Q345qENH weather-resistant bridge steel plate with thickness smaller than or equal to 50 mm and production method thereof

A steel plate and weather-resistant technology, which is applied in the field of Q345qENH weather-resistant bridge steel plate and its production, can solve the problem that the paint-free weather-resistant bridge steel has not been widely promoted, so as to improve welding performance and welding crack resistance, not easy to rebound, and improve atmospheric resistance The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

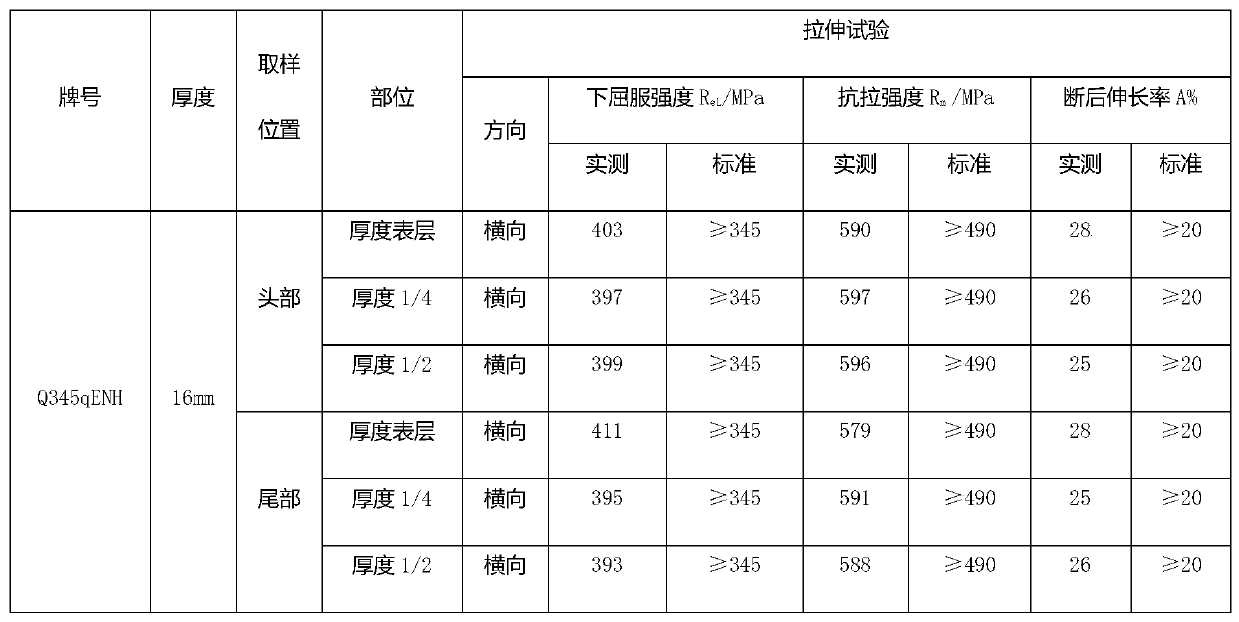

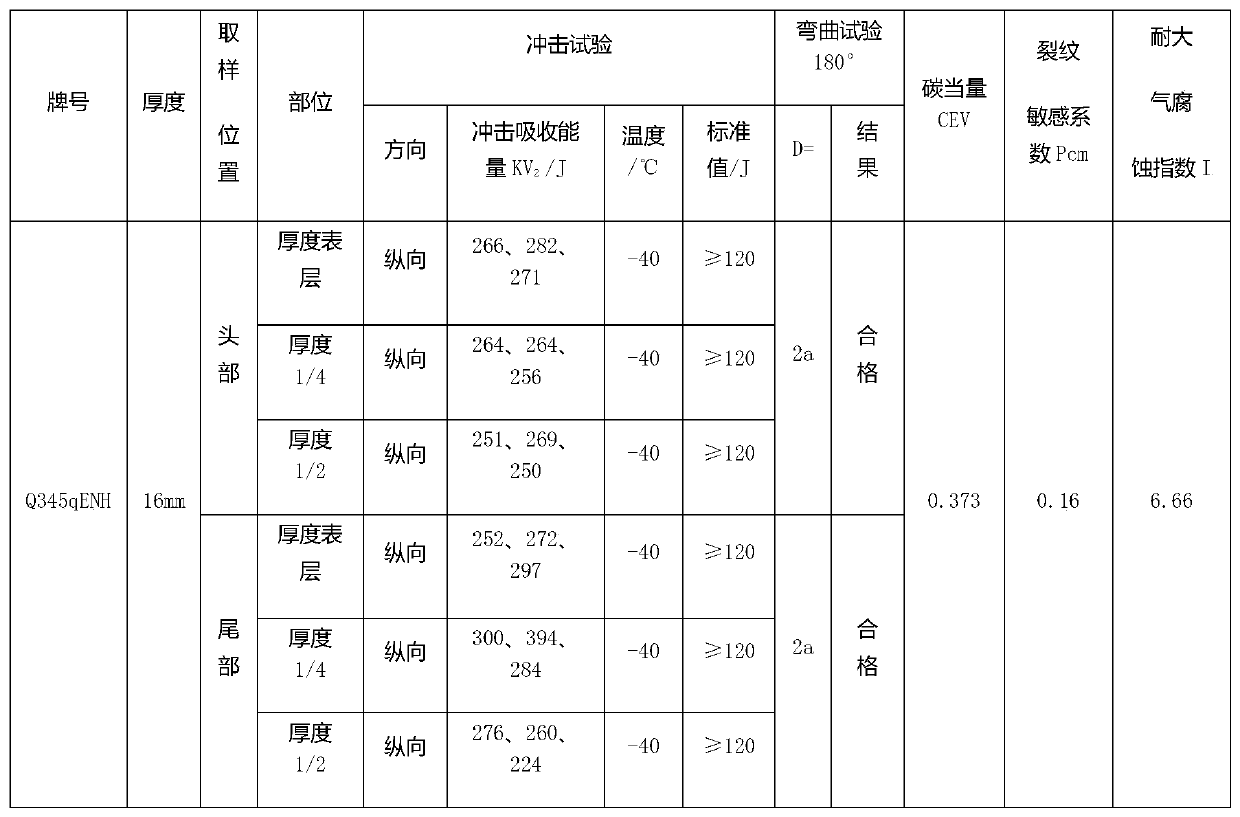

[0028] Example 1: Steel grade Q345qENH, production thickness 16mm.

[0029] 1. This example contains the following chemical components:

[0030] C:0.05%;Si:0.30%;Mn:1.13%;P:0.015%;S:0.003%;Als:0.032%;V:0.016%;Ti:0.009%;Cr:0.42%;Ni:0.37%; Nb: 0.029%; Cu: 0.34%; B: 0.00032%; N: 0.0049%; H: 0.0002%; others are Fe and residual elements. in:

[0031] Nb+V+Ti=0.054%, ≤0.15%

[0032] Carbon equivalent CEV(%)=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.373

[0033] Crack sensitivity coefficient Pcm(%)=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.16

[0034] Atmospheric corrosion resistance index I=26.01(%Cu)+3.88(%Ni)+1.20(%Cr)+1.49(%Si)+17.28(%P)-7.29(%Cu)(%Ni)-9.10(%Ni )(%P)-33.39(%Cu) 2 =6.66

[0035] 2. The production method of this example (implementation of actual process parameters):

[0036] (1) Steel billet heating: In order to ensure that the steel billet is thoroughly burned, and at the same time, the temperature is uniform to facilitate rolling, the steel billet is heated in th...

example 2

[0058] Example 2: Steel grade Q345qENH, production thickness 30mm.

[0059] 1. This example contains the following chemical components:

