Fiber-reinforced plastic and method for producing same

一种纤维增强塑料、制造方法的技术,应用在扁平制品、其他家里用具、家里用具等方向,能够解决结构材机械物性不充分、增强纤维和热塑性树脂流动性不会充分提高、增强纤维短等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

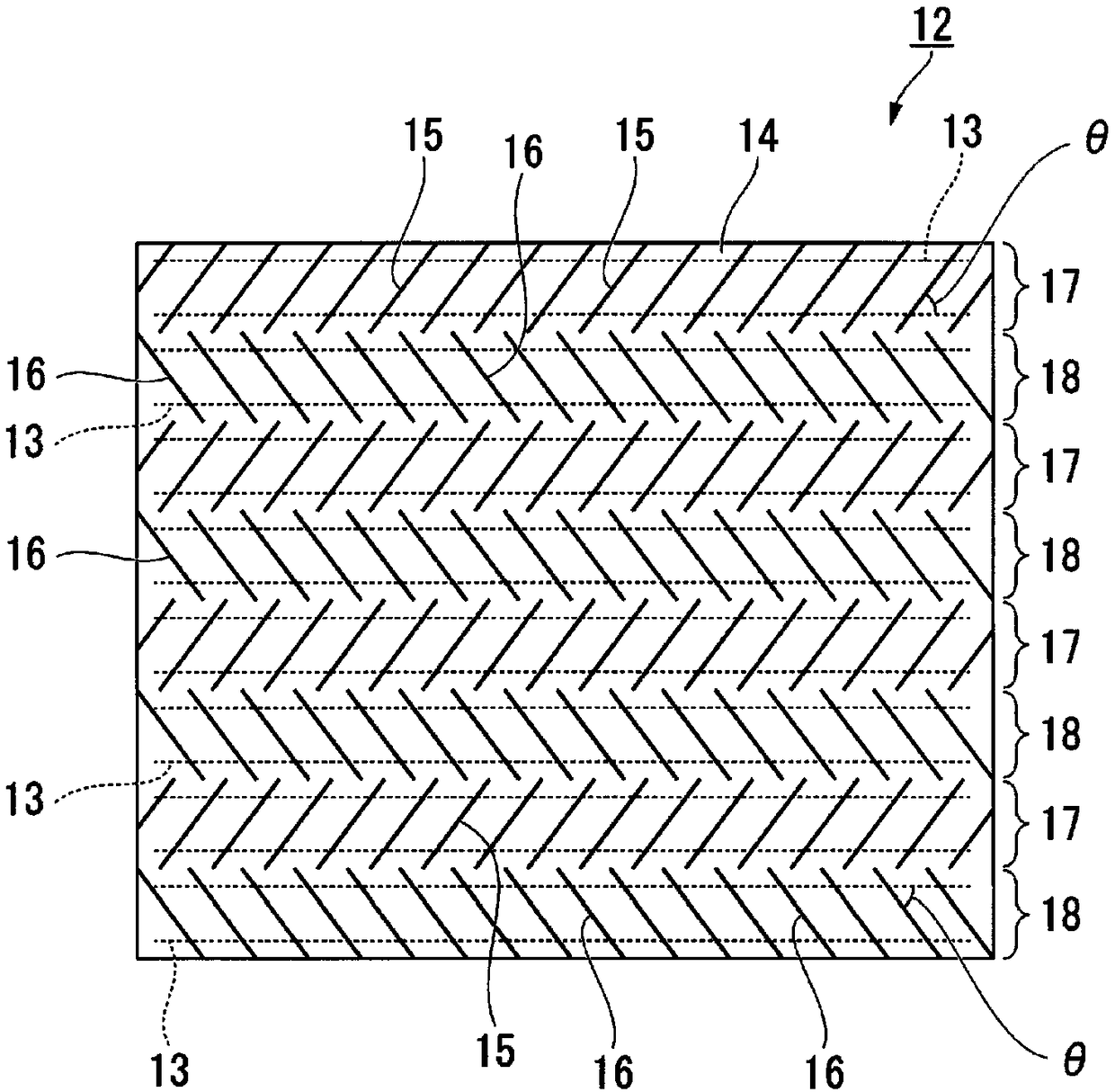

[0798] [Production Example 1: Production of prepreg base material (X-1)]

