One-side-protected polarizing film with pressure-sensitive adhesive layer, image display device, and continuous production method therefor

A technology of adhesive layer and polarizing film, applied in the direction of adhesive type, ester copolymer adhesive, polarizing element, etc. effect of seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18、 comparative example 1~3

[0239]

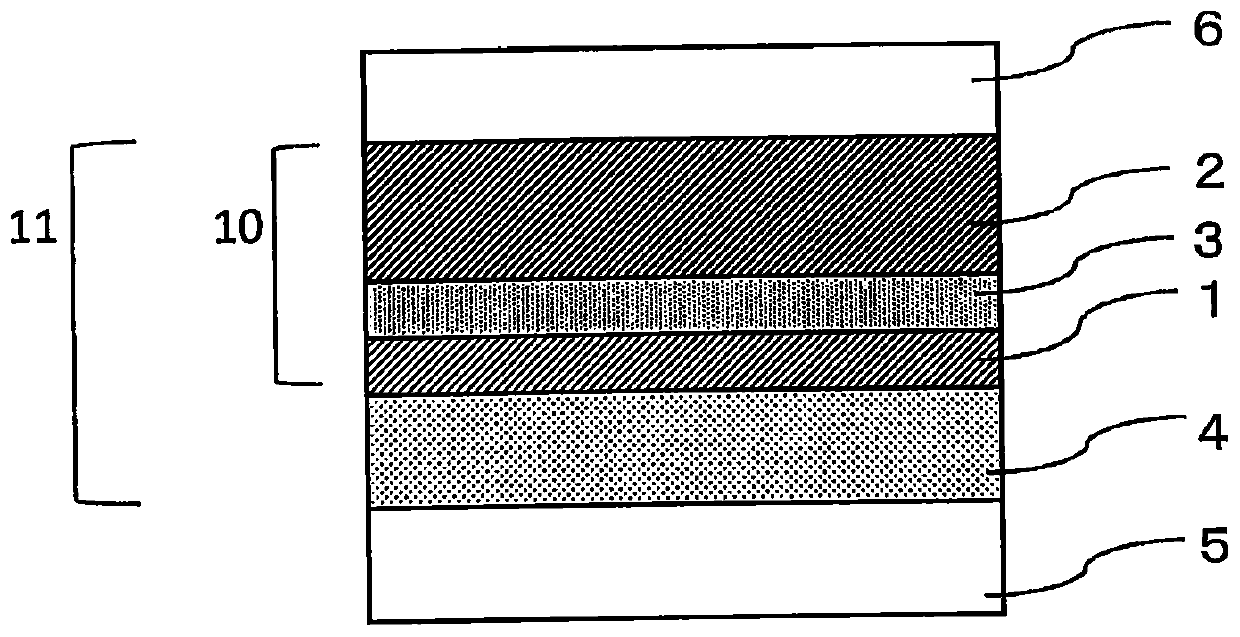

[0240] The produced pressure-sensitive adhesive layers A to S were bonded to the polarizer side of the produced one-side protective polarizing film A or B, respectively, to produce a single-side protective polarizing film with an pressure-sensitive adhesive layer.

[0241] The following measurements and evaluations were performed on the pressure-sensitive adhesive layer and the single-sided protective polarizing film with the pressure-sensitive adhesive layer obtained above. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com