fluorescent glue into the cavities; (3) performing blade coating at the surface of the tape film by employing a scraper; and (4) stripping off the tape film. The tape film is attached to the LED base to prevent the fluorescent glue from pasting to the base; the scraper is employed to scrape the overflowing fluorescent glue on the tape film into the cavities of the LED base to facilitate even glue amount of the cavities so asto display an even luminance effect.

Owner:东莞市谷麦光学科技有限公司 +3

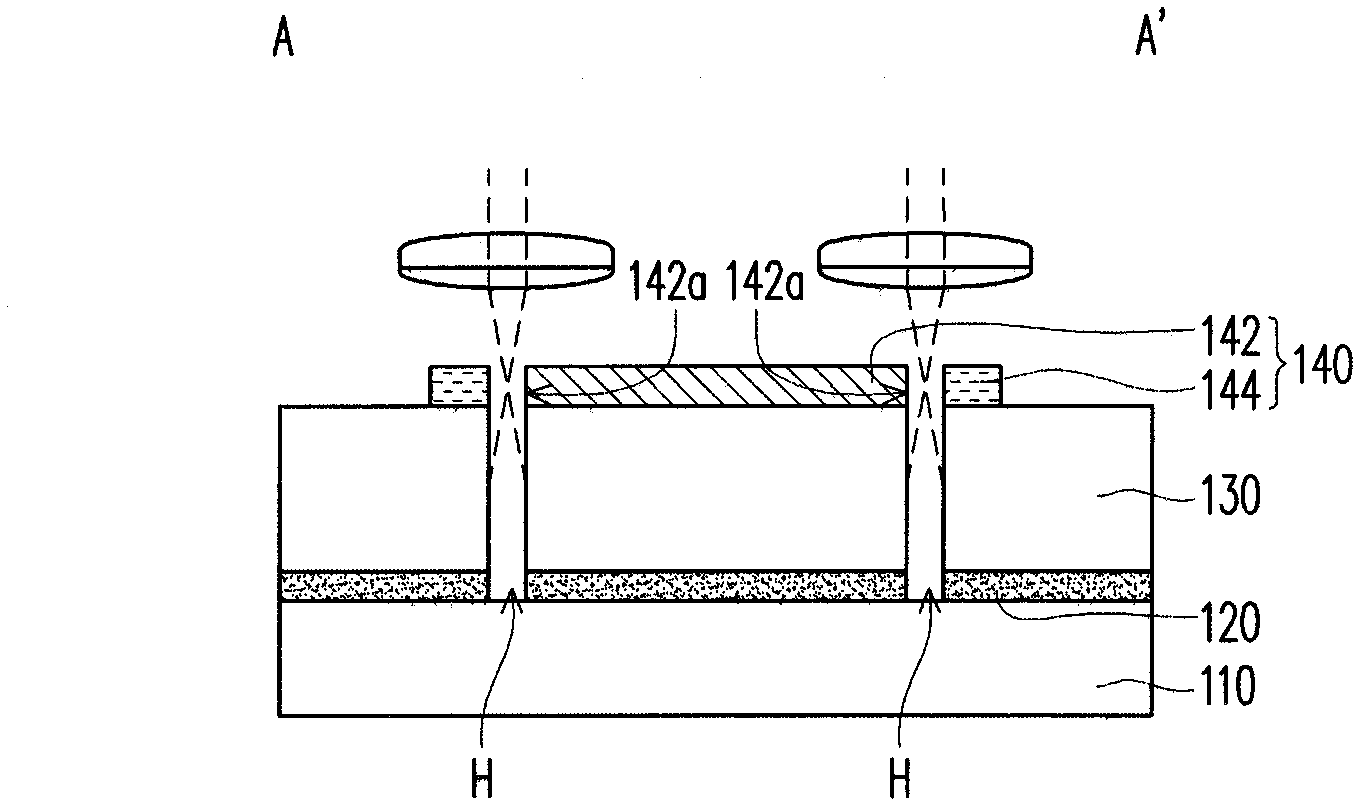

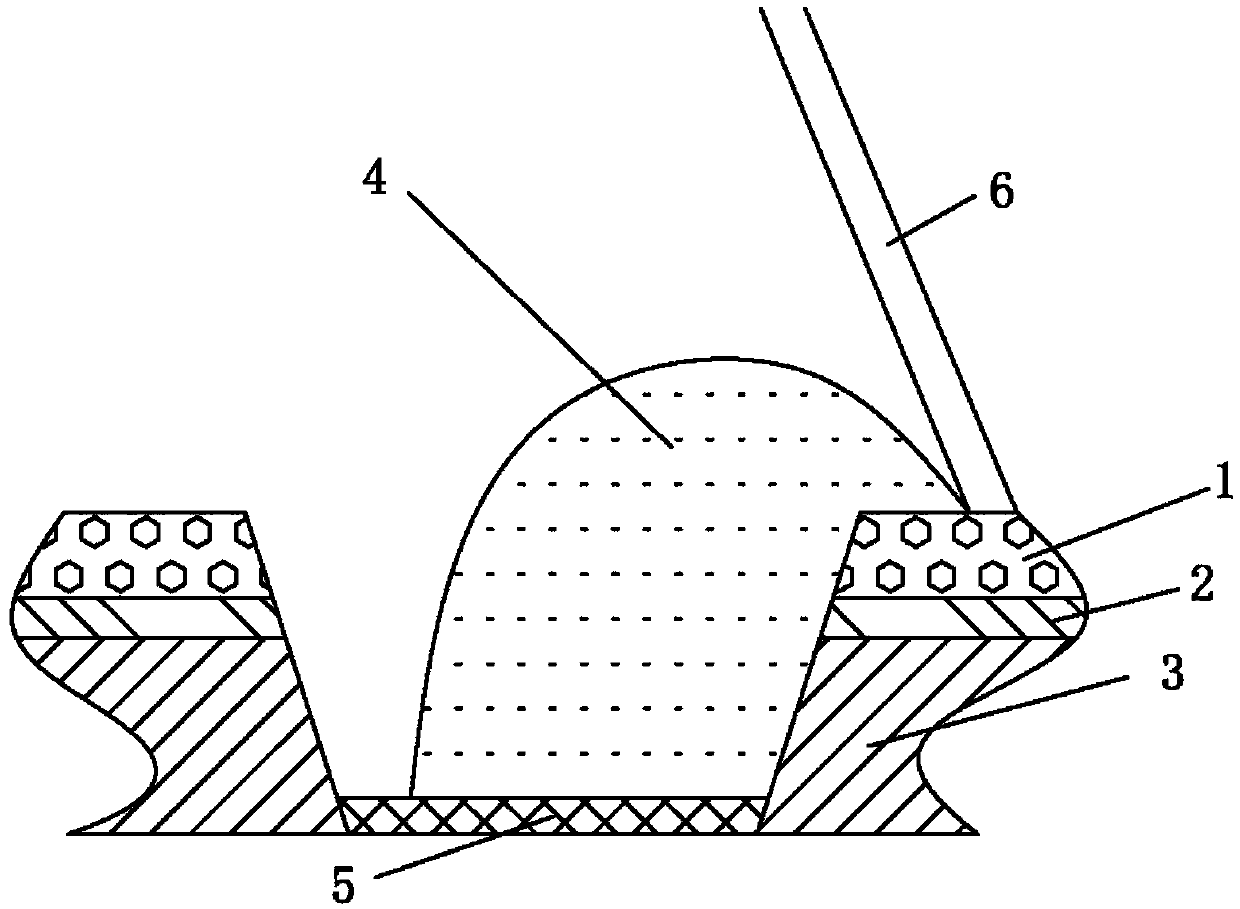

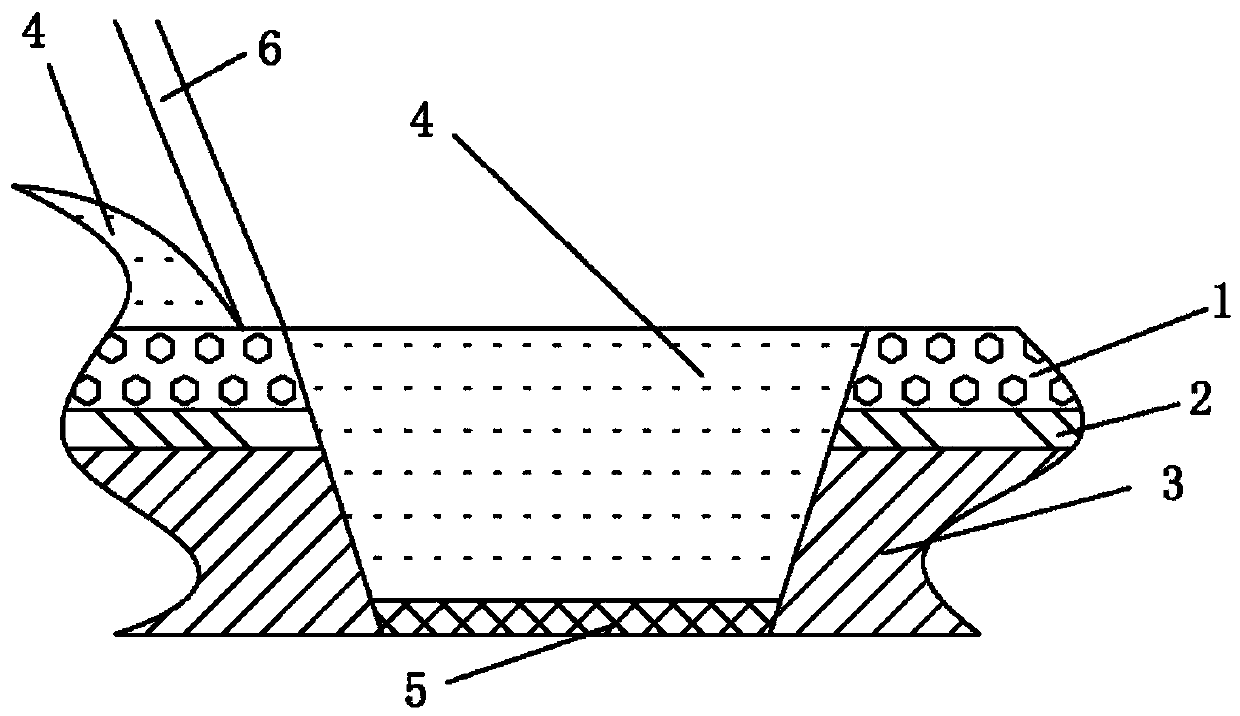

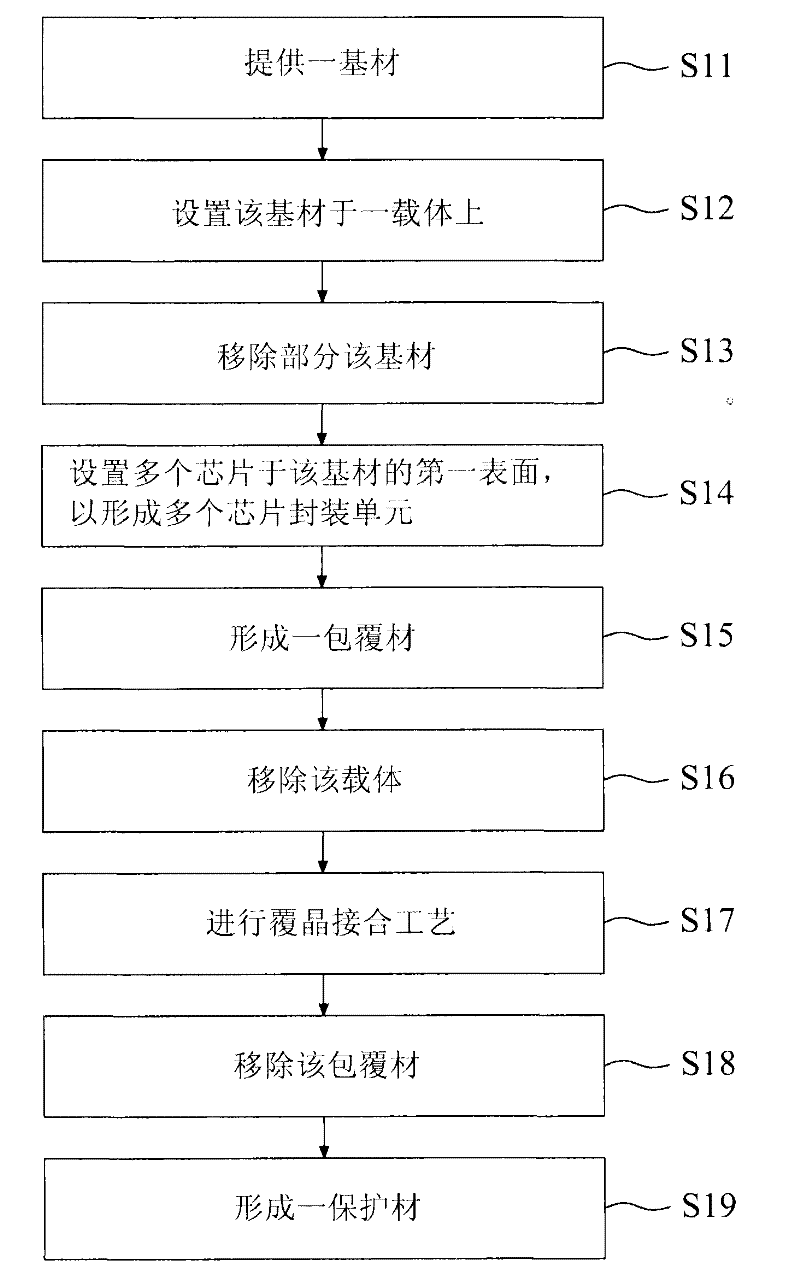

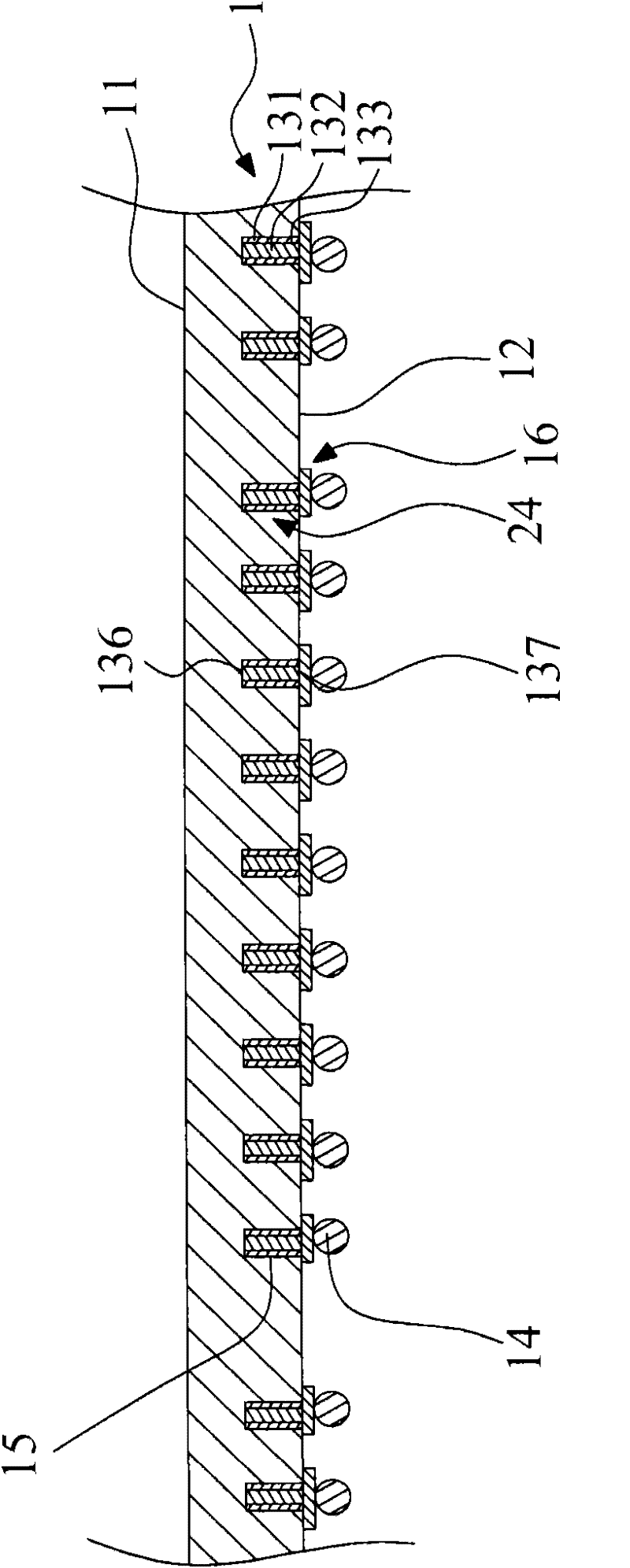

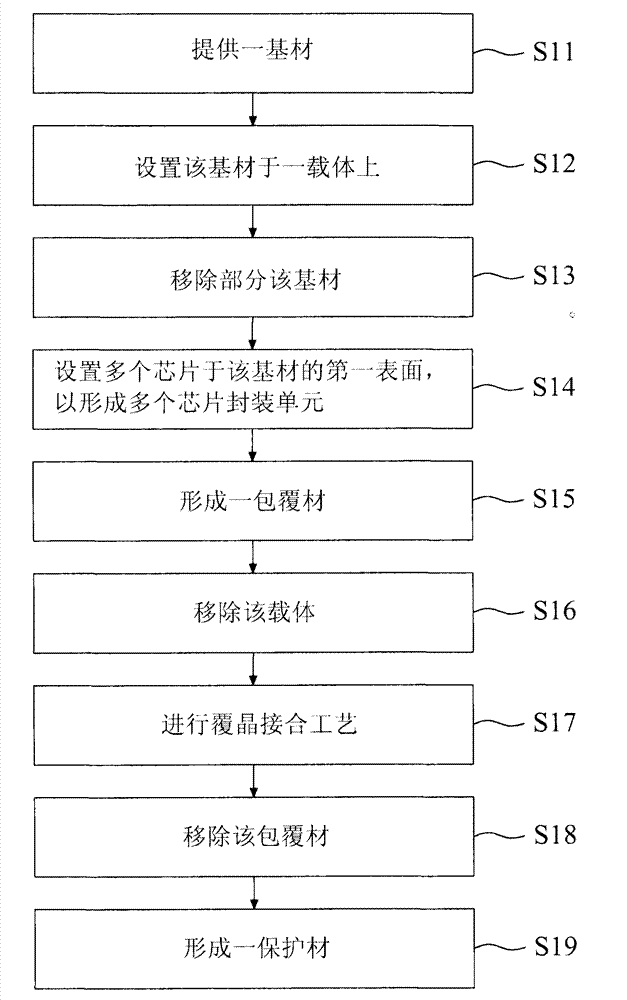

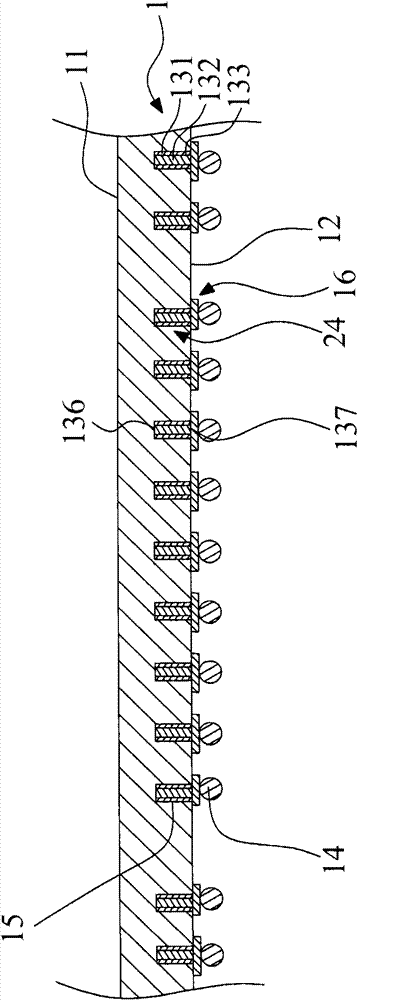

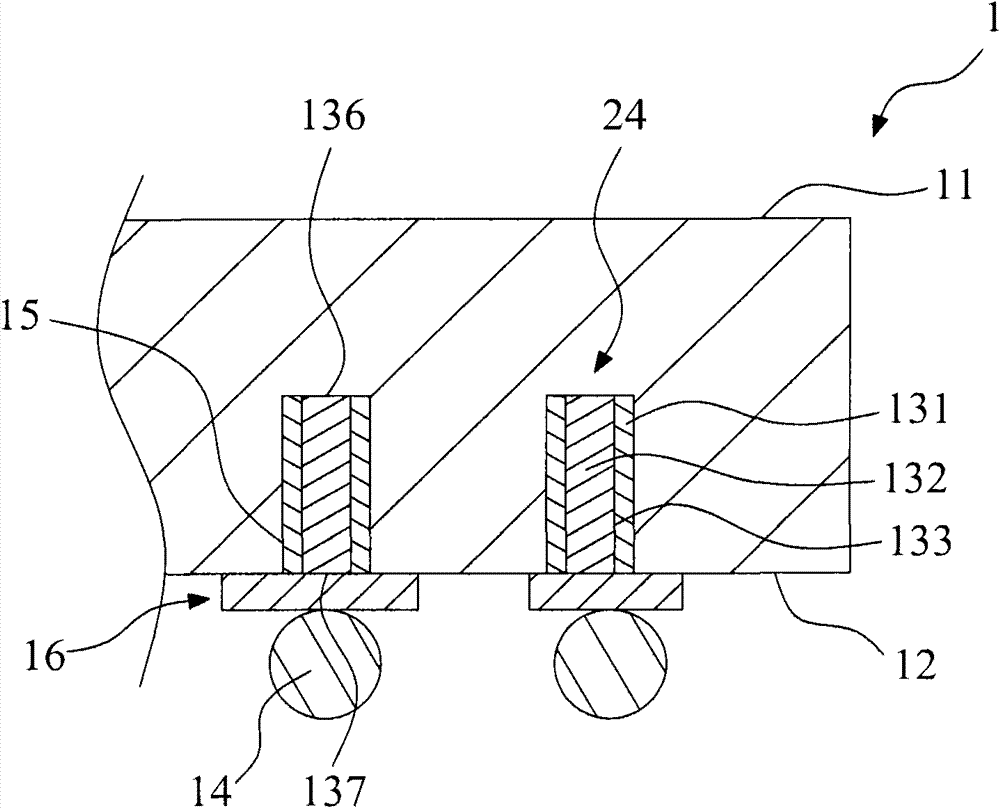

Method for manufacturing chip packaging structure

ActiveCN102163558ALess prone to warpingImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCoating

The invention relates to a method for manufacturing a chip packaging structure. The manufacturing method comprises the following steps of: (a) providing a substrate, wherein the substrate is provided with at least one conductive hole; (b) arranging the substrate on a carrier; (c) removing partial substrate to expose the conductive hole, and forming at least one penetration guide hole; (d) arranging a plurality of chips on the surface of the substrate, and electrically connecting the chips to the penetration guide hole of the substrate; (e) forming a coating material; (f) removing the carrier;(g) carrying out a chip bonding process; (h) removing the coating material; and (i) forming a protective material. Thus, the carrier and the coating material can ensure the substrate to be difficult to warp in a process.