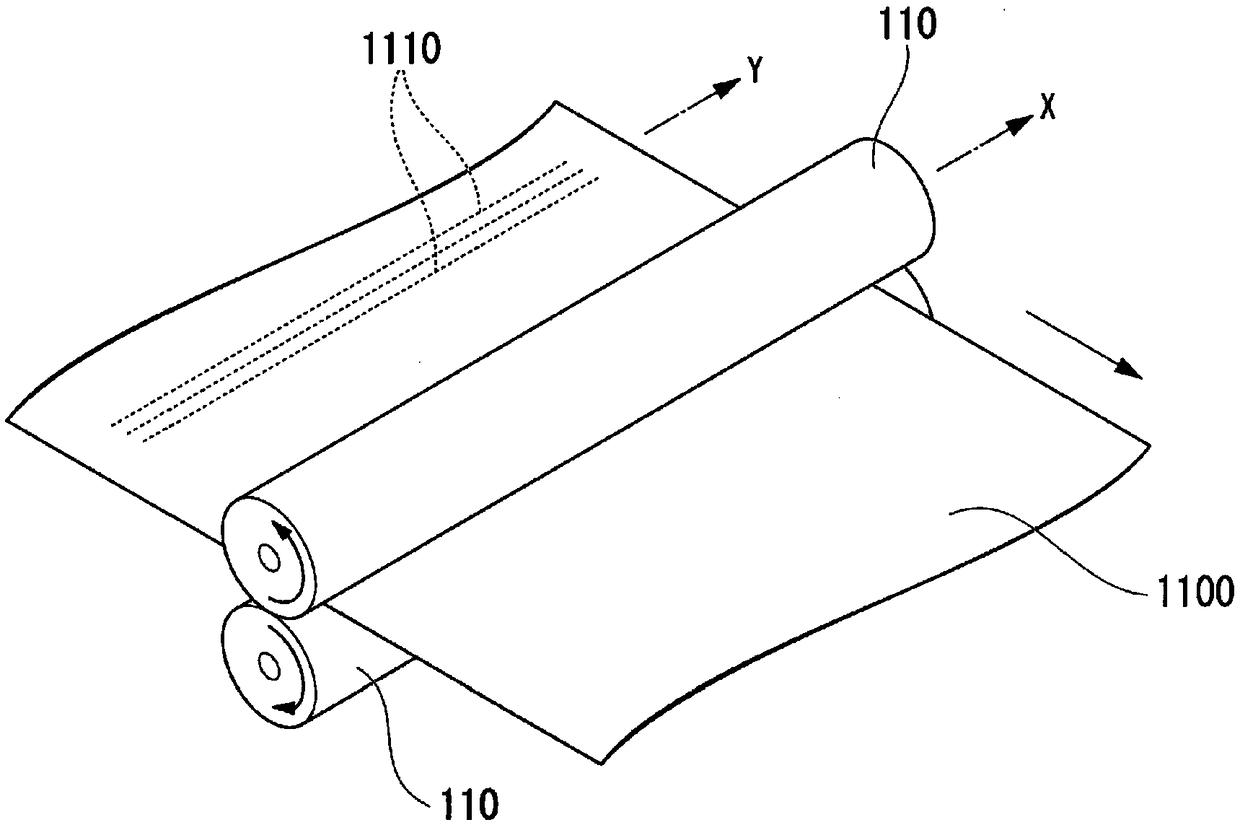

[0799] The PAN-based carbon fiber (PYROFIL CF tow made by Mitsubishi Rayon, model: TR 50S15L, carbon fiber diameter 7μm, number of filaments: 15,000, tow weight per unit area: 1.0g / m, specific gravity 1.82) in one direction and flat Aligned in a shape to form a unit area weight of 72g / m 2 Of fiber pieces. The basis weight formed by acid-modified polypropylene resin (Modic manufactured by Mitsubishi Chemical Corporation, model: P958V, MFR: 50, specific gravity 0.91) is 36 g / m 2 The fiber sheet is sandwiched from both sides, and heated and pressurized through a calender roll several times to impregnate the resin in the fiber sheet to produce a fiber volume content (Vf) of 33% by volume and a weight per unit area of 149g / m 2 , A prepreg substrate (X-1) with a theoretical thickness of 123μm.