[0060] C:0.06%;Si:0.32%;Mn:1.12%;P:0.013%;S:0.002%;Als:0.036%;V:0.015%;Ti:0.010%;Cr:0.41%;Ni:0.34%; Nb: 0.033%; Cu: 0.32%; B: 0.0003%; N: 0.0056%; H: 0.0002%; others are Fe and residual elements. in:

[0061] Nb+V+Ti=0.058%, ≤0.15%

[0062] Carbon equivalent CEV(%)=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.376

[0063] Crack sensitivity coefficient Pcm(%)=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.17

[0064] Atmospheric corrosion resistance index I=26.01(%Cu)+3.88(%Ni)+1.20(%Cr)+1.49(%Si)+17.28(%P)-7.29(%Cu)(%Ni)-9.10(%Ni )(%P)-33.39(%Cu) 2 =6.58

[0065] 2. The production method of this example (implementation of actual process parameters):

[0066] (1) Steel billet heating: In order to ensure that the steel billet is thoroughly burned, and at the same time, the temperature is uniform to facilitate rolling, the steel billet is heated in thr...

example 3

[0088] Example 3: Steel grade Q345qENH, production thickness 50mm.

[0089] 1. This example contains the following chemical components:

[0090] C:0.05%;Si:0.39%;Mn:1.15%;P:0.016%;S:0.002%;Als:0.033%;V:0.019%;Ti:0.008%;Cr:0.43%;Ni:0.38%; Nb: 0.031%; Cu: 0.31%; B: 0.00046%; N: 0.0029%; H: 0.0002%; others are Fe and residual elements. in:

[0091] Nb+V+Ti=0.058%, ≤0.15%

[0092] Carbon equivalent CEV(%)=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.377

[0093] Crack sensitivity coefficient Pcm(%)=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B=0.17

[0094] Atmospheric corrosion resistance index I=26.01(%Cu)+3.88(%Ni)+1.20(%Cr)+1.49(%Si)+17.28(%P)-7.29(%Cu)(%Ni)-9.10(%Ni )(%P)-33.39(%Cu) 2 =6.79

[0095] 2. The production method of this example (implementation of actual process parameters):

[0096] (1) Steel billet heating: In order to ensure that the steel billet is thoroughly burned, and at the same time, the temperature is uniform to facilitate rolling, the steel billet is heated in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com