Curable composition, cured object, overcoat film, and flexible wiring board and production method therefor

A curable composition and wiring board technology, applied in chemical instruments and methods, non-metallic protective layer coating, layered products, etc., can solve the problems of reduced yield of manufacturing process, adverse effects of positioning accuracy, etc., to achieve suppression Occurrence of wire breakage, excellent low warpage and wire breakage suppression, and less warpage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0197] Hereinafter, the present invention will be described in detail by examples and comparative examples.

[0198]

[0199] (Refer to Synthesis Example 1)

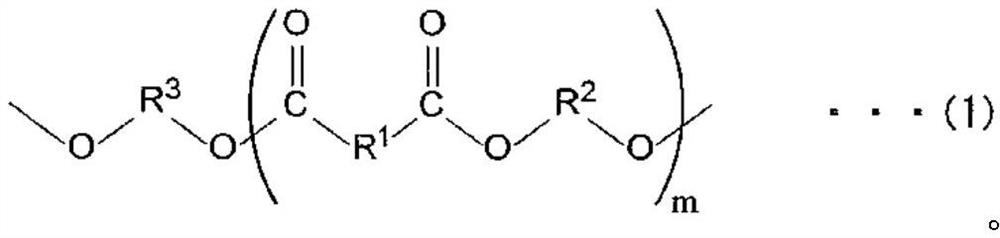

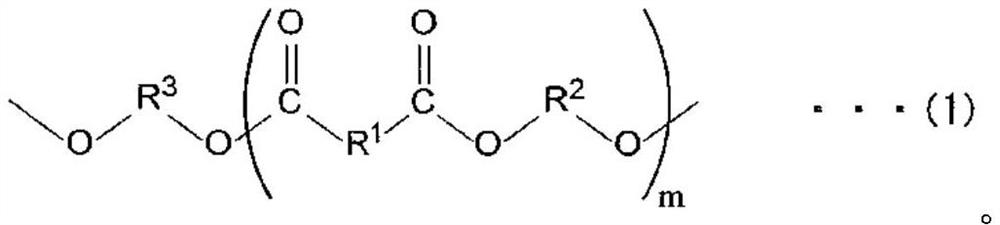

[0200] In the reaction vessel including a stirring device, a thermometer, and a condenser with a distiller, xylene chiphenic anhydride is added, 1,6-hexanediol 879.2g (7.44 mol), using oil bath The temperature of the reaction vessel was raised to 140 ° C and stirring was continued for 4 hours. Then, while continuing, the mono-n-butyltin oxide was added to 1.74 g.

[0201] Then, the inner temperature of the reaction vessel is slowly increased, and the pressure in the reaction vessel is gradually reduced by vacuum pump, and the water is separated to the reaction vessel by decompression distillation. In the end, the temperature was raised to 220 ° C, and the pressure was reduced to 133.32 Pa. After 15 hours, it was confirmed that the water was completely no longer distilled, the reaction ended.

[0202] The hydroxyl value of t...

Synthetic example 1

[0213] Equipped with a stirrer, a thermometer and a condenser was charged with 9,9-bis [4- (2-hydroxyethoxy) phenyl] fluorene (manufactured by Osaka Gas Chemical Co., Ltd., trade name BPEF) 10.7g , with reference to synthesis Example 1 synthesis of polyester diols 61.52g, 2,2- dimethylol propionic acid carboxyl group-containing diol (manufactured by Tokyo Kasei Co., Ltd.) 6.48g, γ- butyrolactone as a solvent ester 137.7g, was heated to 100 deg.] C to dissolve all material.

[0214] After the temperature of the reaction solution was lowered to 90 ℃, the methylene bis diisocyanate compound (4-cyclohexyl isocyanate) (manufactured by Sumika Bayer Urethane Co., Ltd. of DESMODUR-W (trade name)) 28.31g using a dropping dropping funnel over 30 minutes.

[0215] After reaction for 8 hours at 145 ~ 150 ℃, confirmed almost not observed the absorption of C = O stretching vibration of the isocyanate group caused by infrared spectroscopy (IR), 1.5g of ethanol was added dropwise to the reaction ...

Synthetic example 2

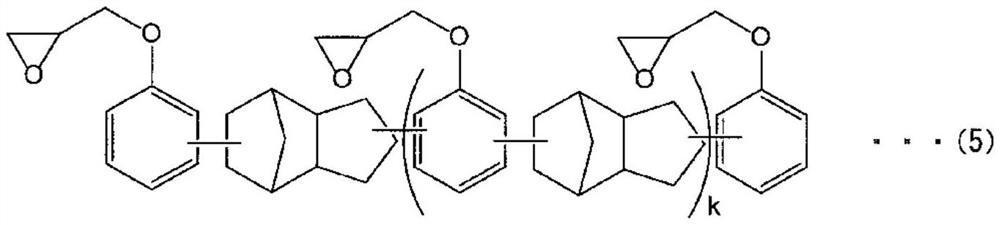

[0218] Except that in place of 11.4g of the compound represented by the following formula (7) 9,9-bis [4- (2-hydroxyethoxy) phenyl] fluorene 10.7g addition, other operations in the same manner as in Synthesis Example 1 , to obtain an aromatic ring containing a carboxyl group and having a concentration of 3.1mmol / g, a concentration of urethane groups of 2.00mmol / g polyurethane solution (hereinafter referred to as "polyurethane solution A2"). .

[0219] Chemicals 8]

[0220]

[0221] The viscosity of the resulting polyurethane solution A2 was 120000mPa · s. Further, the number of the polyurethane solution A2 contained in the polyurethane-average molecular weight (Mn) of 15,000, an acid value of 24.8mgKOH / g. Further, the solid content concentration of the polyurethane solution A2 was 40.0 mass%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com