Steel for assembling type steel structure and preparing method thereof

A steel structure and assembly technology, which is applied in the field of hot continuous rolling strip production, can solve the problems of easy cracking of cast slabs, increase the difficulty of smelting, and difficulty in industrial production, and achieve good welding performance and improve the effect of atmospheric corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

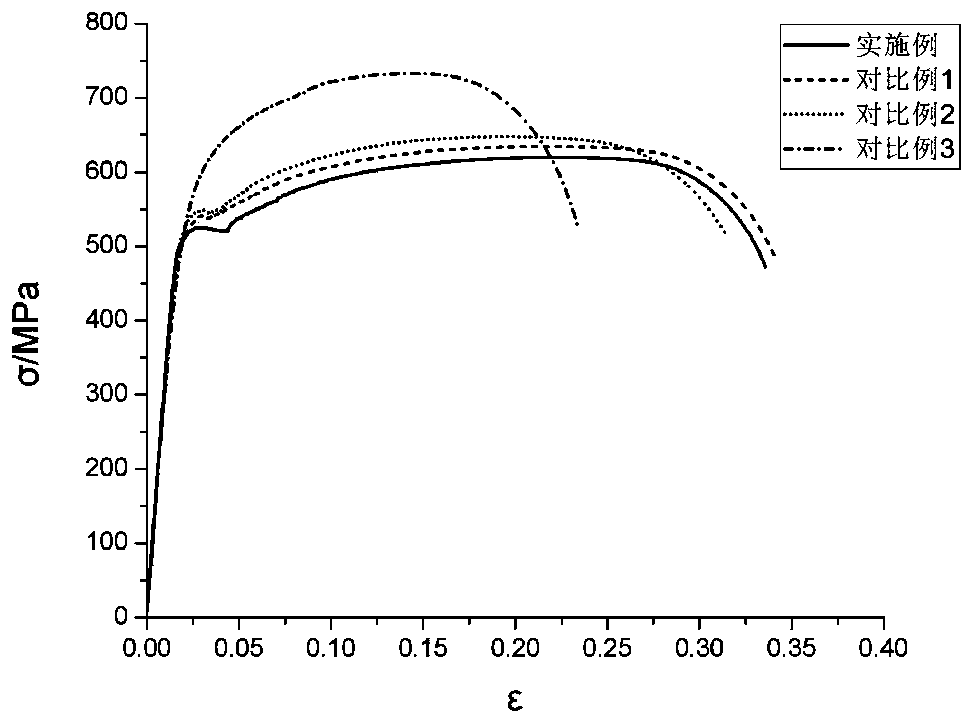

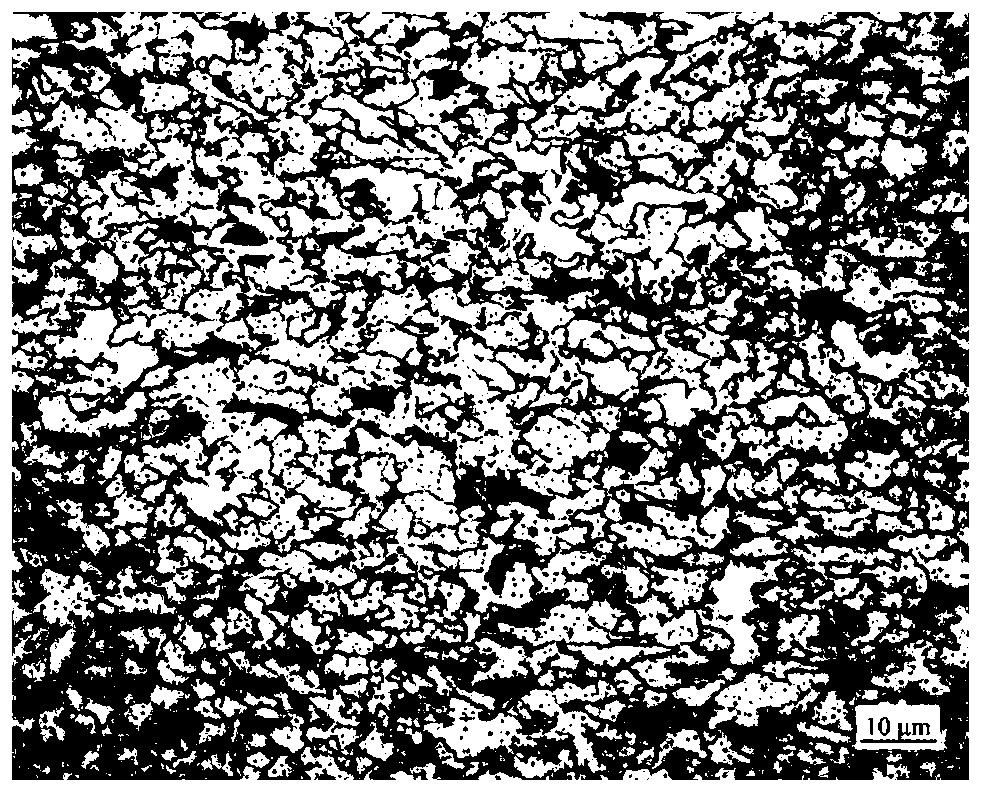

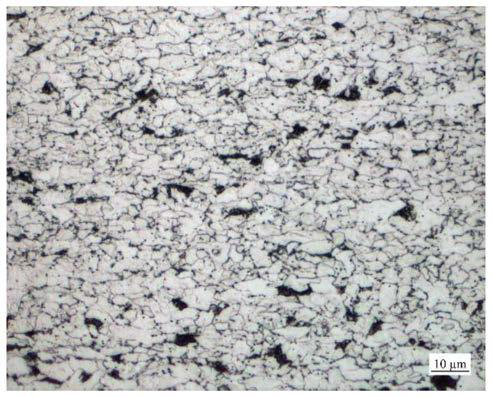

[0021] Specifically, the present invention provides steel for fabricated steel structures, which is composed of the following components by weight percentage: C: 0.06-0.08%, Si: 0.30-0.40%, Mn: 0.85-1.00%, P≤0.018%, S≤ 0.007%, Cu: 0.30~0.40%, Cr: 0.40~0.50%, Ni: 0.20~0.30%, V: 0.04~0.05%, Nb: 0.020~0.030%, Als: 0.015~0.050%, N: 0.0025~0.0035% %, the balance is Fe and unavoidable impurities.

[0022] C is an effective strengthening element in steel, which can dissolve into the matrix to play a role of solid solution strengthening, and can combine with V and Nb to form carbide precipitation particles, which play the role of fine grain strengthening and precipitation strengthening, and increase the carbon content. It is beneficial to increase the strength, but too high carbon content will form more coarse and brittle carbide particles in the steel, which is not good for plasticity and toughness. If the carbon content is too high, it will also segregate in the center of the steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com