manufacture example 2

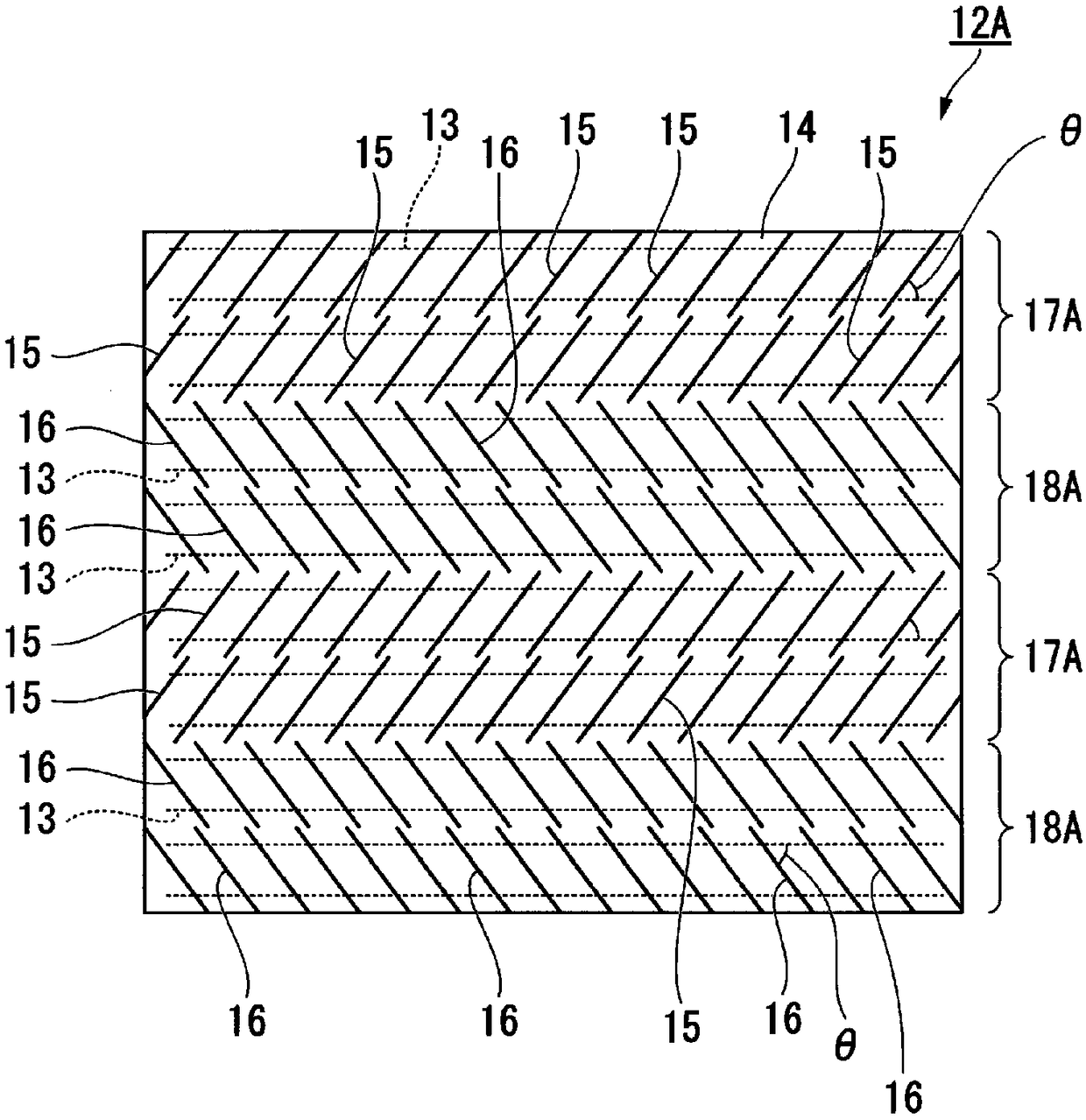

[0800] [Production Example 2: Production of prepreg base material (X-2)]

[0801] The carbon fiber (PYROFIL CF tow made by Mitsubishi Rayon Co., Ltd., model: TR 50S15L, carbon fiber diameter 7μm, number of filaments: 15,000, tow weight per unit area: 1.0g / m, specific gravity 1.82) in one direction and flat Aligned to make a unit area weight of 150g / m 2 Of fiber pieces. The basis weight formed by acid-modified polypropylene resin (Modic manufactured by Mitsubishi Chemical Corporation, model: P958V, MFR: 50, specific gravity 0.91) is 72 g / m 2 The film, the fiber sheet is clamped from both sides. Then, they were heated and pressurized twice through a calender roll to semi-impregnate the resin on the surface of the fiber sheet to produce a porosity of 35%, a fiber volume content (Vf) of 34% by volume, and a basis weight of 296g / m 2 , A prepreg base material (X-2) with a theoretical thickness of 242μm.

manufacture example 3

[0802] [Production Example 3: Production of prepreg base material (X-3)]

[0803] As the single fiber, a tow using carbon fibers (PYROFIL CF tow manufactured by Mitsubishi Rayon Corporation, model: TRW40 50L, single fiber diameter: 7 μm, single fiber roundness: 0.9, number of filaments: 50,000, Tow weight per unit area: 3.75 g / m), except that the same procedure as in Production Example 2 was performed to produce a porosity of 35%, a fiber volume content (Vf) of 34 vol%, and a weight per unit area of 296 g / m 2 , A prepreg substrate (X-3) with a theoretical thickness of 242μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com