Owner:ADVANCED SEMICON ENG INC

Preparation method for 3D printing support material based on photoinduced reversible micelles

InactiveCN108297438AImprove liquidityGood compatibilityAdditive manufacturing apparatus3D object support structuresPolymer scienceFluidized bed

The invention belongs to the technical field of 3D printing and particularly relates to a preparation method for a 3D printing support material based on photoinduced reversible micelles. According tothe preparation method for the 3D printing support material based on the photoinduced reversible micelles, a crosslinking agent and hydroxyazobenzene are sprayed on hollow porous polymer microspheresin a fluidized bed, the surfaces of the polymer microspheres are crosslinked by increasing temperature gradually to introduce azobenzene groups, the microspheres and dimeric surfactant are mixed and frozen and solidified in the microspheres, and the microspheres are made to carry the dimeric surfactant to obtain the support material. According to the preparation method for the 3D printing supportmaterial based on the photoinduced reversible micelles, by means of the manners that the dimeric surfactant is loaded into the hollow microspheres containing the azobenzene groups and a photorheological reversible micelle system is obtained by compounding, the flowability of the supporting material before illumination is increased, the supporting material is made to have the characteristic of rapid response and is taken as the 3D printing supporting material by virtue of the invertible light isomerisation property of the supporting material, meanwhile, the support material has good compatibility with various polymer printing materials, and product warping and other phenomena are not prone to occur.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

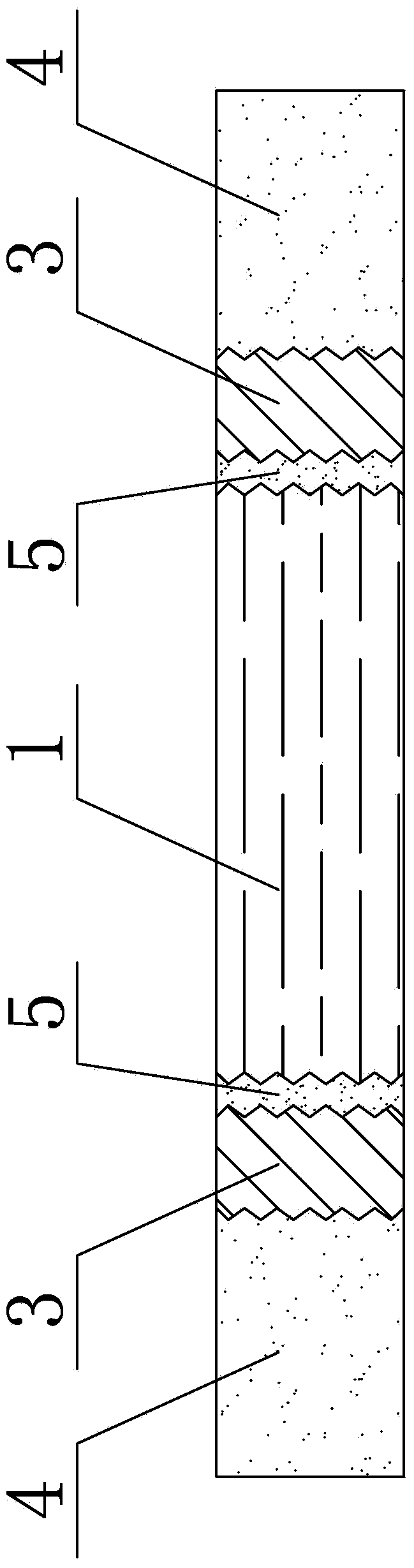

Light-diffusion plate

InactiveCN101107546AGood dimensional stabilityLess prone to warpingTravelling carriersHoldersEngineeringMoisture resistance

Disclosed is a light-diffusion plate for use in a backlight unit of a liquid crystal display or an illumination apparatus. Specifically, this invention provides a light-diffusion plate including a substrate layer composed mainly of a first base resin; and a surface layer composed mainly of fluorine resin formed on either or both surfaces of the substrate layer. Thus, such a light-diffusion plate exhibits high dimensional stability thanks to high heat resistance and moisture resistance, and seldom causes a bending phenomenon even under conditions of high temperature and high humidity. Further, the light-diffusion plate has excellent light properties including total luminous transmittance, and also has a low yellowing index even upon exposure to a light source for a long period of time.

Owner:KOLON IND INC

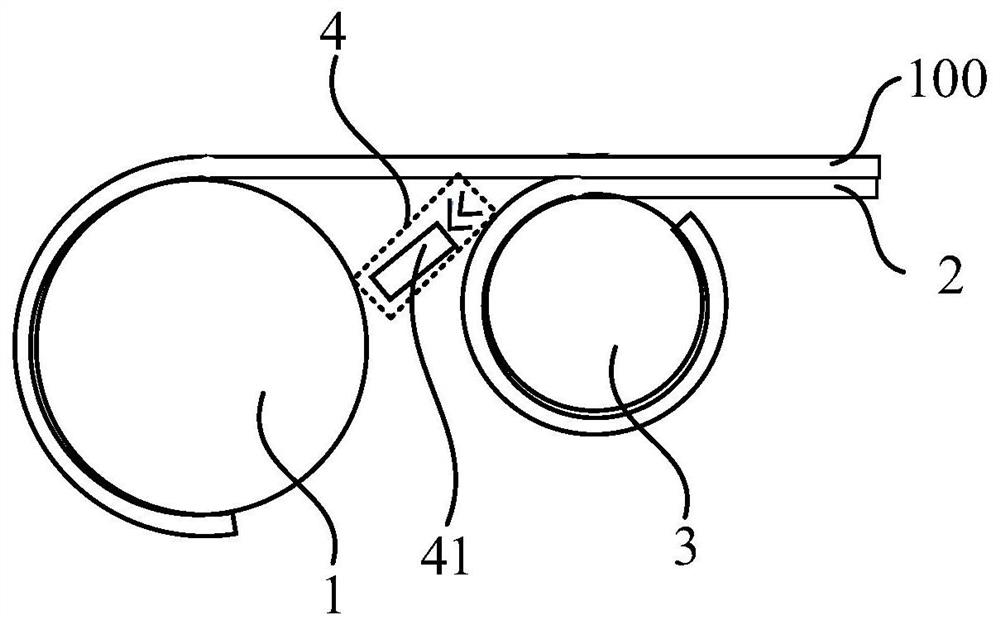

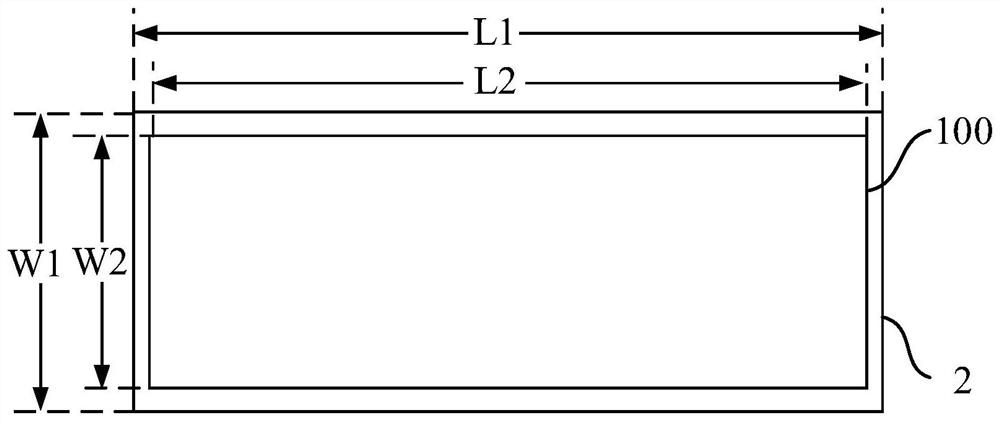

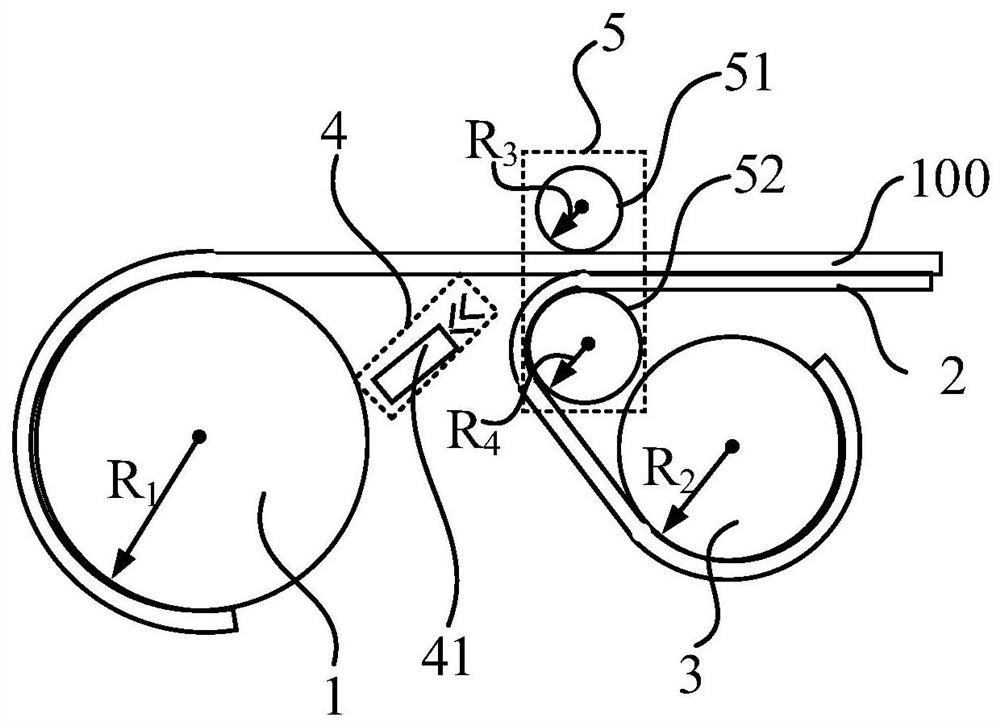

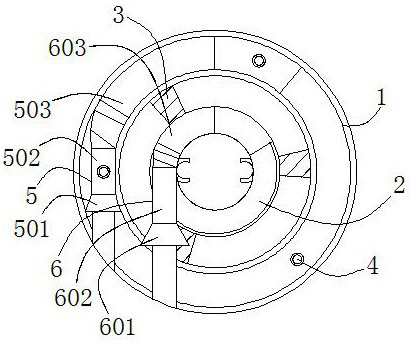

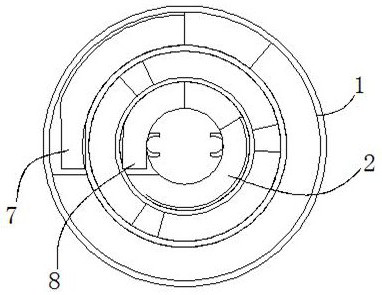

Screen body curling mechanism and curlable device

ActiveCN113380149ALess prone to warpingSolve warpingIdentification meansEngineeringMechanical engineering

The invention discloses a screen body curling mechanism and a curlable device. The screen body curling mechanism comprises a screen body storage shaft used for curling a screen body and winding the screen body on the surface of the screen body storage shaft; a supporting film layer arranged on the non-light-emitting side of the screen body and used for supporting the screen body in an unfolded state; a supporting film storage shaft arranged on the side, away from the screen body in the unfolded state, of the supporting film layer, wherein the screen body storage shaft and the supporting film storage shaft are located at the same end of the screen body, and the supporting film storage shaft is used for curling the supporting film layer and winding the supporting film layer on the surface of the supporting film storage shaft; a laminating module which is arranged between the screen body and the supporting film layer in the unfolded state, wherein the laminating module is not in direct contact with the screen body and the supporting film layer, and the laminating module is used for dedusting and laminating the part, located outside the screen body storage shaft, of the screen body and the part, located outside the supporting film storage shaft, of the supporting film layer. According to the technical scheme, the problem that the screen body is prone to warping in the screen body curling process is solved.

