LED lamp molding printing process

A LED lamp and glue sealing technology, which is applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve problems such as poor cavity filling, unfavorable industrial production, and inaccurate alignment of the injection port. , to achieve the effect of increasing strength, better anti-adhesive effect and improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

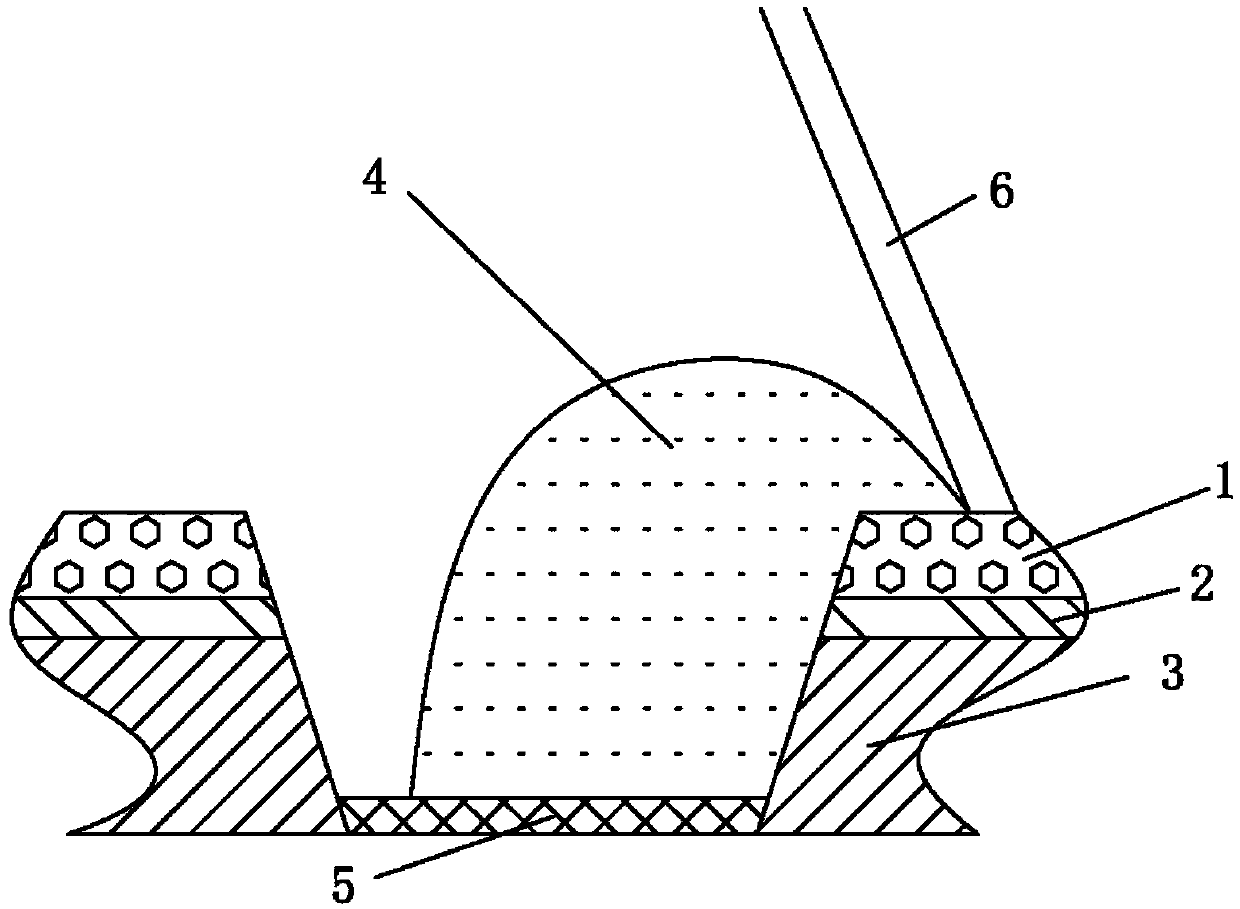

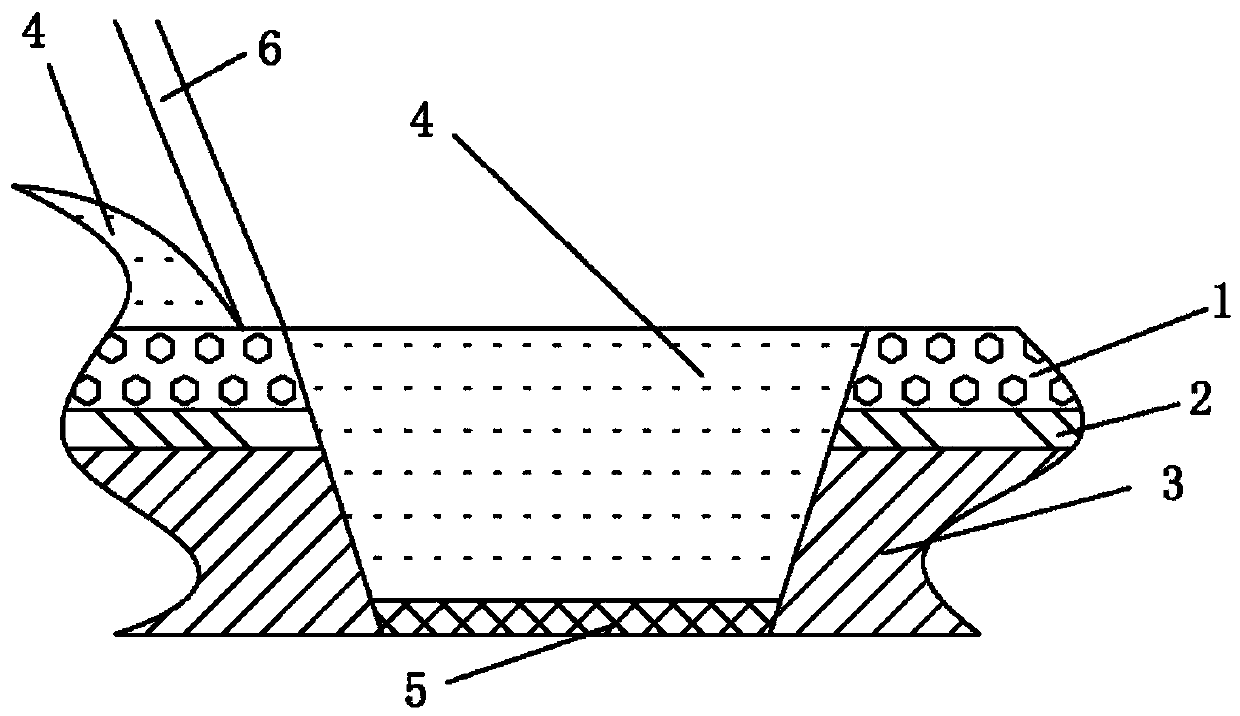

[0051] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

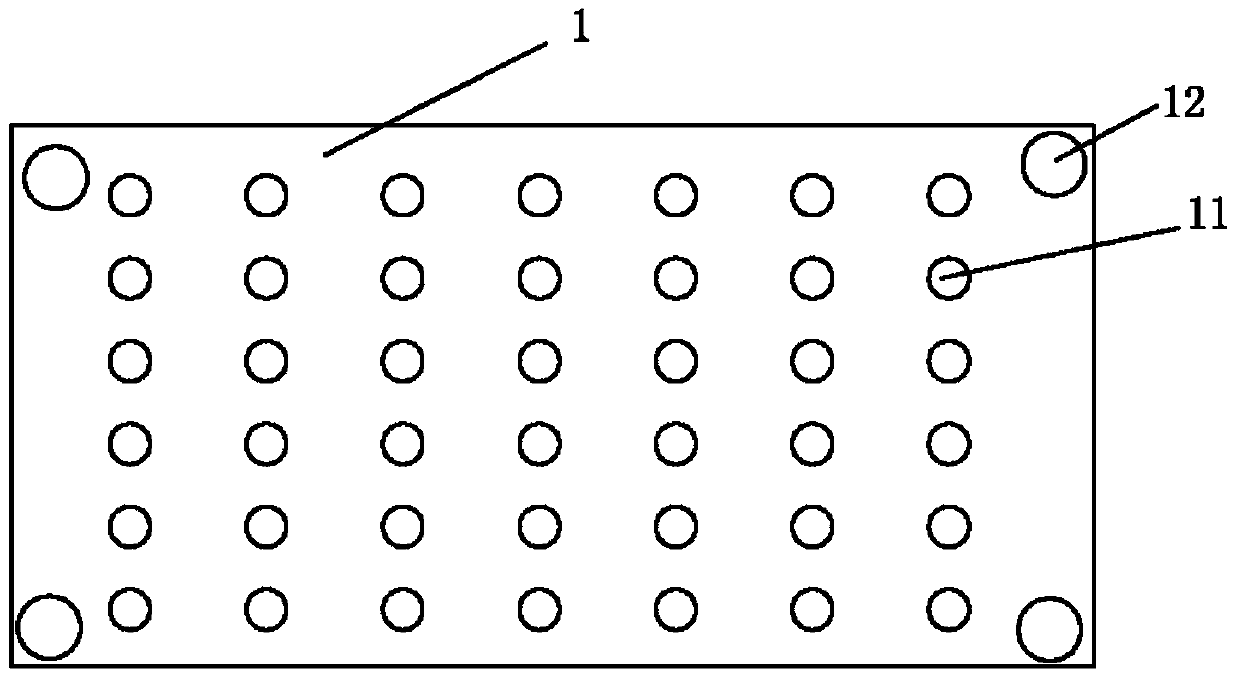

[0052] (1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0053] (2) Inject fluorescent glue 4 into the cavity;

[0054] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0055] (4) The tape film 1 is peeled off.

[0056] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0057] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0058]

[0059] The concrete steps of the preparation method of tape fi...

Embodiment 2

[0083] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

[0084] (1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0085] (2) Inject fluorescent glue 4 into the cavity;

[0086] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0087] (4) The tape film 1 is peeled off.

[0088] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0089] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0090]

[0091] The concrete steps of the preparation method of tape fi...

Embodiment 3

[0115] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

[0116](1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0117] (2) Inject fluorescent glue 4 into the cavity;

[0118] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0119] (4) The tape film 1 is peeled off.

[0120] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0121] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0122]

[0123] The concrete steps of the preparation method of tape fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com