High-temperature-resistant protective film and preparation method thereof

A high-temperature-resistant protective film and high crystallization technology, applied in the direction of film/flaky adhesives, adhesives, etc., can solve the problems of warping, warping, white fog, edge melting, and edge melting of the protective film, and achieve Excellent crystallinity and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

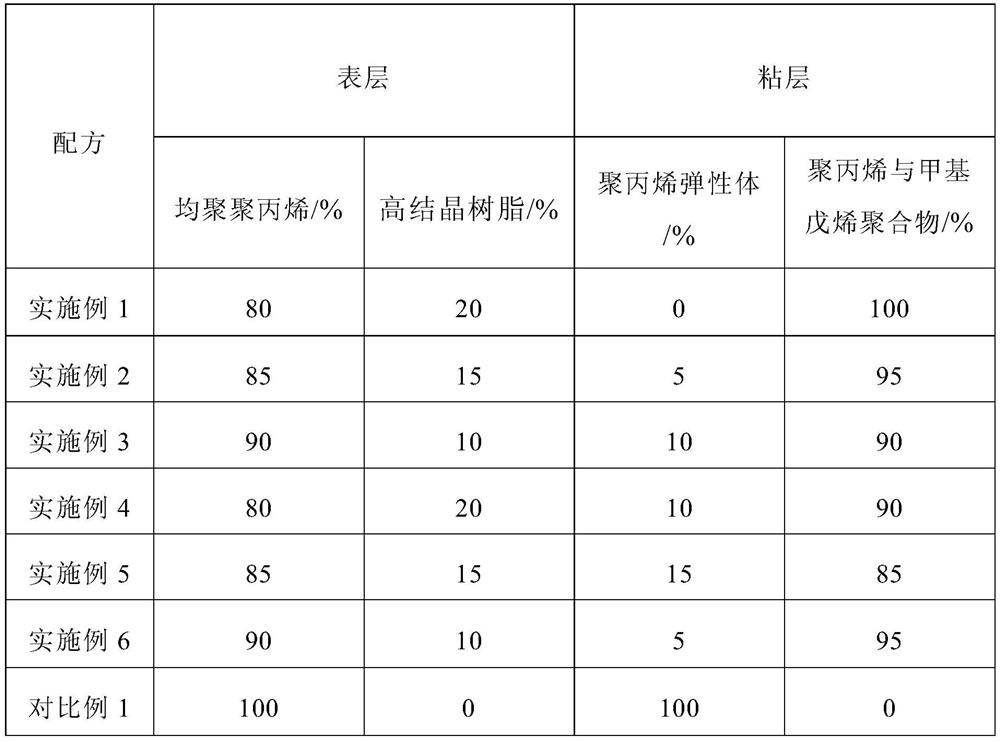

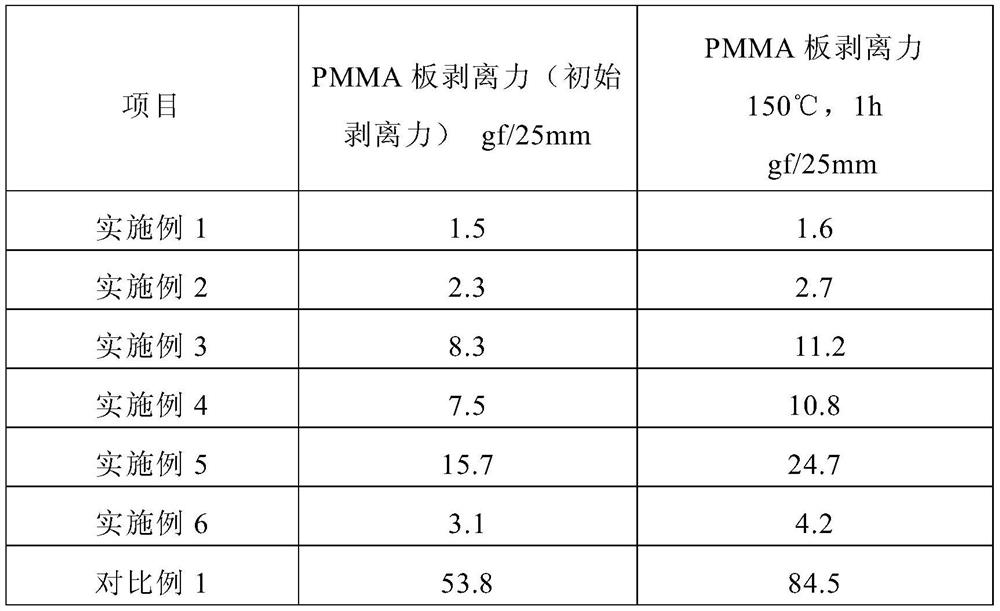

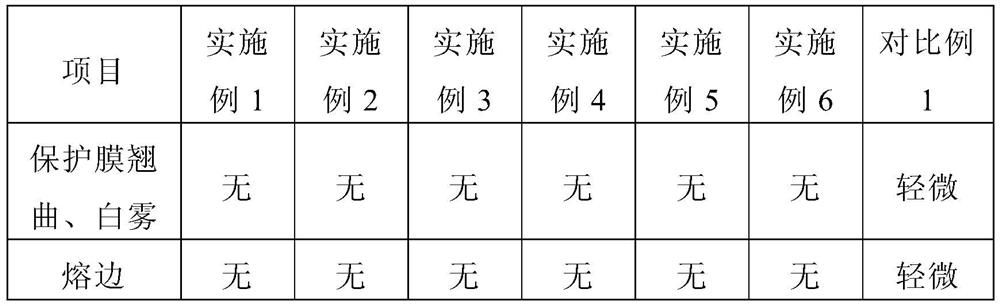

Embodiment 1

[0041] The high temperature resistant protective film provided by the invention comprises a surface layer, a core layer and an adhesive layer in sequence.

[0042] The skin layer consisted of 80% homopolypropylene and 20% methylpentene polymer. The density of homopolypropylene is 0.90g / cm 3 , The melt index is 8.0g / 10min. The density of methylpentene polymer is 0.85g / cm 3 , The melt index is 21.0g / 10min.

[0043] The core layer adopts homopolypropylene with a weight percentage of 100%, and its density is 0.91g / cm 3 , The melt index is 4.5g / 10min.

[0044] The adhesive layer is made of 100% polypropylene and methylpentene polymer with a density of 0.83g / cm 3 , The melt index is 6.0g / 10min.

[0045] The thickness of the surface layer was 6 μm, the thickness of the core layer was 20 μm, and the thickness of the adhesive layer was 4 μm.

Embodiment 2

[0047] As the high temperature resistant protective film that embodiment 1 provides, the difference is:

[0048] The skin layer consisted of 85% homopolypropylene and 15% methylpentene polymer.

[0049] The adhesive layer adopts 5% polypropylene elastomer and 95% polypropylene and methylpentene polymer, and the density of polypropylene elastomer is 0.86g / cm 3 , The melt index is 6.0g / 10min.

Embodiment 3

[0051] As the high temperature resistant protective film that embodiment 1 provides, the difference is:

[0052] The skin layer consisted of 90% homopolypropylene and 10% methylpentene polymer.

[0053] The adhesive layer adopts 10% polypropylene elastomer and 90% polypropylene and methylpentene polymer, and the density of polypropylene elastomer is 0.88g / cm 3 , The melt index is 8.0g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com