Owner:HEFEI VISIONOX TECH CO LTD

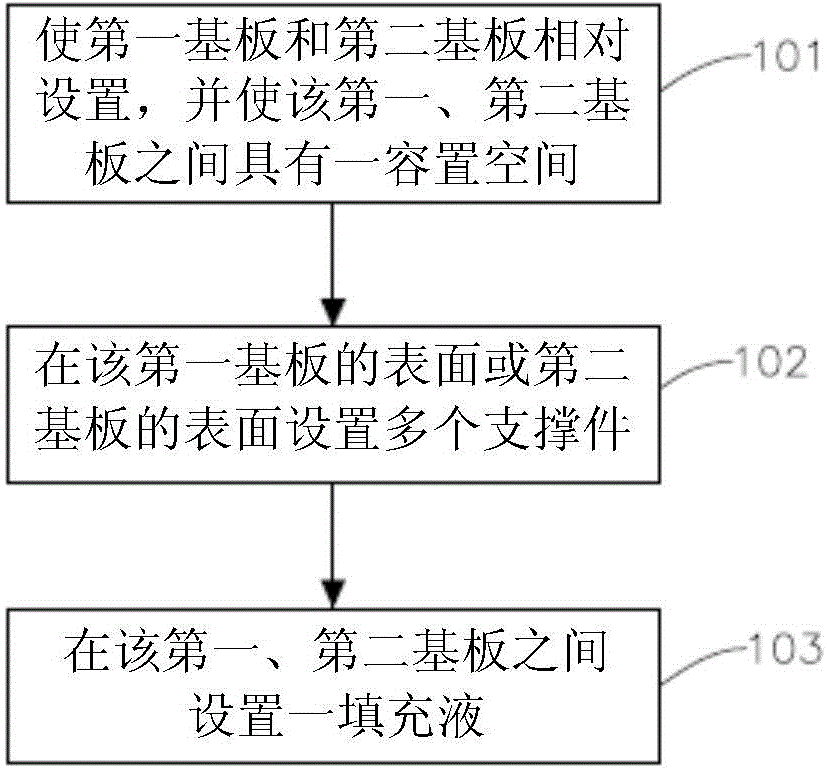

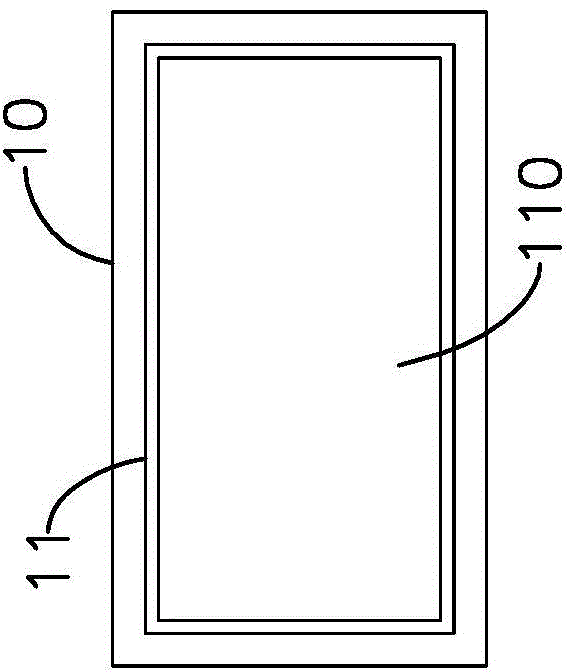

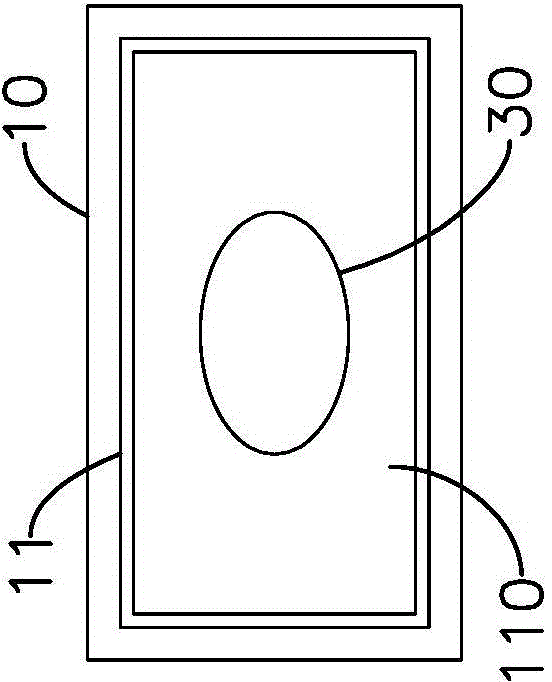

Touch control panel, touch control module and laminating method therefor

InactiveCN104808875ALess prone to warpingAvoid problems with touch detection correctnessInput/output processes for data processingOptical propertyBiochemical engineering

The present invention provides a touch control panel, a touch control module and a laminating method therefor. In the main, a first substrate and a second substrate are disposed opposite to each other, and an accommodating space is formed between the first substrate and the second substrate. The accommodating space is filled with a filling solution and is provided with a plurality of support members. The supporting means between the first substrate and the second substrate is formed by the filing solution and the support members. Based on the above technique, no bubble is generated during the curing process after the laminating process. Therefore, the lamination yield is significantly improved. Meanwhile, the optical property of the above lamination technique is superior to that of the OGS full lamination technique. In addition, due to the effective supporting means formed between the first substrate and the second substrate, the deflection and derived flexible curved interference problem can be effectively solved.

Owner:ELAN MICROELECTRONICS CORPORATION

Low-density outdoor wood plastic floor

InactiveCN107337932AStrong cohesive energyHigh degree of bindingFlooringAntioxidantPolyethylene glycol

The invention discloses a low-density outdoor wood plastic floor. Raw materials of the floor comprise, by weight, 100-140 parts of a main material, 40-50 parts of a filler, 1-4 parts of a polyethylene glycol compound, 0.5-1.2 parts of maleic anhydride, 0.5-1.2 parts of a titanate coupling agent, 1-2 parts of microcrystalline paraffin, 1-2 parts of zinc stearate, 0.5-1.5 parts of an antioxidant, 0.5-1.5 parts of an anti-ultraviolet light absorbent, 0.5-1.5 parts of a fire retardant, 0.5-1.5 parts of an antifreeze agent and 0.5-1.5 parts of a mildew inhibitor, wherein the main material includes PE particles, wood powder and polyurethane according to a weight ratio of (5-10):(6-8):(0.1-0.5). The floor has the advantages of guaranteed dimension stability, light weight and low cost.

Owner:浙江坤鸿新材料有限公司

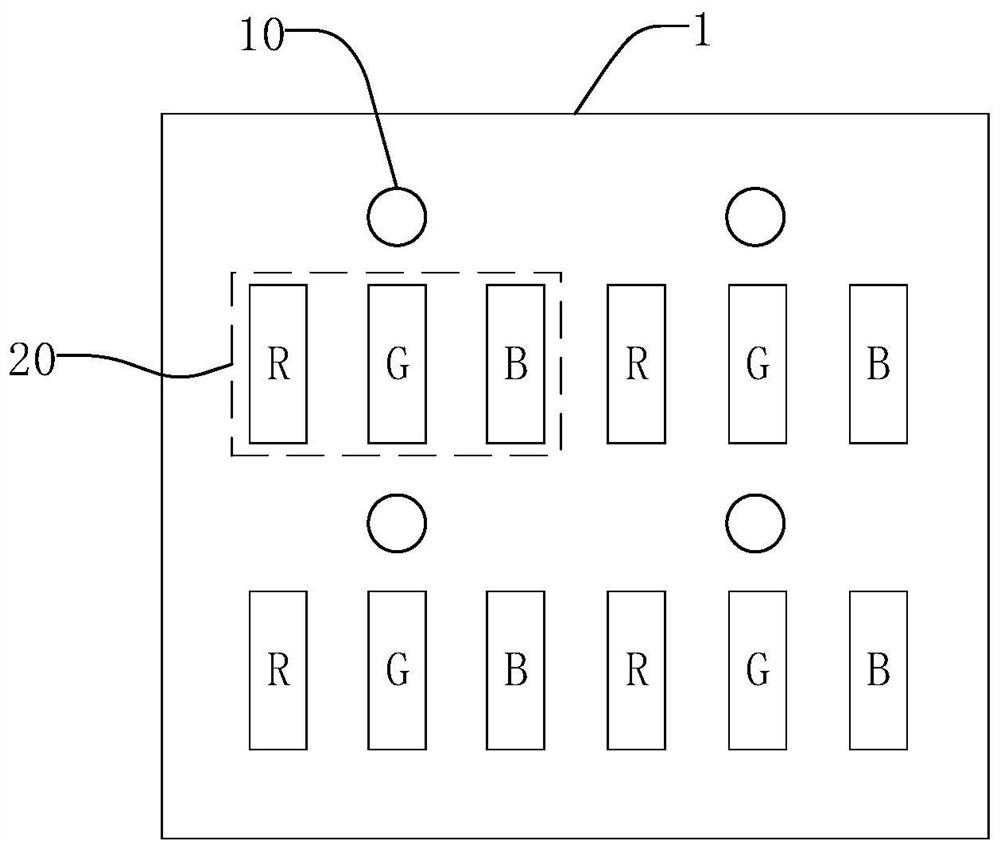

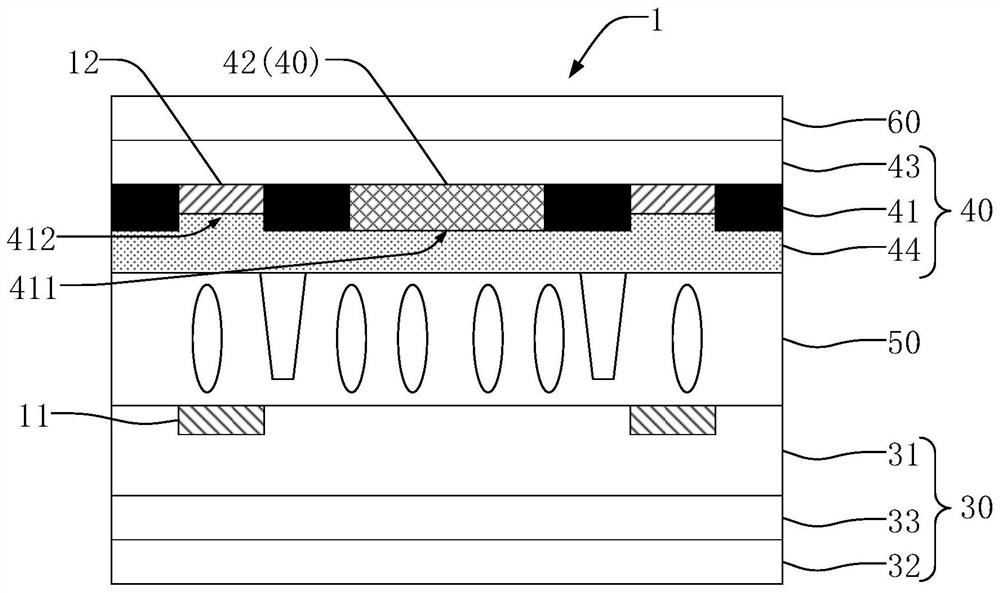

Display panel and preparation method thereof

InactiveCN113093424ADoes not affect resolutionDoes not increase the risk of the processSolid-state devicesCharacter and pattern recognitionEngineeringMaterials science

The invention provides a display panel and a preparation method thereof. The display panel comprises a first substrate, a second substrate and fingerprint identification units, wherein the first substrate and the second substrate are arranged in a laminated mode. Each fingerprint identification unit comprises a sensor and at least one super-structure lens. The sensors are arranged in the first substrate. And the super-structure lenses are arranged in the second substrate and corresponds to the sensors.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

