A kind of wood-plastic floor and preparation method thereof

A wood-plastic floor and substrate layer technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of poor mixing and dispersion of flame retardants, decline of various indicators of the floor, and poor dimensional stability, etc., to achieve The effects of small dimensional change, good wear resistance, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

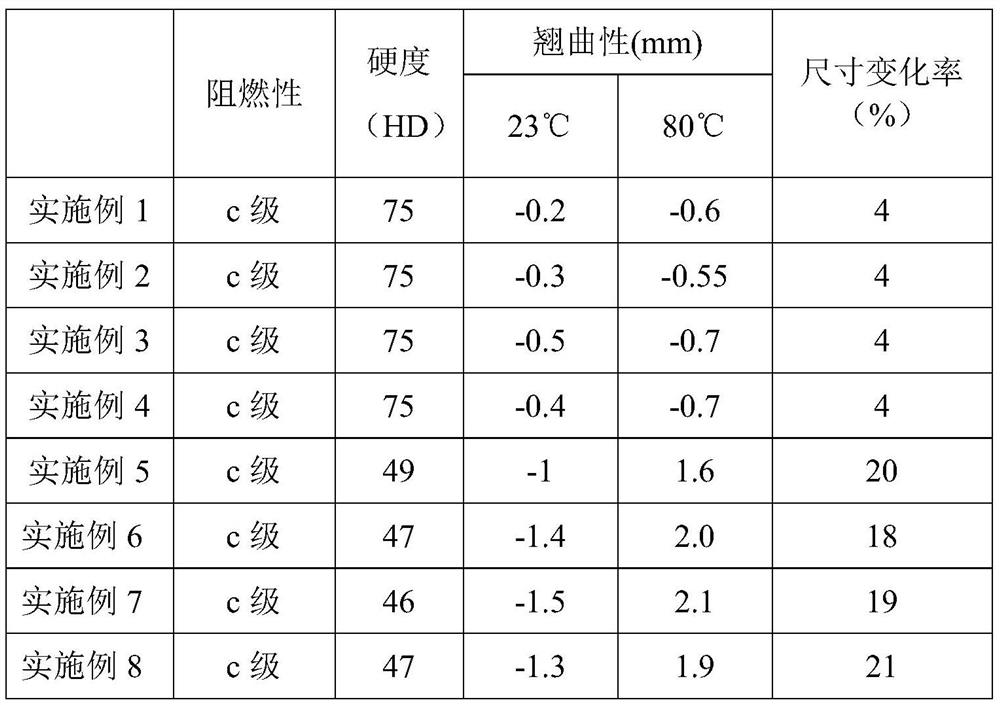

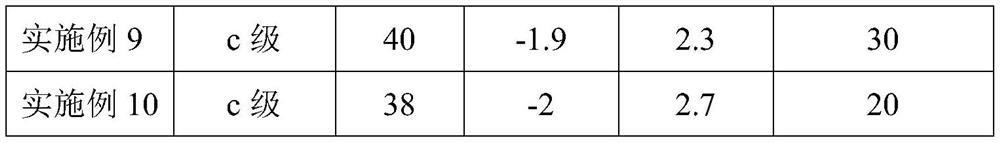

Examples

preparation example Construction

[0078] The preparation raw material of the second base material layer in the present invention is the same as that of the first base material layer, except that there is no glass fiber in the filler of the second base material layer and the content is less, and the lubricant in the auxiliary agent is different.

[0079] In one embodiment, when the preparation raw materials of the first substrate layer include 10% resin, 5% toughening agent, 5% compatibilizer, 5% wood flour, 25% flame retardant, 0.7% additive , the balance is filler, the preparation raw material of described second substrate comprises 15% resin, 10% toughening agent, 10% compatibilizer, 10% wood powder, 20% flame retardant, 0.72% auxiliary agent, balance For the filler.

[0080] In another embodiment, the raw materials for preparing the second substrate include 22% resin, 8% toughening agent, 5% compatibilizer, 15% wood flour, 20% flame retardant, 0.72% additive, The balance is filler.

[0081] In another emb...

Embodiment 1

[0139] Embodiment 1 of the present invention provides a wood-plastic floor, which is a substrate layer, a connecting layer, and a wear-resistant decorative layer from bottom to top; the substrate layer includes a first substrate layer and a second substrate layer from top to bottom. Substrate layer; The wear-resistant decorative layer includes a wear-resistant protective layer and a printed decorative layer from top to bottom; The wear-resistant protective layer includes a wear-resistant UV coating layer and a transparent protective layer from top to bottom; The printed decorative layer Including ink layer and printing substrate layer from top to bottom.

[0140] The raw materials for the first substrate layer include 10% resin, 5% toughening agent, 5% compatibilizer, 5% wood powder, 25% flame retardant, 0.7% auxiliary agent, and the balance is filler.

[0141] The resin is PP, purchased from Formosa Plastics Polypropylene 3005.

[0142] The toughening agent is EMA, purchased...

Embodiment 2

[0173] Example 2 of the present invention provides a wood-plastic floor, the specific implementation of which is the same as in Example 1, the difference is that the preparation raw materials of the second base material are 22% resin, 8% toughening agent, 5% phase Compatibilizer, 15% wood powder, 20% flame retardant, 0.72% auxiliary agent, and the balance is filler; the compatibilizer is MAH-EBA, purchased from DuPont coupling agent Fusabond A560 in the United States.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com