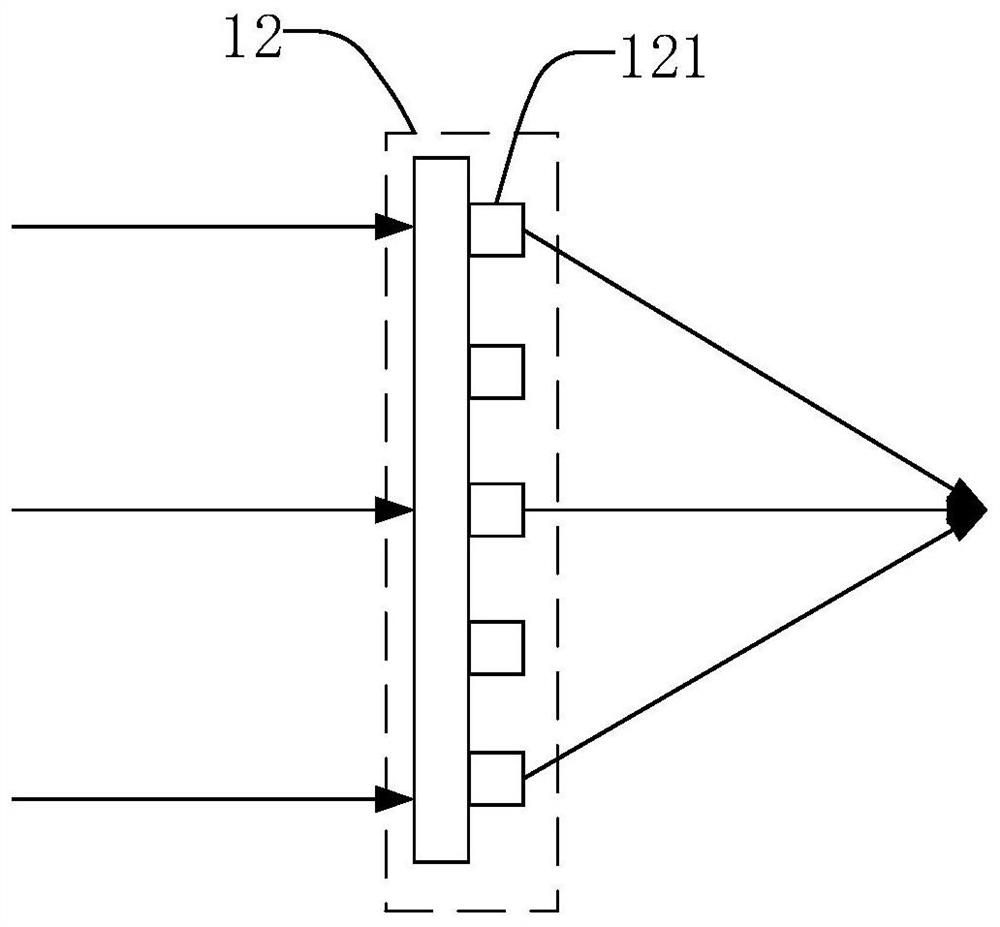

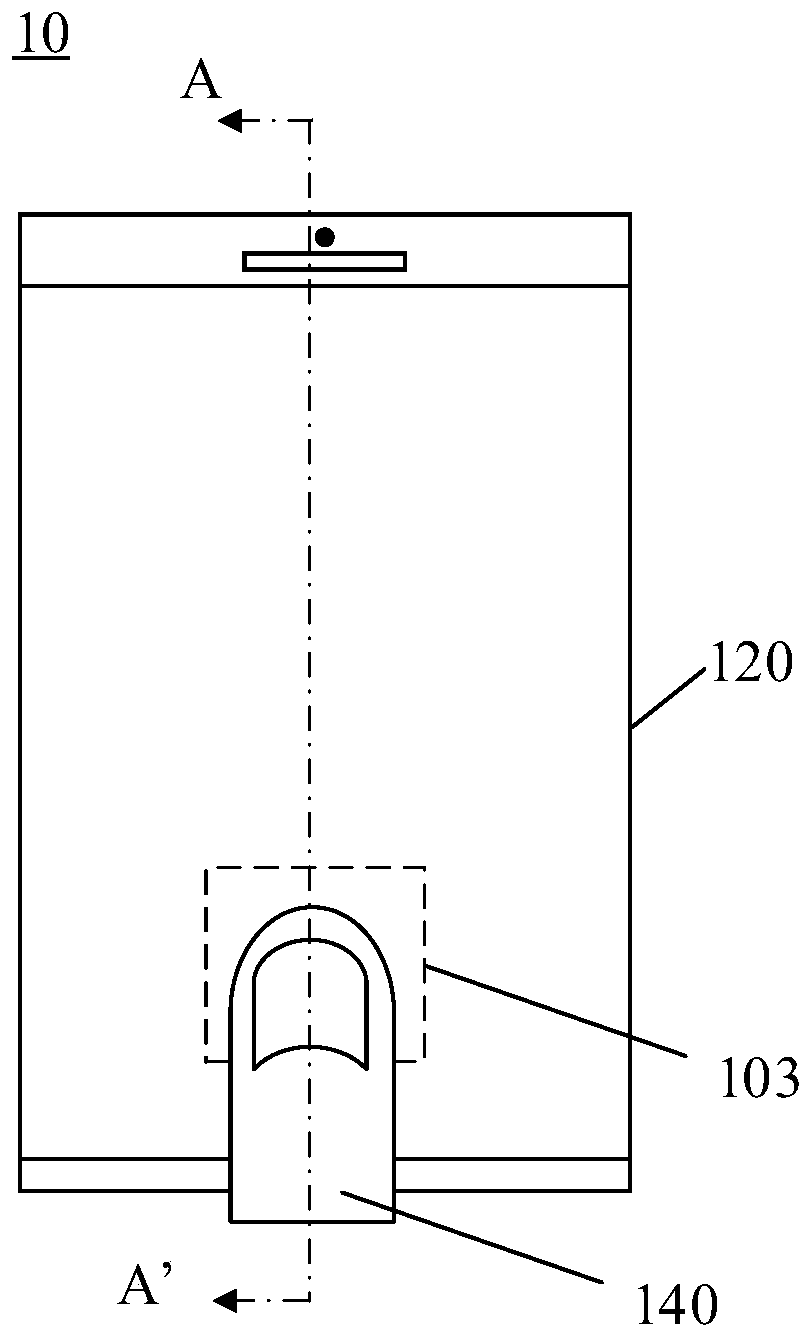

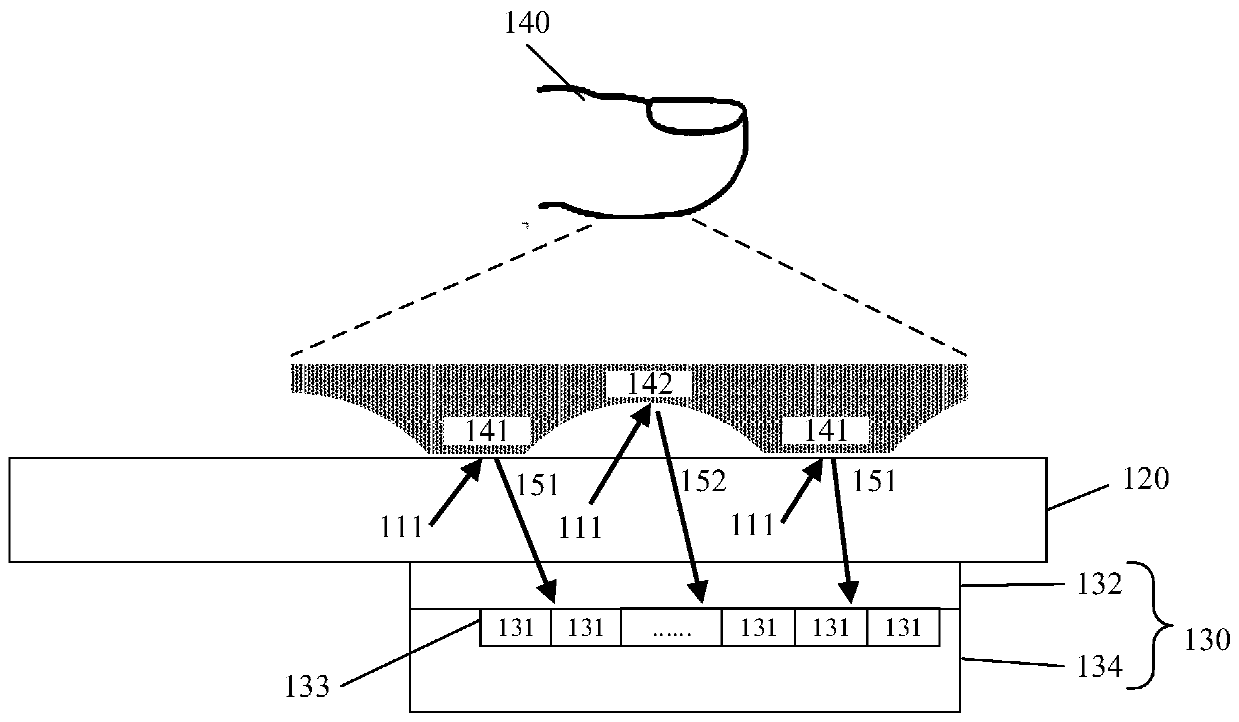

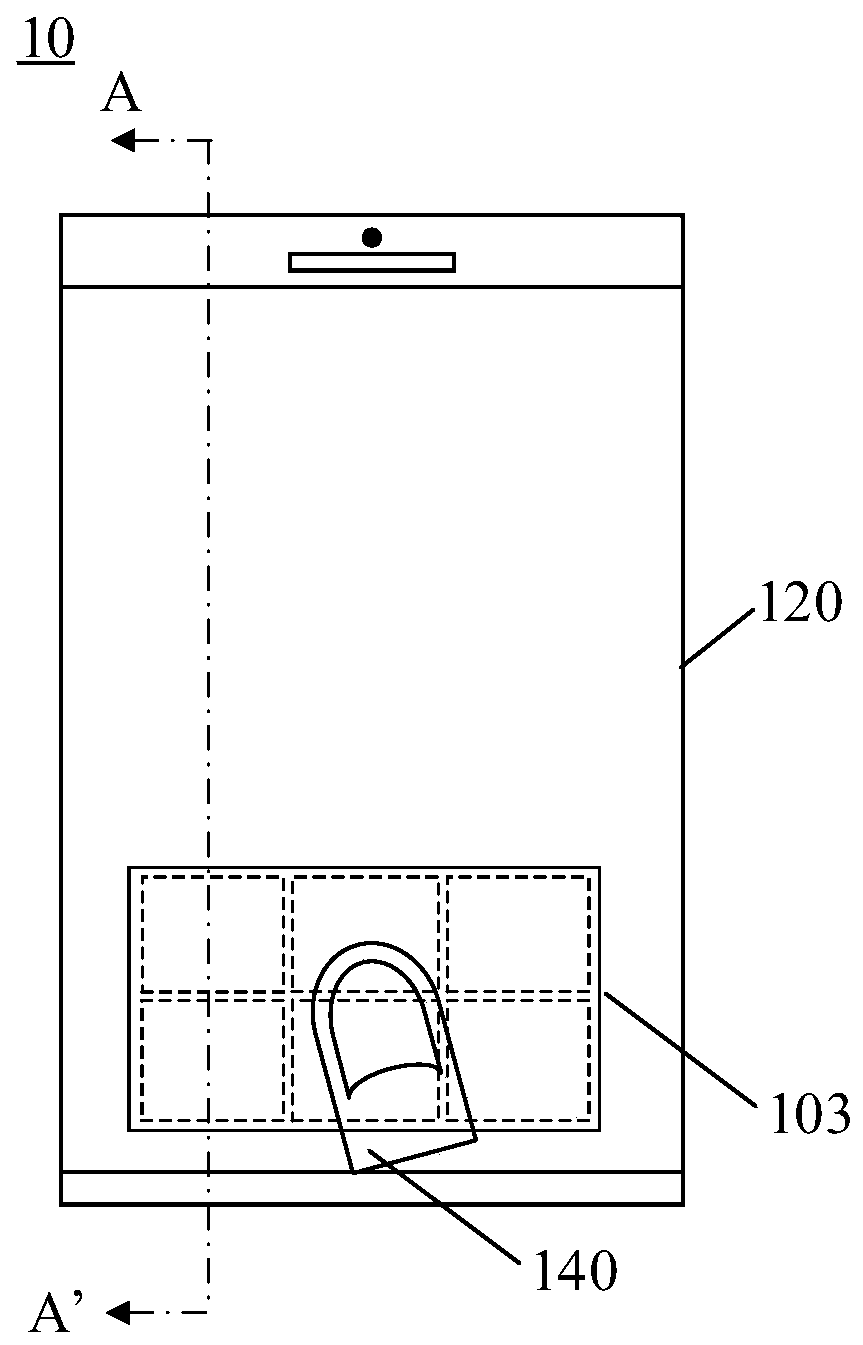

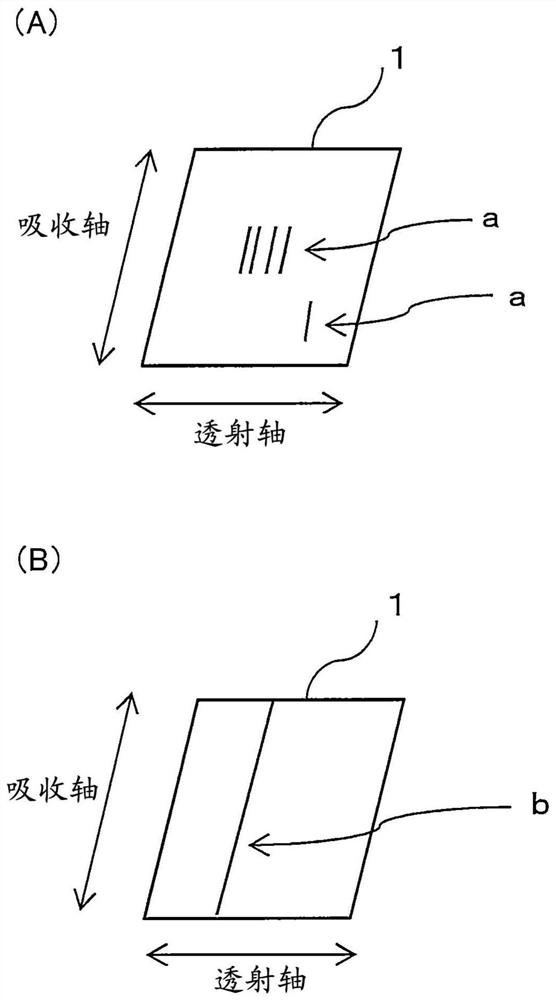

Optical filter, fingerprint detection device and electronic device

ActiveCN111066032ALess prone to "warping"Avoid "red spots"Character and pattern recognitionEngineeringLight signal

The invention provides an optical filter, which does not influence the visual perception of a user while ensuring the fingerprint detection performance, and has good structural stability. The opticalfilter is arranged between the display screen and the optical fingerprint sensor. The optical fingerprint sensor is used for detecting an optical signal returned by a finger above the display screen.The optical filter is used for filtering an optical signal of a non-target waveband in an optical path of the optical fingerprint sensor, the optical signal of the non-target waveband comprises an optical signal of a red light waveband and an optical signal of an infrared waveband, and the optical filter comprises a substrate; at least one cut-off film layer, used for reflecting the optical signals of the non-target waveband, and the at least one cut-off film layer is located on the two sides of the substrate; and at least one coating, used for absorbing the optical signal of the non-target waveband.

Owner:SHENZHEN GOODIX TECH CO LTD

Configuration method of self-catalyzed electroless copper plating epoxy resin solution and electroless copper plating method

InactiveCN104789949BImprove stabilityEvenly distributedLiquid/solution decomposition chemical coatingEpoxyCopper plating

The invention relates to a configuration method of self-catalyzed electroless copper-plating epoxy resin solution and an electroless copper-plating method, belonging to the technical field of material surface treatment. It includes the following steps: adding the active ion source into the organic solvent under constant stirring, and adding a certain amount of curing catalyst, stirring fully to form a uniform active agent solution; and then stirring the epoxy resin in a certain proportion Add to the curing agent to form an epoxy resin organic solution; while stirring continuously, slowly add the active agent solution to the epoxy resin organic solution to form a uniform and stable system, that is, to obtain an epoxy resin solution with self-catalytic active electroless copper plating . The prepared resin solution is uniformly coated on the printed circuit board substrate by casting method or screen printing method, and then through curing, micro-etching, reduction, chemical plating and other processes, the bright pink copper coating can be obtained. After the performance test, the copper layer-resin bonding force and electrical conductivity of the sample are excellent, and it is suitable for the electroless copper plating process.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

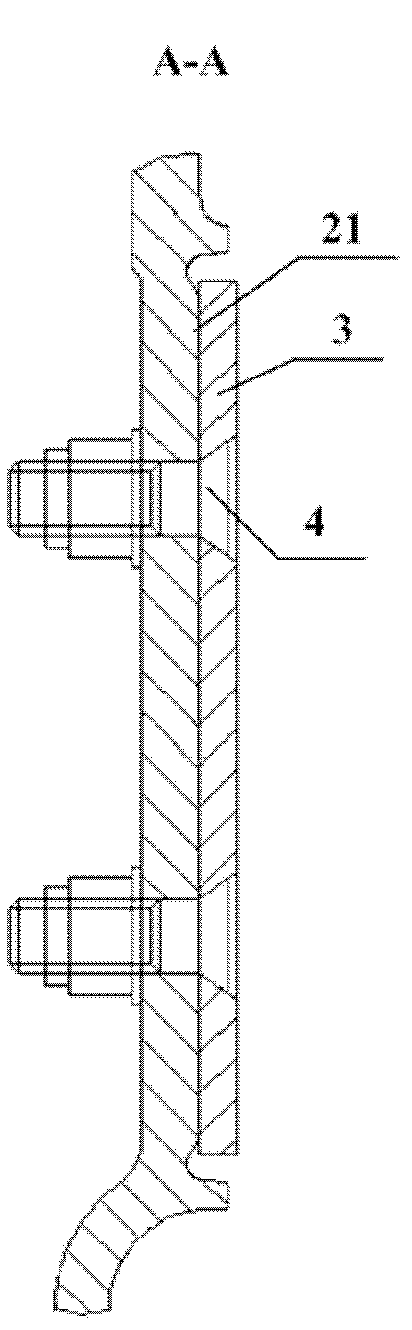

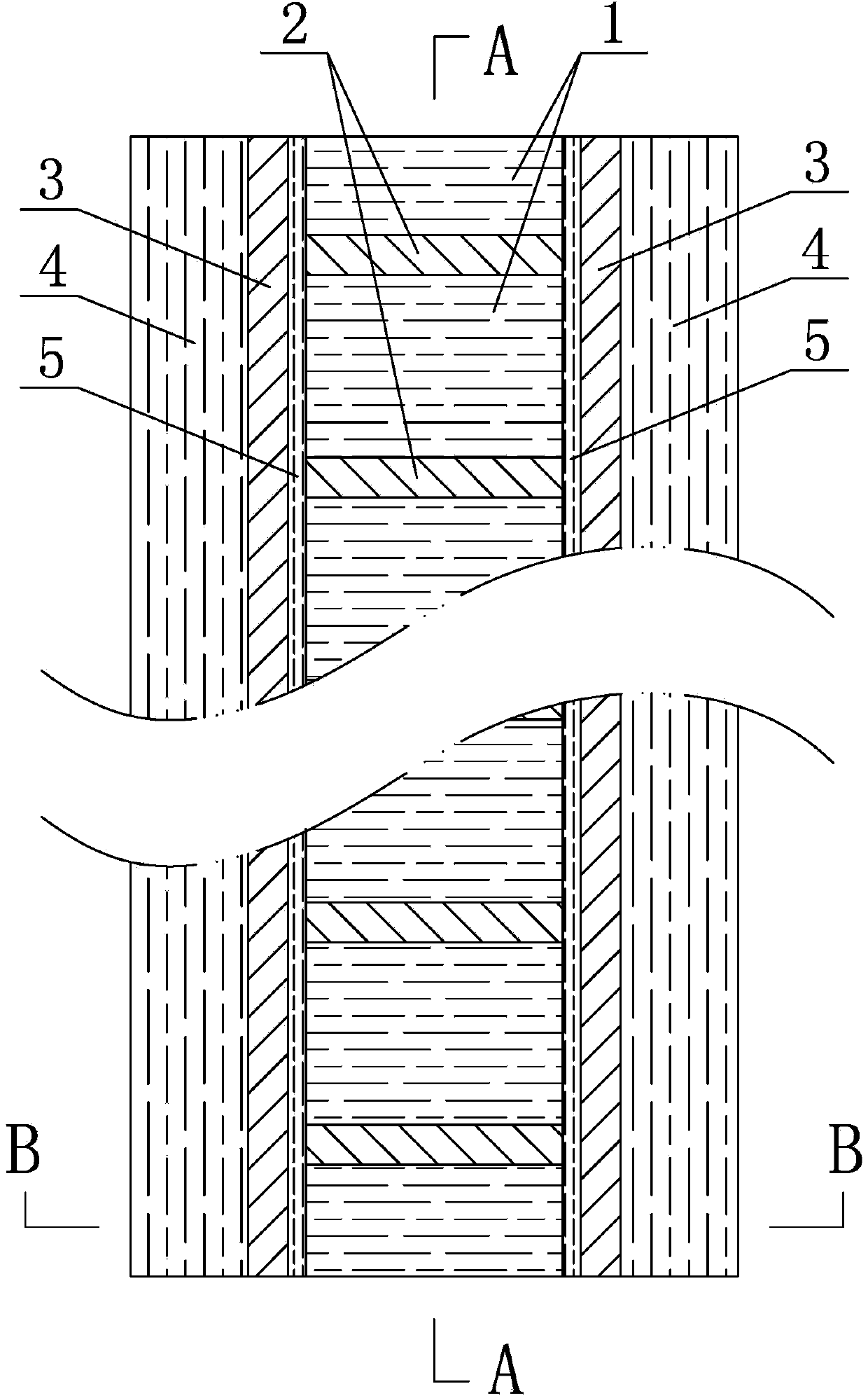

Column wearing plate, steering frame and railway truck

InactiveCN102501870AExtended service lifeLess prone to warpingBogiesBogie-underframe connectionsBogieAgricultural engineering

The invention provides a column wearing plate, a steering frame and a railway truck. The column wearing plate comprises a trough bottom and two ledges oppositely arranged on the trough bottom, the trough bottom and the two ledges form a concave used for wrapping both the bottom surface and the side surface of a swing bolster shield, the ledges can be stopped on the side surface of the swing bolster shield to play the function of preventing the side surface of the swing bolster shield from being worn down, and in addition, the ledges can play a certain limiting role on the trough bottom after being arranged, so that the trough bottom has low probability of warpage or fracture, and the service life of the column wearing plate is prolonged.

Owner:CRRC SHENYANG CO LTD

A kind of wood-plastic floor and preparation method thereof

Owner:Minghe Technology (Tangshan) Co Ltd

Antibacterial 3D printing line and preparation method thereof

InactiveCN106633595ASimple methodLess prone to warpingAdditive manufacturing apparatusWater basedEpoxy

The invention discloses an antibacterial 3D printing line and a preparation method thereof. The preparation method comprises the following steps: mixing a water-based epoxy resin, silver nitrate and water, filtering, and drying to obtain an antibacterial resin; mixing an acrylonitrile-butadiene-styrene plastic, the antibacterial resin, a polyamide resin, vermiculite powder, barium stearate, aluminum powder, glass fibers, an initiator, a crosslinking agent and a pigment, and melting to form a molten liquid M; and carrying out wire drawing formation on the molten liquid M to obtain the antibacterial 3D printing line. The method solves the following problems: nonuniform shrinkage of the common line caused by different cooling rates can easily result in warping of the formed line; and the surface of the printing material can easily become moldy since the printing material is stored in a humid environment for a long time.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

burner for gas stove

ActiveCN109737404BEvenly distributedAvoid insufficient combustionDomestic stoves or rangesGaseous fuel burnerThermodynamicsEngineering

The invention discloses a combustor of a gas stove, and relates to the technical field of combustors. The combustor comprises an outer ring, a positioning column, an outer ring air inlet injection pipe mechanism and a center air inlet injection pipe mechanism; an inner ring is arranged on the inner side of the outer ring, the inner ring is connected with the outer ring through a linking block, andthe outer ring air inlet injection pipe mechanism is arranged at the bottom of the outer ring. The combustor has the beneficial effects that according to the combustor of the gas stove, through a center mixing cavity and an outer ring mixing cavity, inner arcs of the center mixing cavity and the outer ring mixing cavity are distributed from deep to shallow, through the center mixing cavity and the outer ring mixing cavity, it is ensured that the air flow can be stable during mixing and free of buffer, combustion flames are evenly distributed, the two mixing cavities are formed in the bottom of the outer ring, when the device carries out combustion work, complete upper air inlet combustion is achieved, comprehensive oxygen supplementing is achieved, and the phenomenon that due to long-timecombustion of the combustor, due to insufficient oxygen supplementing, combustion insufficiency of red fire, yellow flames, black smoke and the like is caused is avoided.

Owner:佛山市宇煜五金有限公司

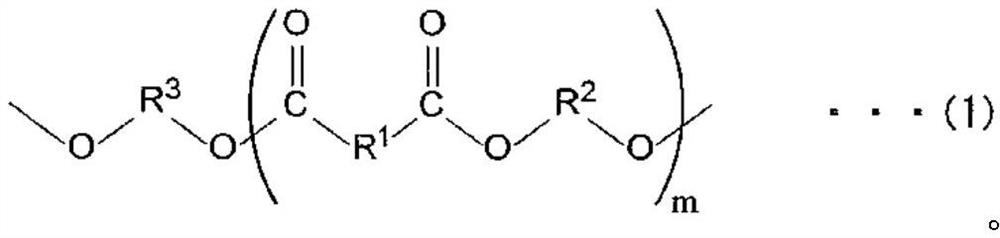

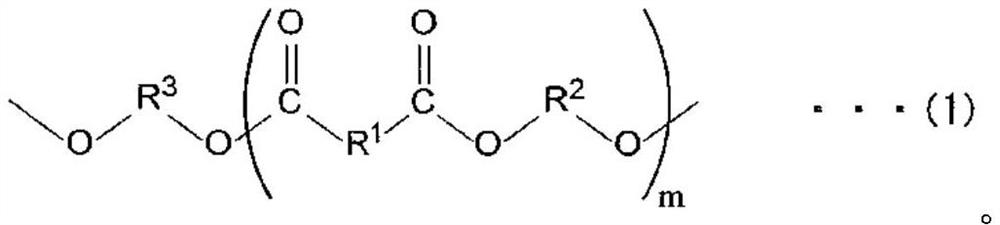

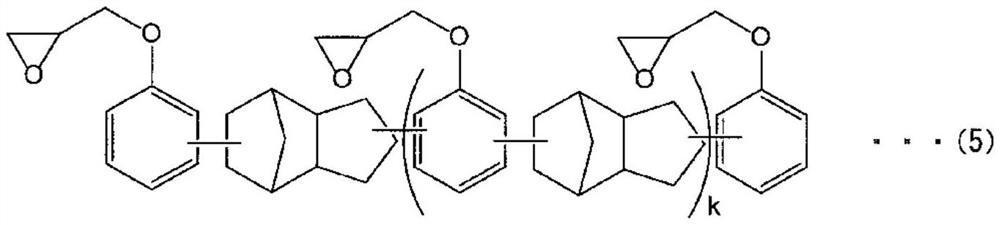

Curable composition, cured object, overcoat film, and flexible wiring board and production method therefor

PendingCN114072444AExcellent Disconnection InhibitionLess prone to warpingNon-metallic protective coating applicationMetal layered productsPolymer scienceEngineering

Provided is a curable composition highly effective in preventing flexible wiring boards from warping and in inhibiting the flexible wiring boards from suffering wiring breakage. The curable composition is for use in producing a flexible wiring board from a flexible substrate having wiring formed thereon, by coating the wiring-including surface portions of the flexible substrate with an overcoat film, the overcoat film being formed by curing the curable composition. The cured object obtained from this curable composition has a tensile modulus of 600-2,000 MPa and a tensile yield strength of 17 MPa or greater.

Owner:NIPPON POLYTECH CORP

Planar fiber vertical structure flooring base material and production process thereof

ActiveCN104213697AControl internal stressReduce the chance of deformationWood working apparatusFlooringEngineeringFiber orientation

The invention relates to a planar fiber vertical structure flooring base material and a production process thereof; in order to solve the technical problems, the invention provides the planar fiber vertical structure flooring base material which is simple in structure, high in stability, does not easy to deform and is environmentally friendly and the production process for the planar fiber vertical structure flooring base material. The technical scheme for solving the problems is that the planar fiber vertical structure flooring base material is characterized by comprising a center plate and two side plates which are respectively located at both sides of the center plate and spliced with the center plate into a whole; the center plate and the side plates are located on the same plane, and the fiber direction of the center plate and the fiber direction of each side plate are vertical to each other. The planar fiber vertical structure flooring base material and the production process thereof disclosed by the invention are mainly used for the technical field of engineered flooring production.

Owner:安吉远峰竹木有限公司

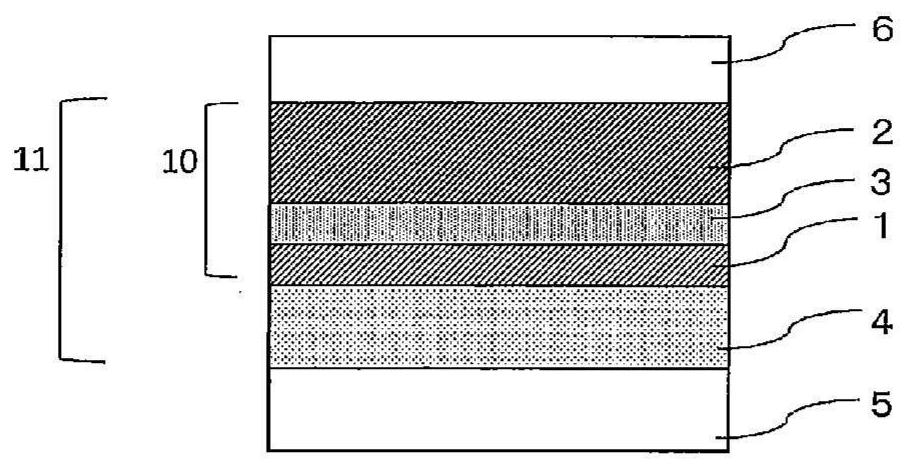

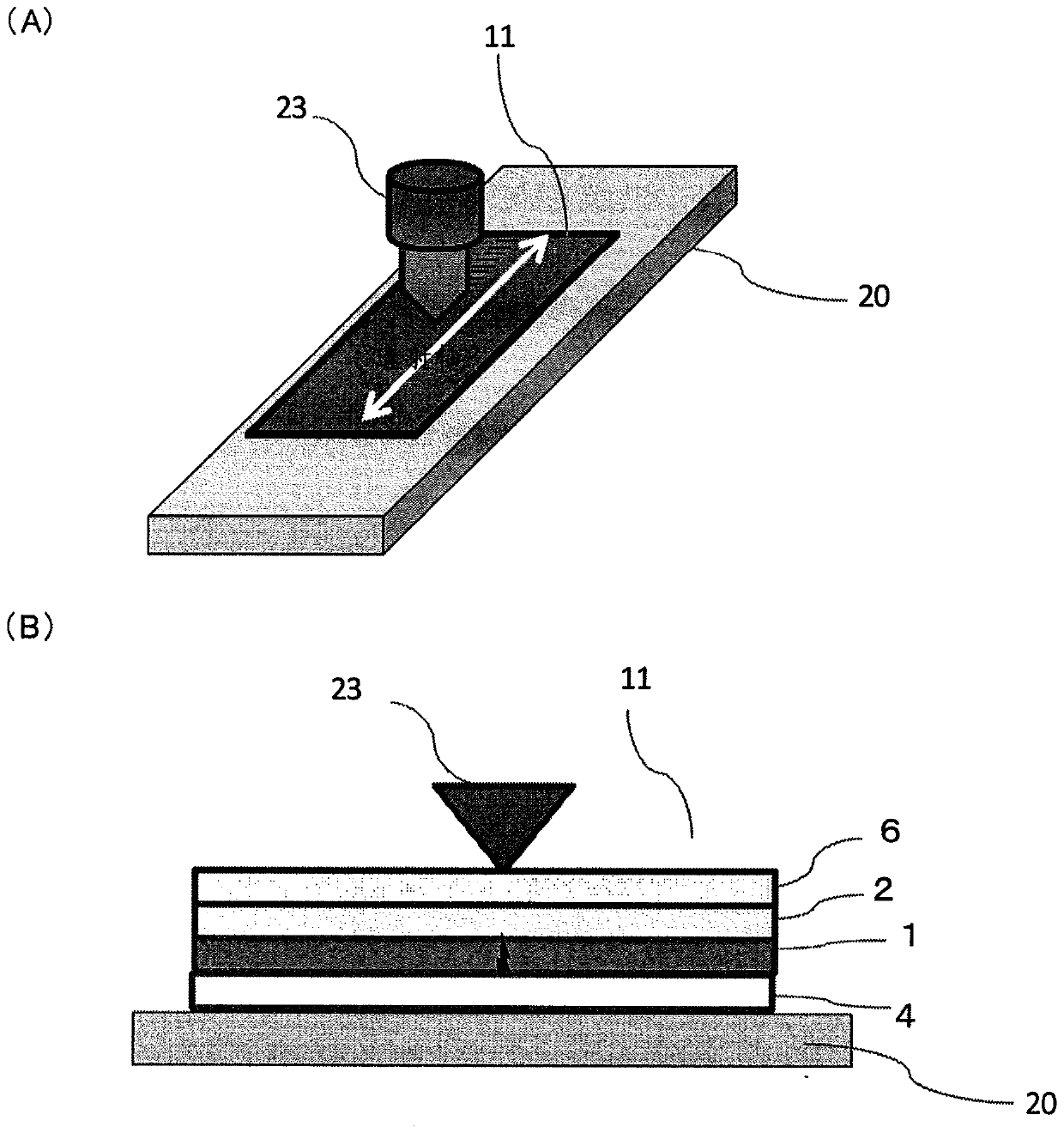

One-sided protective polarizing film with adhesive layer, image display device and continuous manufacturing method thereof

ActiveCN110462473BGood elastic propertiesInhibitionSynthetic resin layered productsPolarising elementsAlkali freeAdhesive

An object of the present invention is to provide a single-sided protective polarizing film with an adhesive layer that can suppress defects due to nano-slits without providing a coating layer between the polarizer and the adhesive layer, and is excellent in reworkability . The single-side protective polarizing film with an adhesive layer of the present invention has a single-sided protective polarizing film having a protective film only on one side of a polarizer, and directly or via the polarizer side of the above-mentioned single-sided protective polarizing film. The coating layer has an adhesive layer, and the storage modulus of the above-mentioned adhesive layer at -40°C is 7.0×10 7 More than Pa, the adhesive force of the above-mentioned adhesive layer relative to the surface of the alkali-free glass at a peeling speed of 300mm / min and a peeling angle of 90 degrees is below 8N / 25mm, and the above-mentioned adhesive layer is relative to the glass with the ITO film. The adhesive force of the surface of the ITO film at a peeling speed of 300mm / min and a peeling angle of 90 degrees is below 8N / 25mm.

Owner:NITTO DENKO CORP

One-side-protected polarizing film with pressure-sensitive adhesive layer, image display device, and continuous production method therefor

ActiveCN110383121AHigh storage modulusGood elastic propertiesSynthetic resin layered productsPolarising elementsAdhesivePolarizer

The purpose of the present invention is to provide a one-side-protected polarizing film having a pressure-sensitive adhesive layer and being capable of suppressing defects resulting from nanoslits without having to provide a coating layer between a polarizer and a pressure-sensitive adhesive layer. This one-side-protected polarizing film with a pressure-sensitive adhesive layer has: a one-side-protected polarizing film having a protective film disposed on only one surface of a polarizer; and a pressure-sensitive adhesive layer that is disposed, either directly or via a coating layer, on the polarizer side of the one-side-protected polarizing film, the polarizing film being characterized in that the pressure-sensitive adhesive layer has a storage elastic modulus of at least 7.0*107 Pa at minus 40 DEG C.

Owner:NITTO DENKO CORP

Method for manufacturing chip packaging structure

ActiveCN102163558BLess prone to warpingImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingBonding processEngineering

The invention relates to a method for manufacturing a chip packaging structure. The manufacturing method comprises the following steps of: (a) providing a substrate, wherein the substrate is provided with at least one conductive hole; (b) arranging the substrate on a carrier; (c) removing partial substrate to expose the conductive hole, and forming at least one penetration guide hole; (d) arranging a plurality of chips on the surface of the substrate, and electrically connecting the chips to the penetration guide hole of the substrate; (e) forming a coating material; (f) removing the carrier;(g) carrying out a chip bonding process; (h) removing the coating material; and (i) forming a protective material. Thus, the carrier and the coating material can ensure the substrate to be difficult to warp in a process.

Owner:ADVANCED SEMICON ENG INC

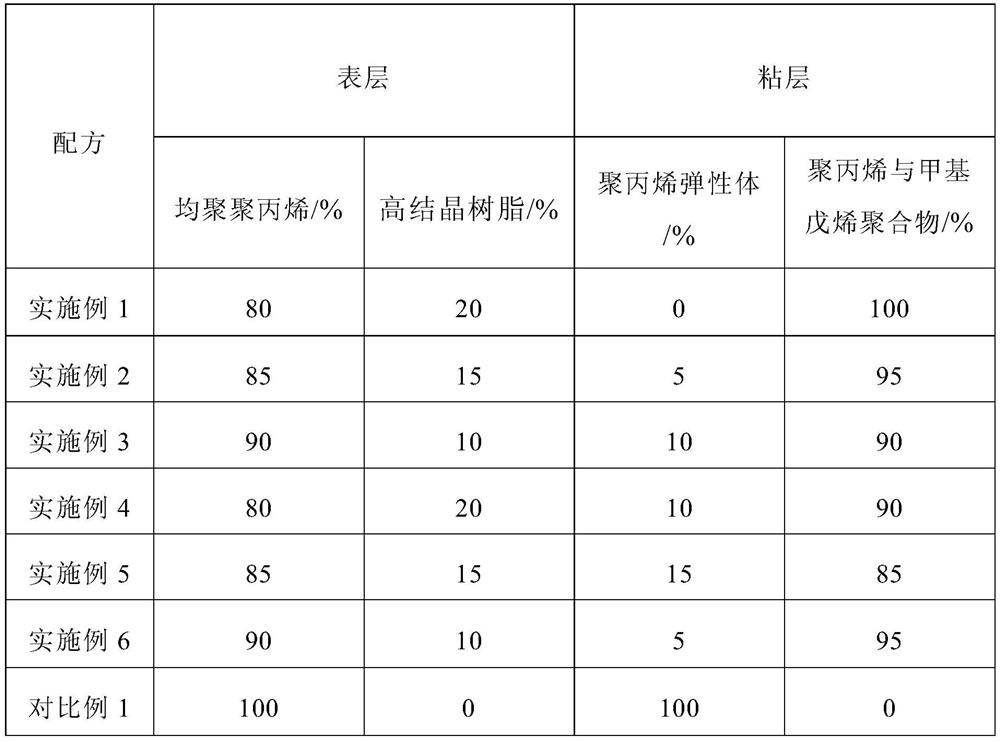

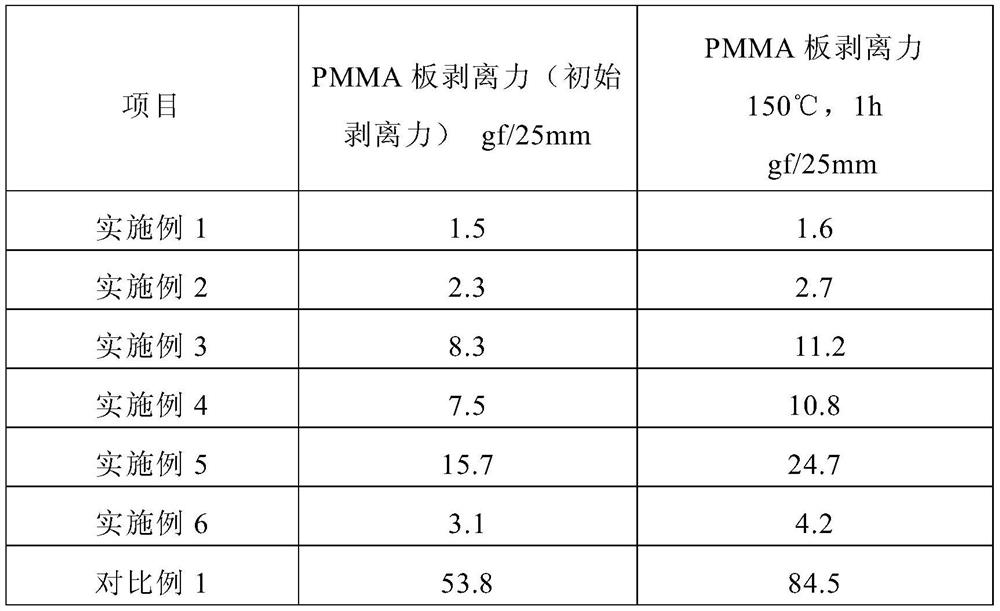

High-temperature-resistant protective film and preparation method thereof

PendingCN114507486AHigh melting pointHigh crystallinityFilm/foil adhesivesPolymer sciencePolypropylene

The invention relates to the field of protective film materials, in particular to a high-temperature-resistant protective film and a preparation method thereof. In order to solve the problems of warping, rime fog and edge melting of the protective film in a high-temperature process environment, and the problems of adhesive residue and difficulty in stripping after tearing, the invention provides the high-temperature-resistant protective film and the preparation method thereof. The protective film sequentially comprises a surface layer, a core layer and an adhesive layer, wherein the surface layer is composed of homo-polypropylene and high-crystallization resin, the core layer is polypropylene resin, and the adhesive layer is a polypropylene mixture. The protective film not only has high-temperature resistance, but also does not have the problems of warping, edge melting and the like after being torn by high-temperature baking, and is suitable for various high-temperature-resistant protection processes.

Owner:XIANGSHAN JIZHI NEW MATERIAL CO LTD

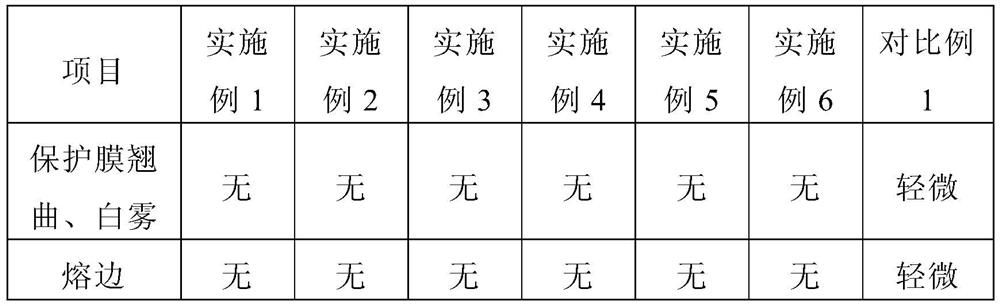

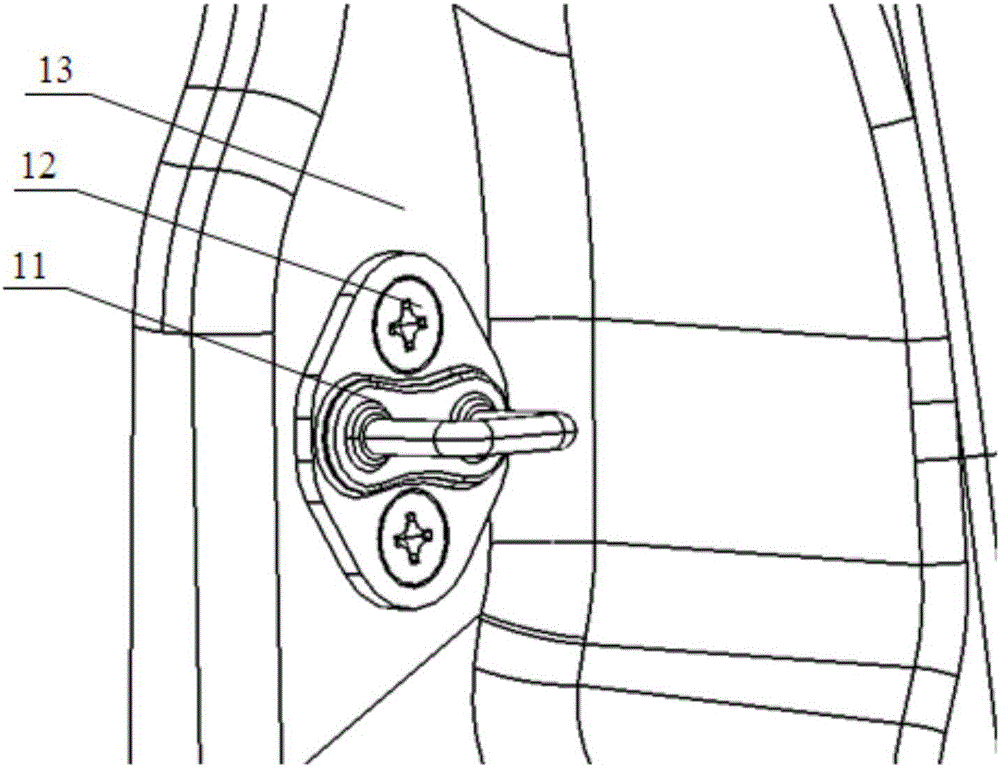

Installation assembly for automobile door locking hook and automobile

InactiveCN104989191AGuaranteed Position AccuracyImprove installation reliabilityVehicle locksThreaded fastenerEngineering

The invention discloses an installation assembly for an automobile door locking hook. The installation assembly comprises an automobile body outer plate (22), an automobile body inner plate (23) and a locking hook installation plate (24), and further comprises a fixed plate (25) fixed to the inner surface of the automobile body inner plate (23). A containing space is formed between the fixed plate (25) and the automobile body inner plate (23). Threaded holes (241) are formed in the locking hook installation plate (24). The locking hook installation plate (24) is movably placed in the containing space. A movable gap is formed between the outer side wall of the locking hook installation plate (24) and the inner side wall of the fixed plate (25). Threaded fastening pieces (26) sequentially penetrate an automobile door locking hook (21), the automobile body outer plate (22), the automobile body inner plate (23), the locking hook installation plate (24) and the fixed plate (25) and are matched with the threaded holes (241) in a threaded mode. By means of the installation assembly, the installation process of the automobile door locking hook can be simplified. The invention further discloses an automobile.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com